Professional Documents

Culture Documents

Testing Report

Testing Report

Uploaded by

hoi0 ratings0% found this document useful (0 votes)

21 views17 pagesOriginal Title

17677 Testing Report

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views17 pagesTesting Report

Testing Report

Uploaded by

hoiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 17

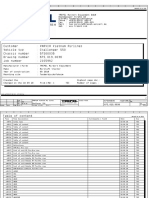

BROMMA

Conceming exami

and controlling of Spreader.

Examination made : 2013-09-02

Customer : Unico Vina JSC

Enduser: Nam Hai Dinh Vu , Vietnam

Adjustable hoisting gear for ISO container 20’ & 40’

Type : EHSU

Serial Number : 17677.

Manufacturer : BROMMA

General drawing : BR1116125.

Material : High Tensile Stee! & Fine Grain Steel.

©PNDHARWON SB

Spreader weight: 9 Tonne.

3

Load test carried out with a max. of 150% overload.

11 Safe Working Load (SWL) : Single 41 Tonne.

Test load of twistlocks to 40 tonne for serial number SINGLE ; WS 5291 , WS 5233,

12. ws 5216, WS 5270.

As a result of this examination we the undersigned find nothing which will prevent the use of

above load gear for the loads presented in the data sheet.

Remarks :

The load gear is to carry attached signs stating manufacturer, production number, year of

manufacture and SWL — max. load.

Enclosed: Spreader data sheet

BROMMA

2013-09-02

he

SHAHRIZAL

Test Certificate QET 1600 Rev (01)

TWISTLOCK-CERTIFICATE

CUSTOMER. _ ____Unico Vina JSC

CUSTOMER ORDER NO. BRO-UNV13-01

BROMMA SPREADER / ORDER NO. 17677

DATE. ee ___ 02" September 2013

This is to certify that the following twistlocks have been proof tested

to 40 tonne’s load.

No visible deformation occured.

The twistlocks have been stamped on the end face with a B/C

stamp and 40 tonne.

QTY. TYPE. DWG. MATERIAL. PARTNo. SERIALNo. MILL CODE

4PCS ISO 1002763 34CRNIMO6 1002763 1, WS 5291 w22

2. WS 5233 © w22

3. WS 5216 w22

4, WS 5270 w22

SIGN. SHAHRIZAL

DATE| 02 September 2013

‘Twistlock Certificate_QEI 16.0 Rev (01)

MF IN-PROCESS -DIMENSION INSPECTION REPORT (Rev 3) BROMMA

ISN # 1463-4 |eustomer Jui /wam fer Ole vu, VIETNAM

IModet EL SY |prawing# | 2citi6/ > article # BEAM C25

}1. General Assembly

@

=

era se one recese oren

Main Beam Main Beam No

A MPLS

== Ta Per es

A-Front = at

‘A-Back > S cal

B-Front. _— v &

a a -

ao 3

C-Back_ LSD 2 oO

—— ma

12. Dimensional Inspection Satisfactory | satisfactory Rectify Result

[center marking.

Center Paint

[Above Dimensional Inspection Result

INote : The measurement point between

Iheadblock must be address between center point

lof the headblock twistlock pocket. Before

Ichecking, QC must confirm the twistlock hole

Tnspgcted AB; By:

Se es

IName: KZ PHI SENG |Name: HBLIN

Designation : Fab. Inspector

[Designation : Supervisor

pate: = ]efi2

Date: =H fefi3

MF in-Process Dimension Inspection Report_QEI7.0 Rev (03)

DIMENSIONAL AND VISUAL REPORT

SN# | /7CTT fSustomer lune fava nei OersH YU. Vie

Model EAC U [Prawing# Jrenvugirtfanicle# ay ciot

lt. General Assembly

Telescopic Beam Frame No Telescopic Beam No

A RVC Dee 7h are

5 TV DICE TH FFE

Location Design | Tolerance | Actual Deviation Remarks

Telescopic A.

