Professional Documents

Culture Documents

Second Batch TRG PGM Week No 8,9,10 and 11

Uploaded by

ASHVIN YADAVOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Second Batch TRG PGM Week No 8,9,10 and 11

Uploaded by

ASHVIN YADAVCopyright:

Available Formats

TRAINING PROGRAM OF SHEET METAL AND WELDER :SECOND SEMESTER (BATCH II)

04-Mar-2024 -08-Mar-2024

Time

S No Course Week No Day

0850h- 0940h- 1115h- 1305h- 1355h- 1445h-

0800-0845h 1030h-1115h 1215h-1300h

0935h 1025h 1215h 1350h 1440h 1530h

TT - A.C. Welding

transformer DC welding TP -Fillet “T” joint on MS plate 10mm Workshop Calculation & Science/TP-Fillet “T” joint

Monday

1 Generator and its thick in flat position on MS plate 10mm thick in flat position Ex No -

04 Mar 24

construction Ex No -1.2.20 1.2.20

Ex No -1.2.20

TT - Gases used for

TP -Setting of Oxy - Acetylene and Employability Skills /TP -Setting of Oxy - Acetylene

Tuesday welding and gas flame

2 make straight cuts and make straight cuts

05 Mar 24 combinations

Ex No -1.1.13 Ex No -1.1.13

Ex No -1.1.13

TP -Perform making straight line

TT -Chemistry of oxy- TP -Perform making straight line cutting of MS plate

LUNCH TIME

Wednesday cutting of MS plate 10mm thick by

3 acetylene flame 10mm thick by gas accuracy within ± 2mm

06 Mar 24 gas accuracy within ± 2mm

Sheet Metal Ex No -1.1.14 Ex No -1.1.14

8 Ex No -1.1.14

& Welder

TP -Beveling of MS plates 10mm TP -Beveling of MS plates 10mm thick cutting regular

TT -Principle of gas thick cutting regular geometrical geometrical

Thursday

4 cutting and application shapes and irregular shapes cutting shapes and irregular shapes cutting champers by

07 Mar 24

Ex No -1.1.15 champers by gas cutting gas cutting

Ex No -1.1.15 Ex No -1.1.15-;

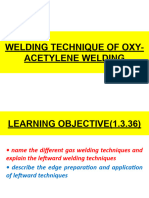

TT- Oxy-acetylene hand

TP- Circular gas cutting on MS plate TP- Circular gas cutting on MS plate 10mm thick by

Friday cutting - Piercing hole

5 10mm thick by profile cutting machine profile cutting machine

08 Mar 24 and profile cutting

EX NO 1.1.16 EX NO 1.1.16

EX NO 1.1.16

TRAINING PROGRAM OF SHEET METAL AND WELDER : SECOND SEMESTER (BATCH II)

11-Mar-2024 -15-Mar-2024

Time

S No Course Week No Day 0850h- 0940h- 1115h- 1305h- 1355h- 1445h-

0800-0845h 1030h-1115h 1215h-1300h

0935h 1025h 1215h 1350h 1440h 1530h

Monday

1 REVISION REVISION

11Mar 24

Tuesday

2 EXAM (THEORY) EXAM (THEORY)

12Mar 24

Wednesday

3 EXAM (PRACTICAL) EXAM (PRACTICAL)

LUNCH TIME

13Mar 24

Sheet Metal

9

& Welder TP -Marking and perform radial cuts, TP -Marking and perform radial cuts, cutting out

TT - Oxy-acetylene

Thursday cutting out holes using oxy-acetylene holes using oxy-acetylene

4 machine cutting

14Mar 24 gas cutting gas cutting

Ex No -1.1.17

Ex No - 1.1.17 Ex No - 1.1.17

TP -Identification of cutting defects

TT -Common defects in TP -Identification of cutting defects viz, distortion,

Friday viz, distortion, grooved, fluted or

5 gas cutting grooved, fluted or ragged cuts

15Mar 24 ragged cuts

Ex No -1.1.18 Ex No - 1.1.18

Ex No - 1.1.18

TRAINING PROGRAM OF SHEET METAL AND WELDER : FIRST SEMESTER (BATCH II)

18-Mar-2024 - 22-Mar-2024

Time

S No Course Week No Day 0850h- 0940h- 1115h- 1305h- 1355h- 1445h-

0800-0845h 1030h-1115h 1215h-1300h

0935h 1025h 1215h 1350h 1440h 1530h

TT -Power source TP -Square butt joint on MS sheet 2 Workshop Calculation & Science/TP -Square butt

Monday

1 selection criteria mm thick in flat position joint on MS sheet 2 mm thick in flat position

18 Mar24

Ex No -1.1.19 Ex No -1.1.19 Ex No -1.1.19

TT - Advantages and

TP-Open corner joint on M.S. sheet 2 Employability Skills/TP-Open corner joint on M.S.

