Professional Documents

Culture Documents

Crack Width For Oht Tank

Uploaded by

selvakumar s0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

CRACK WIDTH FOR OHT TANK

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageCrack Width For Oht Tank

Uploaded by

selvakumar sCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

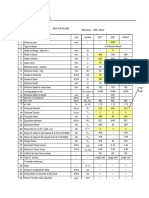

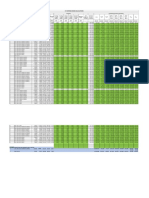

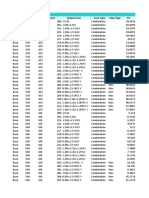

WALL CRACK WIDTH CALCULATION (as per IS 3370)

PROJECT WALL MARK

VERTICAL REINFORCMENT

OHT-W2

Remarks

Description Abr. BOTTOM -VE MID +VE TOP -VE Unit

3 2 1

Max. Service Bending Moment on retained face of the slab due to the Liquid M 10.00 7.00 5.00 kNm/m Unfactored B.M.

Max. Service Shear Force induced on the retaining face of the slab due to the Liquid V 10.00 5.00 KN Unfactored S.F.

Bending Moment Mu 15.00 10.50 7.50 kNm/m 1.5 M

Shear Force Vu 15.00 0.00 7.50 KN 1.5 V

Overall depth of section provided D 200 200 300 mm Thickness of Wall

Width of Designing Strip b 1000 1000 1000 mm Designed for 1m Typical Width

Class of Exposure to which the structure is subjected Severe IS 456, Table 3

Characteristic Strength of Steel fy 500 N/mm2

Characteristic Strength of Concrete fck 30 N/mm2 Shall be Taken as per the IS 456, Table 3 & 5

Diameter of steel bar provided ф 10 10 10 mm

Spacing of bars provided s 150 150 150 mm

Main Reinfocemrnt

Diameter of steel bar provided (Additional in b/w the main bars) ф 0 0 0 mm

Spacing of bars provided (Additional in b/w the main bars) s 200 200 150 mm

Modulus of Elasticity for Steel Es 200000 N/mm2 IS 456 5.6.3

Modulus of Elasticity for Concrete Ec 27386 27386 27386 N/mm2 5000 √fck , IS 456 clause 6.2.3.1

Minimum Cover to Tension Reinforcement Cmin 30 30 30 mm Shall be Taken as per the IS 456, Table 3 & 16

Permissible Bending Stress σcbc 10 10 10 N/mm2 IS 3370, Table-2

Modular ratio obtained m 9.33 9.33 9.33 IS 456 - B-2.1.2

Fall In temperature between the hydration peak and ambient T1 15 15 15 °C IS 3370, Annex-A

Further drop in temperature due to enviormental variations T2 0 0 0 °C IS 3370, Annex-A

Co-ifficient of linear expansion of concrete made of granite α 9.50E-06 9.50E-06 9.50E-06 / °C IS 456 - Clause 6.2.6

Permissible tensile stress in concrete at 3 days fct 1.30 1.30 1.30 N/mm2 IS 3370 - Annex A1.2

Permissible bond stress in concrete fb 1.60 1.60 1.60 N/mm2 IS 3370, Table-2

Surface zone for tempreature reinforcement h 100.00 100.00 150.00 mm

Maximum Allowable Crack Width 0.2 mm IS 1343 - Apeendix-A

Effective depth provided deff 165.00 165.00 265.00 mm =D-(Cmin+ф/2)

Area of Steel provided per meter Ast/m 523.60 523.60 523.60 mm2

Percentage of tensile steel provided on retaining face pt 0.26 0.26 0.17 %

Depth of neutral axis obtained x 35.57 35.57 46.24 mm bx²/2 = mAst(d-x)

Tensile stress in reinforcement obtained { M.R.= Ast x fst (d-x/3) } t 124.71 87.30 38.26 N/mm2

Should be less than 0.8fy (IS 3370, B1)

CHECK FOR STEEL TENSILE STRESS SAFE SAFE SAFE

Compressive stress in concrete obtained { c/(t/m) = n/(d-x) } 2

c 3.67 2.57 0.87 N/mm

Should be less than 0.45fck (IS 3370, B1)

CHECK FOR CONCRETE COMPRESSIVE STRESS SAFE SAFE SAFE

Strain in steel at the level of reinforcement Єs 6.24E-04 4.36E-04 1.91E-04 mm Es = t / Єs