lat (Top Side) TESS FS] Tso aT

iaz (Bottom Sida) yoo + TOG o

[bt (Top Side) S08 3 S80 q

[bz (Bottom Side); SOS a Tpee GC

Telescopic

{ai (Top Sidey Tes 7 TS Ot] a1

{a2 (Bottom Side) | 7S FT Beta

1 (Top Side) ROOT a 1gou it

2 (Bottom Side) | —7Co S| 7 Wor [at

z Not z

2. Dimensional inspection Satisfactory | «ststactory Rectity Result

[Above Dimensional Inspection Result e

'. Visual Welding Inspection

\Visual Welding Inspection Result

\Note : The Weld Quality / Visual Welding LE

|Acceptance Criteria shall comply according to EN

liso 5817 Table 1

Inspected By = ‘Approved By :

) h

je ual %

IName= Kan Name: A/D PMC

[Designation : Fab. Inspector Designation : Supervisor

[Pate : Sie 13 Date: sie ii}

Tolescopic Frame Dimensional Visual Report_QEI 7.0 Rev (02)

MF IN-PROCESS -MPI INSPECTION REPORT (Rev 3)

[ane TE PE [Pestomer yiics foam yar DIN WU, VIETNAM

toast Ge Uprwing® (BLUES [Aric

Bey cos

[f/ MAGNETIC PARTICLE INSPECTION (FRESH/REJNSPECT)

TEM INSPECTED : AS SHOWN,

Test Equipment

(Chemical Used agnat White Canrast Paint

[Equipment Used Yore Magnetic nk THF

[Gleaneremever KC.

Toeation Tadament

7 RECEPT HieeoT—

z ACCEPT TREIEET—

3 ‘ACCEPT BEKECT—

+ ‘ACCEPT REET

3 ACCEPT REJECT.

@ CEPT Taevecr |

T SOCEPT REJECT

8 ACCEPT Ree

oT ‘ACCEPT TREHEET

a2 ‘ACCEPT REJECT

eo ACCEPT RECT.

ot ‘ACCEPT RESEGT-

Tot CEPT RGWeGT™

702 ‘ACCEPT ReveCo

703 ‘ACCEPT TREIEET

0 SCEPYTRETECT

Judgment - Accept! Reject —

Visual Welaing Inspection: Satisfactory ot Gatstactory

Inspected By

Name

Mike

Designation

Qialicaton ASNT Lovo)

Date of inspection $)

Note: Acceptance criteria ofthe weld quality shall comply wit the requirements of BS EN 1291

All fiishing and rough edges shall be smoothly rounded,

[MF in-Process MPI inspection Repor_QE6.1 Rev (03)

BU IN-PROCESS -MPI INSPECTION REPORT (Rev 4) BROMMA

ISN # [3 547 Jeustomer LaicoF atate Why DANN Us VIETNAM

IModet etsy |prawing # be Wibiis [Article # Pe Were

/1. MAGNETIC PARTICLE INSPECTION (FRESH /BE-4NSPECT)

Judgment - Accept / Reject

Visual Welding Inspection: Satisfastery / Not Satisfactory

Inspected By

Name

Designation sl

Qualification ASNT Leva Il

Date of Inspection: 25/712

Telescopic B ine Frame No# Beam 1# Beam 1#

‘lescopic Beam Un

V3366 Gs! [DAC |

‘Test Equipment

[Ghemieal Used Magnafux White Contrast Paint

Equipment Used Yoke Magnetic Ink 7HF

[eieanerfRemover | _Skc-S

Location ‘Judgment

7 “BEGEPT [REJECT INA

AGCEFT TEEIEGT AR

3 AGEEPT/ REJECT / NA

4 ACCEPT / BidECTTNA ~

Note: Acceptance criteria of the weld quality shall comply with the requirements of BS EN 1291.

All finishing and rough edges shall be smoothly rounded.

‘TBU In-Process MPI Inspection Report_QEI 6.1 Rev (04)

TBU IN-PROCESS -MPI INSPECTION REPORT (Rev 4)

BROMMA

[sn # {2044 [eustomer unico] Anan HA DIN Wa, VERMAMA

Model ets Drawing # Lil6 QS |Articte # BeNK6aS

H. MAGNETIC PARTICLE INSPECTION ( FRESH/RE-INSPECT)

ITEM INSPECTED : AS SHOWN

Judgment - Accept / Reject —~

Visual Welding Inspection: Satisfactory / Not Satistactery

Inspected By

Name

Designation ib. Inspector

Qualification “ASNT Level,

Date of Inspection Sof: ic

Note: Acceptance criteria of the weld quality shall comply with the requirements of BS EN 1291.

