Professional Documents

Culture Documents

Szafraska Fatacidity

Uploaded by

alias brownOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Szafraska Fatacidity

Uploaded by

alias brownCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/275644331

Fat acidity as a factor of deterioration changes during cereal products storage

Conference Paper · April 2015

CITATION READS

1 6,480

1 author:

Anna Szafranska

Instytut Biotechnologii Przemysłu Rolno-Spożywczego

28 PUBLICATIONS 105 CITATIONS

SEE PROFILE

All content following this page was uploaded by Anna Szafranska on 30 April 2015.

The user has requested enhancement of the downloaded file.

Fat acidity as a factor of deterioration changes

during cereal products storage

Anna Szafrańska

Prof. Wacław Dąbrowski Institute of Agricultural and Food Biotechnology Department of Grain Processing and Bakery Rakowiecka 36, 02-532 Warsaw Poland e-mail: anna.szafranska@ibprs.pl

INTRODUCTION

When cereal products deteriorate in storage, various chemical changes occur. Under ideal storage conditions, these changes progress very slowly, but when storage conditions are unfavorable, they progress more

rapidly, reflecting faster deterioration. The breakdown of fats by lipases and the liberations of free fatty acids is the most rapid chemical change during grain products deterioration. A fat acidity test (ISO 7305) has been

developed to estimate the degree of soudness of grain and cereal products. Fat acidity can be an indicator of biochemical changes during storage of cereal products. Fat acidity is defined as the number of miligrams of

potassium hydroxide required to neutralize the free fatty acids from 100 g of cereal products and calculated to a moisture-free basis. The limit of fat acidity (50 mg KOH/100 g db) was applied by Codex Allimentarius only

to white flours of extraction rates up to 75%. Control analyzed made by Agricultural and Food Quality Inspection in Poland showed that fat acidity level in fresh wheat and rye flour with ash content above 0.5% db often do

not meet this requirement of Codex Allimentarius.

OBJECTIVE

The aim of this study was to determine the differences in fat acidity in selected cereal grain and cereal products (wheat, rye and corn flours; barley, buckwheat and corn groats; oat and barley flakes) obtained from the

milling companies in Poland. The level of changes of this parameter during storage of cereal products in different temperature condition was also determined.

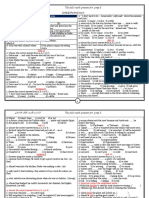

MATERIAL AND METHODS

To assess the fat acidity level in fresh cereal products different types of wheat flour (130 samples), rye flour (50 samples), wheat grits (20 samples), barley flakes (12 samples), buckweat groats (15 samples), corn groats

(14 samples), barley groats (15 samples) and oat flakes (15 samples) were tested. Cereal products samples were collected just after production from milling companies in Poland.

Choosen cereal products were stored separately for above 10 months at 10oC and at a room temperature of 20-25oC. The samples were analyzed for fat acidity (according to PN-ISO 7305), moisture content

(PN-EN ISO 712) and ash content (PN-EN ISO 2171).

RESULTS

130 220 220

Fat acidity (mg KOH/100 g db)

120

Fat acidity (mg KOH/100 g db)

200

Fat acidity (mg KOH/100 g db)

200

110

180 180

100

160 160

90

80 140 140

70 120 120

60 100 100

50 80 80

40

60 60

30

40 40

20

10 20 20

0 0 0

0,0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 1,6 1,7 1,8 1,9 2,0 0 4 8 12 16 20 24 28 32 36 40 0 4 8 12 16 20 24 28 32 36 40

Ash content (% db) Storage time (weeks) Storage time (weeks)

type 450 type 450 Krupczatka type 500 type 550 type 650 type 750 type 1050 type 1400 type 1850 type 450 type 750 type 1850 Graham type 450 type 750 type 1850 Graham

Fig. 1. Fat acidity and ash content of tested wheat flour samples. Fig. 4. Fat acidity changes during storage of wheat flour type 450, Fig. 5. Fat acidity changes during storage of wheat flour type 450,

type 750 and type 1850 Graham at room temperature. type 750 and type 1850 Graham at 10oC.

