Professional Documents

Culture Documents

Test Report LV 080324 r1

Uploaded by

The GunnersOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Report LV 080324 r1

Uploaded by

The GunnersCopyright:

Available Formats

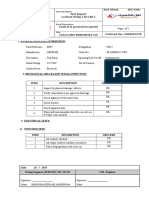

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate Contract No: Tialoc- Truong Giang 190819-1 Seri number: 190780002E

Equipment: Busbar, flexible labour and accessories

connect from Trans 630kVA to MSB 2000A\

Customer: TIALOC MALAYSIA SDN BHD Date of test: 16/08/2019

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test Performed Non applicable

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 2200 x 1800 x1000mm √

1.1.2 Painting: RAL7032 √

1.1.3 Thickness: Steel sheet 2.0mm √

1.2 Verification of lock and hinge and rubber gasket √

1.3 Correspondence between electrical diagram and assembly √

1.4 Correspondence between material list and material installed √

1.5 Visual wiring inspection √

1.6 Visual inspection of degree of protection √

1.7 Visual inspection of form √

1.8 Verification of clearances between busbar and the metal structure √

1.9 Verification of minimum distance amon busbar supports √

1.10 Verification of tighness of nuts and bolts and all electric connections √

1.11 Verification busbar and cables coulor √

2. Electrical operation test √

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Control devices test √

2.4 Phase squence √

2.5 Verification of instruments √

3. Dielectric test

3.1 Test voltage 2500 V application time 5 s

Phases checked 1000 VDC 2500 VAC

Before HV test After HV test Leakage current (mA)

L1 - L2L3NE √

L2 - L1L3NE √

L3 - L1L2NE √

N-E √

3.2 Contact Resistance Test

No Phase 1 Phase 2 Phase 3 Phase N

main circuit resistance ( μΩ ) √

connected contact resistance ( μΩ √

3.3 Check voltage

No L1 - L2 L2 - L3 L1 -L3 L1 -N L2 - N L3 - N

Input (V) √

Output (V) √

3.3 Test voltage 500 V minimum resistence verifiable for control circuit (M Ω) √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

4.1 Water proof protection IPx2 √

4.2 Soild proof protection IP3x √

4.3 Form 4b √

6.Final check

5.1 Label descriptions √

5.2 Enclosed documentation √

Test responsible Approved

Tong Phuoc Nhan Nguyen Dinh Cam

TRUONG GIANG Electric company JSC

Lot Q, Road No 6B - 7A,Hoa Khanh INZ, Da Nang City, Viet Nam

Tel: (+84 511) 3737939 Fax: 84.511.3731838

Test Certificate

Equipment:

Date of test:

Test procedure as per IEC 61439-1 for low voltage switchgear and controlgear assemblies

Routine test PASSED NA

1. Inspection

1.1 Verification of dimension

1.1.1 Dimension: 700 x 500 x 225mm √

1.1.2 Painting: Siemens grey 059/71348 √

1.1.3 Thickness: Steel sheet 2.0mm √

1.2 Wiring check

1.3 Verification of lock and hinge and rubber gasket √

1.4 Correspondence between electrical diagram and assembly √

1.5 Correspondence between material list and material installed √

1.6 Visual wiring inspection √

1.7 Visual inspection of degree of protection √

1.8 Visual inspection of form √

1.9 Verification of clearances between busbar and the metal structure √

1.10 Verification of minimum distance amon busbar supports √

1.11 Verification of tighness of nuts and bolts and all electric connections √

1.12 Assembly inspection

1.13 Verification busbar and cables color √

2. Electrical operation test

2.1 Main circuit test all devices on √

2.2 Auxiliary circuit test all devices on √

2.3 Mechanical test (Open -Close the door, ES, Draw-in & Draw-out VCB, buttons, indicators, switchs, etc)

√

2.4 Function tests of control circuit & Equipments operation (VCB, Relay, Meter…) √

2.5 Check electrical control log √

2.6 Phase sequence √

2.7 Verification of instruments √

3. Testing

3.1 Dielectric test

Power frequence

Insulation resistance test at 1000 VDC

Phases checked withstand voltage 2500

(MΩ)

