Professional Documents

Culture Documents

No. 22

Uploaded by

UPGM Ingenieria petroleraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No. 22

Uploaded by

UPGM Ingenieria petroleraCopyright:

Available Formats

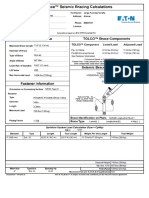

Connection Performance Sheet

www.NOV.com/GrantPrideco Phone: +1 (281) 878-8000

Advisory: Connection OD is smaller than Bevel Diameter. Note: Unbalanced Connection, Box weak (Connection OD should be larger or ID larger).

Connection Configuration

Connection XT39

Tool Joint OD (in) 4.750

Tool Joint ID (in) 2.500

Tool Joint SMYS (psi) 120,000

Friction Factor 1.0

Connection Performance

Applied Make-up Tension at Shoulder Tension at Connection

Torque Separation Yield

(ft-lbs) (lbs) (lbs)

Maximum Make-up Torque 20,300 Tensile Limited 685,200

Minimum Make-up Torque 16,900 583,400 692,600

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 20,100 (ft-lbs) should be applied.

Tool Joint Torsional Strength (ft-lbs) 33,900

Tool Joint Tensile Strength (lbs) 692,600

Tool Joint Dimensions

Balanced OD (in) 5.024

Minimum Tool Joint OD for 4.653

Counterbore (in)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box ID’s, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback Customer Created 01-18-2018

You might also like

- No. 16Document1 pageNo. 16UPGM Ingenieria petroleraNo ratings yet

- Connection Performance, XT57 (7.000 X 4.250) 110,000 (Psi)Document1 pageConnection Performance, XT57 (7.000 X 4.250) 110,000 (Psi)Diego LeonNo ratings yet

- Drill Collar Performance SheetDocument1 pageDrill Collar Performance SheetИнженер Луис А. ГарсиаNo ratings yet

- No. 3Document1 pageNo. 3Luis Alberto García CórdovaNo ratings yet

- Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)Document1 pageDrill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)juan moralesNo ratings yet

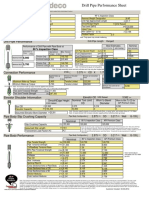

- Drill-Pipe Performance SheetDocument8 pagesDrill-Pipe Performance SheetrahulNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Luis Alberto García CórdovaNo ratings yet

- HWDPDocument15 pagesHWDPjinyuan74No ratings yet

- Bolt Sizing EngineerdogDocument44 pagesBolt Sizing EngineerdogHormedo RodriguezNo ratings yet

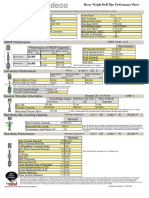

- For Reference Only: Drill Pipe Performance Characteristics ©Document3 pagesFor Reference Only: Drill Pipe Performance Characteristics ©alekz89100% (1)

- Drill pipe performance and safety advisoryDocument3 pagesDrill pipe performance and safety advisoryLuis Alberto García CórdovaNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- 4英寸短钻杆 HT40质量文件包裹模板Document17 pages4英寸短钻杆 HT40质量文件包裹模板zhaibo666No ratings yet

- 6.625 HWDPDocument23 pages6.625 HWDPözgüncNo ratings yet

- Press TAB To Cycle Through .: Input VariablesDocument43 pagesPress TAB To Cycle Through .: Input VariablesSuryaprakashNo ratings yet

- HWDP Configuration: Performance of HWDP AssemblyDocument3 pagesHWDP Configuration: Performance of HWDP AssemblyMamani Vargas WiljhoNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- Drill CollarDocument1 pageDrill CollarGuillermo Rangel AvalosNo ratings yet

- Archer DP 5.875 Inch XT 57 SpecsDocument3 pagesArcher DP 5.875 Inch XT 57 SpecsMamani Vargas Wiljho100% (1)

- Heavy Weight Drill Pipe PerformanceDocument3 pagesHeavy Weight Drill Pipe PerformanceHomero NavarroNo ratings yet

- Bolt Sizing EngineerdogDocument43 pagesBolt Sizing EngineerdogHans GoetheNo ratings yet