{Al finishing and rough edges shall be smoothly rounded,

‘TBU In-Process MP! Inspection Report_QEI 6.1 Rev (04)

a Beart Frame No# Beam 1# Beam 1#

relescopic Beam Uni

Y2366 D462 \ [04696

‘Test Equipment

[Chemical Used Magnatiux White Contrast Paint

[Equipment Used Yoke Magnetic Ink THF

[CleanerRemover SKG-S

Location | ‘Judgment

e 1 "ACCEPT | BEJECTTNA

2 AGOEPT | REJECT FRA

3 ACCEPT / BEET NA

4 ACCEPT IREJEETTNA

TBU IN-PROCESS -MPI INSPECTION REPORT (Rev 4)

ee

ISN # OFF ” \euetonier yurce funn Hat DIN YU, VIETNAM

Model CHU {Drawing # pewtcles Jartite # BRE DS

1. MAGNETIC PARTICLE INSPECTION (FRESH/ REINSPECT)

ITEM INSPECTED : AS SHOWN

fen

ne

Pee

ferret

eet

Judgment - Acgept/ Reject

Visual Welding Inspection: Ssatistgctory I Not Satisfactory

Inspected By

A

Name Mh

Designation Fab, Inspector

Qualification ASNT Level

Date of inspection : 5/6]!

Note: Acceptance criteria of the weld quality shall comply with the requirements of BS EN 1291

All finishing and rough edges shall be smoothly rounded.

‘TBU In-Process MPI Inspection Report_QEI 6.1 Rev (04)

Fr lesc opie Baan Unk Frame No# Beam 1# Beam 1#

elescopic Beam Uni

144 ee |b yee

Test Equipment

[Ghemical Used Magnafx Wie Contrast Paint

Equipment Used Yoke Magnetic ink THE

leaneremover | _SKC-S

Location Judgment,

A "ACCEPT / REGECT/ NA

e z AGDEPT REJECT INA

3 ACCEPT) REAECTINA

4 ‘ACCEPT [REJECT [A

TBU IN-PROCESS -MPI INSPECTION REPORT (Rev 4) BROMMA

ISN# \46+2 |eustomer UNH [wan HAY BINH VU, VIETNAM

|Model Yu Drawing # PRI EILS Article # neers

11. MAGNETIC PARTICLE INSPECTION (FRESH | RE-INSPECT)

ITEM INSPECTED : AS SHOWN

ording

Pre)

Clem

a matin Frame No# Beam 1# Beam 1#

‘lescopic Beam Uni :

Poy gy [pee

‘Test Equipment

|Chemical Used Magnaflux ‘White Contrast Paint

[Equipment Used Yoke ‘Magnetic Ink 7HF

[cleanerfRemover | _SkC-S

Location ‘Judgment

1 ACCEPT / REJECT / NA

e 2 ACCEPT / RESECT / NA

3 "ACCEPT / REJECT [NA

4 ACCEPT REIECT INET

Judgment - Accept / Rej

Visual Welding Inspection: Satisfactory / Not Sdtisfactory

Inspected By

Name f PET

Designation Fab. Inspector

Qualification ASNT Level It

Date of inspection = S/ 5

Note: Acceptance criteria ofthe weld quality shall comply withthe requirements of BS EN 1291

Allfinishing and rough edges shall be smoothly rounded.

TBU In-Process MPI Inspection Report_QE! 6.1 Rev (04)

BROMMA

Project unico Serial Number ster

End User, RAM ATOR W_ VTA Model

Beam No, ; SMPT60, SMP76i

Ultrasonic Testing Report-Main Beam Auto Welding

a Mateal Thekne ‘a= 8-10mm,b= 8mm

dont Tipe Shale Bevel Yoo sont

Walang Process Rep We

Surface Conston ‘lean Satstactory

4. eusant ‘Wall Paper Paste

Probe or

Ultrasonic Testing Report-Main Beam - Top Plate

JOINT DETAILS

o tor Teka a=emm, b=20-20mm

dont Tyee Shale Bevel Sut vi

ri ® Surface Condon Clean Satetactony

eusant ‘Wal Paper Paste.