VAC

Before HV test After HV test Leakage current (mA)

L1 - L2+L3+N+E √

L2 - L1+L3+N+E √

L3 - L1+L2+N+E √

N-E √

3.2 Contact Resistance Test

No Phase 1 Phase 2 Phase 3 Phase N

Main circuit resistance (mΩ) √

Connected contact resistance (mΩ √

3.3 Check voltage

No L1 - L2 L2 - L3 L1 -L3 L1 -N L2 - N L3 - N

Input (V) √

Output (V) √

3.4 Test voltage 500 V minimum resistence verifiable for control circuit (MΩ) √

4. Electrical continuity of the protective circuit verification

4.1 With visual signal √

4.2 Visual verification of connections √

5. Protective verification

5.1 Water proof protection IPx2 √

5.2 Soild proof protection IP4x √

5.3 Form 2b √

6.Final check

6.1 Review of documents (certificates, drawings, inspection reports, etc.) √

6.1 Namplate, marking √

6.2 Packing inspection √

Test responsible Approved

Truong Quyet Nguyen Ngoc Thong

You might also like

- PXX 57Document10 pagesPXX 57The GunnersNo ratings yet

- Installation Ground Terminal Block - UTI 2,5-PE/L/L - 3076029Document7 pagesInstallation Ground Terminal Block - UTI 2,5-PE/L/L - 3076029EngChengLengNo ratings yet

- Feed-Through Terminal Block - UK 5 - 3004016: Key Commercial DataDocument25 pagesFeed-Through Terminal Block - UK 5 - 3004016: Key Commercial DataA. Muhsin PamungkasNo ratings yet

- Knife Disconnect Terminal Block - UK 5-MTK-P/P - 3004032: Key Commercial DataDocument16 pagesKnife Disconnect Terminal Block - UK 5-MTK-P/P - 3004032: Key Commercial DatapoweranalystNo ratings yet

- Component Terminal Block - PT 2,5-DIO/L-R - 3210224: Key Commercial DataDocument4 pagesComponent Terminal Block - PT 2,5-DIO/L-R - 3210224: Key Commercial DataminurajraNo ratings yet

- Test Disconnect Terminal Block - URTKSP - 0311126Document20 pagesTest Disconnect Terminal Block - URTKSP - 0311126Praneeth Madhushan BandaraNo ratings yet

- Feed-Through Terminal Block - UK 2,5 N RD - 0719074: Key Commercial DataDocument22 pagesFeed-Through Terminal Block - UK 2,5 N RD - 0719074: Key Commercial Datasherub wangdiNo ratings yet

- Power Transformer Diagnostics - Introduction: Rafik FouadDocument45 pagesPower Transformer Diagnostics - Introduction: Rafik FouadiraqnewNo ratings yet

- Feed-Through Terminal Block - UK 2,5 B - 3001035: Key Commercial DataDocument21 pagesFeed-Through Terminal Block - UK 2,5 B - 3001035: Key Commercial DatacauvongkhongmauNo ratings yet

- Motor Terminal - PT 2,5-PE/3L - 3210542: Key Commercial DataDocument28 pagesMotor Terminal - PT 2,5-PE/3L - 3210542: Key Commercial DatamohamedNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocument3 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNo ratings yet

- Udk 4 - 2775016Document20 pagesUdk 4 - 2775016A. Muhsin PamungkasNo ratings yet

- Fat Report MV - 080324Document5 pagesFat Report MV - 080324The GunnersNo ratings yet

- Feed-Through Terminal Block - UK 2,5 N BK - 0719100: Key Commercial DataDocument22 pagesFeed-Through Terminal Block - UK 2,5 N BK - 0719100: Key Commercial Datasherub wangdiNo ratings yet

- Double-Level Terminal Block - UTTB 4 - 3044814: Key Commercial DataDocument5 pagesDouble-Level Terminal Block - UTTB 4 - 3044814: Key Commercial DataMauricio AguilarNo ratings yet

- Feed-Through Terminal Block - TB 2,5 EI - 3246010: Key Commercial DataDocument9 pagesFeed-Through Terminal Block - TB 2,5 EI - 3246010: Key Commercial DataAssad ShafiqueNo ratings yet