- Generate Data Sheet for Oil Country Tubular GoodsDocument1 pageGenerate Data Sheet for Oil Country Tubular GoodsKuOneMohdAzrulNo ratings yet

- 5.5in Hwdp Ht55质量文件包裹模板Document20 pages5.5in Hwdp Ht55质量文件包裹模板zhaibo666No ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- Drill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUDocument9 pagesDrill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUFernando Ruiz ArroyoNo ratings yet

- 5.5 HWDPDocument3 pages5.5 HWDPözgüncNo ratings yet

- 2.500 X 1.375 DC With MW20 SlickDocument1 page2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanNo ratings yet

- Datasheet 30in Casing Ichalkil 4-Fieldwood (00000002)Document2 pagesDatasheet 30in Casing Ichalkil 4-Fieldwood (00000002)Claudio Israel Godinez SomeraNo ratings yet

- 5.5英寸短钻杆 HT55质量文件包裹模板Document17 pages5.5英寸短钻杆 HT55质量文件包裹模板zhaibo666No ratings yet

- 3.5 In. 15.50# EU X-95 R2 XT39 (5.0 X 2.6875) - 10P.15BDocument3 pages3.5 In. 15.50# EU X-95 R2 XT39 (5.0 X 2.6875) - 10P.15BIng. Luis A. García CórdovaNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument7 pagesDrill Pipe Configuration: 80 % Inspection ClassWaleedm MariaNo ratings yet

- Luxon Bolt Torque CalculatorDocument10 pagesLuxon Bolt Torque CalculatorBharath YemireddyNo ratings yet

- CDS 7.000IN 29.00PPF L80-13CR TP-G2 V2024.03.05Document1 pageCDS 7.000IN 29.00PPF L80-13CR TP-G2 V2024.03.05Kaveh BahiraeeNo ratings yet

- Technical Data Sheet TMK UP FMT 3.5 X 9.2 N80Document1 pageTechnical Data Sheet TMK UP FMT 3.5 X 9.2 N80earlangga rmpNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection ClassLuis Manuel García GuillénNo ratings yet

- 20009K CRTi4 7.0 Specification Summary PDFDocument5 pages20009K CRTi4 7.0 Specification Summary PDFRichard PinontoanNo ratings yet

- DWC Technical SpecificationsDocument2 pagesDWC Technical SpecificationsYamid Caballero SolanoNo ratings yet

- Technical Specifications 5Document2 pagesTechnical Specifications 5ChoriChorroNo ratings yet

- Drill pipe data sheetDocument2 pagesDrill pipe data sheetoscar0% (1)

- 4in DP 14# IU S135T XTF39 (5.00 x2.5625)Document7 pages4in DP 14# IU S135T XTF39 (5.00 x2.5625)Pavin PiromNo ratings yet

- 1-5/8" CELLFLEX Lite Low-Loss Foam-Dielectric Coaxial Cable: LCF158-50JLDocument4 pages1-5/8" CELLFLEX Lite Low-Loss Foam-Dielectric Coaxial Cable: LCF158-50JLLuciano Silvério LeiteNo ratings yet

- Volant Specs CRTi2-8.63Document5 pagesVolant Specs CRTi2-8.63Raymond ChuNo ratings yet

- Technical Features: 7-16 DIN Female Connector For 7/8" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingDocument2 pagesTechnical Features: 7-16 DIN Female Connector For 7/8" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingLuciano Silvério LeiteNo ratings yet

- Performance Sheet Tubing: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Tubing: Pipe Body: Tubular Assemblykm1790No ratings yet

- Rr220 Series Standard Air Bearing Bits: Drilling ApplicationsDocument2 pagesRr220 Series Standard Air Bearing Bits: Drilling ApplicationsandraNo ratings yet

- IBT 0.6m Single Polarization Compact C3 Antenna Datasheet (A80S06TAC-3NX)Document4 pagesIBT 0.6m Single Polarization Compact C3 Antenna Datasheet (A80S06TAC-3NX)Youness Abdelhakim LouardyNo ratings yet

- 3.500 P110 12.95ppf TSHDDocument1 page3.500 P110 12.95ppf TSHDDeepak RanaNo ratings yet

