Professional Documents

Culture Documents

EA-MF-WH-S-080 - Connector Holder

EA-MF-WH-S-080 - Connector Holder

Uploaded by

Amina El AnsariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EA-MF-WH-S-080 - Connector Holder

EA-MF-WH-S-080 - Connector Holder

Uploaded by

Amina El AnsariCopyright:

Available Formats

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

PROCESS FLOW:

PTC

Start

New

Request Connector 3D model

Connector

PTC

N Request Re-draw

Exist connector sample connector

C/H Drawing (from plant)

“Trial” Y PTC PTC

Design C/H Drawing

PTC

C/H

Review C/H

Drawing

drawing Upload data base with “Trial”

“Validated”

PTC C/H Drawing

PTC

Check data base if C/H “Trial”

Plant Drawing exist

Plant

New Central PTC

Connector Request PTC N C/H drawing

Holder Exist

Plant Data Base

Y

Connector Plant Order 1 sample from supplier A

holder

approval B Plant must validate prototype C/H

form

EA-MF-WH- PTC Change status

S-080-F1 NG drawing to “Validated”

Analyze problem Result and upload data base

Plant/PTC/Supplier

Connector Ok

Holder

Progress Plant must send approval report to PTC End

Follow Up

Chart

EA-MF-WH- A Supplier must download C/H drawing

S-080-F2

Suppier must manufacture 1 C/H sample

Supplier

Check C/H functionality with connector

Review C/H jig sample

Supplier Supplier

NG

Inform PTC Result

Supplier

Ok

Supplier send C/H prototype to plant B

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 1 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

1. PURPOSE:

The purpose of this procedure to define the rules and the responsibilities with process flow needed to

design new (or to improve existing) connector holder; to manufacture, to approve, and to release

Connector Holder based on Yazaki created drawing according to the technical standard, requirements

and specification agreed during Global benchmarking, including Best in Practice latest result.

2. SCOPE:

This document is valid for all YEL/YWT manufacturing plant, PTC, original holders makers and must be

applied to each connector holder, being used in the assembly area.

If the customer’s specifications do not contain any or insufficient directions with regard to the

connector’s holder design, the standards laid down in this document are to be applied.

3. TERMS & DEFINITIONS:

• BM-18 - 18th Global Yazaki benchmarking “Assembly Fixture”

• Connector - Housing for joining electrical circuits together: usually made up of a plug (male)

and a socket (female)

• Connector holder - A jig for securely fixing and holding connector (thereafter C/H)

• EME - European Manufacturing Engineering

• PTC - Porto Technical Center

• TCC /COSEE - Process Engineering/ Committee Of Standardization Equipment Evaluation

• YEG: Yazaki Europe Group

4. PROCESS DETAILS:

4.1 CONNECTOR HOLDER DESIGN

4.1.1 Due to the different types, shapes, and sizes of connectors, it is very difficult to make a

complete standardization and unification of all connector holders. Therefore, in this

document main criteria are described and should be applied to connector holders in all

cases, whatever it possible.

4.1.1.1 All connector holders must have the next design features (basic):

• same as connector shape and wrong connector can not be mounted

• a connector can not be mounted in a wrong orientation

• all gates and locking features can be left in an open position to enable the fitments

to be inserted

• connector holders must be the same color as connectors (or dot color when several

different components are existing in one part)

• engraved data panel included (Yazaki identification number/ manufacture batch

code for traceability)

4.1.1.2 Connector holder must be equipped with:

• fitted with ejector pin (plastic with spring)

• equipped with a secure locking device

• equipped with cable form part

• equipped with wire’s holder

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 2 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.1.1.3 Connector holders must be always used (ordered) for the connector:

• if the connector has a secondary lock

• if the connector has more than 3 cavities

• when the terminal insertion is made by the operator into connector’s cavities

• if wires are taken out from the side (or back) of the connector

• if connector do not have any fragile parts (or body) which can be broken or made

connector unusable after usage of connector holders

• if connector holder fixture is fix type (not fall down)

• if the connector is an airbag connector (due to quality risk for handling process)

• if wire size cross-section bigger than 6.00 mm2

If there are no special customer requirements existing and the connector are not matching to

criteria described above, YEG plants may use a pin fork with a connector stopper (low-cost

solution) for each individual case.

4.1.2 Connector Holder Types

There are existing 3 types of connector holders, based on connector position:

a) Sided (Yokodashi) connector holder

b) Straight connector holder

c) Angled connector holder (optional)

Pic.1 a)Sided connector holder Pic. 2 b) Straight connector holder Pic.3 c) Angled connector holder

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 3 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.1.2.1 Sided (or Yokodashi type) connector holder: Jig for holding a connector with

wires bent by 90 degrees (with wires side taking out).

Pic.4 Sided Connector Holder

4.1.2.2 Straight connector holder: Jig for holding a connector without wires bent (with

straight wire).

Pic.5 Straight Connector Holder

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 4 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.1.2.3 Angled connector holder (optional): Jig for holding a connector – to easy

terminal insertion operation.

