Professional Documents

Culture Documents

A2.01-Min Max Burial Depth CorrHDPE Pipe

Uploaded by

baltazarpaulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A2.01-Min Max Burial Depth CorrHDPE Pipe

Uploaded by

baltazarpaulCopyright:

Available Formats

TECHNICAL NOTE

Minimum and Maximum Burial Depth for Corrugated HDPE Pipe

TN 2.01

September 2008

Introduction

The information in this document is designed to provide answers to general cover height questions; the data provided is not

intended to be used for project design. The design procedure described in the Structures section (Section 2) of the Drainage

Handbook provides detailed information for analyzing most common installation conditions. This procedure should be utilized

for project specific designs.

The two common cover height concerns are minimum cover in areas exposed to vehicular traffic and maximum cover heights.

Either may be considered "worst case" scenario from a loading perspective, depending on the project conditions.

Minimum Cover in Traffic Applications

Pipe diameters from 4- through 48-inch (100-1200 mm) installed in traffic areas (AASHTO H-25 or HS-25 loads) must have at

least one foot (0.3m) of cover over the pipe crown, while 54- and 60-inch (1350 and 1500 mm) pipes must have at least 24

inches (0.6m) of cover. The backfill envelope must be constructed in accordance with the Installation section (Section 5) of

the Drainage Handbook and the requirements of ASTM D2321. The backfill envelope must be of the type and compaction

listed in Table 2-3 of the Drainage Handbook. In Table 1 below, this condition is represented by a Class III material

compacted to 90% standard Proctor density, although other material can provide similar strength at slightly lower levels of

compaction. Structural backfill material should extend six inches (0.15m) over the crown of the pipe; the remaining cover

should be appropriate for the installation and as specified by the design engineer. If settlement or rutting is a concern, it may

be appropriate to extend the structural backfill to grade. Where pavement is involved, sub-base material can be considered in

the minimum burial depth. While rigid pavements can be included in the minimum cover, the thickness of flexible pavements

should not be included in the minimum cover.

Additional information that may affect the cover requirements is included in the Installation section (Section 5) of the Drainage

Handbook. Some examples of what may need to be considered are temporary heavy equipment, construction loading ,

paving equipment and similar loads that are less than the design load, the potential of pipe flotation, and the type of surface

treatment which will be installed over the pipe zone.

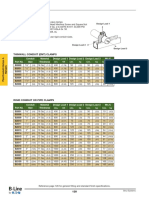

Table 1

Minimum Cover Requirements for ADS N-12®, N-12® ST, and N-12® WT with AASHTO H-25

or HS-25 Load

Inside Minimum Minimum

Inside Diameter,

Diameter, ID, Cover Cover

ID, in.(mm)

in.(mm) ft. (m) ft. (m)

3 (75) 1 (0.3) 24 (600) 1 (0.3)

4 (100) 1 (0.3) 30 (750) 1 (0.3)

6 (150) 1 (0.3) 36 (900) 1 (0.3)

8 (200) 1 (0.3) 42 (1050) 1 (0.3)

10 (250) 1 (0.3) 48 (1200) 1 (0.3)

12 (300) 1 (0.3) 54 (1350) 2 (0.6)

15 (375) 1 (0.3) 60 (1500) 2 (0.6)

18 (450) 1 (0.3)

Note: Minimum covers presented here were calculated assuming Class III backfill material compacted to 90% standard Proctor

density around the pipe and a minimum of 6-inches (0.15m) structural backfill over the pipe crown, as recommended in Section

5 of the Drainage Handbook, with an additional layer of compacted traffic lane sub-base for a total cover as required. In shallow

traffic installations, especially where pavement is involved, a good quality compacted material to grade is required to prevent

surface settlement and rutting.

4640 TRUEMAN BLVD. HILLIARD, OH 43026 (800) 821-6710 www.ads-pipe.com 1

ATN201 © ADS 2008

Maximum Cover

Wall thrust generally governs the maximum cover a pipe can withstand and conservative maximum cover heights will result

when using the information presented in the Structures section (Section 2) of the Drainage Handbook.

