Professional Documents

Culture Documents

Sand Procedure Fall 2013

Sand Procedure Fall 2013

Uploaded by

OMEGA CONSULTANT0 ratings0% found this document useful (0 votes)

9 views2 pagesThe document describes three experimental procedures:

1) An acid solubility test to determine the percentage of sand lost in acid by dissolving it in HCl and measuring the mass lost.

2) A porosity test to find the porosity of a sand sample by measuring the volume of dry sand and volume of water it displaces.

3) A uniformity coefficient test where sand is sieved through different sized sieves to determine the effective size and uniformity coefficient from a graph of percentage passing versus pore size.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes three experimental procedures:

1) An acid solubility test to determine the percentage of sand lost in acid by dissolving it in HCl and measuring the mass lost.

2) A porosity test to find the porosity of a sand sample by measuring the volume of dry sand and volume of water it displaces.

3) A uniformity coefficient test where sand is sieved through different sized sieves to determine the effective size and uniformity coefficient from a graph of percentage passing versus pore size.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pagesSand Procedure Fall 2013

Sand Procedure Fall 2013

Uploaded by

OMEGA CONSULTANTThe document describes three experimental procedures:

1) An acid solubility test to determine the percentage of sand lost in acid by dissolving it in HCl and measuring the mass lost.

2) A porosity test to find the porosity of a sand sample by measuring the volume of dry sand and volume of water it displaces.

3) A uniformity coefficient test where sand is sieved through different sized sieves to determine the effective size and uniformity coefficient from a graph of percentage passing versus pore size.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Experimental Procedure 2

Wednesday, November 13, 2013

Procedure:

Acid Solubility Test: DATA:

Source: (page 16) of AWWA b100 Mass of filter paper (g):

Materials: P=

Funnel Mass sand (initial) (g):

Large filter paper I=

6N HCl solution Mass of sand + paper (final) (g):

100 g sample of sand T=

Deionized water

2 500 g beakers CALCULATIONS:

1. Weigh a piece of large filter paper and record the Mass of sand (final) (g):

(T – P) = F =

mass. Place the filter paper over a funnel and the

Percent lost to acid (%):

funnel over a waste beaker.

(F / I) * 100 =

2. Fill second beaker with 100 g HCl solution.

3. Record the mass of a sample of sand so that it is roughly

100 g.

4. Pour dry sand into the solution so that the sand is

submerged.

5. Stir the beaker contents occasionally and allow to stand

for 30 minutes.

6. Pour solution over the filter paper. Continue to add

deionized water to rinse the beaker and pour it over the

filter paper to remove all particles of sand from the

beaker.

7. Rinse the sand in the filter paper with more deionized

water.

8. Place filter paper and wet sand in oven to dry.

9. When the sand is dry, record the mass of the filter paper

with the dry sand on top.

10. Preform calculations. If the percent lost due to acid is

less than 5%, the sand passes.

DATA:

Porosity Test: Volume of dry sand (mL):

Materials: S=

Graduated cylinder (with gradations of .1 mL) Volume of water (mL):

150 mL beaker W=

100 g sample of sand

Water CALCULATIONS:

Total Volume (mL):

1. Use the graduated cylinder to add the sample of sand to (S + W) = T =

the beaker. Record the volume of the dry sand. Porosity:

S/T =

2. Use the graduated cylinder to add water to the sand sample.

Record the volume of water added when the water just

reaches the top of the sand.

3. Add the volume of the dry sand to the volume of water

added to the sand. This value is the total volume.

4. Calculate the Porosity of the sample.

Unifomity Coeff (K) and Effective Size (D10)

Materials:

100 g sample of sand Data from graph:

Pan D10 (mm) =

Lid D60 (mm) =

Sieves: No. 4, 10, 20, 40, 60, 70, 200

Calculations:

1. Record the mass of roughly 100 g dry sand (Wt). Effective size

2. Record the original mass of each clean sieve (Wp). (d60) =

3. Arrange a set of sieves in a stack with largest pore size Uniformity coefficient

on top, with a pan under the smallest pore size. (d60/d10) =

4. Pour the sand sample through the stack of sieves.

5. Shake the stack of sieves for 5 to 10 minutes with the

lid on top so no sand escapes the stack.