Probe ”

Ultrasonic Testing Report-Main Beam - Bottom Plate

JOINT DETAILS

° Sten Thesness 8mm, b=30-s0mm

dont Tee Shale Bevel But views

b—_Wilung Process Fiucore

le Suite Condition iar Stacy

w

Peer Sean

o -

70 Fsu ie a8

oo" FSH 468

aNcOrAS

nore:

Ipmeomecr = KRUSM 35S. 0068 ‘)Inspecton as care ton asses ae ony

learonsect V1.2 8 ranma retrace bck inspection rest a5 opted ste tie of spect.

lee ANSI. Aanen

Icaptca cafe Pam BO StERIYBOAE 3 Rev?

INSPECTED By:

coeateecen aire

[BRommA|

‘Mat BEAM UTINSPECTION REPORT

Frame TUNES fe SMP _FEO [moar YEO, We

ed er TEA FEAT BINT, vie TVA eo roe bn Tso # or co

rath Tae4T ie Pate VertoeL ae [aca

eta eit

rantane [PRREFOR] one | tenet | core | foot

Ly

“5 ut (0) Z

5

&

Ls N x

L =

smo sertom t() Tore

oo

aE

lrovoamsa CT EPOGHT 7 USM Kaativamer TEPOGHTI en

leniatonsace —:VL¥28 Bona retrere ct

cede No BRMY/BORL Rev? co Terao

persoer pesmi ‘vert ra ‘one: PASS FAL

Frcnmncecade :Pwa 0st RMY/00P61.3 ev oe

seth ring not tose

‘Abdmenden in reer)

Inspection ress reports ethetime of ispection

Benton OT MERON osm

Guten OH UT Le cuthnions

foe of rapecton m7 [Ez [on teens

sas Sean 9A UT espection Cec 87.0 (03)

(MAIN BEAM UT INSPECTION REPORT

[pRomma|

Datumn X

rae URES [commoner ENB FZ] [waco WOO

fausr NAW seg D/H WO, WETHA Wt each Tanoe T oct nomi ro

era Ttete fic ite natch tert i a

st ae estes

fomaan [Porm | oe | teen | oem | fer

2 TopondSodomion cae ot wth mar welt

2a eg oto ee

4. Aainensnie mle tom)

5 specton ress arreportdi athe ofngetin

=. ats oe 8 Z

é

L, x

‘Bottom Joint (A) Bottom Joint (8)

fox Onean TOOT TT Ua aut EPO

cmne ot vi"20 meemarsrwent ener

eerie Swanenetia ms == =

oo ws ames Lerancren soup) gece = ——

[rrparmée, srintamonenonlai2 oo rer

= =

—— fea

fsx oe

ersten: 29) 7/13 —lpurctnpn

Mun Ba?4/ UT pecon nd 0170 Re 8),

TELESCOPIC BEAM UT INSPECTION REPORT

rae Te [set ach no i TROAG [waar WAGb WIG]

eadtae WAVY DH V7, GET |noves2-taenno | A[ 230 B acon nur ‘aa tae

Fwesrmetescane [TA a0 6 ost ra eratne TFEFF

[web rates no [V1 20.6 my ieamnanter 1) 463]

* beta eat

i = Sect

a ve

a — yet

a j 1/2

j Gate

4 22/7

LS rae |

ea

aa Soe

a Manet Hideests 2+ gpm b= Com 22/3)

Wotegroces: tld Ke ™

: ae sya

conta ware rte alt

re soe tet sonnet tee

e om 930m th am

we isa 88 om a a a

Finbar. USM RSER Sa ERTa

rato bk

rowaue no cemnfonii ater? Peery

eam, AWS CL Mess ‘oentmans aserran

cpt tnt omuraorsih?

lets: 2

i! UT cretion son oe ea ee tt wi

2 Sch egottrete fenee

A. Aildimension in mBimeter (men) —Td

5 Inspection results as reported is atthe time of inspection Epeiieaien es Orissa 5. [palin scuer inns.

ous cthwpecion: 220/873 [tropes

[BROMMA|

TELESCOPIC BEAM UT INSPECTION REPORT

[rec WHO [Farge Bachna Topp. AL [wider 0 We, whee:

