Professional Documents

Culture Documents

Checklist - HACCP

Uploaded by

alias brownOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checklist - HACCP

Uploaded by

alias brownCopyright:

Available Formats

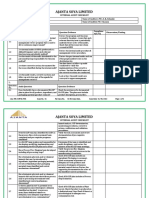

Gap Audit – Nyagatare Maize Processing Factory

Hazard Analysis Critical Control Point (HACCP)

Gap Audit Checklist

Food safety management systems — Hazard Analysis Critical Control Point (HACCP)

No. Requirements Observations In Compliance

4 Documentation requirements

1 4.1 HACCP manual Yes

Does the organization have a No

HACCP manual?

2 4.2 Control of documents and Yes

records No

Does the organization has control of

documents and records procedures

5 Management responsibilities

1 5.1 General Yes

No

Is there any evidence that the top

management is committed to the

development and implementation of

the HACCP based food safety

system and to continually improving

2 5.2 Establishing the food safety

policy

Does the organization define and

document its food safety policy

3 5.3 Responsibility and authority

Does the organization’s top

management define responsibilities

and authorities and communicated

within the organization to ensure the

effective operation and maintenance

of the food safety system.

Clause 5.3: The HACCP Team

Does the organization have a Yes

1 documented HACCP Team? No

Do the HACCP Team members have Yes

the process skills and knowledge to No

Gap Audit – Nyagatare Maize Processing Factory

Hazard Analysis Critical Control Point (HACCP)

Gap Audit Checklist

develop and maintain the HACCP

2 Plan?

Does the HACCP Team Leader have Yes

3 operational accountability within the No

organization?

Clause 8.5.1.2: Characteristics of raw materials, ingredients, and product-contact materials

The organization shall ensure that all applicable statutory and regulatory food safety requirements are identified for all

raw materials, ingredients, and product contact materials.

Does the organization define biological, Yes

1 chemical, and physical characteristics No

of raw materials, ingredients, and

product contact materials?

Is the composition of formulated Yes

2 ingredients, including additives and No

processing aids described?

Is the source of raw materials, Yes

3 ingredients, and product contact No

materials (e.g., animal, mineral or

vegetable) described?

Is place of origin (provenance) for raw Yes

4 materials, ingredients, and product No

contact materials indicated?

Does the organization define method of Yes

5 production, packaging and delivery of No

raw materials, ingredients, and product

contact materials?

Does the organization documents Yes

6 storage conditions, shelf life, preparation No

and/or handling before use or processing

for raw materials, ingredients?

Does the organization set acceptance Yes

7 criteria related to food safety or No

specifications of purchased materials

and ingredients appropriate to their

intended use?

Clause 8.5.1.3 Characteristics of end products

The organization shall maintain documented information concerning the characteristics of end products to the extent

needed to conduct the hazard analysis

Gap Audit – Nyagatare Maize Processing Factory

Hazard Analysis Critical Control Point (HACCP)

Gap Audit Checklist

1 Does the organization have product Yes

name or similar identifications? No

2 Is the composition of the product clearly Yes

documented? No

3 Are biological, chemical, and physical Yes

characteristics relevant for food safety No

well defined?

4 Is the intended shelf life and storage Yes

conditions of the product documented? No

5 Is the packaging methodology Yes

described? No

6 Does the organization describe Yes

labelling relating to food safety and/or No

instructions for handling, preparation,

intended use, distribution, and delivery

of the product?

Clause 8.5.1.4: Intended use

The intended use, including reasonably expected handling of the end product and any unintended use but reasonably

expected mishandling and misuse of the end product, shall be considered and shall be maintained as documented

information to the extent needed to conduct the hazard analysis

1 Did the organization defined the Yes

intended use for every product? No

Clause 8.5.1.5: Flow diagrams and descriptions of processes

Clause 8.5.1.5.1: Preparation of the flow diagrams

Flow diagrams shall be clear, accurate and sufficiently detailed to the extent needed to conduct the hazard analysis.

Are documented flow diagrams in Yes

1 place? No

2 Is the sequence and interaction of the Yes

steps in the operation clearly indicated? No

3 Are outsourced processes indicated? Yes

No

4 Is the entrance of raw materials, Yes

ingredients, processing aids, packaging

Gap Audit – Nyagatare Maize Processing Factory

Hazard Analysis Critical Control Point (HACCP)

Gap Audit Checklist

materials, utilities and intermediate No

products clearly indicated?