Strain in concrete at the extreme fibre end of section Є1 7.92E-04 5.55E-04 2.22E-04 mm Є1 = Єs . ( D-x)/(d-x)

Strain due to stiffening effect of concrete between cracks Є2 6.65E-04 6.65E-04 9.37E-04 mm IS 3370, Annex-B-3

Average strain in concrete where cracking in been considered { Єm=Є1-Є2 } Єm 1.27E-04 -1.10E-04 -7.15E-04 mm IS 3370, Annex-B-3

Distance from the point considered to the nearest bar acr 80.78 80.78 80.78 mm

Design surface crack width obtained due to moments { IS 3370, Annex-B1 } wcr 0.019 -0.017 -0.124 mm

CHECK FOR ALLOWABLE CRACKING DUE TO LOADING SAFE SAFE SAFE

Design surface crack width obtained due to shrinkage and temp wcr 0.055 0.055 0.083 mm

CHECK FOR ALLOWABLE CRACKING DUE TO SHRINKAGE SAFE SAFE SAFE

Ultimate moment of resistance developed Mu 35.59 35.59 58.37 kNm/m

CHECK FOR ULTIMATE MOMENT SAFE SAFE SAFE

Ultimate shear resistance developed Vu 66.74 66.74 93.65 kN

CHECK FOR ULTIMATE SHEAR SAFE SAFE SAFE

Page 1 of 1

You might also like

- Incest Story WalkthroughDocument14 pagesIncest Story Walkthroughjustin patterson67% (3)

- Base Plate DesignDocument21 pagesBase Plate Designtitir bagchi100% (1)

- Concrete Mix Design Lab ReportDocument42 pagesConcrete Mix Design Lab ReportShaluka Wijesiri100% (4)

- LiquidRet IndianDocument13 pagesLiquidRet Indianchandra BandaraNo ratings yet

- SLABS DesignDocument23 pagesSLABS DesignDeepak Kumawat100% (1)

- H&H Culverts With Out CushionDocument15 pagesH&H Culverts With Out CushionSreedhar BhuduruNo ratings yet

- Rectangular Footing SlopedDocument1 pageRectangular Footing SlopedSyed Azhar UddinNo ratings yet

- Foundation Design ReportDocument5 pagesFoundation Design ReportShashankSinghNo ratings yet

- Solution To Assignment-3-T2-2019Document8 pagesSolution To Assignment-3-T2-2019Adrian VuNo ratings yet

- Deep BeamDocument3 pagesDeep BeamvineetukNo ratings yet

- Beam Design Beam Mark:B1 Similar Beams:: Sl. NoDocument3 pagesBeam Design Beam Mark:B1 Similar Beams:: Sl. NopandianNo ratings yet

- Cep PRCDocument2 pagesCep PRCZain ul HassanNo ratings yet

- Design For Area of Steel For Continuous/fixed Deep Beam - Limit State DesignDocument1 pageDesign For Area of Steel For Continuous/fixed Deep Beam - Limit State DesignHoàng NgọcNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)christi SNo ratings yet

- Industrial Park 2Document14 pagesIndustrial Park 2Zack DaveNo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- Beam CheckDocument16 pagesBeam Checkdheeraj SureshNo ratings yet

- IsDocument2 pagesIsvishnumani3011No ratings yet

- Ang Residence (Flatdeck 1.0mm X 100mm THK Slab)Document6 pagesAng Residence (Flatdeck 1.0mm X 100mm THK Slab)Pandaman227No ratings yet

- Bending Axial WORKING STRESSDocument4 pagesBending Axial WORKING STRESSgade phaniNo ratings yet

- Main Tunnel First CheckDocument9 pagesMain Tunnel First CheckDara HajebiNo ratings yet

- RCC Design of Toe-Slab: Input DataDocument2 pagesRCC Design of Toe-Slab: Input DataAnkitaNo ratings yet

- BeamDocument3 pagesBeamLinoNo ratings yet

- Spreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3Document4 pagesSpreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3Camel FangNo ratings yet

- Calculation Sheet: Yb For UB BeamDocument2 pagesCalculation Sheet: Yb For UB BeamrammohanNo ratings yet

- Gravity Wall (RCC) R0 (27!11!2017) 5m For TestingDocument81 pagesGravity Wall (RCC) R0 (27!11!2017) 5m For TestingLandon MitchellNo ratings yet

