Professional Documents

Culture Documents

SIN00343

Uploaded by

Gaetano MuccioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIN00343

Uploaded by

Gaetano MuccioCopyright:

Available Formats

RTA58T-B Operation 5512–2/A1

Cutting Out and Cutting In of the Injection and Actuator Pump

1. Injection pump

1.1. General

Injection pumps can be cut in or out as required during operation. This should, whenever possible, be done at greatly

reduced speed. The device for it is built into the injection pumps.

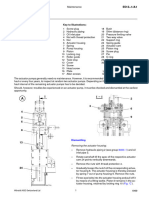

Manner of functioning while cutting out (see Fig. ’A’):

Every time the roller 2 is on the addendum of the cam 1, the hole 4 in the roller guide 3 comes into line with the cut-out

pin ’AZ’.

The eccentric pin 9 and therewith the spring dowel 10 are kept in the short slot ’SS’ of the guide groove by the force of

the spring 7. If eccentric pin 9 is pressed inwards, cut-out pin ’AZ’ rests on the roller guide. When hole 4 and cut-out

pin ’AZ’ now come in line with each other, the latter is pushed into roller guide 3 by pressing inwards. In this way the

piston is held fast in this position.

By turning the eccentric pin 9 through 100 _( in an anticlockwise direction, the roller guide 3 is raised slightly so that

some clearance exists between roller 2 and the addendum of the cam 1.

Manner of functioning while cutting in (see Fig. ’A’):

When cutting the injection pump back in, the eccentric pin 9 is turned so that the roller guide 3 is dropped until the

roller 2 lies on the addendum of cam 1. This results in the cut-out pin ’AZ’ being unloaded. By the force of spring 7

eccentric pin 9 is pressed outwards and, therefore, spring dowel pin 10 enters into the short slot ’SS’ of the guide

groove. The pump is again in operating position.

Device for cutting out and cutting in of the injection pump

A (Figure shows injection pump in cut-off position)

AZ 7 6 5 SS

3

9

2

LS

10

GAP

11

1

96.7416

4

Key to Illustrations: ’A’ to ’G’

1 Cam 9 Eccentric pin

2 Roller 10 Spring dowel pin

3 Roller guide 11 Inspection cover

4 Hole

5 Cover

6 Guide sleeve AZ Cut-out pin

7 Spring LS Long slot of guide groove

8 Open end ring spanner SS Short slot of guide groove

Wärtsilä NSD Switzerland Ltd 1 1999

5512–2/A1 Operation RTA58T-B

Cutting Out and Cutting In of the Injection and Actuator Pump

2. Cutting out and cutting in an injection pump

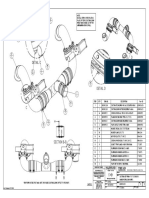

2.1. Cutting out procedure (see Fig. ’B’ to ’D’)

Starting position: Injection pump in service, engine either running at reduced speed or being turned with

turning gear.

D Attach open end ring spanner 8 (keeping on the in- 8

spection cover of the injection pump) to the hexa- B

gon of the eccentric pin 9 as shown in Fig. ’B’.

SS

5

9 10

D Subsequently press eccentric pin 9 together with

open end ring spanner 8 inwards until spring dowel C 8

pin 10 is located at the long slot ’LS’ of the guide

groove (see Fig. ’C’).

10

5

3 LS 9

2

0 mm

1

D As soon as this is the case, turn the open end ring

spanner 8 through 100 _( in an anticlockwise D

direction (Fig. ’D’) as quickly as possible when the

engine is running.

Spring dowel pin 10 has to remain at 100°

Attention

the lower end of the long slot ’LS’ of

the guide groove.

10 5

8

3 LS 9

D Remove open end ring spanner 8 (position of the 2

GAP 96.7428

cut-out device corresponds with Fig. ’D’ when

pump is cut out). 1

1999 2 Wärtsilä NSD Switzerland Ltd

RTA58T-B Operation 5512–2/A1

Cutting Out and Cutting In of the Injection and Actuator Pump

2.2. Cutting-in procedure (see Fig. ’E’ to ’G’)

Starting position: Injection pump is out of service (position of the cut-out device corresponds with Fig. ’E’).