[end er Tigtn HBY Dinh VV, TIT TAZA Ty range: ener no 1130. [Boot nerber FAB 08

oe TEM [Moder Wsu Fara ne THEFT.

oo rx wt co Dae

on veomvew een

z ‘Joint | Distance From ‘We OF

: a ee es eo

: ———— fara

& be:

L, Sut

rs 23/3

ay hae a

; *

: Syakir

23/9

> [ion Accept |

Gaol

a

a Motel Thickness: as yg mm bs Gm 23/7

vee teeta ¢ ra aa

ch

toes tae

® Surface Condon: Chan = Syeda

cote vie Pte

a 23 1F

rote Poueey ste weet Sig noe

° Tne 910m fh Biles

to 7s mie 88am a ee

fowoneaer USB Sho S08 PEROT

earaionsick —:VANZA renmarertsiok

Prac ho—Oracrei 3 hv =a Sa

jenny AWS DLE Manes ‘overainesuit: (Pass yan ‘Overaltmesuit: PASS / FAL

JeceouceCote te 0m on/eons ter? k

he {eee tn mt edhe ter UW)

paren ramen ew ne

Ahan etter oeigton: WT RECTOR peaeaien mare

5 tpecen ritmo tt et pon ston rave [anon orien

one thspens 52731 pe ten

tamsctoic beam FA/ VE asnerben Chesite. 081 70h ESD

Escort

Fra DRC mecrennne [190 /300G, rere ITE IAT

ena User Wm 15) DIMA VU, Vipr Nap |Penae 2-tancrno | 1BOL3O Aly eooth nanber Fab 108

[uct rei onnne [130200 F [Mover CASy [rane TR

[wet Plate 2- Batch No (20 206 E [Beam Number 0% FE

2 aes From ‘No Of

E sas meen | he ae |

a |

Syeve

ace

* t Par

i Saki

26/7

bare a

oF

sya

‘eae

3 Mattes: eGo mm Oe Com 26/2

le rea

Y soot seat iont m

> Sueno: Gam Syed

cours Wa oer Pate 261

probe Feqeny see rete seanngst—taree

4 em 810mm a a on

or Sam mm wx Gh db 00mm

Jimwoweaar USM RSS She 176270

seratonBck VERE ema ec ok

Jreceirene, tH /sOre6L Re? Remedy

[cmomecade now t/BOMGL 2 on tttioee sree pane iri

way

lana 3 cea )

1 Sch dig aia sate as ono SE re

4. Atemerson nine om) oevratn T RSPECTOR [nso ROT RERCOR

5 pectin es trp at thane of apecten [sattcnon POW UTEEWELE [tention VUTEC

bee tinpecions DOI F/Z3__[oectinspecion:

‘ele Bem PA UTnpeson esr)

TELESCOPIC BEAM UT INSPECTION REPORT

ma

Price TRICE. [Foret annne [130030 AG, [tae Wace, WAG

aie igh HOY Daa VO, ETAT rast onerne — [50130 AM sean cares

IWeoraet eacne —|130206F ose EySU erate TH

[weornte2-eaiane [130206 F bor ober Wag

Co ‘ne Front View 100mm

x “ Detect Detail

Sain | Be wor

i Se eae eee ae

8 te |

Syeere.

L,

> 26/7

* fa ma

i a sgatiz

267

Ls

faa

ve

Syatr

ie Mrarcltiines: 2+ 20m bs § mm 261?

tae Teta anor

weeing Process Rapid Arc ’

. Soteendice: Goan Syobie

cui. water rate nea

tele seoming so

pa nr er)

= a a)

Jaw weaor USM RESEK SIN 76270

test Back V2.8 amma ence ok

recete to rempeey

leet ANSDLA Aves a0

JperceCle Pas B OL MY/20NEL ey? so Ran BETA ren: ASFA

a mupgogare

Gi! Too cre ot on 100mm oc nam ees arse wel Leesan

2. See wngrttosale = Mov SAR [anes

4. Alden aes om Deignron 07 naPETOR Deena OT EPCTOR

5 mien resis sone ett tpn sateen nov UTURVECN elena ron UT av

fons tspecion 2579713

[Bes cfinepecion:

“Telescopic eam PA/ UT pectin helt O87. Rev 08)