The maximum burial depth is highly influenced by the type of backfill and level of compaction around the pipe. General

maximum cover limits for ADS N-12, N-12 ST, N-12 WT pipe, (ASTM F2306 and AASTHO M252/M294 Type S pipes) are

shown in Table 2 for a variety of backfill conditions. Maximum Cover limits for ADS Single Wall pipe, (ASTM F405/F667 and

AASHTO M252/M294 Type C pipes) are shown in Table 3.

Table 2 and Table 3 were developed assuming pipe is installed in accordance with ASTM D2321 and the Installation section

(Section 5) of the Drainage Handbook. Additionally, the calculations; assume zero hydrostatic load, incorporate the maximum

safety factors represented in structures section of the Drainage Handbook, and assume the native soil is of adequate strength

and is suitable for installation. For applications requiring fill heights greater than those shown in Table 2 and Table 3, contact

the ADS Regional Engineering or Application Engineering departments.

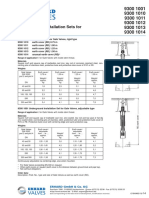

Table 2

Maximum Cover for ADS N-12, N-12 ST, and N-12 WT Pipe, ft (m)

Diameter Class 1 Class 2 Class 3

in (mm)

Compacted Dumped 95% 90% 85% 95% 90% 85%

4 (100) 44 14 29 20 14 21 15 13

(13.4) (4.3) (8.8) (6.1) (4.3) (6.4) (4.6) (3.9)

6 (150)

8 (200) 40 13 27 18 13 19 14 12

10 (250) (12.2) (3.9) (8.2) (5.5) (3.9) (5.8) (4.2) (3.7)

43 15 29 20 15 21 16 14

12 (300)

(13.1) (4.6) (8.8) (6.1) (4.6) (6.4) (4.9) (4.2)

45 15 30 21 15 22 16 15

15 (375)

(13.7) (4.6) (9.1) (6.4) (4.6) (6.7) (4.9) (4.6)

40 13 27 19 13 19 14 12

18 (450)

(12.2) (3.9) (8.2) (5.8) (3.9) (5.8) (4.2) (3.7)

36 12 25 17 12 17 12 11

24 (600)

(11.0) (3.7) (7.6) (5.2) (3.7) (5.2) (3.7) (3.4)

29 10 21 14 10 15 10 9

30 (750)

(8.8) (3.0) (6.4) (4.2) (3.0) (4.6) (3.0) (2.7)

34 10 23 15 10 16 11 9

36 (900)

(10.4) (3.0) (7.0) (4.5) (3.0) (4.9) (3.4) (2.7)

31 10 23 15 10 16 11 9

42 (1050)

(9.4) (3.0) (7.0) (4.5) (3.0) (4.8) (3.3) (2.7)

30 8 20 13 8 14 9 8

48 (1200)

(9.1) (2.4) (6.1) (3.9) (2.4) (4.2) (2.7) (2.4)

54 (1350) 33 9 22 14 9 15 10 8

60 (1500) (10.1) (2.7) (6.7) (4.2) (2.7) (4.5) (3.0) (2.4)

Notes:

1. Results based on calculations shown in the Structures section of the ADS Drainage Handbook. Calculations assume no

3

hydrostatic pressure and a density of 120 pcf (1926 kg/m ) for overburden material.

2. Installation assumed to be in accordance with ASTM D2321 and the Installation section of the Drainage Handbook.

3. Backfill materials and compaction levels not shown in the table may also be acceptable. Contact ADS for further detail.

4. Material must be adequately “knifed” into haunch and in between corrugations. Compaction and backfill material is assumed

uniform throughout entire backfill zone.

5. Compaction levels shown are for standard Proctor density.

6. For projects where cover exceeds the maximum values listed above, contact ADS for specific design considerations.

2 4640 TRUEMAN BLVD. HILLIARD, OH 43026 (800) 821-6710 www.ads-pipe.com

7. Calculations assume no hydrostatic pressure. Hydrostatic pressure will result in a reduction in allowable fill height.

Reduction in allowable fill height must be assessed by the design engineer for the specific field conditions.