Tuesday disadvantages of AC and

2 mm thick in flat position sheet 2 mm thick in flat position

19 Mar24 DC welding

Ex No - 1.2.21 Ex No - 1.2.21

Ex No -1.2.21

LUNCH TIME

Sheet Metal

10 TT - Weld slop and

& Welder TP-Fillet ‘T’ joint on M.S. sheet 2mm TP-Fillet ‘T’ joint on M.S. sheet 2mm thick in flat

Wednesday rotation

3 thick in flat position position Ex No -

20 Mar24 Ex No -

Ex No - 1.2.23 1.2.23

1.2.23

TT -Basic welding TP -Fillet lap joint on M.S. plate 10 TP -Fillet lap joint on M.S. plate 10 mm thick in flat

Thursday

4 positions mm thick in flat position position

21 Mar24

Ex No -1.2.22 Ex No - 1.2.22 Ex No - 1.2.22

TT -Weld symbol and

TP -Open corner joint on MS plate TP -Open corner joint on MS plate 10mm thick in flat

Friday welding symbol -

5 10mm thick in flat position position

22 Mar24 Description and uses

Ex No -1.2.24 Ex No -1.2.24

Ex No -1.2.24

TRAINING PROGRAM OF SHEET METAL AND WELDER : FIRST SEMESTER (BATCH II)

25-Mar-2024 - 29-Mar-2024

Time

S No Course Week No Day 0850h- 0940h- 1115h- 1305h- 1355h- 1445h-

0800-0845h 1030h-1115h 1215h-1300h

0935h 1025h 1215h 1350h 1440h 1530h

TT -Arc length and its TP -Fillet lap joint on MS sheet 2mm Workshop Calculation & Science/TP -Fillet lap joint

Monday

1 effects thick in flat position on MS sheet 2mm thick in flat position

25 Mar 24

Ex No -1.2.25 Ex No -1.2.25 Ex No -1.2.25

TP -Polarity in DC arc TP -Single “V” butt joint on MS plate Employability Skills/TP -Single “V” butt joint on MS

Tuesday

2 welding 12mm thick in flat position plate 12mm thick in flat position

26 Mar 24

Ex No -1.1.26 Ex No -1.1.26 Ex No -1.1.26

LUNCH TIME

TT -Weld quality and

Sheet Metal TP-Testing of weld joint by visual

11 Wednesday inspection (Visual TP-Testing of weld joint by visual inspection

3 & Welder inspection

27 Mar 24 inspection) Ex No -1.2.27

Ex No -1.2.27

Ex No -1.2.27

TP -Weld gauges and its TP-Inspection of welds using weld

Thursday TP-Inspection of welds using weld gauges

4 uses gauges

28 Mar 24 Ex No -1.2.28

Ex No -1.2.28 Ex No -1.2.28

TT -Calcium carbide TP -Square butt joint on MS sheet TP -Square butt joint on MS sheet 2mm thick in

Friday

5 properties and its uses 2mm thick in horizontal position horizontal position

29 Mar 24

Ex No -1.2.29 Ex No -1.2.29 Ex No -1.2.29

You might also like

- 2 - Week No 9,10,11,12,& 13 BATCH II TRG PgmeDocument6 pages2 - Week No 9,10,11,12,& 13 BATCH II TRG PgmeASHVIN YADAVNo ratings yet

- Second Semester Batch II Week No 01 & 02 TRG PgmeDocument2 pagesSecond Semester Batch II Week No 01 & 02 TRG PgmeASHVIN YADAVNo ratings yet

- Material List For Tender Cum e - Auction DT 26.04.2011Document24 pagesMaterial List For Tender Cum e - Auction DT 26.04.2011Deepak Kumar AgrawalNo ratings yet

