Professional Documents

Culture Documents

Pipe Support Table

Uploaded by

htoomyat.chrisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Support Table

Uploaded by

htoomyat.chrisCopyright:

Available Formats

Piped gas services Plumbing Engineering ServicesDesign Guide

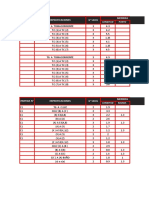

Table 6 Pipesupports Table 7 Pipe supports

Nominalsize . Intervalfor Interval for

Nominal size

Cast iron, Stainless Interval for Interval for vertical runs horizontalruns

mild steel steel vertical runs horizontalruns (mm) (in) (m) (II) (m) (ft)

(mm) (mm) (in) (m) (if) (m) (if) Up to 15 Up to 1/2 2.0 6 1.2 4

15 15 1/2 2.5 8 2.0 6 22 3/4 2.5 8 1.8 6

20 22 3/4 3.0 10 2.5 8 28 1 2.5 8 1.8 6

25 28 1 3.0 10 2.5 8 35 11/4 3.0 10 2.5 8

32 35 1¼ 3.0 10 2.7 9 42 11/2 3.0 10 2.5 8

40 42 11/2 3.5 12 3.0 10 54 2 3.0 10 2.7 9

50 54 2 3.5 12 3.0 10 66.70 21/2 3.5 12 3.0 10

80 76.1 2 3.5 12 3.0 10 76.1 3 3.5 12 3.0 10

100 108 4 3.5 12 3.0 10 108 4 3.5 12 3.0 10

Maximum intervalforcast iron, mild steeland stainless steelpipes Maximum interval forlight gaugecopperpipes

Domestic properties

Normal gas usage would be satisfied by the following meter size:

Table 8a Meter characteristics

Model Capacity Standard Pressure loss Capacity Proving Meter

type per hour working pressure at capacity per revolution dial/circle connections

(ft3) I (m3) (psi) (mbar) (wg) (mbar) (if3) (dm3) (ft3) I (dm3)

U4/G2.5 141 4 0.7 50 <0.5 <1.22 .043 I 1.25 1 10 1'screwed

U6/G4 212 6 0.7 50 <0.5 <1.22 .071 2.0 1 10 to BS 746

. .

Commercial properties

Usage will vary but the following Table wouldgenerally give a meter sizeto suit requirements:

Table 8b Meter characteristics

U16 U25 U40 U65 U100 U160

Capacity per 16m3 565ff3 25m3 833ft3 40m3 1412ft3 65m3 2296ff3 lOOm3 353ff3 160m3 5650ff3

hour

Std. working

7smbar 1.Opsi 7smbar 1.Opsi 7smbar 1.Opsi 75mbar 1 .Opsi 7smbar 1.Opsi 7smbar 1 .Opsi

Pressure

Mean pressure

loss l.22mbar 0.5"wg l.62mbar 0.65"wg 1.22mbar 0.5"wg 2.36mbar 0.95"Wg l.32mbar 0.53"wg 2.glmbar l.17wg

Capacity per 4dm3 0.142ft3 10dm3 0.353ft3 20dm3 0714ff3 25dm3 lOft3 50dm3 2.0ff3 71.4dm3 2.5ff3

revolution

Proving circle 100dm3 itt3 , 100dm3 lOft3 100dm3 loft3 100dm3 lOft3 100dm3 loft3 100dm3 lOft3

(1 pulse =)

Standard 1 1/4 screwed to 2"screwed to 2" screwed to 65mm flanged 80mm flanged 100mm flanged

connections BS746 BS746 B5746 BS4505.l 16/1 BS4505.1 16/1 BS4505.l 16/1

Shipping 20.751b 36lb 61.5lb 921b 154lb 165lb

9.43kg 16.40kg 28kg 41.8kg 70kg 75kg

weight I I I I I

Standard working pressure is shownat 75mbar(1.0 psi) —meterscan be supplied forhigher working pressures.