Pic.6 Angled Connector Holder

4.2 Types of legs for connector holder: There are two types of connector holder legs:

• Adjustable

• Fixed

4.2.1 Adjustable Connector Holder Legs

a) T-type (20 mm and 30 mm pitch adjustment)

b) L-type (10 mm pitch adjustment)

Pic.7 T-type leg Pic.8 L-type leg

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 5 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

Pic.9 Measure point for Sided Pic.10 Measure point for Straight Pic.11 Measure point for Angled

holder with T-type leg holder with L-type leg holder with L-type leg

4.2.1.1 Basic design and dimension of T-type 20mm and 30mm pitch adjustment and L

type 10mm pitch adjustment legs.

Pic 12. 20 and 30 mm pitch Pic.13 10mm pitch adjustment L- Pic.14 Outer column

adjustment T-type type

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 6 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

Specification

No Name Definition 10 mm 20 mm 30 mm

pitch pitch pitch

1) Base Width Width of the base 24 mm 15 mm 15 mm

2) Base Length Length of the base 35 mm 30 mm 40 mm

4 holes x 2 holes x 2 holes x

3) Holder Joint Hole A hole to joint the holder and the leg

4 ,2 mm 5,2 mm 5,2mm

4) Holder Joint Hole Pitch Joint hole pitch for holder 10 mm 20 mm 30 mm

5) Base Thickness Thickness of base 3.2 mm

A hole provided inner column for height Short leg 4 holes 3,5mm

6) Up-down Slide Hole

adjustment (2 options) Long leg 7 holes 3,5mm

7) Inner Column A square column provided inside 8 mm

8) Height Height of leg 35 mm and 50 mm

9) Fixing Hole for Up-down A fixing section to fix the height M4

10) Outer Column A column provided outside 17 mm

11) Leg Washer Diameter Diameter of the leg washer 30 mm

A projection to prevent a jig from

12) Whirl stopper 2 mm

rotating

Length of a screw to fix on the assembly

13) Leg L. Dimension 23 mm

jig board

Bolt size of the screw to fix on the

14) Leg Bolt Size M8

assembly jig board

15) Leg Material steel with zinc plating treat

4.2.1.2 Base dimensions:

Pic.15 base L type 10mm pitch Pic.16 base T type 20mm pitch Pic.17 base T type 30mm pitch

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 7 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.1.3 Inner column:

The diameter of the column must be 8mm square in shape (The inner and outer

columns are separated and the leg screw section is provided on the outer column).

There are 2 heights available: 35 and 50mm.

Up and downslide hole:

a) 35mm - 4 holes are placed in diameter 3, 5 at 5mm intervals (Slide height; 15mm)

10mm pitch 20mm pitch 30mm pitch

Pic.18 Inner – Short Leg

b) 50mm - 7 holes are placed in diameter 3, 5 at 5mm intervals (Slide height; 30mm)

10mm pitch 20mm pitch 30mm pitch

Pic.19 Inner – Long Leg

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 8 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.1.4 Outer Column

The outside diameter of the column: 17mm, inside diameter: 8.1mm square shape.

There are two heights available for the outer column: H=30 mm (short) and H=50 mm

(long)

The short leg should be used when it is necessary to adjust height

Pic. 15 Short with height H = 30mm

range from minimum 45mm till maximum – 55mm

Min.

Pic.20 Outer Short Leg

Pic. 16 Long with height H = 50mm The long leg should be used when it is necessary to adjust the height

range from minimum – 60 mm till maximum – 90 mm.

Pic.21 Outer Long Leg

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 9 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.2 Fixed type connector holder legs:

The base dimensions of the fixed type of connector holders are the same as adjustable

legs defined in chapter 4.1.3.1.2. The difference between both options (adjustable and

height) is the height. These legs should be used when need to adjust connector holder leg

height less than 45mm.

Pic.22 Fixed Type Legs

4.2.2.1 The height “A” range: Is between 15mm to 40mm for both options (T Shape

pitch 20 & 30, L Shape)

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 10 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.3 Locking Device: The locking device is a tool to keep the connector in Connector Holder during

insertion and taping processes.

4.2.3.1 There are two types of locking devices:

4.2.3.1.1 Standard Locking Device: All connector holders must be equipped with a

standard locking device as shown below. There are existing two types of locking device

with heights of 25 mm and 35 mm

Pic.23 Locking Device

The proper height is depending on the connector holder design which will be decided by

the designer of the connector holder. Using this type of locking device is strongly advised

when there is an ejector mechanism (pin) fitted inside the connector holder.

4.2.3.1.2 Optional (plastic) - loose connector prevention lever: This part prevents the

connector from getting out of the holder (should be used only for molded connector

holders)

Pic.24 Prevention lever Pic.25 Connector holder with prevention lever

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 11 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.3.2 Criteria to design Lockin Device position on Connector Holder:

• The locking device can not block or limit access to connector cavities, where terminals

are being inserted.

• It is very important that the locking device should be placed in the correct position

towards to connector surface.

• Holder locking devices should not touch any part of the connector's locking system or

any fragile areas for fear of damage.

Pic.26 Wrong position of locking device Pic.27 Wrong position of locking device

• When there is a female connector with sensitive male terminals (for example 050

Terminals) there might be a risk that the locking device can damage the terminals. For that

reason, it is necessary to hide the locking device inside the gravity (to prevent terminals

touching.