5 Where reworking and recycling take Yes

place? No

6 Where end products, intermediate Yes

products, by-products and waste are No

released or removed?

Clause 8.5.1.5.2 On-site confirmation of flow diagrams

The food safety team shall confirm on-site the accuracy of the flow diagrams, update the flow diagrams where

appropriate and retain as documented information.

1 Was the flow diagram confirmed? Yes

No

Clause 8.5.1.5.3: Description of processes and process environment

a) Was the layout of premises, including Yes

food and non-food handling areas No

described?

b) Were processing equipment and Yes

contact materials, processing aids and No

flow of materials described?

c) Were existing PRPs, process Yes

parameters, control measures (if any) No

and/or the strictness with which they

are applied, or procedures that can

influence food safety;

d) Were external requirements (e.g., from Yes

statutory and regulatory authorities or No

customers) that can impact the choice

and the strictness of the control

measures described?

e) Does the HACCP team verify the flow Yes

diagrams annually and whenever there No

are any significant changes to the

product or process?

Principle-1: Hazard analysis

a) Has hazard analysis been conducted Yes

and documented at each step of the No

process?

b) Has a hazard analysis been conducted Yes

for each raw material input? No

Gap Audit – Nyagatare Maize Processing Factory

Hazard Analysis Critical Control Point (HACCP)

Gap Audit Checklist

c) Have all potential food safety hazards Yes

been identified and assessed to No

determine what needs to be prevented,

eliminated, or reduced to acceptable

levels?

d) Have all potential allergenic hazards Yes

been considered, identified, and No

documented?

e) For any hazard deemed significant, has Yes

at least one control measure been No

determined to prevent it from occurring

or reduce it to an acceptable level?

Principle-2: Determining Critical Control Points (CCP)

a) If the hazard analysis indicates any Yes

significant hazards not minimized or No

eliminated by Good Manufacturing

Practices (GMPs) that are present

within the food manufacturing process,

are they identified as Critical Control

Points (CCPs)?

Principle-3: Establish Critical Limits

a) Are Critical Limits established for each Yes

CCP? No

Principle-4: CCP Monitoring

a) Has the organization documented how Yes

each CCP is monitored to ensure it is No

within set critical limits?

b) Is the assigned person(s) to undertake Yes

the monitoring trained in correct No

methods?

c) Are records signed by the person Yes

responsible for monitoring? No

Principle-5: Corrective Actions

a) Have CCP corrective actions been Yes

developed, documented, and No

implemented that define the action(s) to

be taken when monitoring reveals that

Gap Audit – Nyagatare Maize Processing Factory

Hazard Analysis Critical Control Point (HACCP)

Gap Audit Checklist

the critical limit has not been met?

Principle-6: Verification Activities

a) Are verification procedures Yes

established? No

b) Are verification procedures effectively Yes

implemented? No

Principle-7: Record-keeping and documentation

a) Is record keeping and documentation Yes

for HACCP procedures established? No

b) Are all HACCP-related record-keeping Yes

and documentation procedures No

effectively implemented?

You might also like

- Checklist - ISO 22000Document8 pagesChecklist - ISO 22000alias brownNo ratings yet

- Quality Assurance for Animal Feed Analysis LaboratoriesFrom EverandQuality Assurance for Animal Feed Analysis LaboratoriesNo ratings yet

- Haccp Audit FormDocument6 pagesHaccp Audit FormMarsit Med AmineNo ratings yet

- Internal Audit Checklist Food Safety-MRDocument5 pagesInternal Audit Checklist Food Safety-MRRavi BaghelNo ratings yet

- Scope of HACCP AuditDocument9 pagesScope of HACCP AuditAbdul QaiyuumNo ratings yet

- Olives and Olive Oil as Functional Foods: Bioactivity, Chemistry and ProcessingFrom EverandOlives and Olive Oil as Functional Foods: Bioactivity, Chemistry and ProcessingApostolos KiritsakisNo ratings yet

- ISO 22000 Check ListDocument10 pagesISO 22000 Check ListYasser Hassan100% (6)

