Professional Documents

Culture Documents

Workover Daily Report - PHR - Benar-013 - 2024-03-28

Uploaded by

maikelmareaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workover Daily Report - PHR - Benar-013 - 2024-03-28

Uploaded by

maikelmareaCopyright:

Available Formats

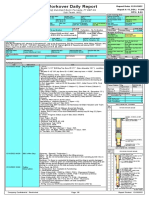

Workover Daily Report Report Date: 28/03/2024

Rig: Arjuna Petrogas Indonesia, PT. ARJ-15 Repot #: 7, DOL: 6,08

Sub Team NO2 DFS: 5,29

Well Header Last Casing Size

Field Name Well Name Legal Well Name Surface UWI State/Province Casing Description String Nominal OD (in)

Benar Benar 00013 N3-O-74 BENA00013 Riau Production Casing 7

Latitude (°) Longitude (°) Easting (X) (m) Northing (Y) (m) Set Depth (MD) (ftKB) Total Depth (ftKB)

1° 42' 25,266" N 100° 58' 17,804" E 719.338,66 188.790,48 2414 2.414,0

Gr Elev (ft) Original RKB (ft) Orig. KB to Gnd (ft) Start Date End Date Current RKB Elevation Curr. KB to Groun… Well Type Directional Type

25,64 39,64 14,00 06/03/2024 08/03/2024 37,64, 06/03/2024 12,00 Oil Producer Vertical

16.00 PBTD

Jobs Date Type PBTD (ftKB)

Job Category Primary Job Type Job Detail 29/09/1975 Cement Plug 2.369

Major Rig Work Over (MRWO) Return to Production ACT03 - Reactivate Oil Producer 20/12/1977 Cement Plug 2.333

Program Number Objective Create Date Record Tag

BENA0001320230809ACT03 Sqz all intervall 21/12/2023 Data Loader 22/03/1982 Cement Plug 2.414

Perf 2350-2352 10.07 Add-In Budget Summary

Conduct SWAB AFE Number Cost Center

Actual Start Date Job Spud Date Actual End Date D&C Status Job Complexity Complex Job Assessment 2202CC230142A/C 2202CC230142A/C

06/03/2024 06/03/2024 In Progress Low Not a Complex Job W12 W12

04.00 23.00 Planned AFE Cost (Cost)

Job Summary 87.556

#Rig GBT-17 Sum: R/D at Benar-041. MoMi to Benar-013. R/U Rig+Equipment. Initial Killing. N/D Tree. N/U BOP, Daily Field Est Total (Cost) Cum To Date (Cost)

N/U BOP. R/U WPF. BOP Test.TOH, Dismantle ESP. R/T Scraper. TIH OE Tbg. Sqz Cmt.WOC.TOC, TOH 3.5 OE 3.289 27.577

tubing, Set Tbg Hanger. OE at 78 ft. N/D WPF, N/D BOP. Suspended well. AFE Duration (days) Cum Time Log (days)

6,20 6,08

#Rig ARJ-15 Sum: R/D Rig at Benar-037, MOMI from Benar-37 to Benar-13 Time Log Total Hours (hr) Total Time Log Hours (hr)

24,00 146,00

Rig/Unit

Problem Time Hours (hr) Cum Prob Hrs (hr)

Rig/Unit # / Name Rig/Unit Type Rig/Unit Sub-type Rig/Unit Start Date Rig/Unit End Date

24,00 66,00

GBT-17 Land Workover Unit Workover 06/03/2024 04.00 08/03/2024 16.00

Daily Contacts

Rig/Unit # / Name Rig/Unit Type Rig/Unit Sub-type Rig/Unit Start Date Rig/Unit End Date

Contact Title Office

ARJ-15 Land Workover Unit Workover 25/03/2024 10.00

HES Incidents Devid Afianto Team 26964

Bestari Manager

Date Employee Category Incident Category Sub-Category Spill Volume (bbl)

Rachman Sr. 24455

HES Incident Description Roniko Coordinator

Windo Completions +6281275

Safety/Inspections Prasetyo Engineer 101388

Date Safety Check Com

Yusuf Ari Completions 27504

28/03/2024 07.30 Safety [A] Certificate Information : Wibowo Engineer

Procedures • Rig PLO : No: 373/56-896/PLO/DMT/2023 Expired: 18 May 2027

Rifwanto Day WSR 27630

Max hook load: 180 klbs/6 lines. Kapasitas Hook Load: 140 klbs/6 lines.

Abdul Rasyid Night WSR 27630

[B] Equipment Inspection Amrin

• LGI Expiration Date: March 25, 2024 (LGI completed Robby HES 27504

on Sept 25, 2023 & no finding) LGI color code : Blue. Risguanto Specialist

• 11" Annular BOP (shaffer) (Substitute) S/N: K13-022 Rudi Rig 27630

Last COC Date: 28 Jan 2022. MPI 03 Jun 2023. Pakpahan Supervisor

• 11" Blind Ram BOP and Pipe Ram (New Contract) S/N:K14-010,

Last COC Date: 30 Mar 2022. Last yearly test (30 Mar 22), Roy Martin Toolpusher 27630

Maintenance record: 14 Mar 2023. Hendra Toolpusher 27630

• Choke Manifold S/N.14110400, MPI Report Date: 29 March 2023. Andreas

• Accumulator S/N.C1407267-1. MPI Report Date: 30 March 2023. Simanjuntak

• Start 1st Yearly Maintenance verification on 11 May 2023.