- Knife Disconnect Terminal Block - UT 2.5 MT - 3046362: Key Commercial DataDocument24 pagesKnife Disconnect Terminal Block - UT 2.5 MT - 3046362: Key Commercial DataPrabhu DevNo ratings yet

- Feed-Through Terminal Block - UT 2,5 - 3044076: Key Commercial DataDocument27 pagesFeed-Through Terminal Block - UT 2,5 - 3044076: Key Commercial Datanet natNo ratings yet

- Test Disconnect Terminal Block - URTK/SP - 0311126: Key Commercial DataDocument20 pagesTest Disconnect Terminal Block - URTK/SP - 0311126: Key Commercial DataMatko ŽajaNo ratings yet

- S.NO. Equipment Details Test Details List of Pre-Commissioning Tests of Ac EquipmentsDocument5 pagesS.NO. Equipment Details Test Details List of Pre-Commissioning Tests of Ac EquipmentsnagarajanNo ratings yet

- Feed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataDocument25 pagesFeed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataJemeraldNo ratings yet

- Distribution Block - PTFIX 16X1,5-NS15A YE - 3002960: Key Commercial DataDocument10 pagesDistribution Block - PTFIX 16X1,5-NS15A YE - 3002960: Key Commercial DatasantiagoNo ratings yet

- Feed-Through Terminal Block - UK 5 N - 3004362: Key Commercial DataDocument27 pagesFeed-Through Terminal Block - UK 5 N - 3004362: Key Commercial DataChung NguyenNo ratings yet

- Double Level TB 3210567Document31 pagesDouble Level TB 3210567adamnorazlanNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- DET4TCR2 Product SpecificationDocument3 pagesDET4TCR2 Product SpecificationAmer KhanNo ratings yet

- Mhob 04-Pw Protection (Translay) RelayDocument1 pageMhob 04-Pw Protection (Translay) RelayTHILAKKUMARNo ratings yet

- Asefa - MV Test Procedure (SWG)Document6 pagesAsefa - MV Test Procedure (SWG)Magicneering PredictNo ratings yet

- Feed-Through Terminal Block - PT 2,5 - 3209510: Key Commercial DataDocument34 pagesFeed-Through Terminal Block - PT 2,5 - 3209510: Key Commercial Dataomar zaquinaulaNo ratings yet

- Single 4 Point TB 3211797Document31 pagesSingle 4 Point TB 3211797adamnorazlanNo ratings yet

- Feed-Through Terminal Block - UT 16 BK - 3044197: Key Commercial DataDocument15 pagesFeed-Through Terminal Block - UT 16 BK - 3044197: Key Commercial DataJediKnight012No ratings yet

- Electrical Testing and DocumentationDocument3 pagesElectrical Testing and DocumentationMohamad AshNo ratings yet

- Feed-Through Terminal Block - UT 4 - 3044102: Key Commercial DataDocument5 pagesFeed-Through Terminal Block - UT 4 - 3044102: Key Commercial DataAlicia AltamiranoNo ratings yet

- Feed-Through Terminal Block - UT 2,5 - 3044076: Key Commercial DataDocument26 pagesFeed-Through Terminal Block - UT 2,5 - 3044076: Key Commercial Datasyahril boonieNo ratings yet

- HV Power Cable TestDocument9 pagesHV Power Cable TestMohammad Nasar100% (1)

- Feed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataDocument5 pagesFeed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataHendra WiratamaNo ratings yet

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- Megger Det4tc2 Earth Tester DatasheetDocument3 pagesMegger Det4tc2 Earth Tester DatasheetEMD NSPCLNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- Disconnect Terminal Block - TB 6-T EI - 3075838: Key Commercial DataDocument17 pagesDisconnect Terminal Block - TB 6-T EI - 3075838: Key Commercial DataEdciel EbuenNo ratings yet

- Knife Disconnect Terminal Block - UT 2,5-MT - 3046362: Key Commercial DataDocument6 pagesKnife Disconnect Terminal Block - UT 2,5-MT - 3046362: Key Commercial DataDarwin LibrandaNo ratings yet