- Validating Preventive Food Safety and Quality Controls: An Organizational Approach to System Design and ImplementationFrom EverandValidating Preventive Food Safety and Quality Controls: An Organizational Approach to System Design and ImplementationRating: 5 out of 5 stars5/5 (1)

- Palm Olein Supplier Assessment FormDocument12 pagesPalm Olein Supplier Assessment FormNéstor VargasNo ratings yet

- Sample Audit Checklist For HACCPDocument16 pagesSample Audit Checklist For HACCPAprilJoyBascosNo ratings yet

- Sample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorDocument16 pagesSample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorMonica SinghNo ratings yet

- General Controls: Instructions/Questions Note Any Exceptions and Comments in Notebook Yes/No/NADocument15 pagesGeneral Controls: Instructions/Questions Note Any Exceptions and Comments in Notebook Yes/No/NAMubarak PatelNo ratings yet

- DraftDocument5 pagesDraftAhmad Masoom JamshidiNo ratings yet

- Ehaccp - Allergen Control SOPDocument2 pagesEhaccp - Allergen Control SOPAlfred Rangel100% (1)

- Checklist WHO GMPDocument20 pagesChecklist WHO GMPShivanand Bharti50% (4)

- ISO 22000 Checklist Sample PDF ReportDocument24 pagesISO 22000 Checklist Sample PDF ReportNayely GonzálezNo ratings yet

- Audit Checklist TemplateDocument16 pagesAudit Checklist TemplateManasa Ravi100% (3)

- NCIMS Hazard Guide Version 1 1 Revised 6-16-06Document77 pagesNCIMS Hazard Guide Version 1 1 Revised 6-16-06Hardik PatelNo ratings yet

- GMP Chklist PDFDocument34 pagesGMP Chklist PDFkhan nomanNo ratings yet

- GMP+ B2 Production of Feed Ingredients: 02 Feed Safety Management System ObjectiveDocument26 pagesGMP+ B2 Production of Feed Ingredients: 02 Feed Safety Management System ObjectiveAnonymous iTzCnMNo ratings yet

- Annex 4 DNDi IMP Packaging Quality QuestionnaireDocument11 pagesAnnex 4 DNDi IMP Packaging Quality QuestionnairelovelyamoreslactawanNo ratings yet

- FSMS Guidance Documents Ghee Draft V4 For Website2Document60 pagesFSMS Guidance Documents Ghee Draft V4 For Website2Shyamalendu DattaNo ratings yet

- SEO-Optimized Supplier Quality Questionnaire FormDocument2 pagesSEO-Optimized Supplier Quality Questionnaire FormsutharitesshNo ratings yet

- HACCP audit checklistDocument15 pagesHACCP audit checklistMuse ManiaNo ratings yet

- audit_checklist_templateDocument16 pagesaudit_checklist_templateAsif HabibNo ratings yet

- HACCP OverviewDocument21 pagesHACCP OverviewSherylleneAguileraNo ratings yet

- ChecklistDocument9 pagesChecklistrenukaNo ratings yet

- AJANTA SOYA LIMITED INTERNAL AUDIT CHECKLISTDocument3 pagesAJANTA SOYA LIMITED INTERNAL AUDIT CHECKLISTRavi Baghel100% (1)

- 4th Module 1Document18 pages4th Module 1Mha RizNo ratings yet

- Checklist Gmpplus b2 en 20150101Document26 pagesChecklist Gmpplus b2 en 20150101Soledad RiscoNo ratings yet

- Supplier Qualification Form v2019.02.20Document2 pagesSupplier Qualification Form v2019.02.20Alfred RangelNo ratings yet

- Why food analyzed key quality assuranceDocument8 pagesWhy food analyzed key quality assuranceNaveed Ul Hasan100% (1)

- PUR 06 Supplier Audit - Questionnaire 2Document9 pagesPUR 06 Supplier Audit - Questionnaire 2pakhidhokariyaNo ratings yet

- Checklists For Vendors AuditDocument7 pagesChecklists For Vendors AuditDeepak GargNo ratings yet

- Allergen ControlDocument4 pagesAllergen Controlmedtaher missaoui67% (6)

- Food Safety Management System: Asc Consultants (Pty) LTDDocument6 pagesFood Safety Management System: Asc Consultants (Pty) LTDMohammed Imran100% (2)