130 220 220

120

Fat acidity (mg KOH/100 g db)

Fat acidity (mg KOH/100 g db)

200 200

Fat acidity (mg KOH/100 g db)

110

180 180

100

160 160

90

80 140 140

70 120 120

60 100 100

50 80 80

40

60 60

30

20 40 40

10 20 20

0 0 0

0,0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 1,6 1,7 1,8 1,9 2,0 0 8 12 16 20 24 28 32 36 40 44 48 52 0 8 12 16 20 24 28 32 36 40 44 48 52

Ash content (% db) Storage time (weeks) Storage time (weeks)

type 500 type 720 type 1150 type 1400 type 2000 Buckwheat groats Oat flakes Rye flour type 720 Corn flour Buckwheat groats Oat flakes Rye flour type 720 Corn flour

Fig. 2. Fat acidity and ash content of tested rye flour samples. Fig. 6. Fat acidity changes during storage of buckwheat groats, Fig. 7. Fat acidity changes during storage of buckwheat groats,

oat flakes, rye flour type 720 and corn flour at room temperature. oat flakes, rye flour type 720 and corn flour at 10oC.

180 180

Table 1. Proposed maximum requirements for fat acidity in 160 160

Fat acidity (mg KOH/100 g s.m.)

different cereal products 150

Fat acidity (mg KOH/100 g db)

160 160

140 140

Cereal product Fat acidity (mg KOH/100 g db) 130

140 140

120 120

120 120

Wheat flour: 110

type 450 50 100 100

100 100

type 750 90 90

80 80

80 type 1850 160

80

70

60 60

60 60

Wheat grits 50 50

40 40

40 40

Rye flour:

30

type 720 90 20 20

20 20

type 2000 140 10

0 0

Corn products: 0 0

Wheat Triticum Barley Rye Corn Oat wheat grits barley buckweat corn groats barley oat flakes

grits and groats 100

Cereal grain flakes groats groats

flour 200 Cereal products

Mean min max mean min max

Oat flakes 160

Fig. 3. Fat acidity in cereal grains. Buckwheat groats 90 Fig. 8. Fat acidity in cereal products.

CONCLUSION

1. Fat acidity of fresh wheat and rye flour samples delivered directly from the production were different according to type of flour and ash content. Wheat flour samples type 450, type 500 and type 550 which ash content

is below 0.60 % db were characterized by the lowest fat acidity, in the range of 18-38 mg KOH/100 g db. Fat acidity in these types of flour met requirements of Codex Allimentarius for this parameter which should not

exceed 50 mg KOH/100 g db. Wheat flour type 750, type 1400 and type 1850 with ash content above 0.60% db were characterized by higher fat acidity, in the range of 33-127 mg KOH/100 g db.

2. Fat acidity of fresh rye flour type 500, type 720, type 1400 and type 2000 was higher than in wheat flours.

3. Fat acidity was positively correlated with ash content (correlation coefficient respectively: r = 0.811 for wheat flour and r = 0.607 for rye flour).

4. Fat acidity determined in cereal products was different according to cereal from which it was produced, form of a product, granularity and technological process. Fat acidity in tested cereal products can be rank from

the lowest to the highest as follow: wheat grits (fat acidity in the range of 14-31 mg KOH/100 g db), barley flakes (34-66 mg KOH/100 g db), buckwheat groats (45-77 mg KOH/100 g db), corn groats (35-86 mg

KOH/100 g db), barley groats (51-82 mg KOH/100 g db), oat flakes (50-160 mg KOH/100 g db).

5. Fat acidity increased during storage of all tested cereal products regardless of storage temperature, type of package and mass unit. Faster deterioration was detected for products stored at room temperature than at

10oC. Fat acidity of wheat flours with ash content below 0.50% db increased during storage but did not exceed the level 50 mg KOH/100 g db. Fat acidity increased from 79 to 205 mg KOH/100 g db after 40 weeks of

storage at 20-25oC of wheat flour type 1850 Graham. 40 weeks of storage at room temperature increased the fat acidity by 30, 61 and 84% for buckwheat groats, rye flour type 720 and corn flour, respectively.