8. Fill height for dumped Class I material incorporate an additional degree of conservatism that is difficult to assess due to the

large degree of variation in the consolidation of this material as it is dumped. There is limited analytical data on its

performance. For this reason, values as shown are estimated to be conservatively equivalent to Class 2, 85% SPD.

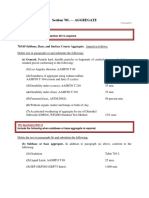

Table 3

Maximum Cover for ADS Single Wall Heavy Duty and Highway Pipe, ft (m)

Diameter Class 1 Class 2 Class 3

in (mm) Compacted Dumped 95% 90% 85% 95% 90% 85%

4 (100) 41 13 27 18 13 19 13 11

(12.5) (4.0) (8.2) (5.5) (4.0) (5.8) (4.0) (3.9)

6 (150)

8 (200)

10 (250)

38 12 25 17 12 18 12 10

12 (300) (11.6) (3.7) (7.6) (5.2) (3.7) (5.5) (3.7) (3.0)

15 (375)

18 (450)

32 11 21 15 11 16 11 9

24 (600)

(9.8) (3.4) (6.4) (4.6) (3.4) (4.9) (3.4) (2.7)

Notes:

1. Results based on calculations shown in the Structures section of the ADS Drainage Handbook. Calculations assume no

hydrostatic pressure and a density of 120 pcf (1926 kg/m3) for overburden material.

2. Installation assumed to be in accordance with ASTM D2321 and the Installation section of the Drainage Handbook.

3. Backfill materials and compaction levels not shown in the table may also be acceptable. Contact ADS for further detail.

4. Material must be adequately “knifed” into haunch and in between corrugations. Compaction and backfill material is assumed

uniform throughout entire backfill zone.

5. Compaction levels shown are for standard Proctor density.

6. For projects where cover exceeds the maximum values listed above, contact ADS for specific design considerations.

7. Calculations assume no hydrostatic pressure. Hydrostatic pressure will result in a reduction in allowable fill height.

Reduction in allowable fill height must be assessed by the design engineer for the specific field conditions.

8. Fill height for dumped Class I material incorporate an additional degree of conservatism that is difficult to assess due to the

large degree of variation in the consolidation of this material as it is dumped. There is limited analytical data on its

performance. For this reason, values as shown are estimated to be conservatively equivalent to Class 2, 85% SPD.

4640 TRUEMAN BLVD. HILLIARD, OH 43026 (800) 821-6710 www.ads-pipe.com 3

ATN201 © ADS 2008

You might also like

- C Ot 25 001 - Rev B - Process Description Control PhilosophyDocument50 pagesC Ot 25 001 - Rev B - Process Description Control PhilosophyAngel CuyaNo ratings yet

- Astm A615m PDFDocument12 pagesAstm A615m PDFAnonymous q8HhQ4w50% (2)

- Drainage Handbook (02-17) PDFDocument177 pagesDrainage Handbook (02-17) PDFHéctor M. PauthNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Beardsley Later Work of Aubrey Beardsley 1930Document204 pagesBeardsley Later Work of Aubrey Beardsley 1930baltazarpaul100% (7)

- Week 2 - Vitasek Et Al. 2005Document8 pagesWeek 2 - Vitasek Et Al. 2005Murtaza PatraNo ratings yet

- A2.04-Min-Max Cover Heights For N-12HPDocument3 pagesA2.04-Min-Max Cover Heights For N-12HPbaltazarpaulNo ratings yet

- A5.02-Flowable Fill For Thermoplastic PipeDocument3 pagesA5.02-Flowable Fill For Thermoplastic PipebaltazarpaulNo ratings yet

- Reinforcing Saddle Dimensions ChartDocument1 pageReinforcing Saddle Dimensions ChartRyan DuhonNo ratings yet

- WL Plastic Hdpe Pipe FM UpgratedDocument4 pagesWL Plastic Hdpe Pipe FM Upgratedrolando reto ancajimaNo ratings yet

- SPDT paddle flow switchDocument2 pagesSPDT paddle flow switchJuan Luis Loaiza CorreaNo ratings yet