6. Weigh sand in each sieve and in the pan (W).

7. Calculate the sand caught on each sieve (Ws) by

subtracting the sieve weight (Wp) from the combined

weight (Wc).

8. Calculate the percent retained by each sieve.

9. Calculate the percent passing by subtracting the

percent retained PR from the values in the previous

column (PL). The PL values are the P values from the

row above.

10. Graph percent passing for each sieve versus pore size.

11. Using the graph, determine the pore size where 10% of

the sand passes (d10) and where 60% of the sand

passes (d60).

Uniformity coefficient test:

Total dry washed sand (Wt) (g)=

Sieve Pore Size Original mass Sand and % passing last

No. (mm) of sieve (g) sieve (g) Sample Weight (g) % retained larger sieve % passing

Wp Wc Wc – Wp = Ws (Ws / Wt) *100 = PR PL PL – PR = P

3.5 5.6 100

10 2

20 0.85

30 0.6

40 0.425

60 0.25

pan

You might also like

- AIH - Advanced Hypnotherapy CertificationDocument60 pagesAIH - Advanced Hypnotherapy CertificationGUSREYES69100% (4)

- Presentation On Soil TestingDocument77 pagesPresentation On Soil Testingahm555No ratings yet

- Quality Control TestsDocument22 pagesQuality Control Testsvarma369vinaNo ratings yet

- r2900g Xtra.Document4 pagesr2900g Xtra.percyNo ratings yet

- Item 101 - Removal of Structures and Obstructions - DPWH Accredited Contractors Materials EngineerDocument3 pagesItem 101 - Removal of Structures and Obstructions - DPWH Accredited Contractors Materials EngineerJeff D. AgustinNo ratings yet

- Lecture Notes On IRC 37Document8 pagesLecture Notes On IRC 37AdhirajNo ratings yet

- Sally S. Smith: Professional SummaryDocument2 pagesSally S. Smith: Professional SummaryJustine ManoosNo ratings yet

- Principal of Soil Science (Practical)Document30 pagesPrincipal of Soil Science (Practical)Sarwar M. Rasheed67% (3)

- Soil LabDocument60 pagesSoil LabBalakrishnan PandianNo ratings yet

- Sand Displacement TestDocument15 pagesSand Displacement TestshuhadaNo ratings yet

- DVB A001 Specification For The Use of Video and Audio Coding in Broadcasting Applications Based On The MPEG-2 Transport StreamDocument113 pagesDVB A001 Specification For The Use of Video and Audio Coding in Broadcasting Applications Based On The MPEG-2 Transport StreamEvan StergiouNo ratings yet

- The Chemistry of Soils - Including Information on Acidity, Nitrification, Lime Requirements and Many Other Aspects of Soil ChemistryFrom EverandThe Chemistry of Soils - Including Information on Acidity, Nitrification, Lime Requirements and Many Other Aspects of Soil ChemistryRating: 4 out of 5 stars4/5 (1)

- Regulation and Registration of Engineering Profession and The Problem With The EBKDocument20 pagesRegulation and Registration of Engineering Profession and The Problem With The EBKCharles Ondieki100% (2)

- 5.determination of Shrinkage Limit of SoilDocument3 pages5.determination of Shrinkage Limit of Soilashrithareddy yeddula19No ratings yet

- Proctor Compaction TestDocument12 pagesProctor Compaction Testmathirenga88No ratings yet

- University of Dar Es SalaamDocument10 pagesUniversity of Dar Es SalaamBernard KitosiNo ratings yet

- Soil - Lab Report 7Document5 pagesSoil - Lab Report 7Maricar De LeonNo ratings yet

- January 20, 2021 CE 401 - CE31S6 Geotechnical Engineering 1 (Soil Mechanics) GROUP - (5 Members)Document3 pagesJanuary 20, 2021 CE 401 - CE31S6 Geotechnical Engineering 1 (Soil Mechanics) GROUP - (5 Members)Katy PerryNo ratings yet