View publication stats

You might also like

- Caie Igcse Geography 0460 Case Studies v1Document12 pagesCaie Igcse Geography 0460 Case Studies v1Steven FieldsNo ratings yet

- BENEO Hard Candies 1 PDFDocument27 pagesBENEO Hard Candies 1 PDFThuy PhanNo ratings yet

- Handbook of Drainage Engineering ProblemsDocument126 pagesHandbook of Drainage Engineering ProblemsJay Makwana83% (6)

- Sdo Aurora Tle10 Afa-Acp q4 m3Document13 pagesSdo Aurora Tle10 Afa-Acp q4 m3miel park100% (1)

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationNo ratings yet

- D6.2 - Biomethane Tool For Economic Analysis of Biogas Production, Gas Upgrading and Utilization of BiomethaneDocument38 pagesD6.2 - Biomethane Tool For Economic Analysis of Biogas Production, Gas Upgrading and Utilization of BiomethaneNilesh GordeNo ratings yet

- Fibrele VitacelDocument65 pagesFibrele VitacelBalteanu Marin100% (1)

- Manufacturers of Sorbitol Powder - Sorbitol 70% - Sorbitol Exporter IndiaDocument2 pagesManufacturers of Sorbitol Powder - Sorbitol 70% - Sorbitol Exporter IndiahtgfhgvmNo ratings yet

- Sugars and SweetenersDocument9 pagesSugars and SweetenersAhmed GoudaNo ratings yet

- Cheese - CodexDocument5 pagesCheese - CodexIndah NurvitasariNo ratings yet

- Milk and Milk Products - Dairymark - Com - Dairy Industry (PDFDrive) - 63-69Document7 pagesMilk and Milk Products - Dairymark - Com - Dairy Industry (PDFDrive) - 63-69Christina A. SaleebNo ratings yet

- LupuloDocument31 pagesLupuloMitzy TorresNo ratings yet

- Saudi Arabia Table TopDocument9 pagesSaudi Arabia Table TopElviraNo ratings yet

- Production of Sorbic AcidDocument2 pagesProduction of Sorbic AcidhonghongliuNo ratings yet

- A Kinetic Model For Citric Acid Production From Apple Pomac byDocument3 pagesA Kinetic Model For Citric Acid Production From Apple Pomac byclaranoviaNo ratings yet

- 002-Alimon Ketik SettingDocument8 pages002-Alimon Ketik Settingambo wellangNo ratings yet

- Ridascreen Fast GliadinDocument10 pagesRidascreen Fast GliadinpiagiopersempreNo ratings yet

- Biodiesel - Wpi 2016Document65 pagesBiodiesel - Wpi 2016Giovani de MoraisNo ratings yet

- 72 Jmbs Litwinek2 FBP FDocument10 pages72 Jmbs Litwinek2 FBP Fma hNo ratings yet

- Price List-ShctDocument2 pagesPrice List-Shctprakash mondalNo ratings yet

- Comparative Study of Various Treatments For Dairy Industry WastewaterDocument6 pagesComparative Study of Various Treatments For Dairy Industry Wastewatersunshe30No ratings yet

- Sugar 101Document15 pagesSugar 101royalstar.louiesyNo ratings yet

- Codex General Standard For Process (Ed) Cheese Preparations (Process (Ed) Cheese Food and Process (Ed) Cheese Spread)Document3 pagesCodex General Standard For Process (Ed) Cheese Preparations (Process (Ed) Cheese Food and Process (Ed) Cheese Spread)lox agencyNo ratings yet

- Almidon Cargilltex BlendtechDocument4 pagesAlmidon Cargilltex Blendtechinnovacionydesarrollo SuplacolNo ratings yet

- Base Elena: Code 02136 Name Type of ProductDocument2 pagesBase Elena: Code 02136 Name Type of ProductPedro barriaNo ratings yet

- Cloud PointDocument1 pageCloud PointRavi ShankarNo ratings yet

- Whey Processing: Utilization and ProductsDocument7 pagesWhey Processing: Utilization and ProductsThasya TamaraNo ratings yet

- Verol EP-90 - Ed01.2080Document2 pagesVerol EP-90 - Ed01.2080Omar MNo ratings yet

- Salt-3900 Top-Flo Product Sheet (Granulated Salt)Document2 pagesSalt-3900 Top-Flo Product Sheet (Granulated Salt)Graziella CathleenNo ratings yet

- All Product ListDocument5 pagesAll Product Listkas_udayNo ratings yet

- Bozanic Et Al, 2014. Fulltext - ajnfs-V2-Id1036Document7 pagesBozanic Et Al, 2014. Fulltext - ajnfs-V2-Id1036Isfari DNo ratings yet

- Formula RS 2Document1 pageFormula RS 2Donna PakpahanNo ratings yet

- Lactose: Properties and Uses: J. G. Zadow Dairy Research Laboratory Highett, Victoria, Australia, 3190Document26 pagesLactose: Properties and Uses: J. G. Zadow Dairy Research Laboratory Highett, Victoria, Australia, 3190LuisNo ratings yet