Pic.28 Locking device hidden in gravity Pic.29 Locking device hidden in gravity

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 12 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.3.3 Optional (plastic) - loose connector prevention lever: This part prevents the

connector from getting out of the holder (should be used only for molded connector

holders)

Pic.30 Prevention lever Pic.31 Connector holder with prevention lever

4.2.4 Ejector Pin:

Ejector helps the operator to release the connector from the holder automatically when the

locking device is unlocked. The mechanism is placed at the bottom of the connector holder.

Ejector Tip

Ejector Spring

Screw M5 x 4 mm

Pic.32 Ejector Mechanism Pic.33 Connector holder with ejector

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 13 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.5 Cable form part

A part should be fixed to the sided holder (from wires take-out direction) to assure branch’s

shape with wires bent 90 degrees (main target - to minimize extra-tension of terminated wires

and to prevent TPO - Terminal Push Out or Not fully inserted terminals defect, caused by tension).

Pic.34 Cable form Pic.35 Connector holders with cable form parts

part

Cable form part has 2 different shape options:

4.2.5.1 Thinner (5mm) Cable form part: It is directly mounted on Connector Holder. This

option should be used when there is the distance between the first insertion

cavity is longer than 20mm from the cable form part surface.

Pic.36 Cable form part 5mm Pic.37 Proper distance to the first cavity

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 14 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.5.2 Larger (10mm) Cable Form Part: There is an additional 5mm wall on the Cable

form part. In this way, it is possible to bring the surface of the Cable Form part

more away to make insertion possible when the cavities are closer to Cable

Form Part. If the fist insertion cavity dimension is less than 20mm, this option

should be used.

Pic.38 Cable form part 10mm Pic.39 Proper distance to the first cavity

4.2.5.3 The width of the Cable form part: For both options, the “B” dimension is

between 12mm to 35mm.

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 15 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.6 Wires holder: A part should be fixed to jig when temporarily placing wires for the terminal

insertion on the assembly jig board is required.

Pic.40 Wire’s holder Pic.41 Connector holder with wire’s holder

4.2.7 Wire Color Identification (for sided and angled connector’s type)

Additional row with grooves for wire’s color identification template should be made on

top of connector holder when wires insertion is done in the assembly line.

Pic. 42 Connector holder with color identification template in channels

4.2.8 Nano MQS marking on connector holders

It is necessary to mark connector holders with 2mm gravity and orange color inside. The idea is to

identify Nano MQS connector holders because of the sensitive terminals and not allowed / high

risk of the rework process. This color marking must e applied in all type of connector holders

(Sided, Straight, Angled, and as well Sub Assembly)

Pic. 43 Marking Nano MQS Connector holder with orange color

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 16 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.9 Airbag Connector Holders

All airbag connector holders’ color must be yellow as it is a critical process and not allowed

rework. The idea is to identify Airbag connector holders because of the not allowed rework

process. All types of connector holders (Sided, Straight, and as well Sub Assembly) must be yellow.

Angled type of connector holder should not be used for Airbag connectors.

Pic. 44 Airbag Connector Holder

4.2.10 Standard Sub-assembly jig

It is recommended to use this jig in the sub-assembly station to fix the connector inside when the

terminal insertion is necessary to perform.

Sub-assembly holders must have the below features:

A - Color identification

B - Locking device

C - Ejection pin

D - Visual aid (color)

Pic. 45 Standard Sub Assembly Holder

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 17 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

4.2.11 Sub-assembly holder with template

This jig has the same function as a standard sub-assembly connector holder but is additionally

equipped with Alum plates (as a color template), which closes unused cavities and preventing from

the wrong insertion.

Pic.46 Connector holder with mask plate

4.3 Connector Holder Height Adjustment: All connector holder heights should be adjusted

according to the height of BM1 Forks. Adjusting CH heights according to forks’ heights is an

important point because of the below reasons:

• To prevent the Quality Risk of damaging wires. Because operators have to place the

wires inside the forks before starting the taping process. During this process, wires are

been pulled by the operator and stressed onto the pins of the forks while placing them

inside.

• To have a negative impact on efficiency. Because when the wires are not kept in the

forks, then operators on the taping side have to reorganize the wires which are causing

an impact of losing time.

Some variants of the forks can be different but in general, the center of the BM1 fork's height is

100mm. The purpose is to keep the brunch/trunk center always at the center of the fork.

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 18 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

Pic.47 Center of the brunch / trunk into the assembly fork

4.3.1 Height Adjustment for Straight Connector Holders: The center of the connector into

the connector holder should be equal to the branch center in the fork. A correct height of

leg (in chapters 4.2.1.5, 4.2.1.6, or 4.2.2.2) should be chosen for Connector Holder.

The same logic should be applied in Angled Type of Connector Holders (The dimensional

center should be the center of the connector into the Angled Connector Holder)

Point A should be equal to Point B

Pic.48 Height Adjustment for Straight Connector Holder

4.3.2 Height adjustment for Sided Connector Holders: The center of the branch coming

from the sided Connector holder should be equal to the branch center in the fork. A correct

height of leg (in chapters 4.2.1.5, 4.2.1.6, or 4.2.2.2) should be chosen for Connector Holder.