Heatenergyrates The gas discharge rate tables expressed Wobbe No = (cv)

The rate at which gas is used and heat as m3/h, can be converted to energy

produced in gas appliances may be input rates usingone or moreof the

expressed in several ways. The heat listed conversion calculations from 1-8 Therefore if using natural gas witha cv

input rate can be calculated by and 9 for thermalefficiency. of 39.70 and a sg of 0.58

multiplying the gas rate in m3 or ft3 by It is essential however, that the heat

the relevant calorificvalue (CV). The = (39.70) = 52.12

output of appliances are keptreasonably (v'0.58)

relevant cv mayvary seasonally slightly constant and the gas quality maintained

from region to region, within close limits. The wobbe number WobbNo = 52.12

The current CV'sare generally will give an indication of the heat output

expressed as follows: from burnersusingany of the three

a. cv Btu/ft3 = 1065.64 familygases. The wobbe number can be

derived usingthe following formula:-

b. cv MJ/m3 = 39.70

84

You might also like

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- No. 2 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Document32 pagesNo. 2 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Hilmi Haidar AlifNo ratings yet

- Technical Data Sheet Steel Fibers With Hooked Ends: PerformanceDocument2 pagesTechnical Data Sheet Steel Fibers With Hooked Ends: PerformanceviolettaNo ratings yet

- No. 1 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Document32 pagesNo. 1 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Hilmi Haidar AlifNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Sag & Tension (GAP Conductor)Document1 pageSag & Tension (GAP Conductor)Subodh SontakkeNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Henco TM 1.2.1 PDFDocument1 pageHenco TM 1.2.1 PDFAnonymous O0T8aZZNo ratings yet

- Cooling LoadDocument6 pagesCooling LoadMuhammad YusufNo ratings yet

- PVC Pipes - Friction Loss and Flow Velocities Schedule 40Document9 pagesPVC Pipes - Friction Loss and Flow Velocities Schedule 40VitrophoenicsNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and Btarek eidNo ratings yet

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and BAngel PintoNo ratings yet

- NNDDocument9 pagesNNDdardakNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Ventilation Systems Equal Friction Method CalculationDocument2 pagesVentilation Systems Equal Friction Method CalculationabuNo ratings yet

- University of Zimbabwe Transportation Systems DesignDocument8 pagesUniversity of Zimbabwe Transportation Systems Designkundayi shavaNo ratings yet

- Termistor NTC Mf73t-1Document4 pagesTermistor NTC Mf73t-1Tatys SoleNo ratings yet

- Cantherm mf73t1Document4 pagesCantherm mf73t1ariasaldemarNo ratings yet

- Calculate Reynolds Number and Friction FactorDocument10 pagesCalculate Reynolds Number and Friction FactorSam SenterNo ratings yet

- Pipe DimensionDocument7 pagesPipe DimensionLily NurdianaNo ratings yet

- Garage Ground Floor: Project DateDocument6 pagesGarage Ground Floor: Project DateAmir Shafiq AdhamNo ratings yet

- SEO-Optimized Technical Data Sheet Title for SEVO 1230 Clean Agent CylindersDocument1 pageSEO-Optimized Technical Data Sheet Title for SEVO 1230 Clean Agent Cylinderstribhuvan ShankarNo ratings yet

- GATE VALVES - 800 - Bolted Bonnet - SWDocument1 pageGATE VALVES - 800 - Bolted Bonnet - SWJuan ShunaNo ratings yet

- Partida #Especificaciones Medidas: #Veces Longitud PuntoDocument3 pagesPartida #Especificaciones Medidas: #Veces Longitud PuntoEder Aroon Capcha JuradoNo ratings yet

- API specification for oilfield casing and tubing dimensionsDocument4 pagesAPI specification for oilfield casing and tubing dimensionsGabriela MotaNo ratings yet

- REX INDUSTRIES Co.,LTDDocument4 pagesREX INDUSTRIES Co.,LTDCY LamNo ratings yet

- MCCW ss203 Rev2Document2 pagesMCCW ss203 Rev2edu_3No ratings yet

- Chapter 3 Swingaway DINDocument166 pagesChapter 3 Swingaway DINJosé barriosNo ratings yet