- Experiment-No 1Document5 pagesExperiment-No 1Paul Justin MangatNo ratings yet

- SM PracticalsDocument4 pagesSM PracticalsBikash ChaudharyNo ratings yet

- Lab2 02Document6 pagesLab2 02de_wightNo ratings yet

- pdf24 MergedDocument28 pagespdf24 MergedVivekNo ratings yet

- Lab No. 6Document10 pagesLab No. 6Johnrev Philip AcopioNo ratings yet

- Rubber Balloon TestDocument5 pagesRubber Balloon TestNurul SyafiqahNo ratings yet

- Consistency LimitsDocument10 pagesConsistency LimitsAbinavNo ratings yet

- Bio Demo ExperimentsDocument8 pagesBio Demo ExperimentskhushiNo ratings yet

- Soil Ex6Document4 pagesSoil Ex6Azeezan AlessaNo ratings yet

- CE-315E, Geo Exp-2Document2 pagesCE-315E, Geo Exp-2Manik GoyalNo ratings yet

- Physical Soil Parameters: (Experimental Determination of Properties of Soil)Document30 pagesPhysical Soil Parameters: (Experimental Determination of Properties of Soil)Jodel ann LangresNo ratings yet

- Atterberg Limit RanaDocument6 pagesAtterberg Limit RanaRana Abdelbaset BostanjiNo ratings yet

- Lab Report No. 4Document4 pagesLab Report No. 4Muhammad YounasNo ratings yet

- 97-2003 The Standard and The Modi̇fi̇ed Proctor TestsDocument12 pages97-2003 The Standard and The Modi̇fi̇ed Proctor TestsHaydar TaşNo ratings yet

- Engineering Properties of Soil PDFDocument55 pagesEngineering Properties of Soil PDFJam Apizara Chaizalee100% (1)

- Hand Auger MethodDocument4 pagesHand Auger Methodnrsyhira salihinNo ratings yet

- Fineness Test of SandDocument13 pagesFineness Test of SandShien QinNo ratings yet

- Assignment 5 SolnsDocument10 pagesAssignment 5 SolnsS Kiong TingNo ratings yet

- Ce14b1 - Group 5 - Pre-Lab - Experiment10Document5 pagesCe14b1 - Group 5 - Pre-Lab - Experiment10Ela Mae CoNo ratings yet

- Soil Mechanics - Chapter 4Document6 pagesSoil Mechanics - Chapter 4Emily Faith BelcenaNo ratings yet

- Lab Reports (4, 10, 7)Document14 pagesLab Reports (4, 10, 7)Ela Mae CoNo ratings yet

- CE2812 - Sieve Analysis and Hydrometer AnalysisDocument12 pagesCE2812 - Sieve Analysis and Hydrometer AnalysisRashmiNo ratings yet

- Activity 1Document11 pagesActivity 1Jayran BolonganNo ratings yet

- Soil AnalysisDocument43 pagesSoil AnalysisPragya PandeyNo ratings yet

- KA31802 Geotechnic Lab ManualDocument37 pagesKA31802 Geotechnic Lab ManualRuszaimi KamsahNo ratings yet

- Experiment 3 Field Density Test: Sand Replacement Method: (Prepared By: Muhammad Munsif Ahmad)Document5 pagesExperiment 3 Field Density Test: Sand Replacement Method: (Prepared By: Muhammad Munsif Ahmad)Hidayat AzisNo ratings yet

- Practical Test 1: (A) Moisture Density Relationship of SoilsDocument8 pagesPractical Test 1: (A) Moisture Density Relationship of SoilsBernard KitosiNo ratings yet

- Determination of The Dry Density of Soil in SituDocument29 pagesDetermination of The Dry Density of Soil in SituMJ ArboledaNo ratings yet

- Compaction Test ReportDocument7 pagesCompaction Test ReportNajihaNo ratings yet

- M. Lampiran PDFDocument21 pagesM. Lampiran PDFVeblin RuhulessinNo ratings yet

- Physical Test On FADocument15 pagesPhysical Test On FAসন্দীপ চন্দ্রNo ratings yet

- Particle Size Analysis of SoilDocument6 pagesParticle Size Analysis of SoilJunrey LumangyaoNo ratings yet