Engine is either running or being turned with the turning gear.

D Attach open end ring spanner 8 (Fig. ’E’) and turn E

the eccentric pin 9 through 100 _( in a clockwise

direction (see Fig. ’F’).

10 5

8

3 LS 9

2

GAP

1

D By the force of spring 7 eccentric pin 9 is pressed 8

outwards and, therefore, spring dowel pin 10 en-

F

ters into the short slot ’SS’ of the guide groove (see

Fig. ’G’). 100°

Remark By the force of spring 7 eccentric pin

9 is first pressed out when the roller

2 is running on the addendum of

cam 1, i.e. when the roller guide 3 is

raised slightly from the cut-out pin 10

’AZ’. 5

3 LS 9

2

0 mm

1

If the pumps are cut in on the running engine the pro- G

cess will become possible after a short delay. If this hap- 8

pens, however, when the engine is rotated with the turn-

ing gear, then it may sometimes take several minutes till

the eccentric pin 12 is pressed out. In the latter case it is

best to watch for the cam to reach the top, and then the

open end ring spanner is to be turned through 100 _( in

a clockwise direction.

D Remove open end ring spanner 8 and store it at the

SS

depository.

5

9 10

96.7428

Wärtsilä NSD Switzerland Ltd 3 1999

5512–2/A1 Operation RTA58T-B

Cutting Out and Cutting In of the Injection and Actuator Pump

3. Actuator pump

3.1. General

Actuator pumps for actuating the exhaust valves can neither be cut out nor cut in when the engine is running. Should

it be necessary, such pumps can be put out of action by fitting the device (tool 94430) contained in the tool kit or put

back into service by removing it.

Attention Should an engine have to be started with a cut out actuator pump, the injection pump of the rele-

vant cylinder must also be cut out. In addition, the exhaust valve of the relevant cylinder must be

open (see group 0520–1).

Failure to comply with this requirement can have serious consequences.

When it is intended to put the engine into service later with a cut-out actuator pump, it is recommended that the

relevant injection pump be cut out at this time (in this case, see group 0520–1).

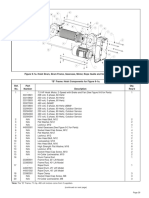

Device for cutting out and cutting in of the actuator pump

H (Figure shows actuator pump in cut-off position)

TOOL 94430

AZ 5 12 9 11 10

13

GAP

96.7416

1

4

Key to Illustrations: ’H’ to ’R’

1 Cam 9 Screw

2 Roller 10 Flange

3 Roller guide 11 Eccentric pin Tool 94430

4 Hole 12 Screw

5 Guide sleeve 13 Inspection cover

6 Open end ring spanner

7 Blank flange AZ Cut-off pin

8 Screw DB Through bore in flange 11

GB Tap hole in pump housing

1999 4 Wärtsilä NSD Switzerland Ltd

RTA58T-B Operation 5512–2/A1

Cutting Out and Cutting In of the Injection and Actuator Pump

4. Cutting out and cutting in an actuator pump

I

4.1. Cutting-out procedure (see Fig. ’I’ to ’K’)

Starting position: Engine at standstill. 8

7

D Slacken off screws 8 and remove blank flange 7

(Fig. ’I’).

D Remove the inspection cover 13 on the front side of 8

the injection pump actuator housing and determine

the position of the cam for the relevant pump. Turn

the engine with the turning gear in the required di-

rection until the roller 2 of the roller guide 3 is at the

T.D.C. of the cam (Fig. ’H’).

6

J GB

D Now push the tool 94430 into the position shown on

Fig. ’J’ as far as the stop of the flange 9 on the 100° 9

pump housing. Note that O-ring 12 is not dam- DB

aged.