- Aço X6NiCrTiMoVB25!15!2 - 1.4980 Austenitic SteelDocument2 pagesAço X6NiCrTiMoVB25!15!2 - 1.4980 Austenitic SteelMoacir MachadoNo ratings yet

- Tungsten Carbide Grades - WOKSALDocument1 pageTungsten Carbide Grades - WOKSALTaner DemirelNo ratings yet

- Based On Grades Based On Applications (Coated Carbide) : HarderDocument1 pageBased On Grades Based On Applications (Coated Carbide) : HardermihaidelianNo ratings yet

- Based On Grades Based On Applications (Coated Carbide) : HarderDocument1 pageBased On Grades Based On Applications (Coated Carbide) : HarderSaranjit ChatterjeeNo ratings yet

- RM Constraints 010211Document1 pageRM Constraints 010211Suvra DasNo ratings yet

- Price Quotation Form: Technical Education & Skills Development AuthorityDocument2 pagesPrice Quotation Form: Technical Education & Skills Development AuthorityKhael Angelo Zheus JaclaNo ratings yet

- Guard Pond: 08-Dec-14 JBF Petrochemicals LTD 1Document5 pagesGuard Pond: 08-Dec-14 JBF Petrochemicals LTD 1SajeshKumarNo ratings yet

- Mildly Corrosive Solution Applications: Dimensions (Inches)Document2 pagesMildly Corrosive Solution Applications: Dimensions (Inches)Alejandro VegaNo ratings yet

- EN8 Carbon Steel Bar - EN8 Forging - EN8 Flat - Saaj Steel CorporationDocument4 pagesEN8 Carbon Steel Bar - EN8 Forging - EN8 Flat - Saaj Steel CorporationNaiduNo ratings yet

- WPQR Status Register For EPS ProjectDocument3 pagesWPQR Status Register For EPS ProjectIlkin hasanovNo ratings yet

- Emer WPS 004Document1 pageEmer WPS 004cesarNo ratings yet

- Abrasivity of Rock and Soil: KeywordsDocument10 pagesAbrasivity of Rock and Soil: KeywordsNicolas AguilarNo ratings yet

- Air Lifting Schedule. - 06062015Document9 pagesAir Lifting Schedule. - 06062015vikneshNo ratings yet

- Automotive Differential HousingDocument5 pagesAutomotive Differential Housingfileuse.fNo ratings yet

- Overview of Bokaro Steel Plant: Suman SourabhDocument48 pagesOverview of Bokaro Steel Plant: Suman SourabhabhishekNo ratings yet

- CCMT09T304 MP3025Document1 pageCCMT09T304 MP3025sdhgwdNo ratings yet

- S010444 - 1 NosDocument1 pageS010444 - 1 NosJignesh Jagjivanbhai PatelNo ratings yet

- Engineers Handbook: Download: WWW - Tungaloyuk.co - Uk/handbookDocument32 pagesEngineers Handbook: Download: WWW - Tungaloyuk.co - Uk/handbookGnwantt RajputNo ratings yet

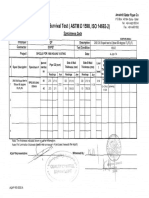

- 1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataDocument24 pages1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataNADEEM AHMEDNo ratings yet

- Bonded Seal Size ChartDocument6 pagesBonded Seal Size Charts bNo ratings yet

- Eqt Test RecordsDocument12 pagesEqt Test RecordsBabu Pro50% (2)

- RT Request For Sivert Date 13-Apr-17: Hail Surface FacilitiesDocument1 pageRT Request For Sivert Date 13-Apr-17: Hail Surface FacilitiesAnonymous AdofXEYAgENo ratings yet

- Shut-Down Maintenance and Pending Job List: (Lime Stone Crusher & Raw Mil Section) Month: November-2017Document15 pagesShut-Down Maintenance and Pending Job List: (Lime Stone Crusher & Raw Mil Section) Month: November-2017vinodsnNo ratings yet

- SPCCDocument10 pagesSPCCDeepak JainNo ratings yet

- Sanwa Engineering (Thailand) LTD.: SCLP Chip Conveyor V7000 SET190103-010-000 190103 SCLP Chip Conveyor V7000Document1 pageSanwa Engineering (Thailand) LTD.: SCLP Chip Conveyor V7000 SET190103-010-000 190103 SCLP Chip Conveyor V7000Anel EspinozaNo ratings yet