Point A should be equal to Point B

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 19 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

Pic.49 Height Adjustment for Sided Connector Holder

4.4 Responsibilities:

4.4.1 EME TCC COSEE Assembly is responsible: for creating, approval and controlling this

specification. In addition, EME TCC COSEE Assembly will support the Plants/PTC to

resolve any problem/difficulty on the appliance of this procedure.

4.4.2 PTC team (connector holder designer) is responsible:

▪ To create connector’s holder drawing according to Yazaki technical specification and

design criteria

▪ To update C/H drawing whenever it is necessary (according to feedback from the

plant)

▪ To support YEG plants with the C/H drawing validation process

▪ To upload and maintain C/H drawings in PTC Data Base, in order to have the latest

version of C/H drawing available

▪ To maintain properly “Connector Holder Progress Follow Up Chart” document and to

update with new any information, status progress or revision each time wherever is

necessary

4.4.3 Supply Management – Capital Equipment:

To negotiate commercial conditions of business model between Yazaki plants, PTC, and

suppliers described in this document and to sign Connector Holder - Service Agreement

with preferred supplier certificated by Yazaki.

4.4.4 YEG (each individual) plant is responsible:

▪ To check with PTC if a C/H drawing exists for the connector in Central C/H Drawing

DataBase, and request to PTC to create a new drawing if the drawing is not existing.

▪ For the new connector, the holder must full fill all necessary information according

to the “Connector Holder Progress Follow Up Chart” form EA-MF-WH-S-080-F2

requirement and define the type of C/H.

▪ To make validation of C/H physical sample (first prototype - if it is required) and to

make C/H acceptance according to checklist

▪ To inform the PTC team in all case, when the connector is not fitting to C/H (when

drawing is incorrect, dimension inaccurate or any part is designed wrongly)

▪ To contact and to inform the supplier in all cases, when connector holder (or any

part) is not manufactured according to drawing and holder’s correction is necessary.

▪ To make the ordering process according to Yazaki rules in terms of the procurement

for C/H

▪ To purchase connector’s holders and its part (sub-assembly holder, holders leg,

wire’s holders, ejection pin, locking device, cable form part, prevention lever and

etc.) – only from certificated by YAZAKI suppliers in accordance to purchasing

agreement with YEL Supply management.

▪ After receiving connector holders from the connector holder’s supplier, the

responsible person in the YEG plant must check and verify that the connector holder

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 20 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

is not a damaged connector or its fragile parts. Only after verification, it is possible to

start to build up an assembly jig board.

4.4.5 Supplier (certificated by Yazaki) must:

▪ Manufacture C/H according to PTC drawing and guarantee the function of the holder

with respect to all connector features that conform to the connector drawing.

▪ The supplier should assure that all connector holders and their accessories must

conform to the YAZAKI technical specification. The cycle life of C/H should not be less

than 1.000.000.

▪ Assure that all connector holders shall be handled carefully so that surface scratching

and other damage is avoided. The outside surface of connector holders shall not be

dragged or slid over other material during handling operation.

▪ Assure that all connector holders shall be packed in a suitable cardboard box (each

cardboard box must have advised notes attached that records the contents of that

box) with the delivery note.

▪ Ensure handling and delivering of connectors holders in the secured way (all

products is cushioned and will not move inside the cardboard box during normal

condition or transportation).

4.5 Procedure:

4.5.1 Connector Holder procurement

4.5.1.1 The YEG plants must purchase connector’s holders and their part (leg, locking

device, cable form part, etc.) - only from certificated YAZAKI suppliers in

accordance with the purchasing agreement with YEG Supply management. In

any special case, plants should contact and receive permission from YEG SM or

EME TCC COSEE Assembly team leader.

4.5.1.2 YEG plant needs to check central PTC database, before preparing purchasing

order, if individual C/H drawing with Yazaki part number exists.

If an individual C/H drawing exists in the PTC database (with status “Validated”)

then the YEG plant needs to order to the supplier by means of standard YEG

“Calculation Quotations Sheet for Assembly Jig Board and Clip Checker Fixture”.

4.5.1.3 If a C/H drawing exists with a status marked “Trial”, then the plant can order

only one sample (it is not allowed to order to duplicate/copied jig, if jig had

been not validated).

4.5.1.4 If a C/H drawing does not exist then, YEG plants need to request PTC to create a

drawing and upload it in the database.

4.5.1.5 All connector holders shall be handled carefully so that surface scratching and

other damage are avoided. The outside surface of connector holders shall not

be dragged or slid over other material during handling operation.

4.5.1.6 All connector holders shall be packed in a suitable cardboard box (each

cardboard box must have advised notes attached that records the contents of

that box) with a delivery note.

4.5.1.7 The supplier must ensure handling and delivery of connectors holders in a

secured way (all products are cushioned and will not move inside the cardboard

box during normal condition or transportation).

4.5.1.8 After receiving connector holders from the connector holder’s supplier, the

responsible person in the YEG plant must check and verify that connector

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 21 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

holder is not damage the connector or its fragile parts. Only after verification, it

is possible to start to build up an assembly jig board.