- FXBW 220 160 204 Test ReportDocument8 pagesFXBW 220 160 204 Test ReportbinodeNo ratings yet

- TDS 400kVA 20kV 400V 50Hz Dyn5 - 5 IndoorDocument2 pagesTDS 400kVA 20kV 400V 50Hz Dyn5 - 5 IndoorAfrizal AntariksaNo ratings yet

- Lor Ri 16-Rp 94f-2 6rp2Document2 pagesLor Ri 16-Rp 94f-2 6rp2Humayun AhsanNo ratings yet

- Feed-Through Terminal Block - UK 5 N - 3004362: Key Commercial DataDocument26 pagesFeed-Through Terminal Block - UK 5 N - 3004362: Key Commercial DataIdos AkmalNo ratings yet

- Mvtp11-Ct Supervision RelayDocument2 pagesMvtp11-Ct Supervision RelayTHILAKKUMARNo ratings yet

- NEMA Contactor and Starter Specifications: Technical DataDocument18 pagesNEMA Contactor and Starter Specifications: Technical DataNelsonNo ratings yet

- TR Differential Ret670Document19 pagesTR Differential Ret670Mahdi AlamriNo ratings yet

- TR Differential Ret670 Y YDocument19 pagesTR Differential Ret670 Y Ym khNo ratings yet

- Installcheck Cca 240euraDocument2 pagesInstallcheck Cca 240eurazeljkoNo ratings yet

- Feed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataDocument9 pagesFeed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataBinhvvNo ratings yet

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser MahamidNo ratings yet

- TB Diode 3211430Document27 pagesTB Diode 3211430adamnorazlanNo ratings yet

- 3UG45111AP20 Datasheet enDocument4 pages3UG45111AP20 Datasheet enMohammed FarahatNo ratings yet

- Lighting Wiring Diagrams 2010 NEWDocument36 pagesLighting Wiring Diagrams 2010 NEWAbdallah GhannamNo ratings yet

- Mvax31-Trip Circuit SupervisionDocument2 pagesMvax31-Trip Circuit SupervisionTHILAKKUMARNo ratings yet

- Mvaj205 - Trip RelayDocument2 pagesMvaj205 - Trip Relayratheeshkumard100% (1)

- HG Power Transmission Sdn. BHD.: Method StatementDocument5 pagesHG Power Transmission Sdn. BHD.: Method StatementNabil MazelanNo ratings yet

- Đính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)Document9 pagesĐính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)The GunnersNo ratings yet

- Test Report LV 080324 r1Document3 pagesTest Report LV 080324 r1The GunnersNo ratings yet

- Bảo hành-57Document1 pageBảo hành-57The GunnersNo ratings yet

- Fat Report MV - 080324Document5 pagesFat Report MV - 080324The GunnersNo ratings yet

- Fat Report MV - 080324Document5 pagesFat Report MV - 080324The GunnersNo ratings yet

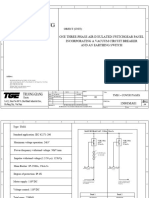

- Drawing of TMS1 Tge 15012024Document5 pagesDrawing of TMS1 Tge 15012024The GunnersNo ratings yet

- Drawing of TMS1 Tge 15012024Document5 pagesDrawing of TMS1 Tge 15012024The GunnersNo ratings yet

- Drawing of TMS1 Tge 15012024Document5 pagesDrawing of TMS1 Tge 15012024The GunnersNo ratings yet

- 1.2 TMS1 Type Test - Secondary-04.07.23Document25 pages1.2 TMS1 Type Test - Secondary-04.07.23The GunnersNo ratings yet

- BRT SylabussDocument29 pagesBRT SylabussAadityaNo ratings yet

- Design Guide For Overhead CranesDocument3 pagesDesign Guide For Overhead CranesralluinNo ratings yet

- Twinmotion 2016 Edition Full CrackDocument3 pagesTwinmotion 2016 Edition Full CrackGivi Andriyanto0% (1)

- Analy Tisch e Chemie EnglischDocument168 pagesAnaly Tisch e Chemie EnglischHas GomNo ratings yet

- Nursing Education Field TripDocument5 pagesNursing Education Field TripIshika Roy67% (3)