- Cutting Tools cataloge-CNC Inserts - OTOMODocument16 pagesCutting Tools cataloge-CNC Inserts - OTOMOOTOMO CUTTING TOOLSNo ratings yet

- Nexter 120MM NATO GunsDocument2 pagesNexter 120MM NATO Gunsleonardo leoNo ratings yet

- ToughMet Copper Nickel TinDocument2 pagesToughMet Copper Nickel TinBuchan65No ratings yet

- Tower-02 Pour-01: End Date Num of Days Labour Requirement Description of Work Start DateDocument2 pagesTower-02 Pour-01: End Date Num of Days Labour Requirement Description of Work Start Datekhadar babuNo ratings yet

- Daily Progress 09.02.2024 APRDocument1 pageDaily Progress 09.02.2024 APRadigamerz751No ratings yet

- Inspeksi - Steel StructureDocument9 pagesInspeksi - Steel StructureyuwantoniNo ratings yet

- Welder Performance Report PDFDocument1 pageWelder Performance Report PDFAzhar AhmadNo ratings yet

- 7.5 Kva BomDocument2 pages7.5 Kva BomDinesh MNo ratings yet

- Weekly Planning M/S Quality Infrastucture PVT LTD Client:-M/S Suzlon Energy Ltd. Project - Blade Testing Extension, Suzlon Limited, Por, VadodaraDocument3 pagesWeekly Planning M/S Quality Infrastucture PVT LTD Client:-M/S Suzlon Energy Ltd. Project - Blade Testing Extension, Suzlon Limited, Por, VadodaraAnonymous cE5jCmUWNo ratings yet

- Din en 10149-2Document12 pagesDin en 10149-2Just In TimeNo ratings yet

- Adobe Scan 20 Jan 2022Document1 pageAdobe Scan 20 Jan 2022MURALINo ratings yet

- 1.PL Drilling Main CatDocument42 pages1.PL Drilling Main CatBojan RadovanovicNo ratings yet

- Mabel Engineers Pvt. LTD Priliminary Welding Procedure Specification (PWPS) EN ISO 15609-1 2004Document2 pagesMabel Engineers Pvt. LTD Priliminary Welding Procedure Specification (PWPS) EN ISO 15609-1 2004dayalram100% (1)

- Preparation Method EN Titanium AlloyDocument1 pagePreparation Method EN Titanium AlloyRaj RajeshNo ratings yet

- Tata Metal: LestariDocument2 pagesTata Metal: Lestariyoanda adimas putraNo ratings yet

- Trade Theory Welder-SyllabusDocument4 pagesTrade Theory Welder-SyllabusUmang SoniNo ratings yet

- FOC US FOC US: Products ProductsDocument24 pagesFOC US FOC US: Products ProductsmichaelguzziNo ratings yet

- Nace Index 2002Document7 pagesNace Index 2002Alin TomozeiNo ratings yet

- Hk78adto B62dca6cDocument18 pagesHk78adto B62dca6cpadla downloadNo ratings yet

- X17CrNi16-2 HTTP - WWW - Steelnumber.com - en - Steel - Composition - Eu - PHP - Name - IdDocument2 pagesX17CrNi16-2 HTTP - WWW - Steelnumber.com - en - Steel - Composition - Eu - PHP - Name - IddabarcinaNo ratings yet

- Wps 11Document2 pagesWps 11Avishek GuptaNo ratings yet

- 0 Gtaw TR-235 FW-10 Field TW-665 N/A 10.00 S-20 Butt Pipe To Pipe HD-EC-TF-DR5001-008Document1 page0 Gtaw TR-235 FW-10 Field TW-665 N/A 10.00 S-20 Butt Pipe To Pipe HD-EC-TF-DR5001-008Anonymous AdofXEYAgENo ratings yet

- Weekly Schedule - 20230901Document1 pageWeekly Schedule - 20230901CV.LAGADAR NANJUNGNo ratings yet

- PRM PurchaseDocument6 pagesPRM PurchaseRajkumar RajendranNo ratings yet

- Hostaperm Red Violet ERX A High Purity SS-Quinacridone Pigment With Outstanding PropertiesDocument2 pagesHostaperm Red Violet ERX A High Purity SS-Quinacridone Pigment With Outstanding PropertiesMaximiliano MackeviciusNo ratings yet