D In this position the cut-out pin ’AZ’ of the eccentric 11

pin 10 has engaged in the hole 4 in the roller guide

(Fig. ’J’). 10

3

0 mm

2

1

3 AZ 12 10

D Attach open end ring spanner 6 to the hexagon of

eccentric pin 10 (Fig. ’J’). Turn it through 100 _( in

an anticlockwise direction until through bore ’DB’

in flange 9 and tap hole ’GB’ in pump housing come

in line with each other.

D Now screw in screw 8 to secure the tool in service K

(Fig. ’K’).

8

Attention Before starting the engine with cut-

out actuator pump, the measures

described in group 0520–1 must be

3

taken. ~2 mm

11 2

96.7436

Wärtsilä NSD Switzerland Ltd 5 1999

5512–2/A1 Operation RTA58T-B

Cutting Out and Cutting In of the Injection and Actuator Pump

4.2. Cutting-in procedure (see Fig. ’L’ to ’N’)

Starting position: Engine at standstill.

L

8

D Remove the inspection cover 11 from the side of

the injection pump housing and determine where

the cam of the relevant pump lies. Turn the engine

with turning gear in the required direction until roller 6

2 of roller guide 3 lies on the addendum of the cam

(see Fig. ’H’).

D Loosen and remove screw 8 (Fig. ’L’). 3

2

~2 mm

1

D Attach open end ring spanner 6 onto the eccentric

pin 12 as shown on Fig. ’L’ and turn it through 100

_( in a clockwise direction until the position

6

shown on Fig. ’M’ has been reached.

M

9

100°

11

D Pull out the complete device 94430, grease and 10

store it.

3

2

0 mm

1

D Fit the blank flange 7 (with gasket) and tighten it N

with the screws 8 (Fig. ’N’).

8

D Measures taken in accordance with group 0520–1

must be cancelled before starting the engine. 7

Finally, the injection pump of the relevant cylinder

can be cut back in again. 8

96.7436

1999 6 u Wärtsilä NSD Switzerland Ltd

You might also like

- TECO AEEB AEVB-Pump (Dimension)Document6 pagesTECO AEEB AEVB-Pump (Dimension)Naqib FuadNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- AR26.60-Y-6510A Disassembling, Assembling Shift Shaft 06.09.2021 Transmission 400.720 in Model 400.216/241/243/262/281/300Document3 pagesAR26.60-Y-6510A Disassembling, Assembling Shift Shaft 06.09.2021 Transmission 400.720 in Model 400.216/241/243/262/281/300Faiz CeboolNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Desen de AnsambluDocument1 pageDesen de AnsambluVlad BoleaNo ratings yet

- W-K-M Dynaseal 310D Ball Valve: ScopeDocument4 pagesW-K-M Dynaseal 310D Ball Valve: ScopeElinton SarmientoNo ratings yet

- Montacarga Eléctrico 25bt HyundaiDocument24 pagesMontacarga Eléctrico 25bt HyundaimichaelshelterNo ratings yet

- Zaenal Mutaqin Prof.H.Soemarto, M.Sie Sps PTK Upi 27-9-2018 19-9-2018Document1 pageZaenal Mutaqin Prof.H.Soemarto, M.Sie Sps PTK Upi 27-9-2018 19-9-2018Fauziah WahidaNo ratings yet

- AlgapdfDocument22 pagesAlgapdfDaniel BahamondeNo ratings yet

- Job Sheet Assembly Dynamic PumpDocument5 pagesJob Sheet Assembly Dynamic Pumputomob938No ratings yet

- Illustration 29 07 2017 PDFDocument1 pageIllustration 29 07 2017 PDFGlenn D. KleinNo ratings yet

- Angle CockesDocument4 pagesAngle CockescoolmaleankurNo ratings yet

- Section 8 Mast: Group 1 StructureDocument3 pagesSection 8 Mast: Group 1 StructureAndré TarginoNo ratings yet