- Enhanced Management For Increased Soybean Yield - Ross BenderDocument45 pagesEnhanced Management For Increased Soybean Yield - Ross BenderDanail Danailov DanailovNo ratings yet

- Glucoamylase AN: Technical Enzymes Product InformationDocument2 pagesGlucoamylase AN: Technical Enzymes Product InformationOlajide Habib OlaniranNo ratings yet

- Mcdonald'S Australia Main Menu Allergen - Ingredients - Nutrition InformationDocument24 pagesMcdonald'S Australia Main Menu Allergen - Ingredients - Nutrition InformationAnonymous Pjbdf4wWNo ratings yet

- Nutritional Guide 7february2023 Final Bundle Meals PDFDocument2 pagesNutritional Guide 7february2023 Final Bundle Meals PDFAlexandra Patrono-SmithNo ratings yet

- D V Bhaskar - 2020 - 12 - 30Document6 pagesD V Bhaskar - 2020 - 12 - 30asdfNo ratings yet

- Fermentation 07 00001 v2Document10 pagesFermentation 07 00001 v2kanikaNo ratings yet

- Dairy Waste ManagementDocument26 pagesDairy Waste ManagementAnirudh MetlaNo ratings yet

- Sweeteners: Bringing You Nature's FinestDocument12 pagesSweeteners: Bringing You Nature's FinestusmanNo ratings yet

- Galactic - An Innovative, Natural Acidification Solution For Fermented MeatsDocument8 pagesGalactic - An Innovative, Natural Acidification Solution For Fermented MeatsAdinandaNo ratings yet

- C7 - Dehua Liu PDFDocument28 pagesC7 - Dehua Liu PDFJessicalba LouNo ratings yet

- Gazette & Draft Regulations For R&D TeamDocument4 pagesGazette & Draft Regulations For R&D Teamsushant deyNo ratings yet

- Dairy Cheret PricelistDocument4 pagesDairy Cheret PricelistTorsten KnackstedtNo ratings yet

- Feedlot Fattening - HPC 85Document3 pagesFeedlot Fattening - HPC 85engkjNo ratings yet

- Quillaja Saponins, The Natural FoamersDocument15 pagesQuillaja Saponins, The Natural FoamersDavid Uribe100% (1)

- CXS 322reDocument8 pagesCXS 322reMinh Trường TrươngNo ratings yet

- Breaking New Ground Via Partnerships Between Smallholder Farmers, Agribusinesses and Financial InstitutionsDocument14 pagesBreaking New Ground Via Partnerships Between Smallholder Farmers, Agribusinesses and Financial InstitutionsInterActionNo ratings yet

- Sales and Distribution Management: AssignmentDocument10 pagesSales and Distribution Management: AssignmentAachran JainNo ratings yet

- Babcock Brown CS Cage English GuideDocument16 pagesBabcock Brown CS Cage English GuideJenny PgNo ratings yet

- FoSCoS - FSSAI - ProductsDocument42 pagesFoSCoS - FSSAI - ProductsSameer NaikNo ratings yet

- Bovans Brown CS Cage English GuideDocument16 pagesBovans Brown CS Cage English GuideKenesaNo ratings yet

- Verolec F-62 - SpecDocument1 pageVerolec F-62 - SpecKevinNo ratings yet

- Daily Patterns: 8.6% or 70 Mmol/molDocument6 pagesDaily Patterns: 8.6% or 70 Mmol/molasdfNo ratings yet

- Product Price List SHCTDocument1 pageProduct Price List SHCTStatus loverNo ratings yet

- By-Products For CattleDocument5 pagesBy-Products For Cattleharikrishnaa.vetNo ratings yet

- D V Bhaskar - 2020 - 12 - 14Document5 pagesD V Bhaskar - 2020 - 12 - 14asdfNo ratings yet

- 35v2-505 - Tds Choco Wafer Covered W-Soy - 190523Document1 page35v2-505 - Tds Choco Wafer Covered W-Soy - 190523Francisco OrtizNo ratings yet

- Effects of Dietary Soybean Curd Residue On The Growth Performance and Carcass Characteristics in Hanwoo (Bos Taurus Coreanae) SteerDocument6 pagesEffects of Dietary Soybean Curd Residue On The Growth Performance and Carcass Characteristics in Hanwoo (Bos Taurus Coreanae) SteerGaryong VlogNo ratings yet