- NMRDocument135 pagesNMRKhan Sameer100% (1)

- Siop RTSG2016Document336 pagesSiop RTSG2016Mohammed HaiderNo ratings yet

- A Simple and Convenient Synthesis of Pseudo Ephedrine From N-MethylamphetamineDocument2 pagesA Simple and Convenient Synthesis of Pseudo Ephedrine From N-Methylamphetaminedh329No ratings yet

- INST240 Sec4Document127 pagesINST240 Sec4bhanu6212No ratings yet

- CHAPTER 5 Work MeasurementDocument24 pagesCHAPTER 5 Work MeasurementAiman SupniNo ratings yet

- AAE Migration GuideDocument29 pagesAAE Migration GuideNguyen Hung0% (1)

- Survey Questionnaire 3 - Student EngagementDocument2 pagesSurvey Questionnaire 3 - Student EngagementDAN MARK CAMINGAWANNo ratings yet

- Anatomy Book For DoctorsDocument3 pagesAnatomy Book For DoctorsMuhammad JunaidNo ratings yet

- Advance Strategic Marketing: Project Report of Nayatel.Document46 pagesAdvance Strategic Marketing: Project Report of Nayatel.Omer Abbasi60% (15)

- Spark RPG Colour PDFDocument209 pagesSpark RPG Colour PDFMatthew Jackson100% (1)

- Group 10 - Stem 11 ST - DominicDocument34 pagesGroup 10 - Stem 11 ST - Dominicchristine ancheta100% (1)

- 2course Codes For 1 SEMESTER S.Y. 2021-2022: GE 2/ GE 1: Readings in The PhilippineDocument10 pages2course Codes For 1 SEMESTER S.Y. 2021-2022: GE 2/ GE 1: Readings in The PhilippineRexson Dela Cruz TagubaNo ratings yet

- ACCSA Module 1 - 8 Practice Dimensions & Skillsets of Addiction CounsellingDocument148 pagesACCSA Module 1 - 8 Practice Dimensions & Skillsets of Addiction Counsellingskye42817No ratings yet

- Psychology - Masters in Psychology Entrance Examination Book (Power Within Psychology, Amit Panwar) (Z-Library)Document414 pagesPsychology - Masters in Psychology Entrance Examination Book (Power Within Psychology, Amit Panwar) (Z-Library)Suraj100% (12)

- Motherboard Manual 6vem eDocument67 pagesMotherboard Manual 6vem eAri Ercilio Farias FereirraNo ratings yet

- 02 RgebDocument1,168 pages02 Rgebprožnik100% (3)

- Filcro - LabrevDocument19 pagesFilcro - LabrevKim ArniñoNo ratings yet

- Coastal Boards Co Is A Merchandising Business The Account BalancesDocument1 pageCoastal Boards Co Is A Merchandising Business The Account BalancesFreelance WorkerNo ratings yet

- Huawei Sne Mobile Phone User Guide - (Emui9.0.1 - 01, En-Uk, Normal)Document68 pagesHuawei Sne Mobile Phone User Guide - (Emui9.0.1 - 01, En-Uk, Normal)FarzadNo ratings yet

- Benjamin Gomez v. Enrico PalomarDocument11 pagesBenjamin Gomez v. Enrico PalomarUlyung DiamanteNo ratings yet

- Magellan 8300Document540 pagesMagellan 8300Fleming AlexanderNo ratings yet

- FSED 1F Application Form FSEC For Building Permit Rev02Document2 pagesFSED 1F Application Form FSEC For Building Permit Rev02Angelito RegulacionNo ratings yet

- Mcmurdo S4 SART User GuideDocument20 pagesMcmurdo S4 SART User Guidesathish kumar100% (2)

- Survey-Questionnaire For The Study "Factors Affecting The Level of Comprehension in English of Grade 3 Students School Year 2021-2023"Document13 pagesSurvey-Questionnaire For The Study "Factors Affecting The Level of Comprehension in English of Grade 3 Students School Year 2021-2023"Rosalinda SamongNo ratings yet

- Catalogue For TubingDocument1 pageCatalogue For Tubingprabhakaran.cNo ratings yet