- KIP 3000 Parts Manual: Ver 5.0 Type A and B - Both ModelsDocument121 pagesKIP 3000 Parts Manual: Ver 5.0 Type A and B - Both ModelsjoeNo ratings yet

- Auxiliary Valve Kit For NEW HOLLAND NEW MODEL HARRITAGE 3600 3230 3037 4710 1Document2 pagesAuxiliary Valve Kit For NEW HOLLAND NEW MODEL HARRITAGE 3600 3230 3037 4710 1Manoj YadavNo ratings yet

- Mdi Mdis SeriesDocument8 pagesMdi Mdis SeriesAnonymous Wu6FDjbNo ratings yet

- Mobareyanj PDFDocument14 pagesMobareyanj PDFron jamesNo ratings yet

- Clutch Hino 2.5Document4 pagesClutch Hino 2.5Yeam_90No ratings yet

- 8-1 Section 8 MastDocument5 pages8-1 Section 8 Maststefan corjucNo ratings yet

- Draper Sistema Hidraulico PDFDocument16 pagesDraper Sistema Hidraulico PDFFernando SabinoNo ratings yet

- Orbitrol Repairing1Document13 pagesOrbitrol Repairing1Islam ShoukryNo ratings yet

- Despiece Trasero Parte 2Document2 pagesDespiece Trasero Parte 2leogerguzNo ratings yet

- KIP 3000 Parts Manual Ver 1 PDFDocument91 pagesKIP 3000 Parts Manual Ver 1 PDFivanoquirozNo ratings yet

- Hino Freno de Ahogo 3Document4 pagesHino Freno de Ahogo 3Yeam_90No ratings yet

- MCV110A Pressure Control Pilot Valve Installation Guide en-USDocument8 pagesMCV110A Pressure Control Pilot Valve Installation Guide en-USmoyNo ratings yet

- Pontiac: Installation InstructionsDocument3 pagesPontiac: Installation InstructionsGabe SilvaNo ratings yet

- Repair Manual 125 Series PDFDocument16 pagesRepair Manual 125 Series PDFWichain RotchuNo ratings yet

- Mastil B55 F60MT-270848 MT-PARTS MANUALDocument19 pagesMastil B55 F60MT-270848 MT-PARTS MANUALChristian BedoyaNo ratings yet

- Pressure Relief Valve-NewDocument4 pagesPressure Relief Valve-Newnikaro1989No ratings yet

- SIN00226Document3 pagesSIN00226Gaetano MuccioNo ratings yet

- Illustration 29 07 2017 PDFDocument1 pageIllustration 29 07 2017 PDFGlenn D. KleinNo ratings yet

- Gripper Parts ListDocument4 pagesGripper Parts Listjhon jairo arangoNo ratings yet

- 90 Series ManualDocument13 pages90 Series ManualJL Z AvilesNo ratings yet

- 90 Series Manual PDFDocument13 pages90 Series Manual PDFHoney KumarNo ratings yet

- Boxer-100-AT-Ktec-1998-2000 AR-BAJAJDocument52 pagesBoxer-100-AT-Ktec-1998-2000 AR-BAJAJJuan Manuel Ortega100% (5)

- Instruction Manual: Lock Valve CL-420 CL-500Document10 pagesInstruction Manual: Lock Valve CL-420 CL-500निखिल बायवारNo ratings yet

- Centrifugal Pump Repair Parts "CJ101, EL101" SERIES: (For Pricing Refer To Repair Parts Price List)Document1 pageCentrifugal Pump Repair Parts "CJ101, EL101" SERIES: (For Pricing Refer To Repair Parts Price List)Henry Avilés ChongNo ratings yet

- Orbitrol RepairingDocument19 pagesOrbitrol RepairingIslam ShoukryNo ratings yet

- Ue1002a20 1Document2 pagesUe1002a20 1MARTIN GONZALEZNo ratings yet

- Service Manual SM1-76-38.0: Collector Ring, ReconditionDocument4 pagesService Manual SM1-76-38.0: Collector Ring, ReconditionJorge YuniorNo ratings yet