4.5.2 Newly designed Connector holder process flow

If YEG plants need to have a group of new C/H (example: more than 5 C/H for a new

project) then it is necessary to full fill the “Connector Holder Progress Follow Up Chart”

document and to submit it to the PTC team.

4.5.2.1 PTC design team need to prepare a 3D drawing (*r.X_T format) and 2D (*pdf

format) of the connector holder based on the 3D model file, received from the

component supplier. If the 3D model is not available – then PTC needs to

request a physical connector sample and make a re-drawing of the connector

based on the physical sample. Connector holder drawing should be uploading

to the database with marked “Trial” status.

4.5.2.2 The supplier must download the C/H drawing from the PTC database and

manufacture one prototype jig sample. If tolerance in PTC drawing can not be

supplied, suppliers must guarantee the function of the connector holder with

respect to the samples provided – clearance dimension 0.2 mm.

The supplier must check with a physical sample of the connector’s holder:

dimensions and functionality. If any problem is detected with the C/H drawing

or its accessories then the supplier must contact and inform the PTC team

about deviation. PTC must review drawing – and when it is necessary, to solve

the jig design issue or to correct the dimensional problem.

4.5.2.3 The supplier must manufacture a new jig based on drawing correction, which

was done from PTC, and repeat the test with the connector sample.

Only if test results will be good and connector holder is functional – it is allowed

to send jig prototype to YEG plant for final functional approval.

4.5.2.4 YEG plant must make validation of first C/H prototype according to “Connector

holder approval form “EA-MF-WH-S-080-F1 checklist and send with approval

results in written form to PTC.

In case when some malfunction is found with the jig (or its parts), then the

plant needs to analyze the problem and to inform:

A) PTC team:

If any dimensional problem is detected with C/H or its accessories in drawing

(when the jig is fully matching to drawing, but not functional), then the plant

must contact and inform the PTC team about drawing deviation;

B) Supplier:

If any functional problem is found with a jig or its part (sample is not matching

drawing or connector is not fitting properly to the holder), then it is necessary

to contact and inform the supplier about holder (or it’s accessories) problem;

PTC or supplier must analyze requests from the plant and take corrective

actions accordingly.

4.5.2.5 When the “Connector holder approval form “EA-MF-WH-S-080-F1is received

from the plant and C/H is approved – then the PTC team needs to approve the

C/H drawing and to change status from “Trial” to “Validated” (which means

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 22 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

valid for mass production). A new C/H drawing “Validated” should be uploaded

in the data base and a “Trial” drawing should be deleted with immediate effect.

4.5.2.6 PTC team must coordinate all activity between plant and supplier by means of

“Connector Holder Progress Follow Up Chart” document and by consolidating

all reports from all sides.

4.5.3 Connector holder improvement

4.5.3.1 If there any improvements should be done with C/H or its part, then the YEG

plant needs to submit a Kaizen request with described changing content in

written form to the PTC team.

4.5.3.2 PTC must make analyze improvement requests and describes acceptance or

rejection judgment result in the defined time period (not longer than two

weeks). If the subject requires some more time (longer than two weeks) making

the judgment, the revision period should be set accordingly and inform via e-

mail to the requesting plant.

If the result is accepted by all plants, PTC makes the final judgment. Update the

drawing on the database, and inform the relevant plant via email that revision

of the document is completed.

4.5.3.3 When the Kaizen request is rejected, PTC needs to describe its reason and send

it back to the requesting plant.

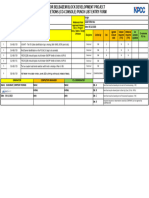

4.5.4 How to fulfill the Quotation Sheet

The quotation sheet is separated between Category A (The simplest and cheapest one) to

Category O (The most complicated and expensive one)

Pic.50 Quotation Sheet

The Quotation Sheet must be fulfilled according to the below table which shows the Size

and Complexity classification. A category should be selected between “a” and “o” (if the

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 23 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

Connector Holder dimensions are not clear, the plant should select option “g” as

temporary)

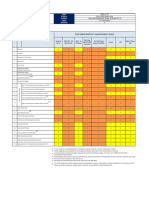

Pic.51 Connector holder price matrix

4.5.4.1 How to decide the classification of a connector holder:

4.5.4.1.1 Based on size: The classification of size is decided based on cm3 of

connector holder. According to size, it should be selected if the connector holder is S,

M, L, XL, or XXL size.

Pic.52 Connector holder price matrix – how to decide the Size

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 24 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

Pic.53 How to calculate cm3 of the connector holder

4.5.4.1.2 Based on complexity: The classification of complexity is decided based

on the processing complexity of the connector holder. In this way, it should be

decided if the design & production complexity is Simple, Medium, or Complex

Pic.54 Connector holder price matrix – how to decide the complexity

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 25 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

5. REFERENCES & RELATED DOCUMENTS:

Number References

5.1 Assembly Jig Component Design Standards

5.2 Assembly Fixture Design Standards Management Regulation

Number Related Documents

EA-MF-WH-S-080-F1 Connector holder approval form

EA-MF-WH-S-080-F2 Connector Holder Progress Follow-Up Chart

6. DOCUMENT APPROVAL:

Process Owner:

Title/ Role Name Authorization* Revision Date

TCC COSEE Karim Mahfoud Electronic 0.2 08/Feb/2021

Authored by:

Title / Role Name Authorization* Revision Date

TCC COSEE Assembly Adem Eren Electronic 0.2 08/Feb/2021

Reviewed by:

Title / Role Name Authorization* Revision Date

EQ QMS Sr.Specialist Serpil Zandolu Electronic 0.2 08/Feb/2021

Cross Functional Team (by functions) EQMS Issue No # 596

*The signatures from XFR team is not required

Approved by:

Title / Role Name Authorization* Revision Date

EME Director J.Geisinger Electronic 0.2 08/Feb/2021

*Evidence of authorization is either an electronic approval or a physical signature and stored in a secure

location.