- SSL - Cold Planer MB - 26feb2020Document13 pagesSSL - Cold Planer MB - 26feb2020potenzaengenhariaNo ratings yet

- HB Piping PDFDocument3 pagesHB Piping PDFGeambasuNo ratings yet

- A 716 - 99 Qtcxni1sruqDocument7 pagesA 716 - 99 Qtcxni1sruqwahyudiNo ratings yet

- Storm Installation Guide, 04-20Document40 pagesStorm Installation Guide, 04-20Zhenhe SongNo ratings yet

- Ficha Tecnica Mylard Tipo A DupontDocument2 pagesFicha Tecnica Mylard Tipo A DupontJuan Hilares AlejandroNo ratings yet

- H06157Document3 pagesH06157kirankirkNo ratings yet

- Pipe Clamps & Hangers Spec SheetDocument1 pagePipe Clamps & Hangers Spec SheetAlejandro Ayrton Zambrano CinceNo ratings yet

- A2.05-Min-Max Cover Heights For SaniTite HPDocument3 pagesA2.05-Min-Max Cover Heights For SaniTite HPbaltazarpaulNo ratings yet

- Table - SelectionDocument2 pagesTable - SelectionSoumya SameerNo ratings yet

- Pipe Pocket Guide1 PDFDocument37 pagesPipe Pocket Guide1 PDFbetojulioNo ratings yet

- Kelken US Metric Chart ASTM A615 Grade 60 RebarDocument1 pageKelken US Metric Chart ASTM A615 Grade 60 RebarAvsin CevaNo ratings yet

- WL130-0116 FM PipeDocument3 pagesWL130-0116 FM Pipedaniel manuel garces davilaNo ratings yet

- Underground Installation Sets For Gate ValvesDocument1 pageUnderground Installation Sets For Gate Valvesanon_908626193No ratings yet

- Riveted Joints: SymbolsDocument23 pagesRiveted Joints: SymbolsbobcrystoNo ratings yet

- 78-8127-6976-4 Rev DDocument16 pages78-8127-6976-4 Rev DAli SurachmanNo ratings yet

- Flange Dimensions For DN600 AltDocument3 pagesFlange Dimensions For DN600 AltNapiorkowskiNo ratings yet

- Platform Size 600x600 MM: Easy System IntegrationDocument4 pagesPlatform Size 600x600 MM: Easy System IntegrationleomedalloNo ratings yet

- Claw Tooth of Mole CricketsDocument5 pagesClaw Tooth of Mole CricketsAmeer BA-faiadhNo ratings yet

- Reference Data: Schedule 40 Steel Pipe DataDocument2 pagesReference Data: Schedule 40 Steel Pipe DataKareem HelalNo ratings yet

- Chapter 6 PDFDocument20 pagesChapter 6 PDFKenan KiliçaslanNo ratings yet

- Serie 523 - ISO 15552Document69 pagesSerie 523 - ISO 15552NixiusNo ratings yet

- High Strength Welded Wire Reinforcement For High Performance ConcreteDocument21 pagesHigh Strength Welded Wire Reinforcement For High Performance ConcreteDiego Pinto MendezNo ratings yet

- WL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Document3 pagesWL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Tanwir AhmadNo ratings yet

- Vibration Eliminators: Refrigeration ConnectorsDocument4 pagesVibration Eliminators: Refrigeration ConnectorsIskandar FirdausNo ratings yet

- D 2609 - 00 - Rdi2mdktukve PDFDocument5 pagesD 2609 - 00 - Rdi2mdktukve PDFAndre CasteloNo ratings yet

- Hoja Tecnica - G5+Document3 pagesHoja Tecnica - G5+fabians77No ratings yet

- Dimensional Drawings: Single Transmitter Dimensions and WeightsDocument2 pagesDimensional Drawings: Single Transmitter Dimensions and WeightsAlejo SilvaNo ratings yet

- FT 854715.11 - (Vortex)Document2 pagesFT 854715.11 - (Vortex)Alejo SilvaNo ratings yet

- How To Calculate Conduit FillDocument4 pagesHow To Calculate Conduit FillAliNo ratings yet