- CHIYODA WELDING PRODUCTS Combination Welding and Cutting Torches GuideDocument13 pagesCHIYODA WELDING PRODUCTS Combination Welding and Cutting Torches Guideandi permanaNo ratings yet

- IMI_CCI_Product_MSDlll-actuator_AW_DigDocument6 pagesIMI_CCI_Product_MSDlll-actuator_AW_DigpanametshNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Ordering Code 5.3.1 Heavy Duty Series Technical Information 5.3.2 SpecificationsDocument12 pagesOrdering Code 5.3.1 Heavy Duty Series Technical Information 5.3.2 SpecificationsDyna ClementeNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- Din 2458Document0 pagesDin 2458student_blNo ratings yet

- 3 Design of I5 As RCDocument12 pages3 Design of I5 As RCRaphael KennethNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Crosby ShackleDocument1 pageCrosby ShacklevrandyNo ratings yet

- Mission 3-Pass: Smoke Tube Shell Boiler in Wet Back DesignDocument2 pagesMission 3-Pass: Smoke Tube Shell Boiler in Wet Back DesignMauricio CarestiaNo ratings yet

- Bearing Capacity SPTM27 1 2Document5 pagesBearing Capacity SPTM27 1 2Tarek AbulailNo ratings yet

- Bondstrand PDFDocument8 pagesBondstrand PDFkrisNo ratings yet

- BHCN 3500 123 EBV TS 20253D 0720 EnglishDocument38 pagesBHCN 3500 123 EBV TS 20253D 0720 EnglishGỗ MộcNo ratings yet

- Operational Manual (Screw Air Compressor)Document33 pagesOperational Manual (Screw Air Compressor)purchase sigmaairsource100% (1)

- SAE Size ChartDocument1 pageSAE Size ChartjcNo ratings yet

- U Channel Steel Astm A36Document1 pageU Channel Steel Astm A36Andrés RamírezNo ratings yet

- Pipeline welding consumable calculation sheetDocument10 pagesPipeline welding consumable calculation sheetkeymal9195No ratings yet

- ASME - ANSI B36.10 - 19 - Carbon, Alloy and Stainless Steel Pipes - Dimensions - Metric UnitsDocument10 pagesASME - ANSI B36.10 - 19 - Carbon, Alloy and Stainless Steel Pipes - Dimensions - Metric UnitsSalahiddin AbuselmiyaNo ratings yet

- TenCate Polyfelt TS Nonwoven GeotextilesDocument6 pagesTenCate Polyfelt TS Nonwoven GeotextilesChee Soon LeeNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- RGU ENM 201 Wells Coursework-May2017 FinalDocument7 pagesRGU ENM 201 Wells Coursework-May2017 FinalEmenike Donald EjiejiNo ratings yet

- C662-70 (2010) Standard Specification For Impervious Graphite Pipe and ThreadingDocument4 pagesC662-70 (2010) Standard Specification For Impervious Graphite Pipe and Threadingastewayb_964354182No ratings yet

- 40 Steel Pipe Size and Support DesignDocument1 page40 Steel Pipe Size and Support DesignAbdul Rawoof ShaikNo ratings yet

- ANSI B36.19 ASME B36.10 NB Sizes Weights PDFDocument2 pagesANSI B36.19 ASME B36.10 NB Sizes Weights PDFmohamed faragNo ratings yet

- ANSI B36.19, ASME B36.10 NB Sizes, Weights, Pipe Size ChartDocument2 pagesANSI B36.19, ASME B36.10 NB Sizes, Weights, Pipe Size ChartMetline Industries100% (1)

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Bamboo - 7Document6 pagesBamboo - 7Sumanth NNo ratings yet

- Construction and Building Materials: Negasi N. Gebremichael, Moses Karakouzian, Kazem JadidiDocument8 pagesConstruction and Building Materials: Negasi N. Gebremichael, Moses Karakouzian, Kazem JadidisandroNo ratings yet