- Lab 1 - Group 1Document3 pagesLab 1 - Group 1Pilar MNo ratings yet

- Evans Kipngetich E024-01-0841/2017 Report On Atterbergs Limits Experiment 1. Aims and ObjectivesDocument7 pagesEvans Kipngetich E024-01-0841/2017 Report On Atterbergs Limits Experiment 1. Aims and ObjectivesEVANS KIPNGETICHNo ratings yet

- CH (5) Soil CompactionDocument31 pagesCH (5) Soil CompactionFelopateer EmadNo ratings yet

- Sieve Analysis of Given Soil SampleDocument7 pagesSieve Analysis of Given Soil SampleWaQar SaleemNo ratings yet

- PermeabilityDocument5 pagesPermeabilitybacha01No ratings yet

- Exp - 01 Determination of Moisture Content: SL No Description 1 2 3Document9 pagesExp - 01 Determination of Moisture Content: SL No Description 1 2 3Chethan GowdaNo ratings yet

- Light CompactionDocument4 pagesLight Compactionmanoj kumarNo ratings yet

- Plastic Limit & Shrinkage Limit TestsDocument5 pagesPlastic Limit & Shrinkage Limit Teststushar gautamNo ratings yet

- Liquid LimitDocument8 pagesLiquid LimitAffiy ZayiniNo ratings yet

- Moisture Density Relation (Compaction) TestDocument5 pagesMoisture Density Relation (Compaction) TestshowravNo ratings yet

- Rana Compaction TestDocument4 pagesRana Compaction TestRana Abdelbaset BostanjiNo ratings yet

- Experiment 15 Determination of Dustfall, Rainfall and HumidityDocument10 pagesExperiment 15 Determination of Dustfall, Rainfall and HumidityfitrijasmineNo ratings yet

- Hydrometer Test - Lab Manual PDFDocument3 pagesHydrometer Test - Lab Manual PDFmm0% (1)

- Laboratory 7 PermeabilityDocument13 pagesLaboratory 7 PermeabilityFahad KudaratNo ratings yet

- Lab Report No.: 4 Hydrometer AnalysisDocument5 pagesLab Report No.: 4 Hydrometer AnalysisYousif MawloodNo ratings yet

- MagbujosCharmaine LaboratoryReportNo.5 CE-3109Document6 pagesMagbujosCharmaine LaboratoryReportNo.5 CE-3109Prince RiveraNo ratings yet

- EP Act WaterDocument1 pageEP Act WaterOMEGA CONSULTANTNo ratings yet

- 228 10 1989 Reff2019Document6 pages228 10 1989 Reff2019OMEGA CONSULTANTNo ratings yet

- 191 2007 AMD1 Reff2021Document15 pages191 2007 AMD1 Reff2021OMEGA CONSULTANTNo ratings yet

- 216 2006 Reff2021Document7 pages216 2006 Reff2021OMEGA CONSULTANTNo ratings yet

- 196 1966 Reff2022Document9 pages196 1966 Reff2022OMEGA CONSULTANTNo ratings yet

- Standard Solution Register For Sodium and PotassiumDocument1 pageStandard Solution Register For Sodium and PotassiumOMEGA CONSULTANTNo ratings yet

- Din 17200 Standard PDF FreeDocument42 pagesDin 17200 Standard PDF FreeOMEGA CONSULTANTNo ratings yet

- Standard Solution Register For 0.02 (N) NaOHDocument1 pageStandard Solution Register For 0.02 (N) NaOHOMEGA CONSULTANTNo ratings yet

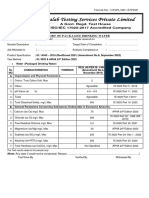

- Omegalab Testing Services Private Limited: A Govt. Regd. Test House An ISO/IEC 17025 - 2017 Accredited CompanyDocument1 pageOmegalab Testing Services Private Limited: A Govt. Regd. Test House An ISO/IEC 17025 - 2017 Accredited CompanyOMEGA CONSULTANTNo ratings yet