- PRO 8.2 Validation Procedure TemplatDocument6 pagesPRO 8.2 Validation Procedure TemplatSuresh SubbuNo ratings yet

- Good Manufacturing Practices and Food Safety Systems Audit: XXXXXXXXXXXXDocument27 pagesGood Manufacturing Practices and Food Safety Systems Audit: XXXXXXXXXXXXAsrel05No ratings yet

- GMP Health Supplements NutraceuticalsDocument84 pagesGMP Health Supplements NutraceuticalsSol RejoiceNo ratings yet

- Checklist ISO 22000Document21 pagesChecklist ISO 22000anggirasti100% (1)

- FSSC v4.1 ChecklistDocument100 pagesFSSC v4.1 Checklistjamil voraNo ratings yet

- ORTHO Clinical DiagnosticsDocument4 pagesORTHO Clinical DiagnosticsHuy Trần ThiệnNo ratings yet

- Checklist ISO 22000Document5 pagesChecklist ISO 22000Juan Armando Cano PeñaNo ratings yet

- Decision Tree For Halal Ingredient AssessmentDocument2 pagesDecision Tree For Halal Ingredient Assessmentazurah3100% (2)

- Operational Plan for Food Safety and CleanlinessDocument10 pagesOperational Plan for Food Safety and Cleanlinessparasmani jhaNo ratings yet

- BRC Food Safety Management System Implementation WorkbookDocument36 pagesBRC Food Safety Management System Implementation WorkbookAbdellah Ftouhi100% (1)

- BRC Issue 8 Whitepaper WebDocument12 pagesBRC Issue 8 Whitepaper WebGaganpreet KaurNo ratings yet

- ISO 22000 Audit ChecklistDocument32 pagesISO 22000 Audit Checklistlouiza100% (2)

- Halal Internal Audit ChecklistDocument11 pagesHalal Internal Audit ChecklistvirendraNo ratings yet

- Internal Audit Checklist STORE, PURCHASE - DISPATCHDocument4 pagesInternal Audit Checklist STORE, PURCHASE - DISPATCHRavi BaghelNo ratings yet

- Mushroom 6Document3 pagesMushroom 6Fredrick MayakaNo ratings yet

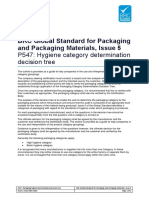

- BRC Global Standard For Packaging and Packaging Materials, Issue 5Document2 pagesBRC Global Standard For Packaging and Packaging Materials, Issue 5Gürkan TohtakNo ratings yet

- Ensuring Quality Nonclinical Safety Studies Through GLP ComplianceDocument18 pagesEnsuring Quality Nonclinical Safety Studies Through GLP ComplianceDr.Subhashish TripathyNo ratings yet

- ISO+22000 PresentationDocument200 pagesISO+22000 PresentationDona CarinaNo ratings yet

- HACCPDocument66 pagesHACCPAbubakker SiddiqNo ratings yet

- Good Food Laboratory Practices (GFLPS)Document41 pagesGood Food Laboratory Practices (GFLPS)Abhishek BanerjeeNo ratings yet

- FSSC Training ReportDocument6 pagesFSSC Training ReportGilbert AgudoNo ratings yet

- 3-2 GMPAspects Q-AssessmentDocument17 pages3-2 GMPAspects Q-AssessmentHardik PatelNo ratings yet

- GMP&HACCP CombinedDocument99 pagesGMP&HACCP Combinedalias brownNo ratings yet

- Updated Guidelines For Licensing To Manufacture To Operate As A Wholesale and Retail Seller of Medical ProductsDocument92 pagesUpdated Guidelines For Licensing To Manufacture To Operate As A Wholesale and Retail Seller of Medical Productsalias brownNo ratings yet

- 208B-F-002 Product Safety GMP TrainingDocument44 pages208B-F-002 Product Safety GMP Trainingjacky786No ratings yet

- F0504 03-2326sudhaDocument5 pagesF0504 03-2326sudhaalias brownNo ratings yet

- Programme Quality Manager-Job DescriptionDocument14 pagesProgramme Quality Manager-Job Descriptionalias brownNo ratings yet

