Professional Documents

Culture Documents

Equipment Erection by Crane Jsa

Equipment Erection by Crane Jsa

Uploaded by

AKBAR ALIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment Erection by Crane Jsa

Equipment Erection by Crane Jsa

Uploaded by

AKBAR ALICopyright:

Available Formats

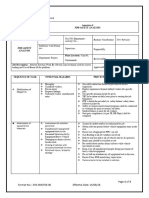

Jubliant Infrastructure Limited-Bharuch

Annexure-6

JOB SAFETY ANALYSIS

JSA NO. Department / Routine/ Non

Job Title: New/ Revised

Activity/ No… Routine

JOB SAFETY Reference work Supervisor:

Prepared By:

ANALYSIS Permit no:

Plant Location: UNIT-1

Department: Project

Reviewed By:

Niacinamide

Job Description:

Approved By:

SEQUENCE OF TASK POTENIAL HAZARDS PREVENTIVE MEASURES

Equipment erection by Incorrect crane positioning Ensure all lifting tools tackles tested should be done.

crane Failure of lifting gears Proper supervision by site supervisor.

Over load. Crane operators and riggers will have proper training, experience and

Collapse of crane. qualification.

Fall of material. Operator with HMV license deployed.

Uneven ground condition. Capacity of the vehicle should be related to the load to be carried.

Overhead power power Trained riggers are deployed.

line. Ensure proper communication between rigger/signal man & operator.

Uncontrolled movement of

Conducted On job site specific training.

load.

Pinch point hazard.

Position the crane on solid ground out riggers fully extended on pads.

Provide guide rope with sufficient man power to balance load.

People under suspended

Operator shall check soil condition working location.

load.

Ensure as per JIL format lifting plan.

Unbalancing of load while

Ensure use of inspected & colour coded hand tools & rigging accessories.

holding it

Area should be properly barricaded during lifting operations

Use tag line to control the load

Ensure equipment weight according to crane capacity.

Ensure all Crane document & check list.

Ensure Crane as per job.

Lifting tools and tackles have valid form-10.

Lifting equipment within SWL of crane.

Crane position area should be levelled and area compacted.

Multiple activity not should be start in the same location.

Page 1 of 1

Format No.: EHS-006/F06-00 Effective Date:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rope Pulley JsaDocument1 pageRope Pulley JsaAKBAR ALINo ratings yet

- Material Lifting Shifting by Farana/craneDocument1 pageMaterial Lifting Shifting by Farana/craneAKBAR ALINo ratings yet

- JSA For Materia/equipment Loading Unloading & Shifting Work JsaDocument3 pagesJSA For Materia/equipment Loading Unloading & Shifting Work JsaAKBAR ALINo ratings yet

- Gas Cutting Work JsaDocument2 pagesGas Cutting Work JsaAKBAR ALINo ratings yet

- Equipment/reactor Erection Work JsaDocument3 pagesEquipment/reactor Erection Work JsaAKBAR ALINo ratings yet

- Chain Pulley Block JsaDocument2 pagesChain Pulley Block JsaAKBAR ALINo ratings yet

- Gritting, Railling and Stair Case Erection Work JsaDocument5 pagesGritting, Railling and Stair Case Erection Work JsaAKBAR ALINo ratings yet

- Shuttring & Deshuttring Work JsaDocument4 pagesShuttring & Deshuttring Work JsaAKBAR ALINo ratings yet

- Shuttring, Deshuttering, Steel Fixing, P.C.C and R.C.C Work JsaDocument5 pagesShuttring, Deshuttering, Steel Fixing, P.C.C and R.C.C Work JsaAKBAR ALINo ratings yet

- Nut Bolt Tighten by Hammering Spanner and Torque Machine JsaDocument4 pagesNut Bolt Tighten by Hammering Spanner and Torque Machine JsaAKBAR ALINo ratings yet

- Plastering Work JsaDocument1 pagePlastering Work JsaAKBAR ALINo ratings yet

- Concrete Breakina Jsa by Breaker MachineDocument2 pagesConcrete Breakina Jsa by Breaker MachineAKBAR ALINo ratings yet

- Confined Space Jsa/excavation JsaDocument2 pagesConfined Space Jsa/excavation JsaAKBAR ALINo ratings yet

- Steel Cutting, Bending, Welding and Grinding Work JsaDocument2 pagesSteel Cutting, Bending, Welding and Grinding Work JsaAKBAR ALINo ratings yet

- Rebaring Work JsaDocument1 pageRebaring Work JsaAKBAR ALINo ratings yet

- Bar Bending and Cutting WorkDocument1 pageBar Bending and Cutting WorkAKBAR ALINo ratings yet

- .Inspection Checklist For Safety BeltDocument1 page.Inspection Checklist For Safety BeltAKBAR ALINo ratings yet

- Deck Sheet Method StatementDocument7 pagesDeck Sheet Method StatementAKBAR ALINo ratings yet