- WHEATLEY® Series 500 Swing Check Valve: Installation, Operation, and Maintenance ManualDocument9 pagesWHEATLEY® Series 500 Swing Check Valve: Installation, Operation, and Maintenance ManualWill Freddy MartinezNo ratings yet

- 35D MQ Quad Mast: Arts ManualDocument44 pages35D MQ Quad Mast: Arts ManualRAYMULROONEYNo ratings yet

- Holland Hitch AdjustmentDocument4 pagesHolland Hitch AdjustmentMarlin StraubNo ratings yet

- DC 5 A/T Practice: Ssangyong Motor CompanyDocument32 pagesDC 5 A/T Practice: Ssangyong Motor CompanyMigue SalazarNo ratings yet

- Taladro RadialDocument8 pagesTaladro RadialHoracio BalcázarNo ratings yet

- Global King 5 Thru 15Document26 pagesGlobal King 5 Thru 15MARTIN FLORESNo ratings yet

- Manual Router Trend t7 - eDocument112 pagesManual Router Trend t7 - eChano KimNo ratings yet

- ELME 817 Manual PDFDocument20 pagesELME 817 Manual PDFniko67% (3)

- S. D. 200 - Drill Cat - Sonda de PerforaciónDocument43 pagesS. D. 200 - Drill Cat - Sonda de PerforaciónKevin BaylonNo ratings yet

- Bill of Material: Bottom ViewDocument1 pageBill of Material: Bottom View민성규No ratings yet

- Orbitrol Repairing1Document22 pagesOrbitrol Repairing1Islam ShoukryNo ratings yet

- 1655Document1 page1655Parker FlyNo ratings yet

- Keystone Manual Operator Twin Grip F415Document2 pagesKeystone Manual Operator Twin Grip F415Robi KeiNo ratings yet

- Esquema Eletrico Freio Motor Mercedes Bens O400Document1 pageEsquema Eletrico Freio Motor Mercedes Bens O400Naiane Fuchs Luiz LopesNo ratings yet

- JB-Det Overhaul ManualDocument64 pagesJB-Det Overhaul ManualMohdYasirNo ratings yet

- Parts Info 211-212-213-241-243 PDFDocument8 pagesParts Info 211-212-213-241-243 PDFmanutecnicoNo ratings yet

- 0000 Expectation Final Machine DrawingDocument14 pages0000 Expectation Final Machine DrawingCursed PirateNo ratings yet

- 8 12 PDFDocument6 pages8 12 PDFTaha RdmanNo ratings yet

- Auxiliary Valve Kit For JOHN DEEREDocument1 pageAuxiliary Valve Kit For JOHN DEEREManoj YadavNo ratings yet

- Service Bulletin A - 14: Technical Information To All The Owners of Sulzer AS25 and AT25 Type Diesel Engines 18.10.96Document3 pagesService Bulletin A - 14: Technical Information To All The Owners of Sulzer AS25 and AT25 Type Diesel Engines 18.10.96Gaetano MuccioNo ratings yet

- Service Bulletin A - 8: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 15.08.94Document5 pagesService Bulletin A - 8: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 15.08.94Gaetano MuccioNo ratings yet

- Service Bulletin A-7.2: 19.12.97 Technical Information To All The Owners of Sulzer A/AS/AT25 Type Diesel EnginesDocument5 pagesService Bulletin A-7.2: 19.12.97 Technical Information To All The Owners of Sulzer A/AS/AT25 Type Diesel EnginesGaetano MuccioNo ratings yet

- SIN00344Document4 pagesSIN00344Gaetano MuccioNo ratings yet

- SIN00341Document1 pageSIN00341Gaetano MuccioNo ratings yet

- Framo Pump by BL-23Oct.02Document16 pagesFramo Pump by BL-23Oct.02Gaetano MuccioNo ratings yet