- Overview ARSO-African Standards (AUDA-NEPAD) - ARSO HermogeneDocument14 pagesOverview ARSO-African Standards (AUDA-NEPAD) - ARSO Hermogenealias brownNo ratings yet

- Transaction Receipt: Receipt Printing Date: StatusDocument1 pageTransaction Receipt: Receipt Printing Date: Statusalias brownNo ratings yet

- Physical Chemistry in Flavor Products PreparationDocument17 pagesPhysical Chemistry in Flavor Products PreparationVALERIA HERRERA CHALARCANo ratings yet

- SMP StandardizationDocument17 pagesSMP Standardizationalias brownNo ratings yet

- KOC0011 Silo Operations Manual Rev BDocument37 pagesKOC0011 Silo Operations Manual Rev Balias brownNo ratings yet

- MQ84139 OcrDocument148 pagesMQ84139 Ocralias brownNo ratings yet

- ISO 22000 Gap Analysis OverviewDocument8 pagesISO 22000 Gap Analysis OverviewJmy GbuNo ratings yet

- EA300623Document1 pageEA300623alias brownNo ratings yet

- SMP StandardizationDocument17 pagesSMP Standardizationalias brownNo ratings yet

- IS 17781 OF 2021 (Specifications FRK Premix)Document10 pagesIS 17781 OF 2021 (Specifications FRK Premix)alias brownNo ratings yet

- Szafraska FatacidityDocument2 pagesSzafraska Fatacidityalias brownNo ratings yet

- Vulnerability Assessment, 5x5,1.0aDocument3 pagesVulnerability Assessment, 5x5,1.0aalias brownNo ratings yet

- IC Supplier Risk Assessment Checklist 11688Document5 pagesIC Supplier Risk Assessment Checklist 11688alias brownNo ratings yet

- Guidance On Food Fraud MitigationDocument55 pagesGuidance On Food Fraud Mitigationjmmfbeijos100% (1)

- SoP Ireland-Africa Stage 2 FinalDocument3 pagesSoP Ireland-Africa Stage 2 FinalSói ThuỷNo ratings yet

- IC Quality Assurance Audit Report 11546 - WORDDocument5 pagesIC Quality Assurance Audit Report 11546 - WORDalias brownNo ratings yet

- COCA COLA MICHIGAN STATE CCP-OPRP TreeDocument1 pageCOCA COLA MICHIGAN STATE CCP-OPRP TreeMuh Nur Afif LuthfiNo ratings yet

- IC Quality Assurance Log 11546Document3 pagesIC Quality Assurance Log 11546alias brownNo ratings yet

- IC Quality Assurance Framework 11546 - PowerpointDocument2 pagesIC Quality Assurance Framework 11546 - Powerpointalias brownNo ratings yet

- Fort - handbook1NDB 3242008 2608Document113 pagesFort - handbook1NDB 3242008 2608Luis UamusseNo ratings yet

- 16800b Reveal For Aflatoxin Bulk Kit Directions - 8085b - KitinsertDocument20 pages16800b Reveal For Aflatoxin Bulk Kit Directions - 8085b - Kitinsertalias brownNo ratings yet

- IC Quality Assurance Policy 11546 - WORDDocument1 pageIC Quality Assurance Policy 11546 - WORDalias brownNo ratings yet

- IC Quality Assurance Dashboard 11546Document8 pagesIC Quality Assurance Dashboard 11546alias brownNo ratings yet

- From Crisis To Opportunity - The 2023 Africa Agribusiness OutlookDocument31 pagesFrom Crisis To Opportunity - The 2023 Africa Agribusiness Outlookalias brownNo ratings yet

- SS 630-2017 - PreviewDocument9 pagesSS 630-2017 - PreviewWeijin LeowNo ratings yet

- Presidential Decree No. 533 Bans Cattle Rustling in PhilippinesDocument3 pagesPresidential Decree No. 533 Bans Cattle Rustling in PhilippinesDonna Flores-TrinidadNo ratings yet

- Food contact safety certificationDocument1 pageFood contact safety certificationpiedadNo ratings yet

- Specifications in The Food Packaging Chain PDFDocument20 pagesSpecifications in The Food Packaging Chain PDFDaniel FloresNo ratings yet