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 26 of 27

Revision Date:

Europe Business Management System

08/FEB/2021

EA-MF-WH-S-080 Revision Level:

SPECIFICATION

CONNECTOR HOLDER 0.2

CONFIDENTIAL: This information is Yazaki property and must follow applicable global and regional confidentiality rules. Copies are

reference only, see network for latest revision.

7. DOCUMENT HISTORY:

*For ONLY new or content revisions, the revision date is equal to the Authored by date and all Authorization

dates are the same or after. Note: See Section 4 Rules in Yx-QM-xx-Y-001 Process Documentation Management

Policy for format or grammar change revision date rules.

Revision Summary Revision Date

New Release ; This specification is replacing YEL_CE_S_414

New 05/Jun/2012

Changes:

4.2.2 Fixed type connector holder legs: Added

4.2.2.1 The height “A” range: Added

4.2.5 Cable form part: Revised The reason of revision is to change Cable

Form Part design and go through more in details.

4.2.5.1 Thinner (5mm) Cable Form Part: Added

4.2.5.2 Larger (10mm) Cable Form Part: Added

4.2.5.3 The width of Cable form part: Added

4.3 Connector Holder Height Adjustment: Added 0.1 18/Jan/2021

4.3.2 Height Adjustment for Straight Connector Holders: Added

4.3.2 Height adjustment for Sided Connector Holders: Added

4.4.2 PTC team (connector holder designer) is responsible: Revised

4.4.4 YEG (each individual) plant is responsible: Revised

4.4.5 Supplier (certificated by Yazaki) must: added

4.5.4 How to fulfill the Quotation Sheet: added.

Minor Change : Definition of Pic. 44 Airbag Connector Holder corrected. 0.2 08/Feb/2021

Template: EA-QM-xx-P-001-F-01 Rev1.0 27/APR/2017 Print Date: 08/FEB/2021 Page 27 of 27

You might also like

- S96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorkDocument2 pagesS96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorktinzarmoeNo ratings yet

- Inspection and Test Plan (Itp) For ElectricalDocument38 pagesInspection and Test Plan (Itp) For ElectricalJames Pol JumarangNo ratings yet

- D5-D16 Commissioning Report - Genset - Aux - 2011-05-21 - US PDFDocument32 pagesD5-D16 Commissioning Report - Genset - Aux - 2011-05-21 - US PDFMina Saeed50% (2)

- Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoDocument2 pagesHazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoVijaya Seharan NairNo ratings yet

- 0-12-VR-191 - 20nov2023 - PM ReporteDocument9 pages0-12-VR-191 - 20nov2023 - PM ReportejeisonNo ratings yet

- Qap - Kongsberg - NabDocument4 pagesQap - Kongsberg - NabDeepak DasNo ratings yet

- Protection Wire Mesh ITPDocument3 pagesProtection Wire Mesh ITPVishnudas MgNo ratings yet

- Cover MDR 33214 GI TanggeungDocument1 pageCover MDR 33214 GI TanggeungAgung PramuraharjoNo ratings yet

- Cathodic Protection ItpDocument9 pagesCathodic Protection ItpHarmalNo ratings yet

- Dokumen - Tips - Inspection Test Plan For ElectricalDocument38 pagesDokumen - Tips - Inspection Test Plan For ElectricalKyle WadsworthNo ratings yet

- Royal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2Document12 pagesRoyal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2arshad iqbalNo ratings yet

- Inspection Test Plan For ElectricalDocument39 pagesInspection Test Plan For Electricalpire.resiNo ratings yet

- Transmittal: Sr. No. Document / Drawing No. Rev Sheets StatusDocument1 pageTransmittal: Sr. No. Document / Drawing No. Rev Sheets StatusJesNo ratings yet

- Technical Bulletin: ACP 5 2.00.0 Version ReleaseDocument8 pagesTechnical Bulletin: ACP 5 2.00.0 Version ReleasedanielNo ratings yet

- Contract TIme & ClaimDocument29 pagesContract TIme & ClaimPratyayaParijaNo ratings yet

- Inspection Test Plan For ElectricalDocument38 pagesInspection Test Plan For ElectricalTao BaoNo ratings yet

- Gallien Krueger Backline 210 Combo Service ManualDocument10 pagesGallien Krueger Backline 210 Combo Service ManualpavelscribdNo ratings yet