- 7-16 DIN Female Connector For 1-5/8" Coaxial Cable, OMNI FIT™ Premium, Straight, O-Ring and Compression SealingDocument2 pages7-16 DIN Female Connector For 1-5/8" Coaxial Cable, OMNI FIT™ Premium, Straight, O-Ring and Compression SealingLuciano Silvério LeiteNo ratings yet

- Datasheet 312 EU-x-1330-x-S135-x-R2-31.5-ft - 478-x-2916-x-TSDS38-x-135-ksi-SMYS - 1412-Box-12-Pin - HB-Box - 60-70-MUT - 1.0-FF-and-1.15-FF - TSC-DP-Web-Site-1Document2 pagesDatasheet 312 EU-x-1330-x-S135-x-R2-31.5-ft - 478-x-2916-x-TSDS38-x-135-ksi-SMYS - 1412-Box-12-Pin - HB-Box - 60-70-MUT - 1.0-FF-and-1.15-FF - TSC-DP-Web-Site-1oscarNo ratings yet

- Escuela Central Atenas - SAAAB Longitudinal Nivel 1Document4 pagesEscuela Central Atenas - SAAAB Longitudinal Nivel 1Jorge FuentesNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- 1-5/8" CELLFLEX Premium Attenuation Low-Loss Foam-Dielectric Coaxial CableDocument4 pages1-5/8" CELLFLEX Premium Attenuation Low-Loss Foam-Dielectric Coaxial CableLuciano Silvério LeiteNo ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetJeremias UtreraNo ratings yet

- 12.250 - PDC BitDocument1 page12.250 - PDC BitMoh Syamsul BahriNo ratings yet

- 3.50 - 9.3 - J55 - FL-4S - Imp - Technical SpecificationsDocument1 page3.50 - 9.3 - J55 - FL-4S - Imp - Technical SpecificationsPavel PetukhovNo ratings yet

- 20007P-CRTi2-8.63 Specification SummaryDocument5 pages20007P-CRTi2-8.63 Specification Summarytibismtx100% (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- No. 31Document2 pagesNo. 31UPGM Ingenieria petroleraNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- No. 31Document2 pagesNo. 31UPGM Ingenieria petroleraNo ratings yet

- No. 31Document2 pagesNo. 31UPGM Ingenieria petroleraNo ratings yet

- No. 31Document2 pagesNo. 31UPGM Ingenieria petroleraNo ratings yet

- Heavy Weight Drill Pipe PerformanceDocument3 pagesHeavy Weight Drill Pipe PerformanceHomero NavarroNo ratings yet

- No. 31Document2 pagesNo. 31UPGM Ingenieria petroleraNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- Heavy Weight Drill Pipe PerformanceDocument3 pagesHeavy Weight Drill Pipe PerformanceHomero NavarroNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- Heavy Weight Drill Pipe PerformanceDocument3 pagesHeavy Weight Drill Pipe PerformanceHomero NavarroNo ratings yet

- Heavy Weight Drill Pipe PerformanceDocument3 pagesHeavy Weight Drill Pipe PerformanceHomero NavarroNo ratings yet

- Heavy Weight Drill Pipe PerformanceDocument3 pagesHeavy Weight Drill Pipe PerformanceHomero NavarroNo ratings yet

- Aluminum Alloy Drill Pipe in Geothermal DrillingDocument126 pagesAluminum Alloy Drill Pipe in Geothermal DrillingAriel MoyanoNo ratings yet

- Bolted Flanged Joint Creep/Relaxation Results at High TemperaturesDocument7 pagesBolted Flanged Joint Creep/Relaxation Results at High TemperaturesjlbarretoaNo ratings yet

- Effects of Kahramanmaras Earthquakes in South of Turkey On Livestock ActivitiesDocument10 pagesEffects of Kahramanmaras Earthquakes in South of Turkey On Livestock ActivitiesIJAR JOURNALNo ratings yet

- Mesozoic Rock Formations of the South-West Rusca Montana BasinDocument27 pagesMesozoic Rock Formations of the South-West Rusca Montana BasinplanessNo ratings yet

- Design and Fabrication of a Small Scale Solar Powered Jaw CrusherDocument90 pagesDesign and Fabrication of a Small Scale Solar Powered Jaw CrusherKevinKivaNo ratings yet