- Real Ingredients, Real Taste: WWW - Actpolyols.C OmDocument13 pagesReal Ingredients, Real Taste: WWW - Actpolyols.C OmusmanNo ratings yet

- BioEase 4210 Benefit Sheet enDocument2 pagesBioEase 4210 Benefit Sheet enjycortesNo ratings yet

- Handbook of Food Science and Technology 3: Food Biochemistry and TechnologyFrom EverandHandbook of Food Science and Technology 3: Food Biochemistry and TechnologyNo ratings yet

- Validation Management (C)Document2 pagesValidation Management (C)alias brownNo ratings yet

- MQ84139 OcrDocument148 pagesMQ84139 Ocralias brownNo ratings yet

- Programme Quality Manager-Job DescriptionDocument14 pagesProgramme Quality Manager-Job Descriptionalias brownNo ratings yet

- GMP&HACCP CombinedDocument99 pagesGMP&HACCP Combinedalias brownNo ratings yet

- F0504 03-2326sudhaDocument5 pagesF0504 03-2326sudhaalias brownNo ratings yet

- Updated Guidelines For Licensing To Manufacture To Operate As A Wholesale and Retail Seller of Medical ProductsDocument92 pagesUpdated Guidelines For Licensing To Manufacture To Operate As A Wholesale and Retail Seller of Medical Productsalias brownNo ratings yet

- Overview ARSO-African Standards (AUDA-NEPAD) - ARSO HermogeneDocument14 pagesOverview ARSO-African Standards (AUDA-NEPAD) - ARSO Hermogenealias brownNo ratings yet

- SMP StandardizationDocument17 pagesSMP Standardizationalias brownNo ratings yet

- KOC0011 Silo Operations Manual Rev BDocument37 pagesKOC0011 Silo Operations Manual Rev Balias brownNo ratings yet

- Transaction Receipt: Receipt Printing Date: StatusDocument1 pageTransaction Receipt: Receipt Printing Date: Statusalias brownNo ratings yet

- IS 17781 OF 2021 (Specifications FRK Premix)Document10 pagesIS 17781 OF 2021 (Specifications FRK Premix)alias brownNo ratings yet

- IC Supplier Risk Assessment Checklist 11688Document5 pagesIC Supplier Risk Assessment Checklist 11688alias brownNo ratings yet

- EA300623Document1 pageEA300623alias brownNo ratings yet

- IC Quality Assurance Dashboard 11546Document8 pagesIC Quality Assurance Dashboard 11546alias brownNo ratings yet

- Production information-CSB++Document1 pageProduction information-CSB++alias brownNo ratings yet

- IC Quality Assurance Policy 11546 - WORDDocument1 pageIC Quality Assurance Policy 11546 - WORDalias brownNo ratings yet

- Vulnerability Assessment, 5x5,1.0aDocument3 pagesVulnerability Assessment, 5x5,1.0aalias brownNo ratings yet

- IC Quality Assurance Log 11546Document3 pagesIC Quality Assurance Log 11546alias brownNo ratings yet

- IC Quality Assurance Audit Report 11546 - WORDDocument5 pagesIC Quality Assurance Audit Report 11546 - WORDalias brownNo ratings yet

- From Crisis To Opportunity - The 2023 Africa Agribusiness OutlookDocument31 pagesFrom Crisis To Opportunity - The 2023 Africa Agribusiness Outlookalias brownNo ratings yet

- 16800b Reveal For Aflatoxin Bulk Kit Directions - 8085b - KitinsertDocument20 pages16800b Reveal For Aflatoxin Bulk Kit Directions - 8085b - Kitinsertalias brownNo ratings yet

- IC Quality Assurance Framework 11546 - PowerpointDocument2 pagesIC Quality Assurance Framework 11546 - Powerpointalias brownNo ratings yet

- ISO FormsDocument11 pagesISO Formsalias brownNo ratings yet

- Draftauditreporttemplate Revision 2015forreviewDocument11 pagesDraftauditreporttemplate Revision 2015forreviewalias brownNo ratings yet

- Gantt ChartDocument5 pagesGantt Chartalias brownNo ratings yet

- Control of Documented Information Procedure - DemoDocument10 pagesControl of Documented Information Procedure - Demoalias brownNo ratings yet