Single lift with one bracket

Proof loading with two cylinders

SINGLE LIFT WITH ONE BRACKET

Bromma Spreader EH5SU

Customer Unico Vina JSC

Serial Number. 17677

General Assembly Drawing. 1116125

Safe Working Load 41 Tonne

Proof Load 150%

Tare Weight 9 Tonne

Weight of Test Equipment 2 Tonne

Cylinders Used 2

en

4 rh,

x LI

ra

(

@ @ ¢G ®

[Pressure

[From Pump [Load In Tonne Measure point mm

In Bar Load Load

i cyl lineach fin each

|A=71.2 cm? |Cylinder {Twistlock 1 2 3 4 5

101 7 a) 0 ° 0 0

203 15) s[ 0 to Mm 0 o

266 19) 1 q @ 7 7

584 2 18) 2 a | $2 We 2

101 7 26 2 2 2 °

TNDER SUPERVISION OF SIGNATURE DATE

Equipment Name: Pressure Gauge (H-Frce HG 1)

Control Number: CPS984

Galeret: =;

MUC Proof Loading Test QEI 17.0 Rev (95)

Moons ana

You might also like

- Ols 120Document1 pageOls 120hoiNo ratings yet

- 04 6750036 EL 180910 enDocument227 pages04 6750036 EL 180910 enhoiNo ratings yet

- Gear Code BookDocument81 pagesGear Code BookhoiNo ratings yet

- DanfossomrDocument30 pagesDanfossomrhoiNo ratings yet

- ActuatorsDocument37 pagesActuatorshoiNo ratings yet

- BasicsDocument170 pagesBasicshoiNo ratings yet

- Parts ListDocument19 pagesParts ListhoiNo ratings yet

- Closed Swage Sockets National Swage ButtonsDocument1 pageClosed Swage Sockets National Swage ButtonshoiNo ratings yet

- 00a 6720169 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720169 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- Sunstar SPS D-B1201Document86 pagesSunstar SPS D-B1201hoiNo ratings yet

- S-423T Super TerminatorDocument1 pageS-423T Super TerminatorhoiNo ratings yet

- Angebot 1042622 (81 - 8492 - 3h)Document2 pagesAngebot 1042622 (81 - 8492 - 3h)hoiNo ratings yet

- A Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..Document74 pagesA Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..hoiNo ratings yet

- 00a 6720168 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720168 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- Angebot 1033668 PDFDocument2 pagesAngebot 1033668 PDFhoiNo ratings yet

- 9 Hydraulic2006Document91 pages9 Hydraulic2006hoiNo ratings yet

- 01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)Document190 pages01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)hoiNo ratings yet

- ServiceInfo15-WT-05 Rev ADocument38 pagesServiceInfo15-WT-05 Rev AhoiNo ratings yet

- 09 6720168-9 EK 200214 enDocument449 pages09 6720168-9 EK 200214 enhoiNo ratings yet

- Angebot 1047857Document2 pagesAngebot 1047857hoiNo ratings yet

- PGP020™ Series: Pumps and MotorsDocument16 pagesPGP020™ Series: Pumps and MotorshoiNo ratings yet

- Angebot 1027718Document2 pagesAngebot 1027718hoi100% (1)

- 08 000 630 0263 Gearbox Dana Wa 041101 D3Document106 pages08 000 630 0263 Gearbox Dana Wa 041101 D3hoi100% (1)

- 01a - 6720168-169 - BRIEFINSTRUCTIONS - 171108 - en (GB)Document8 pages01a - 6720168-169 - BRIEFINSTRUCTIONS - 171108 - en (GB)hoiNo ratings yet

- Xi Lanh Nang HaDocument1 pageXi Lanh Nang HahoiNo ratings yet

- 00b - 6720168-169 - VORSPANN - BA - 191130 - en (Us)Document2 pages00b - 6720168-169 - VORSPANN - BA - 191130 - en (Us)hoiNo ratings yet

- Gasbage Baling MS - GCDocument5 pagesGasbage Baling MS - GChoiNo ratings yet

- 1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90Document2 pages1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90hoiNo ratings yet

- HMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationDocument44 pagesHMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationhoiNo ratings yet

- Accessories AH2342-CA Ȝ: SpecificationDocument1 pageAccessories AH2342-CA Ȝ: SpecificationhoiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)