- SIN00216Document1 pageSIN00216Gaetano MuccioNo ratings yet

- Tesco True Results Casing Running in China Results in Total Depth PDFDocument2 pagesTesco True Results Casing Running in China Results in Total Depth PDF123456ccNo ratings yet

- Pg2022 ResultDocument86 pagesPg2022 ResultkapilNo ratings yet

- Lecture2 GranulopoiesisDocument9 pagesLecture2 GranulopoiesisAfifa Prima GittaNo ratings yet

- Core ValuesDocument1 pageCore ValuesIan Abel AntiverosNo ratings yet

- John L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiDocument12 pagesJohn L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiDivya AggarwalNo ratings yet

- YIC Chapter 1 (2) MKTDocument63 pagesYIC Chapter 1 (2) MKTMebre WelduNo ratings yet

- Performance Task 1Document3 pagesPerformance Task 1Jellie May RomeroNo ratings yet

- Clark SM 616 Service ManualDocument20 pagesClark SM 616 Service Manualenid100% (55)

- Literatura Tecnica 3Document10 pagesLiteratura Tecnica 3Christian PerezNo ratings yet

- Case Study 2Document5 pagesCase Study 2api-247285537100% (1)

- Contents EEMUA Publication 190 Edition1 May 2015Document4 pagesContents EEMUA Publication 190 Edition1 May 2015Aditya JainNo ratings yet

- Dermatology Skin in Systemic DiseaseDocument47 pagesDermatology Skin in Systemic DiseaseNariska CooperNo ratings yet

- Lesson 3 - ReviewerDocument6 pagesLesson 3 - ReviewerAdrian MarananNo ratings yet

- World Insurance Report 2017Document36 pagesWorld Insurance Report 2017deolah06No ratings yet

- Leadership Styles-Mckinsey EdDocument14 pagesLeadership Styles-Mckinsey EdcrimsengreenNo ratings yet

- Sample Monologues PDFDocument5 pagesSample Monologues PDFChristina Cannilla100% (1)

- C2 - Conveyors Diagram: Peso de Faja Longitud de CargaDocument1 pageC2 - Conveyors Diagram: Peso de Faja Longitud de CargaIvan CruzNo ratings yet

- Introduction To Screenwriting UEADocument12 pagesIntroduction To Screenwriting UEAMartín SalasNo ratings yet

- Design of Combinational Circuit For Code ConversionDocument5 pagesDesign of Combinational Circuit For Code ConversionMani BharathiNo ratings yet

- Produktkatalog SmitsvonkDocument20 pagesProduktkatalog Smitsvonkomar alnasserNo ratings yet

- Jackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairDocument65 pagesJackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairTeamMichael100% (2)

- Oxford EAP B1 Pre-Intermediate Student - S Book 2Document167 pagesOxford EAP B1 Pre-Intermediate Student - S Book 2Thư Dương Thị AnhNo ratings yet

- Delonghi Esam Series Service Info ItalyDocument10 pagesDelonghi Esam Series Service Info ItalyBrko BrkoskiNo ratings yet

- Implementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorDocument11 pagesImplementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorChristie YohanaNo ratings yet

- Escaner Electromagnético de Faja Transportadora-Steel SPECTDocument85 pagesEscaner Electromagnético de Faja Transportadora-Steel SPECTEdwin Alfredo Eche QuirozNo ratings yet

- QSP 04bDocument35 pagesQSP 04bakrastogi94843No ratings yet

- Microsmart GEODTU Eng 7Document335 pagesMicrosmart GEODTU Eng 7Jim JonesjrNo ratings yet

- Where We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Document1 pageWhere We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Safia-umm Suhaim- FareedNo ratings yet

- Pidsdps 2106Document174 pagesPidsdps 2106Steven Claude TanangunanNo ratings yet

- Development Developmental Biology EmbryologyDocument6 pagesDevelopment Developmental Biology EmbryologyBiju ThomasNo ratings yet