- Saddle Stress CalculationsDocument8 pagesSaddle Stress CalculationsMuthuNo ratings yet

- All-Welded (AW) Wire-Wrapped ScreensDocument2 pagesAll-Welded (AW) Wire-Wrapped ScreensKamal HamzahNo ratings yet

- Construction Details : Industrial Butterfly Damper (IBFD) - EB Air SeriesDocument4 pagesConstruction Details : Industrial Butterfly Damper (IBFD) - EB Air Serieshond02No ratings yet

- Floor Plate PDFDocument2 pagesFloor Plate PDFdheenasweetNo ratings yet

- Rigid Steel Conduit Reference DataDocument1 pageRigid Steel Conduit Reference DataRitaban222No ratings yet

- Rd-Rigid Steel Conduit ImcDocument1 pageRd-Rigid Steel Conduit ImcSGQNo ratings yet

- Sleeve-All Design Information - Concrete and MasonryDocument3 pagesSleeve-All Design Information - Concrete and MasonryEmad Ahmed KhanNo ratings yet

- D Silter SwacoDocument4 pagesD Silter SwacoJuan Sebastian Diaz CuadrosNo ratings yet

- Section 703. - AGGREGATE: Include The Following When Section 301 Is RequiredDocument3 pagesSection 703. - AGGREGATE: Include The Following When Section 301 Is RequiredPrisscy ChimarroNo ratings yet

- Ficha Tecnica Agru - Geotextil NT Ambiental (2018)Document1 pageFicha Tecnica Agru - Geotextil NT Ambiental (2018)Edward Jose Quispe BaldarragoNo ratings yet

- Conduit Fill CalculationDocument3 pagesConduit Fill CalculationCarl James GranadaNo ratings yet

- D3034 & F679 Sewer Specification DataDocument2 pagesD3034 & F679 Sewer Specification DataRaul ArmendarizNo ratings yet

- Norma AASHTO M 304Document9 pagesNorma AASHTO M 304Vianey MartinezNo ratings yet

- Nominal Pipe Size - WikipediaDocument23 pagesNominal Pipe Size - WikipediaPrakashNo ratings yet

- Insert RoscaDocument5 pagesInsert RoscaVirfranny FaniniNo ratings yet

- Kar-Kaddy: Operators Manual KK260 (8) & KK360 (8-1/2)Document24 pagesKar-Kaddy: Operators Manual KK260 (8) & KK360 (8-1/2)Contact EmailNo ratings yet

- Paratech Brochures RSSDocument12 pagesParatech Brochures RSSTatiana Andrea Carvajal GutierrezNo ratings yet

- Safe Gard Performance 2017Document2 pagesSafe Gard Performance 2017LNo ratings yet

- Checkered Plate: Grades AvailableDocument3 pagesCheckered Plate: Grades Availablevelmurug_balaNo ratings yet

- Checkered Plate: Grades AvailableDocument3 pagesCheckered Plate: Grades Availableprajakt_pieNo ratings yet

- Class VIDocument1 pageClass VIParameshwaran G IyerNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Drainage Handbook ADH3 Hydraulics (07-14) PDFDocument17 pagesDrainage Handbook ADH3 Hydraulics (07-14) PDFRan NNo ratings yet

- ESAB - PipelinesDocument65 pagesESAB - PipelinesLigia114100% (2)

- Awwa - C207-1994Document29 pagesAwwa - C207-1994baltazarpaulNo ratings yet

- MicroStation 8Document922 pagesMicroStation 8jorgemosquete50% (2)

- Derrida Nietzsche and The MachineDocument4 pagesDerrida Nietzsche and The MachineAbo Borape NinoNo ratings yet

- MicroStation 8Document922 pagesMicroStation 8jorgemosquete50% (2)

- Ascension - No. 17 Spanish)Document18 pagesAscension - No. 17 Spanish)baltazarpaulNo ratings yet

- Ascension - No. 02 de 12 (Dave Finch) (Comic-Spanish)Document25 pagesAscension - No. 02 de 12 (Dave Finch) (Comic-Spanish)a00boxNo ratings yet