- Is Code ValuesDocument58 pagesIs Code ValuesPankaj SherwalNo ratings yet

- Site: Date: Job No. Designer: Sheet No.: Calculation/ SketchDocument6 pagesSite: Date: Job No. Designer: Sheet No.: Calculation/ SketchAlma M. LaraNo ratings yet

- Staircase Design RevDocument65 pagesStaircase Design RevYUVARAJ SAMPATHNo ratings yet

- Deep Beam DesignDocument3 pagesDeep Beam DesignmuhannedNo ratings yet

- Ooo Ooo Oooooooooo Oooo Ooooooooo Oo OooDocument3 pagesOoo Ooo Oooooooooo Oooo Ooooooooo Oo Oootejaswini shahapurkarNo ratings yet

- Design of Flood Wall at Tailrace PortionDocument10 pagesDesign of Flood Wall at Tailrace PortionPRAVEEN CHAUDHARYNo ratings yet

- CRTICAL Force and Moment Outputs From SAP2000: SLS ULS Bending Moment (M), Shear Force (V) & Direct Tension (T)Document4 pagesCRTICAL Force and Moment Outputs From SAP2000: SLS ULS Bending Moment (M), Shear Force (V) & Direct Tension (T)risrizNo ratings yet

- Hl707 Adicg CR 001 r0 (Load Out Ramp)Document8 pagesHl707 Adicg CR 001 r0 (Load Out Ramp)dheeraj SureshNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CDocument7 pagesSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CKhan EngrNo ratings yet

- RCC12 Bending and Axial ForceDocument4 pagesRCC12 Bending and Axial ForcerrpenolioNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document7 pagesRCC92 Ribbed Slabs (Tables)Cioabla BogdanNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)RalfNo ratings yet

- Spreader Beam (Planning)Document28 pagesSpreader Beam (Planning)AKSHAY BHATKARNo ratings yet

- A. Module 7: Summary of Results For U-Trough WallsDocument2 pagesA. Module 7: Summary of Results For U-Trough WallsJemicah YumenaNo ratings yet

- 4 Design of End Girder (G1) Units D Away From Support End of Varying Portion Span/2 Beam Number Section DescriptionDocument6 pages4 Design of End Girder (G1) Units D Away From Support End of Varying Portion Span/2 Beam Number Section DescriptionBlessyNo ratings yet

- Design of Underground Water Tank - MylearningsDocument10 pagesDesign of Underground Water Tank - MylearningsKlefa KlefaNo ratings yet

- RCC Tank Design UndergroundDocument20 pagesRCC Tank Design Undergroundkiran_karki_8No ratings yet

- Normal Case: ProvidedDocument3 pagesNormal Case: ProvidedDanish AhmadNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)Murthy GunaNo ratings yet

- RCC12 Bending and Axial ForceDocument4 pagesRCC12 Bending and Axial ForceCioabla Bogdan100% (1)

- 14 M Steel Bridge - Design Review of Cross Beam & End ConnectionDocument4 pages14 M Steel Bridge - Design Review of Cross Beam & End ConnectionvibishnanNo ratings yet

- As Staircase Design-V1 18-01-17Document5 pagesAs Staircase Design-V1 18-01-1798675No ratings yet

- Reinforcement Design of Base Slab (Type-1)Document1 pageReinforcement Design of Base Slab (Type-1)Akshay DuggalNo ratings yet

- Case 1 Positive Moment: Geometrical Properties Material PropertiesDocument3 pagesCase 1 Positive Moment: Geometrical Properties Material PropertiesAbhay ThakurNo ratings yet

- Triangle Beam B1Document6 pagesTriangle Beam B1sallysel90No ratings yet

- Isolated Footing DesignDocument11 pagesIsolated Footing DesignPadmanabh Shridhar DesaiNo ratings yet

- RCC94 Two-Way Slabs TablesDocument3 pagesRCC94 Two-Way Slabs TablesjohnyNo ratings yet

- 33 Concrete BeamDocument48 pages33 Concrete BeamMario Sajulga Dela CuadraNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document8 pagesRCC92 Ribbed Slabs (Tables)lucianduNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document3 pagesRCC94 Two-Way Slabs (Tables)Mohammad Twaha JaumbocusNo ratings yet