- Ground Floor Plan 1:100: Proposed Residen Tial BuildingDocument4 pagesGround Floor Plan 1:100: Proposed Residen Tial BuildingLubangakene BrianNo ratings yet

- Tanjay 5 VariationDocument20 pagesTanjay 5 VariationJet ArcaNo ratings yet

- DLSUL UH - Specs - Plumbing - SanitaryDocument20 pagesDLSUL UH - Specs - Plumbing - SanitaryRyan BacalaNo ratings yet

- Evalene HDPE Grade SlateDocument1 pageEvalene HDPE Grade Slatepalani.djpNo ratings yet

- Schedule of Finishes 20190523 PDFDocument10 pagesSchedule of Finishes 20190523 PDFMuhammad Farhan GulNo ratings yet

- Optimization of Aluminium Alloy Using Mig Welding Process: Sri Ramakrishna Engineering CollegeDocument11 pagesOptimization of Aluminium Alloy Using Mig Welding Process: Sri Ramakrishna Engineering CollegeVARUNBALAJI SELVAMNo ratings yet

- Mirrax Esr Heat Treatm - RecDocument4 pagesMirrax Esr Heat Treatm - RechamidharvardNo ratings yet

- Vacuum-Treated Carbon and Alloy Steel Forgings For Turbine Rotors and ShaftsDocument8 pagesVacuum-Treated Carbon and Alloy Steel Forgings For Turbine Rotors and ShaftsMahsaNo ratings yet

- ADS Product CatalogDocument58 pagesADS Product Catalogvipequi50No ratings yet

- ASME B31.3 InterpretationsDocument338 pagesASME B31.3 InterpretationsRamdasNo ratings yet

- Mediums of SculptureDocument2 pagesMediums of SculptureJhon Brixther CandavaNo ratings yet

- API 607 and 6FA Fire Tested ValvesDocument4 pagesAPI 607 and 6FA Fire Tested ValvesKajer quemarNo ratings yet

- Ok 68.55Document1 pageOk 68.55Sadashiva sahooNo ratings yet

- ARP 107-6001 Mitsubishi Torque SpecsDocument1 pageARP 107-6001 Mitsubishi Torque SpecsJohnTexeiraNo ratings yet

- Test of Paint PropertiesDocument4 pagesTest of Paint PropertiesmaddyNo ratings yet

- Recovery Recrystallization Grain GrowthDocument13 pagesRecovery Recrystallization Grain GrowthsivaenotesNo ratings yet

- Composite MaterialsDocument8 pagesComposite MaterialsSunny Gaekwad100% (1)

- An17822a PDFDocument18 pagesAn17822a PDFhectorsevillaNo ratings yet

- Flange Dimensions Based On Tables D and E of BS 10: 1962Document6 pagesFlange Dimensions Based On Tables D and E of BS 10: 1962윤규섭No ratings yet

- Indiga Indiga: Tech TechDocument32 pagesIndiga Indiga: Tech Techsunny100% (1)

- Six Classifications of Chromium Carbide PlateDocument2 pagesSix Classifications of Chromium Carbide PlateJuan Carlos EspinozaNo ratings yet

- Cast-iron welding guide covers standardsDocument10 pagesCast-iron welding guide covers standardsclnNo ratings yet

- NASM Conservation Exhibit Design Guidelines PDFDocument14 pagesNASM Conservation Exhibit Design Guidelines PDFPrakash KumarNo ratings yet

- Tage Frid Teaches Woodworking PDFDocument232 pagesTage Frid Teaches Woodworking PDFjhfm_xxi88% (8)

- B111B111M-11 Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockDocument12 pagesB111B111M-11 Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockSalma FarooqNo ratings yet

- List of INDIAN METALS SectorDocument6 pagesList of INDIAN METALS SectorSwapnil BagulNo ratings yet

- Felker Piping Products: Stainless Steel Pipe, Tube & FittingsDocument58 pagesFelker Piping Products: Stainless Steel Pipe, Tube & FittingsRahul PillaiNo ratings yet

- 6 BrickworkDocument42 pages6 BrickworkSiti Nurul SyakinahNo ratings yet