- Torsen General Frequently Asked Questions PageDocument4 pagesTorsen General Frequently Asked Questions PagedromakiNo ratings yet

- Islamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafDocument90 pagesIslamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafEwinNo ratings yet

- Tower Semiconductor Ltd's ISO 27001 Security Policy and ControlsDocument6 pagesTower Semiconductor Ltd's ISO 27001 Security Policy and Controlsastaswastika100% (2)

- Overview of IFIC Bank Limited's Products and ServicesDocument54 pagesOverview of IFIC Bank Limited's Products and ServicesTanvir Nayim0% (1)

- International Marketing StrategiesDocument37 pagesInternational Marketing StrategiesAkanksha SonkerNo ratings yet

- Maintain Training FacilitiesDocument14 pagesMaintain Training FacilitiesArlynPorrasBonifacioNo ratings yet

- 09 IGV SystemDocument5 pages09 IGV Systemnabil160874100% (1)

- Conductivity in Power PlantsDocument4 pagesConductivity in Power PlantsdsoNo ratings yet

- Parts List of Engine Assy of FMX 440 (PC-24) - TP-836Document1 pageParts List of Engine Assy of FMX 440 (PC-24) - TP-836Cws0% (1)

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocument25 pagesDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariNo ratings yet

- Iprocurement Setup GuideDocument418 pagesIprocurement Setup GuidepkaruturiNo ratings yet

- Writing A Simulink Device Driver Block: A Step by Step GuideDocument36 pagesWriting A Simulink Device Driver Block: A Step by Step GuideMegaroboMegarobo100% (1)

- Application of A Li-Ion Battery in The Frequency Containment Reserve MarketDocument20 pagesApplication of A Li-Ion Battery in The Frequency Containment Reserve MarketClaysius DewanataNo ratings yet

- DILG Two Serendra Presentation June 7 2013Document59 pagesDILG Two Serendra Presentation June 7 2013SunStar Philippine NewsNo ratings yet

- HP Notebook BIOS Setup GuideDocument8 pagesHP Notebook BIOS Setup GuideBalaRajKumarNo ratings yet

- ANPR Transaction ReportDocument5 pagesANPR Transaction Reportarnab adhikariNo ratings yet

- Gearing BSNL for NGN ServicesDocument27 pagesGearing BSNL for NGN ServicesAlandNo ratings yet

- MSC Madras University SyllabusDocument2 pagesMSC Madras University SyllabusSanthosh MuruganNo ratings yet

- AttachmentDocument33 pagesAttachmentAnkit JaiswalNo ratings yet

- Configure Windows AD Authentication For Business Object Enterprise XI 3.1Document10 pagesConfigure Windows AD Authentication For Business Object Enterprise XI 3.1kphwnNo ratings yet

- Harga Resmi Suku Cadang Motor Honda Januari 2023Document2,363 pagesHarga Resmi Suku Cadang Motor Honda Januari 2023ngangngong9080No ratings yet

- LADDER Program Solution For Multi-Probe Monitoring and Control in Simple Cooling ProcessDocument10 pagesLADDER Program Solution For Multi-Probe Monitoring and Control in Simple Cooling ProcessShivam SinghNo ratings yet

- Dedan Kimathi University of Technolog: SemesterDocument17 pagesDedan Kimathi University of Technolog: SemesterGabriel KamauNo ratings yet

- CMPM ReviewerDocument8 pagesCMPM ReviewerRochel ClareteNo ratings yet

- Birth Certificate AkanshDocument1 pageBirth Certificate AkanshSUDHANSU MOHARANANo ratings yet

- LM5068 Negative Voltage Hot Swap Controller: General Description FeaturesDocument26 pagesLM5068 Negative Voltage Hot Swap Controller: General Description FeaturesRohit SinghNo ratings yet

- Maintenance IndicatorsDocument12 pagesMaintenance IndicatorssatfasNo ratings yet

- FinalMissionReportdefversion Jakarta Coastal Area by NLDocument33 pagesFinalMissionReportdefversion Jakarta Coastal Area by NLLiya DjajadisastraNo ratings yet