- SOP-R-G-2-01 Attending and Documenting Human Resource Development ActivityDocument15 pagesSOP-R-G-2-01 Attending and Documenting Human Resource Development Activityalias brownNo ratings yet

- Prereq Verification TableDocument5 pagesPrereq Verification Tablealias brownNo ratings yet

- Aflatoxin in Cassava Flour - NigeriaDocument3 pagesAflatoxin in Cassava Flour - Nigeriaalias brownNo ratings yet

- Prereq Verification TableDocument11 pagesPrereq Verification Tablealias brownNo ratings yet

- Report Final Ver01Document13 pagesReport Final Ver01amos wabwileNo ratings yet

- Jaiva KrishiDocument21 pagesJaiva KrishiSubin SojanNo ratings yet

- GE-Lec 1Document5 pagesGE-Lec 1Mina FouadNo ratings yet

- Copy of ليلة امتحان الصف الثالث الاعدادى النسخة غيرالمجابةDocument33 pagesCopy of ليلة امتحان الصف الثالث الاعدادى النسخة غيرالمجابةFatma Hamdy BadrNo ratings yet

- Belayet Sir DocumentDocument33 pagesBelayet Sir DocumentHussein MubasshirNo ratings yet

- L.N. OilsDocument10 pagesL.N. OilsSachin UmbarajeNo ratings yet

- Canada - MaturitaDocument2 pagesCanada - MaturitaviktorieNo ratings yet

- New Developments in The Science of Biological Species, T.D. LysenkoDocument14 pagesNew Developments in The Science of Biological Species, T.D. LysenkoMegaFoxStoneNo ratings yet

- TaroDocument4 pagesTaroHezzie KayeNo ratings yet

- A1 GARDEN ACTION PLAN Talingkapor ESDocument3 pagesA1 GARDEN ACTION PLAN Talingkapor ESROBINSON BAYSONNo ratings yet

- 9th CAMC - FIDFDocument7 pages9th CAMC - FIDFSankarMohanNo ratings yet

- Sample Test 01-KEYDocument3 pagesSample Test 01-KEYlylyngoc90No ratings yet

- Paper 2 - PYQDocument26 pagesPaper 2 - PYQnitin khariNo ratings yet

- TATE and TOWNDocument40 pagesTATE and TOWNRanaNo ratings yet

- CH 1 Nutrition in PlantsDocument3 pagesCH 1 Nutrition in Plantsdrushti luteNo ratings yet

- Weed Identification and Chemical Control.Document8 pagesWeed Identification and Chemical Control.Darrel MunasheNo ratings yet

- AFA Grade - 7 - W2 - Perform Estimations and Basic Calculations 2Document10 pagesAFA Grade - 7 - W2 - Perform Estimations and Basic Calculations 2PaulNo ratings yet

- (English (Auto-Generated) ) Webinar 4 - Algae & Seed Oils in Aquafeeds (DownSub - Com)Document84 pages(English (Auto-Generated) ) Webinar 4 - Algae & Seed Oils in Aquafeeds (DownSub - Com)Rizki KurniawanNo ratings yet

- Ollantaytambo and MorayDocument13 pagesOllantaytambo and MorayJI RANo ratings yet

- Unit-3 Whhdakkk Aiii AkmDocument19 pagesUnit-3 Whhdakkk Aiii AkmBobby MatNo ratings yet

- Georgian WheatDocument11 pagesGeorgian WheatBlazsNo ratings yet

- Reading Test 1 Cam 15Document12 pagesReading Test 1 Cam 15Cao Thi HienNo ratings yet

- INTRODUCTIONDocument89 pagesINTRODUCTIONram0% (1)

- Grafting The Cornelian CherryDocument9 pagesGrafting The Cornelian Cherryrichard.schumacherNo ratings yet

- Floriculture and BiotechnologyDocument6 pagesFloriculture and BiotechnologySuhrita ChakrabartyNo ratings yet

- Week 6 Quiz: Latest Submission Grade 20% 1Document4 pagesWeek 6 Quiz: Latest Submission Grade 20% 1Aptu Andy KurniawanNo ratings yet

- SIMFS - WP1 - Context Assessment For Mixed Farming SystemsDocument62 pagesSIMFS - WP1 - Context Assessment For Mixed Farming SystemsgracepetrovaNo ratings yet