- Page No.83 P104 PIPING TOOLSDocument22 pagesPage No.83 P104 PIPING TOOLSBerry UmpolaNo ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-189 Insp. Date. 19.02.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-189 Insp. Date. 19.02.2021kbpatel123No ratings yet

- 45 Batch EnglishDocument6 pages45 Batch EnglishKnowledge NiwasNo ratings yet

- Flow Measurement Solution-General CatalogDocument9 pagesFlow Measurement Solution-General CatalogXu EmilyNo ratings yet

- (A.w), I&CAD ll:30 ofDocument1 page(A.w), I&CAD ll:30 ofRupesh ChowdaryNo ratings yet

- Consumables For SSDocument14 pagesConsumables For SSELongLeeNo ratings yet

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Lesson Plan Sheet Metal & Welder For 03.02.2023Document2 pagesLesson Plan Sheet Metal & Welder For 03.02.2023ASHVIN YADAVNo ratings yet

- Q-First Semester Batch Ii Final Examination Theory Question PaperDocument5 pagesQ-First Semester Batch Ii Final Examination Theory Question PaperASHVIN YADAVNo ratings yet

- Nominal Roll of StudentDocument1 pageNominal Roll of StudentASHVIN YADAVNo ratings yet

- Sheet Metal SectionDocument5 pagesSheet Metal SectionASHVIN YADAVNo ratings yet

- Lesson Plan Sheet Metal & Welder For NewDocument11 pagesLesson Plan Sheet Metal & Welder For NewASHVIN YADAVNo ratings yet

- Trade SyllabusDocument12 pagesTrade SyllabusASHVIN YADAVNo ratings yet

- Sheet Metal Section - 2Document6 pagesSheet Metal Section - 2ASHVIN YADAVNo ratings yet

- Oxy-Acetylene Hand Cutting - Piercing Hole and Profile CuttingDocument21 pagesOxy-Acetylene Hand Cutting - Piercing Hole and Profile CuttingASHVIN YADAVNo ratings yet

- MonogramDocument5 pagesMonogramASHVIN YADAVNo ratings yet

- Assessment Record Batch IIDocument11 pagesAssessment Record Batch IIASHVIN YADAVNo ratings yet

- Raw Material Status Welder and Sheet Metal C2 FinalexjamDocument19 pagesRaw Material Status Welder and Sheet Metal C2 FinalexjamASHVIN YADAVNo ratings yet

- Weld Symbol and Welding Symbol - Description and UsesDocument16 pagesWeld Symbol and Welding Symbol - Description and UsesASHVIN YADAVNo ratings yet

- Block Syllabus As On 06 Jan 24Document3 pagesBlock Syllabus As On 06 Jan 24ASHVIN YADAVNo ratings yet

- Detail Syllabus Sheet Metal and WelderDocument13 pagesDetail Syllabus Sheet Metal and WelderASHVIN YADAVNo ratings yet

- Common Defects in Gas CuttingDocument14 pagesCommon Defects in Gas CuttingASHVIN YADAVNo ratings yet

- MUG Measuring Can 5 LTR Dust Pan Fire Bucket: SectionDocument2 pagesMUG Measuring Can 5 LTR Dust Pan Fire Bucket: SectionASHVIN YADAVNo ratings yet

- Republic DayDocument2 pagesRepublic DayASHVIN YADAVNo ratings yet

- 3rd Semester Assessment SheetDocument11 pages3rd Semester Assessment SheetASHVIN YADAVNo ratings yet

- B-Balance Syllabus Sheet Metal and Welder Batch IIDocument2 pagesB-Balance Syllabus Sheet Metal and Welder Batch IIASHVIN YADAVNo ratings yet

- Welding Technique of Oxy-Acetylene WeldingDocument11 pagesWelding Technique of Oxy-Acetylene WeldingASHVIN YADAVNo ratings yet

- Management Information System: Ch-3: Information Systems, Organizations and StrategyDocument48 pagesManagement Information System: Ch-3: Information Systems, Organizations and StrategySalu RanaNo ratings yet

- Unit 6 Supply Chain ManagementDocument33 pagesUnit 6 Supply Chain Managementटलक जंग सरकारNo ratings yet

- Demand Analysis Question BankDocument3 pagesDemand Analysis Question BanknisajamesNo ratings yet