- Sodium Oxide Potassium OxideDocument1 pageSodium Oxide Potassium OxideOMEGA CONSULTANTNo ratings yet

- Plastiment VZ1Document1 pagePlastiment VZ1OMEGA CONSULTANTNo ratings yet

- QR-157 Pckgd. Drinking Water As Per IS 14543 OTSPLDocument1 pageQR-157 Pckgd. Drinking Water As Per IS 14543 OTSPLOMEGA CONSULTANTNo ratings yet

- ASTM A478 972019 Standard Specification For Chromium Nickel Stainless Steel Weaving and Knitting WireDocument2 pagesASTM A478 972019 Standard Specification For Chromium Nickel Stainless Steel Weaving and Knitting WireOMEGA CONSULTANTNo ratings yet

- Report On Folded Plates & Space FrameDocument12 pagesReport On Folded Plates & Space FrameShez ZyNo ratings yet

- Powerpoint tiếng anh 5 U6-L1-JESSDocument31 pagesPowerpoint tiếng anh 5 U6-L1-JESSanhnguyen.ltgNo ratings yet

- Alineamiento y Perfil 1aupvDocument3 pagesAlineamiento y Perfil 1aupvingeniero civilNo ratings yet

- Citrobacter Freundii: (Atcc 8090™)Document2 pagesCitrobacter Freundii: (Atcc 8090™)carlosNo ratings yet

- Three Phase Inverter-1Document9 pagesThree Phase Inverter-1AdhiNo ratings yet

- WHO Good Manufacturing Practices For Pharmaceutical Products: Main Principles 2014Document1 pageWHO Good Manufacturing Practices For Pharmaceutical Products: Main Principles 2014Ph.Nabil Al-SharafNo ratings yet

- Advancing Scientific Computing With Python's SciPy LibraryDocument19 pagesAdvancing Scientific Computing With Python's SciPy LibraryAbu RayhanNo ratings yet

- WTWDocument84 pagesWTWVildanaNo ratings yet

- Math DLP Q4W5Day4JUNE12023ThursdayRESPINODocument9 pagesMath DLP Q4W5Day4JUNE12023ThursdayRESPINOTalaba ElementaryNo ratings yet

- t-6b Hydraulic DiagramDocument1 paget-6b Hydraulic DiagramSanty SalumNo ratings yet

- Macro-Fiber Composite Piezoelectric Rosettes For Acoustic Source Location in Complex StructuresDocument11 pagesMacro-Fiber Composite Piezoelectric Rosettes For Acoustic Source Location in Complex StructuresSri SaiNo ratings yet

- CAS-CASR-CKSR Series Current Transducers-Low - 1Document24 pagesCAS-CASR-CKSR Series Current Transducers-Low - 1c.cesco8703No ratings yet

- Pumba Puzha LeafletDocument2 pagesPumba Puzha LeafletNishanth GaneshNo ratings yet

- Ultra-Violet Scanner: Bulletin UV 87-R7Document4 pagesUltra-Violet Scanner: Bulletin UV 87-R7Cesar Ivan Parra FigueroaNo ratings yet

- Final ReportDocument33 pagesFinal ReporttsutsenNo ratings yet

- PhET Green House Gases Lab WorksheetsDocument5 pagesPhET Green House Gases Lab Worksheetsbonds nondsNo ratings yet

- Nursing Theorist: Florence Nightingale Theory: Environmental Theory Nursing BackgroundDocument3 pagesNursing Theorist: Florence Nightingale Theory: Environmental Theory Nursing BackgroundAlcala, Mariaden A.No ratings yet

- Research Paper 2022 3Document24 pagesResearch Paper 2022 3api-610238580No ratings yet

- InternDocument19 pagesInternPriyaDeivasikamaniNo ratings yet

- Mechanical Packer 15-01-09Document2 pagesMechanical Packer 15-01-09Marius-Daniel ZlotaNo ratings yet

- Divorce MeenakshiDocument1 pageDivorce MeenakshiMeenakshi ThakurNo ratings yet

- Brochure Dx480lca Hd500lca HD enDocument12 pagesBrochure Dx480lca Hd500lca HD enPutra DesandraNo ratings yet