- Punch List Interim 05-12-23Document1 pagePunch List Interim 05-12-23IGNATIUS MANOSAYNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Inspection Test Plan For ElectricalDocument38 pagesInspection Test Plan For ElectricalkhoerulNo ratings yet

- Annexure-1H - I&C Scope MatrixDocument2 pagesAnnexure-1H - I&C Scope MatrixSridhar VedulaNo ratings yet

- Static Load Test MethodologyDocument2 pagesStatic Load Test MethodologyPritom AhmedNo ratings yet

- Rock Dowels & Rock Nails ITPDocument7 pagesRock Dowels & Rock Nails ITPVishnudas MgNo ratings yet

- (Itp For Cast Insitu Foundation) 4172-Genon-1!25!0002-ADocument45 pages(Itp For Cast Insitu Foundation) 4172-Genon-1!25!0002-ARajesh SinghNo ratings yet

- General Guide To Activities and Documentation Flow From Mechanical Completion To Final HandoverDocument4 pagesGeneral Guide To Activities and Documentation Flow From Mechanical Completion To Final HandoverMahmoud ZeirNo ratings yet

- Construction Process Control Building ProjectDocument2 pagesConstruction Process Control Building Projectjjemmiinnii18No ratings yet

- E-003B Rev C2-MIPS Distribution BoardDocument2 pagesE-003B Rev C2-MIPS Distribution BoardMusab ShabbirNo ratings yet

- Eds Lan S03Document69 pagesEds Lan S03boy leeNo ratings yet

- Modbus Check Sheet ExampleDocument2 pagesModbus Check Sheet ExampleGuston SupriyadiNo ratings yet

- Ge 8261 Engineering Practics Laboratory Group B (Electronics)Document2 pagesGe 8261 Engineering Practics Laboratory Group B (Electronics)Karthikeyan DNo ratings yet

- Pipeline Punch ListDocument2 pagesPipeline Punch ListTanver AliNo ratings yet

- PIPELINE Punch ListDocument2 pagesPIPELINE Punch ListTanveer Rajput EngrNo ratings yet

- TT-201 - Instrument-Commissioning-ChecklistDocument2 pagesTT-201 - Instrument-Commissioning-Checklisttouili majdiNo ratings yet

- Technical Specification - 2023 01 16 18 50 06Document10 pagesTechnical Specification - 2023 01 16 18 50 06abhishekgupta9990No ratings yet

- BDX CGK2 Brownfield - Design Responsibility Matrix DC1D (MEP)Document1 pageBDX CGK2 Brownfield - Design Responsibility Matrix DC1D (MEP)ignasius desky p sNo ratings yet

- Embankment - Fill: Inspection & Test PlanDocument4 pagesEmbankment - Fill: Inspection & Test PlanJeff AlinayaNo ratings yet

- Basic Design Activities and Documents 1644738097Document1 pageBasic Design Activities and Documents 1644738097MC ANo ratings yet

- Dell Vostro 1320 - Compal La-4232p Kal80 - Rev 1.0secDocument48 pagesDell Vostro 1320 - Compal La-4232p Kal80 - Rev 1.0secAriel GuadamuzNo ratings yet

- Inspection Test PlanDocument36 pagesInspection Test PlanShahid IqbalNo ratings yet

- Gallien Krueger - Backline 600Document3 pagesGallien Krueger - Backline 600Trevis O100% (2)

- TT-101 - Instrument-Commissioning-ChecklistDocument2 pagesTT-101 - Instrument-Commissioning-Checklisttouili majdiNo ratings yet

- Low Current ItpDocument5 pagesLow Current ItpMohamedNo ratings yet

- ITP For Diesel Generator .Document3 pagesITP For Diesel Generator .Waleed SalihNo ratings yet

- RFA 20 ES Electric Transformer DetailsDocument6 pagesRFA 20 ES Electric Transformer Detailsjohn.lopezNo ratings yet

- Action Plan - Goal-MOC-18-0001Document2 pagesAction Plan - Goal-MOC-18-0001Sandeep KumarNo ratings yet

- Technical Stuff For Power Plant EngineerDocument113 pagesTechnical Stuff For Power Plant EngineerPopescu Andrei-MihaiNo ratings yet

- 18.review Performance Test Procedure Rev2Document6 pages18.review Performance Test Procedure Rev2Akhmad SyukrieNo ratings yet

- 6 - Baterry&charger17-12-2013Document38 pages6 - Baterry&charger17-12-2013Thi Huyen Trang VuNo ratings yet

- Ffianra: Existing ModificationDocument128 pagesFfianra: Existing ModificationGary ChanNo ratings yet

- Manufacturing Quality Plan (Dynamic Balancing M/C) : NTPC BarhDocument1 pageManufacturing Quality Plan (Dynamic Balancing M/C) : NTPC BarhdhirajiterNo ratings yet

- 400kV Gantry Foundation ReactionDocument2 pages400kV Gantry Foundation ReactionPritom AhmedNo ratings yet

- The Tata Power Company LimitedDocument10 pagesThe Tata Power Company LimitedSinumalathi MathiNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Mechanical&Piping EngineerDocument26 pagesMechanical&Piping EngineerirwanypcNo ratings yet