- FIN202 Group ProjectDocument15 pagesFIN202 Group ProjectNguyen Minh Chien (K16HCM)No ratings yet

- Sol Invty I ActivitiesDocument13 pagesSol Invty I ActivitiesKelsey VersaceNo ratings yet

- Managerial Accounting EssayDocument8 pagesManagerial Accounting EssayPatrick PetitNo ratings yet

- 2 Introduction To Mineral ProcessingDocument94 pages2 Introduction To Mineral Processingzainab alkhafafNo ratings yet

- MIS Case Study Zara IT For Fast Fashion MIS Case Study Zara IT For Fast FashionDocument4 pagesMIS Case Study Zara IT For Fast Fashion MIS Case Study Zara IT For Fast FashionAbhijeet singhNo ratings yet

- Derby Grey Is Leading Manufacturer of Leather Luggage Bags (Up To 62") For The Style-ConsciousDocument3 pagesDerby Grey Is Leading Manufacturer of Leather Luggage Bags (Up To 62") For The Style-ConsciousAnonymous 3tLaI7oLANo ratings yet

- B2B Markets and CRM NDocument252 pagesB2B Markets and CRM NInfotech Edge100% (1)

- Oil and Gas Training TSWDocument59 pagesOil and Gas Training TSWmohannaiduramNo ratings yet

- SAP Model Company For AgribusinessDocument1 pageSAP Model Company For AgribusinesssergioNo ratings yet

- Isb SMM I Assignment 2 Final ProjectDocument3 pagesIsb SMM I Assignment 2 Final ProjectTrúc Nguyễn ThanhNo ratings yet

- Ficoblazeadvisordecisionruleshowitworks4202wp 160302225024Document40 pagesFicoblazeadvisordecisionruleshowitworks4202wp 160302225024RajNo ratings yet

- What Is Income Elasticity of DemandDocument7 pagesWhat Is Income Elasticity of DemandMcusine JambaniNo ratings yet

- Jea 2017-2 Bossert FehskensDocument7 pagesJea 2017-2 Bossert FehskensmayNo ratings yet

- PWC Strategy& (Ex-Booz & Co.) - Industry 4.0 - How Digitization Makes Supply Chain More EfficientDocument32 pagesPWC Strategy& (Ex-Booz & Co.) - Industry 4.0 - How Digitization Makes Supply Chain More Efficientapritul3539No ratings yet

- Report in OutsourcingDocument81 pagesReport in OutsourcingYesha AquinoNo ratings yet

- PEX - 75-Range-Plascoguard-Zinc-Phosphate-Epoxy-PrimerDocument2 pagesPEX - 75-Range-Plascoguard-Zinc-Phosphate-Epoxy-Primersarcozy922No ratings yet

- Logistics ManagementDocument16 pagesLogistics ManagementTracy Van TangonanNo ratings yet

- Does CEMEX Have A Global AdvantageDocument3 pagesDoes CEMEX Have A Global AdvantageCarla Mairal MurNo ratings yet

- Business Process Re-Engineering: Angelito C. Descalzo, CpaDocument28 pagesBusiness Process Re-Engineering: Angelito C. Descalzo, CpaJason Ronald B. GrabilloNo ratings yet

- Lesson 2the Potential Market and The Market NeedDocument39 pagesLesson 2the Potential Market and The Market NeedAngeline Curioso0% (1)

- ET 116 - Chapter 3 - Store Design and LayoutDocument26 pagesET 116 - Chapter 3 - Store Design and LayoutKathlyn AragonNo ratings yet

- A Aravind Bharathi - Resume - 21Document2 pagesA Aravind Bharathi - Resume - 21Aravind BharathiNo ratings yet

- Amazon Target AudienceDocument4 pagesAmazon Target AudienceBruno Halfeld DutraNo ratings yet

- Product Cost by Sales Order - SAP DocumentationDocument3 pagesProduct Cost by Sales Order - SAP DocumentationManas Kumar Sahoo100% (1)

- Mining Operational ExcellenceDocument12 pagesMining Operational ExcellencegarozoNo ratings yet

- Moshood ProjectDocument97 pagesMoshood ProjectGodwin Ndukwu100% (1)

- JIT in Automobile IndustryDocument16 pagesJIT in Automobile IndustryRoshni PatelNo ratings yet