- RCC12 Bending and Axial ForceDocument4 pagesRCC12 Bending and Axial ForceAbdul KarimNo ratings yet

- Design of Reinforcement For RC Capping Beam: ProjectDocument1 pageDesign of Reinforcement For RC Capping Beam: ProjectNikit MaskeNo ratings yet

- 3862 15A01308 Mechanics of SolidsDocument2 pages3862 15A01308 Mechanics of SolidsAnonymous ML4hh4MOyBNo ratings yet

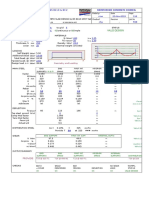

- Checking Design With Basic ModelDocument2 pagesChecking Design With Basic Modelselvakumar sNo ratings yet

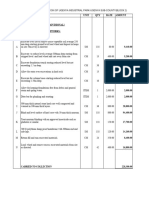

- Gas Bank DPRDocument18 pagesGas Bank DPRselvakumar sNo ratings yet

- MSManojKumar (9y 0m)Document18 pagesMSManojKumar (9y 0m)selvakumar sNo ratings yet

- LOading For SLANT ROOF BUILDINGDocument2 pagesLOading For SLANT ROOF BUILDINGselvakumar sNo ratings yet

- Bolt and Base Plate DesignDocument2 pagesBolt and Base Plate Designselvakumar sNo ratings yet

- Clock Tower FootingDocument8 pagesClock Tower Footingselvakumar sNo ratings yet

- Drain Design - MergedDocument5 pagesDrain Design - Mergedselvakumar sNo ratings yet

- S1, S2 - S3 - S4 - MergedDocument4 pagesS1, S2 - S3 - S4 - Mergedselvakumar sNo ratings yet

- 1893 2 PDFDocument22 pages1893 2 PDFAnito ShobithNo ratings yet

- Mahal 1 ModelDocument1 pageMahal 1 Modelselvakumar sNo ratings yet

- Chennai Egmore RFP Expansion JointDocument1 pageChennai Egmore RFP Expansion Jointselvakumar sNo ratings yet

- TPC Consultants Noida Temperature Ref.Document1 pageTPC Consultants Noida Temperature Ref.selvakumar sNo ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- End Panel S3 Development of Maa Samleswari at Sambalpur: One-WayDocument1 pageEnd Panel S3 Development of Maa Samleswari at Sambalpur: One-Wayselvakumar sNo ratings yet

- Development of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way SlabDocument2 pagesDevelopment of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way Slabselvakumar sNo ratings yet

- TABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXDocument4 pagesTABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXselvakumar sNo ratings yet

- Wall DesignDocument3 pagesWall Designselvakumar sNo ratings yet

- TABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXDocument18 pagesTABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXselvakumar sNo ratings yet

- Development of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way SlabDocument2 pagesDevelopment of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way Slabselvakumar sNo ratings yet

- Rigid Pavement Design IRC 58 2015Document10 pagesRigid Pavement Design IRC 58 2015selvakumar sNo ratings yet

- Studies in Flat Slab Floor Systems Under Pattern Loading Using MatlabDocument113 pagesStudies in Flat Slab Floor Systems Under Pattern Loading Using Matlabselvakumar sNo ratings yet

- TABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXDocument4 pagesTABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXselvakumar sNo ratings yet

- Crematorium - Load Calculation: S.No Location Load Member Load 23.76 KN/M 11.88 KN/MDocument1 pageCrematorium - Load Calculation: S.No Location Load Member Load 23.76 KN/M 11.88 KN/Mselvakumar sNo ratings yet

- TABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXDocument18 pagesTABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXselvakumar sNo ratings yet

- TABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXDocument4 pagesTABLE: Joint Design Reactions Story Label Unique Name Output Case Case Type Step Type FXselvakumar sNo ratings yet

- Column Transverse Reinforcement CalculationDocument23 pagesColumn Transverse Reinforcement Calculationselvakumar sNo ratings yet

- Greenview BrochureDocument20 pagesGreenview BrochurePrannoy ChowdharyNo ratings yet

- 1003 2 PDFDocument17 pages1003 2 PDFRitesh kumarNo ratings yet

- PIMS - Log - iOS - MyPeugeot - 01-06-2023 08-32-34Document111 pagesPIMS - Log - iOS - MyPeugeot - 01-06-2023 08-32-34julianaNo ratings yet