- ITP & Checklist FOR Excavation & Backfilling and CompactionDocument7 pagesITP & Checklist FOR Excavation & Backfilling and CompactionAmran Hossain100% (4)

- ITP Inspection Test Plan For MCCDocument3 pagesITP Inspection Test Plan For MCCCesar Santiago Marquez YanezNo ratings yet

- Pipe Stress AnalysisDocument19 pagesPipe Stress AnalysisJosuaNo ratings yet

- Itp E0841-12Document4 pagesItp E0841-12Asep Barkah MuhadiNo ratings yet

- Fic Vme40 - Rev 0.3 04set2009 PDFDocument47 pagesFic Vme40 - Rev 0.3 04set2009 PDFCarlos Henrique RibasNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- MAPICS TrainingMLMDocument3 pagesMAPICS TrainingMLMVenkatasubramanian SivagnanasundaramNo ratings yet

- Basal Reinforcement: Basetex High-Strength GeotextilesDocument6 pagesBasal Reinforcement: Basetex High-Strength GeotextilesFernanda SequeraNo ratings yet

- Spliced I GirderDocument193 pagesSpliced I GirderJessie Radaza TutorNo ratings yet

- COS 126 - Data CompressionDocument3 pagesCOS 126 - Data CompressionivaneshubhamNo ratings yet

- Cu Xlpe PVC 0.6 1 KV (N2xa)Document1 pageCu Xlpe PVC 0.6 1 KV (N2xa)Fani Dwi PutraNo ratings yet

- Excel Unit 3 Advanced Filter and Conditional Formatting (Autosaved)Document14 pagesExcel Unit 3 Advanced Filter and Conditional Formatting (Autosaved)Kyan VeeraNo ratings yet

- Strategic Management Assessment PDFDocument6 pagesStrategic Management Assessment PDFMuhammad Faraz Hasan100% (1)

- Midterm PrepDocument2 pagesMidterm PrepSAKHAWAT HOSSAIN KHAN MDNo ratings yet

- Eéáfh Tdibn3ihuvbr3792Document9 pagesEéáfh Tdibn3ihuvbr3792Ati AnimationsNo ratings yet

- Artificial Intelligence in Education - A ReviewDocument6 pagesArtificial Intelligence in Education - A ReviewyasmineNo ratings yet

- AHE NotesDocument35 pagesAHE NotesmynameisgunaNo ratings yet

- Agbeshie Et Al 2022 - Fire and SoilDocument23 pagesAgbeshie Et Al 2022 - Fire and SoilrodrigoNo ratings yet

- 2020 World LNG Report (PARTE 3) - OptDocument34 pages2020 World LNG Report (PARTE 3) - Optya100% (1)

- Teks Kisah Nabi NuhDocument8 pagesTeks Kisah Nabi Nuhsyafiqahusna2611No ratings yet

- Whole-Body Human Thermal Models: E. H. WisslerDocument50 pagesWhole-Body Human Thermal Models: E. H. WisslerArinjayKumarNo ratings yet

- 802.11 ArchitectureDocument10 pages802.11 ArchitectureSarath KsNo ratings yet

- Online Assignment SubmissionDocument20 pagesOnline Assignment SubmissionAnesu Mushate50% (2)

- Vocabulary: Look at The Pictures. Write The Names of The Modes of Transport in The Boxes ProvidedDocument4 pagesVocabulary: Look at The Pictures. Write The Names of The Modes of Transport in The Boxes ProvidedNidhi ChandraNo ratings yet

- 3193Document1 page3193Andy YoonNo ratings yet

- B Tech ECE2015SyllabusWebVersion2 PDFDocument98 pagesB Tech ECE2015SyllabusWebVersion2 PDFSandeep KumarNo ratings yet

- Strategy: Choices and Change MN6003 Session 17 Strategic Change Context Lecturer: XXXXXXDocument29 pagesStrategy: Choices and Change MN6003 Session 17 Strategic Change Context Lecturer: XXXXXXVladimir LosenkovNo ratings yet

- Middlebrook S Extra Element TheoremDocument10 pagesMiddlebrook S Extra Element TheoremAnushree SaranNo ratings yet

- Mathematics 8: y y y yDocument5 pagesMathematics 8: y y y yRyan SorianoNo ratings yet

- Guide Conductivity EN 30099121ADocument60 pagesGuide Conductivity EN 30099121AallandNo ratings yet

- Bacs3413 Project II 22.1.16Document4 pagesBacs3413 Project II 22.1.16Rexl RxzNo ratings yet

- Differences Between Critical and Creative ThinkingDocument6 pagesDifferences Between Critical and Creative ThinkingBamitim NryNo ratings yet

- Series PR40/60: Heavy-Duty Repairable Stainless GaugeDocument4 pagesSeries PR40/60: Heavy-Duty Repairable Stainless GaugeJefferson TipánNo ratings yet

- Technical Report MykonosDocument18 pagesTechnical Report MykonosMuhammed MekkiNo ratings yet

- Dagmar Richter Spazieren BerlinDocument15 pagesDagmar Richter Spazieren Berlinpescado13No ratings yet

- Quotation M&E of Velsbov Villa PDFDocument5 pagesQuotation M&E of Velsbov Villa PDFChime MornNo ratings yet