- Difficulties Faced by Traffic Police in MultanDocument2 pagesDifficulties Faced by Traffic Police in MultanMALIK WALEED EJAZNo ratings yet

- MSC Thesis Alan Wijaya 2018Document2 pagesMSC Thesis Alan Wijaya 2018Alan WijayaNo ratings yet

- Submitted By: Alexis T. Lopez, BSHM 3 ASS #1: Quality Service in HM and TMDocument6 pagesSubmitted By: Alexis T. Lopez, BSHM 3 ASS #1: Quality Service in HM and TMWyn TerNo ratings yet

- 10 Power Phrases To Master Your Next ArgumentDocument6 pages10 Power Phrases To Master Your Next ArgumentshaiannnicolebNo ratings yet

- Cell Membrane Structure and FunctionDocument18 pagesCell Membrane Structure and Functionkevin_ramos007No ratings yet

- 2019-10-01 Kitchen Garden PDFDocument110 pages2019-10-01 Kitchen Garden PDFLaura GrėbliauskaitėNo ratings yet

- Ceramage: Light-Curing Microhybrid CompositeDocument3 pagesCeramage: Light-Curing Microhybrid CompositeVero GrambergNo ratings yet

- MENTALISM THEORY EMPHASIZES INNATE LANGUAGE CAPACITYDocument5 pagesMENTALISM THEORY EMPHASIZES INNATE LANGUAGE CAPACITYBilingual Capricon100% (6)

- Ogre Classic CountersDocument6 pagesOgre Classic Countersgianduja100% (1)

- Lecture3 3Document27 pagesLecture3 3himan123No ratings yet

- IISER Aptitude Test 2013: Syllabus ForDocument1 pageIISER Aptitude Test 2013: Syllabus ForSanthoshkumar RayavarapuNo ratings yet

- Cec 208 Lecture Notes 1Document9 pagesCec 208 Lecture Notes 1Zaid Habibu100% (1)

- 002 SillitoeDocument14 pages002 Sillitoesebastian tiriraNo ratings yet

- 2NS SEMESTER Self Instructured Module in Community EngagementDocument31 pages2NS SEMESTER Self Instructured Module in Community EngagementEditha FernandezNo ratings yet

- GRADE:10: Page 1 of 13Document13 pagesGRADE:10: Page 1 of 13Pujan PatelNo ratings yet

- Cover LetterDocument2 pagesCover Letterapi-237243590No ratings yet

- CE Declaration of ConformityDocument2 pagesCE Declaration of Conformitymaria cristina ristagnoNo ratings yet

- 05 Information LiteracyDocument11 pages05 Information LiteracyLaila Ismael SalisaNo ratings yet

- Curiosity in Schools Jiroutetal.2018Document17 pagesCuriosity in Schools Jiroutetal.2018EVA JAZMIN DE LA ROSA RIVERANo ratings yet

- Working Paper No: 384: Amit GuptaDocument26 pagesWorking Paper No: 384: Amit Guptanpr_mishraNo ratings yet

- Genetic Algorithms: Department of Computer Science, University of New Mexico, AlbuquerqueDocument4 pagesGenetic Algorithms: Department of Computer Science, University of New Mexico, AlbuquerqueESMAILNo ratings yet

- CH 2Document28 pagesCH 2CWHNo ratings yet

- Thermo ScientificDocument29 pagesThermo ScientificTaeng SoshiNo ratings yet

- Hubungan Penggunaan Gadget Dengan Prestasi Belajar AnakDocument13 pagesHubungan Penggunaan Gadget Dengan Prestasi Belajar AnakIndahNo ratings yet

- Markov Analysis of Students Performance and AcadeDocument13 pagesMarkov Analysis of Students Performance and AcadeCross LapenzonaNo ratings yet

- Fundamentals of Research Methodology For Healthcare Professionals by Gisela Hildegard Van Rensburg Christa Van Der Walt Hilla BrinkDocument225 pagesFundamentals of Research Methodology For Healthcare Professionals by Gisela Hildegard Van Rensburg Christa Van Der Walt Hilla BrinkLeila RKNo ratings yet