- Trabajo Final Equipo 6 (CHARRICOS)Document40 pagesTrabajo Final Equipo 6 (CHARRICOS)ramon nemeNo ratings yet

- Halal logistics certificationDocument21 pagesHalal logistics certificationMuhd Aizat Md SinNo ratings yet

- FDA Food Facility Registration FormDocument10 pagesFDA Food Facility Registration FormErick BellidoNo ratings yet

- FDA of DR (Model Fs-500ddr)Document2 pagesFDA of DR (Model Fs-500ddr)Ulan Suynbek uuluNo ratings yet

- Republic Act 3720Document16 pagesRepublic Act 3720Kyle Tan DomingoNo ratings yet

- Ethiopian Standard Industrial Classification (ESIC) : (First Publication-January 2010)Document81 pagesEthiopian Standard Industrial Classification (ESIC) : (First Publication-January 2010)Abdi Abraham0% (1)

- W Watert T Alk: Amine RegulationsDocument4 pagesW Watert T Alk: Amine RegulationsSivakumar SelvarajNo ratings yet

- Nliu Bhopal-University Reopening Guidelines-DraftDocument21 pagesNliu Bhopal-University Reopening Guidelines-DraftRashi BakshNo ratings yet

- Commas and Semicolons Made EasyDocument3 pagesCommas and Semicolons Made EasyadelekeyusufNo ratings yet

- PD 533 (Anti-Cattle Rustling Law)Document3 pagesPD 533 (Anti-Cattle Rustling Law)Juan Carlos BorbonNo ratings yet

- Robot Coupe CL50 CL50Ultra User ManualDocument23 pagesRobot Coupe CL50 CL50Ultra User Manualk4kh5svtstNo ratings yet

- Overfishing and Fish Stock DepletionDocument8 pagesOverfishing and Fish Stock DepletionTiger SonNo ratings yet

- Salt Iodization Council of Ministers Regulation No. 204 - 2011ethiopian Legal BriefDocument5 pagesSalt Iodization Council of Ministers Regulation No. 204 - 2011ethiopian Legal BriefHenok DireNo ratings yet

- Activties - ArjayDocument3 pagesActivties - ArjayAlyssa Mae Natividad-Mendoza100% (2)

- LGL MCA MarineGuidanceNote MGN061Document8 pagesLGL MCA MarineGuidanceNote MGN061ИгорьNo ratings yet

- Shell Egg Graders HandbookDocument228 pagesShell Egg Graders HandbookNafisNo ratings yet

- K203209-FDA - AirphysioDocument10 pagesK203209-FDA - AirphysioNandhini SivakumarNo ratings yet

- Module 04 Transport and Store FoodDocument58 pagesModule 04 Transport and Store FoodGechNo ratings yet

- Federal Register - Sunscreen Drug Products For Over-the-Counter Human UseDocument138 pagesFederal Register - Sunscreen Drug Products For Over-the-Counter Human UseOzan SubaşıNo ratings yet

- Islamic Da 'Wah Council V Exec Sec G.R. No. 153888. July 9, 2003Document3 pagesIslamic Da 'Wah Council V Exec Sec G.R. No. 153888. July 9, 2003MWinbee VisitacionNo ratings yet

- School LunchDocument16 pagesSchool LunchMarry Ann GeraldinoNo ratings yet

- Job Desc Server ReviseDocument2 pagesJob Desc Server ReviseReski PratamaNo ratings yet

- A1 - Worksheets Learner - Ver - October - 2019-5Document15 pagesA1 - Worksheets Learner - Ver - October - 2019-5Piyush GuptaNo ratings yet

- Interpretation of Result - Microbiologyby Mr. Angshuman Saha, Assistant Director, EIADocument18 pagesInterpretation of Result - Microbiologyby Mr. Angshuman Saha, Assistant Director, EIAKenth John EvangelistaNo ratings yet

- Roquette - PSPE - Y068 - CLEARAM CH 10 20 - 000000200216 - ENDocument2 pagesRoquette - PSPE - Y068 - CLEARAM CH 10 20 - 000000200216 - ENZahidul IslamNo ratings yet

- Specifikaciya RSF 742 - ENDocument4 pagesSpecifikaciya RSF 742 - ENHéctorNo ratings yet