- VmwareDocument113 pagesVmwareAdnan AdrikaNo ratings yet

- Faculty of Architecture and Planning, AKTU, Lucknow: Research AssignmentDocument12 pagesFaculty of Architecture and Planning, AKTU, Lucknow: Research AssignmentVikash KumarNo ratings yet

- Electrostatic PrecipitatorDocument52 pagesElectrostatic PrecipitatorsergioNo ratings yet

- Jurnal Nur Fitria Metode Pelaksanaan Dan Estimasi Biaya Material Waller BeamDocument13 pagesJurnal Nur Fitria Metode Pelaksanaan Dan Estimasi Biaya Material Waller BeamNur Fitria PermatasariNo ratings yet

- Fyit Sem Ii Apr.19 (Choice Base) Microprocessor Architecture 5.apr.19 (PC.33407)Document2 pagesFyit Sem Ii Apr.19 (Choice Base) Microprocessor Architecture 5.apr.19 (PC.33407)PUBG NoobNo ratings yet

- Length: Foundation Plan Roof Framing Plan Column Footing DetailDocument1 pageLength: Foundation Plan Roof Framing Plan Column Footing DetailZyrose Jardiolin GuevarraNo ratings yet

- 1 399 RecruitmentAPWDDocument27 pages1 399 RecruitmentAPWDAmit Singh BaghelNo ratings yet

- Catalogus ENG AFIX 02-10-2013Document40 pagesCatalogus ENG AFIX 02-10-2013Sizaza BruciaNo ratings yet

- Combined Direct & Bending Stresses PDFDocument24 pagesCombined Direct & Bending Stresses PDFvinod choudhariNo ratings yet

- STD - 011 Typical Det of Lintel Beam Chajja-ModelDocument1 pageSTD - 011 Typical Det of Lintel Beam Chajja-ModelIrshad KhanNo ratings yet

- STUDIO - DetailedDocument6 pagesSTUDIO - DetailedKrupali ThakkarNo ratings yet

- Influences-And-Romanian-Traditional-Motifs-In-The-Architecture-Of-Dr-Nicolae-Minovici-Folk-Art-Museum-In-Bucharest - Content File PDFDocument19 pagesInfluences-And-Romanian-Traditional-Motifs-In-The-Architecture-Of-Dr-Nicolae-Minovici-Folk-Art-Museum-In-Bucharest - Content File PDFOlaru Sergiu-MihailNo ratings yet

- S. NO. Topic 1 2 3 4 5 6 7 8 9 10: DISSERTATION, 4th YEAR (A), 2019-2020Document18 pagesS. NO. Topic 1 2 3 4 5 6 7 8 9 10: DISSERTATION, 4th YEAR (A), 2019-2020BATMAN0% (1)

- Pryda Timber Connectors Bracing GuideDocument3 pagesPryda Timber Connectors Bracing GuidekjdaraNo ratings yet

- Commercial Building Construction Gantt ChartDocument1 pageCommercial Building Construction Gantt Chartteck yu100% (2)

- Single Cycle MIPS ArchiDocument4 pagesSingle Cycle MIPS Archiice1112No ratings yet

- Children's Room WardrobeDocument1 pageChildren's Room WardrobeMohamed AsarudeenNo ratings yet

- A Research Paper On DormitoriesDocument5 pagesA Research Paper On DormitoriesNicholas Ivy EscaloNo ratings yet

- STP Boq Measurement SheetDocument8 pagesSTP Boq Measurement SheetanishmetaNo ratings yet

- Shopping Mall Project Report PDF Free PDFDocument53 pagesShopping Mall Project Report PDF Free PDFFello KimNo ratings yet

- 2022 Yale Mechanical CatalogueDocument25 pages2022 Yale Mechanical CatalogueAmine DhahriNo ratings yet

- LogDocument97 pagesLogAbi AzdyNo ratings yet

- Replacement of Bearings in The Golden Horn Bridge PDFDocument3 pagesReplacement of Bearings in The Golden Horn Bridge PDFVCNo ratings yet

- Tiruchendur Murugan TempleDocument11 pagesTiruchendur Murugan TempleVyash Naveen PrasadhNo ratings yet

- NAFFCO INDONESIA PROJECT REFERENCE LIST in INDONESIADocument2 pagesNAFFCO INDONESIA PROJECT REFERENCE LIST in INDONESIAmarpaung saberindoNo ratings yet