Land, Original Hole, 29/03/2024

Note:

MD

- Last Full Test 11"-3M Class-III BOPE on Mar 19, 2024 at Loc BN-66 (ftKB Vertical schematic (actual)

- Last MP PRV test conducted on Mar 19, 2024 )

- Next full test of 11" BOPE no later than Apr 08, 2024

======================================================== 11,7

28/03/2024 08.00 Safety • COVID-19 Preparedness: 11,8

Observation 1. Temperature Gun: available and function. 11,9

2. Crew body Temperature:

• Day Shift, Total Crew- A : Min Temp: 35.9 'C; Max Temp: 36.5 'C.

12,1

Number of measurement: 1 time. 105,0

Surface; 10 3/4 in; 12-409

• Night shift,Total Crew- B : Min Temp: 36.0 'C; Max Temp: 36.5 'C. 419,0 ftKB

Number of measurement: 1 time. 2.233,9

3. Screening form submission status: Crew A, B & C completed.

4. Vaccination program (booster) status: Crew A, B & C completed. 2.325,1

5. Blood pressure check: 2.330,1

• Day shfit : Min 110/70 ; Max 130/80. 2.336,9

• Night Shift : Min 110/70; Max 135/84

• Day WSR : Rifwanto : 118/70 2.341,9

• Night WSR : Abdul Rasyid Amrin: 110/70 2.357,9

6. Emergency Response Plan: 2.373,4

• PHR Benar GS FAS Ambulance Services : 082233132394 2.414,0

Production Casing; 7 in;

• PHR Klinik Bangko: 0811-703-4541 (dr. Laily / dr. Bakrie) 12-2414 ftKB

• Drilling Rig BN-18: PHR Line: 27552/ 08117543780 2.497,0

• Drilling Rig PDSI 52.2: PHR Line: 27608/ 27643 2.710,0

• PHR Balam GS FAS Ambulance Services, PHR Line : 28272/ 28213 Land, Original Hole, 29/03/2024

========================================================== TVD Inc

(ftK l Directional schematic (actual)

B) (°)

14,1 0,0

105,0 0,0

409,1 0,0

2.157,2 0,0 1-1; Casing Joint; 10 3/4;

10,063; 12-407,4; 395,40

2.233,9 0,0 1-2; Float Shoe; 10 3/4;

10,050; 407,4-409; 1,60

2.324,1 0,0

2-1; Casing Joint; 7; 6,340; 12-

2.341,9 0,0 2371,8; 2.359,80

2.357,9 0,0

2.371,7 0,0 2-2; Float Collar; 7; 6,340;

2371,8-2373,4; 1,60

2.404,9 0,0

2-3; Casing Joint; 7; 6,340;

2373,4-2412,4; 39,00

2.414,0 0,0

2-4; Float Shoe; 7; 6,340; 2412,4

-2414; 1,60

2.493,1 0,0

2.543,0 0,0

Note: Directional schematic does not correlate

2.710,0 0,0

to other tracks.

Company Confidential - Restricted Page 1/8 Report Printed: 28/03/2024

Workover Daily Report Report Date: 28/03/2024

Rig: Arjuna Petrogas Indonesia, PT. ARJ-15 Repot #: 7, DOL: 6,08

Sub Team NO2 DFS: 5,29

Safety/Inspections BBS/Safety Observations

Date Safety Check Com Observation Typ # Rpts

28/03/2024 19.30 Safety Meeting • Incident Sharing Tracker in Mar 2024: JSA 4

STUM Weekly Mar 2024: PTW 2

- STUM Week 1 : Lifting Rigging (LR) Exclusion Zone

Safe Behavior 8

- STUM Week 2 : WUNPL

- STUM Week 3 : Pengelolaan kelelahan dan Tips keselamatan SWA 4

Ramadhan. Un-Safe Behavior 4

- STUM Week 4 : Stop Work Authority Un-Safe Condition 5

- STUM Week 5 : Head Count

39,0

• Emergency Drill in Mar 2024:

- Crew A (D) : Medivac drill (Sim) on 27 Mar 2024 at BNR-13

Medivac drill (Table Top) on 15 Mar 2024 at BKO-339

Medivac drill (Sim) on 08 Mar 2024 at BKO-95

- Crew B (N) : Medivac drill (Sim) on 27 Mar 2024 at BNR-13

Medivac drill (Table Top) on 21 Mar 2024 at BNR-37

Medivac drill (Table Top) on 10 Mar 2024 at BKO-95

- Crew C (Off) : Medivac drill (Sim) on 26 Mar 2024 at BNR-13

Medivac drill (Table Top) on 21 Mar 2024 at BNR-37

Medivac drill (Sim) on 19 Mar 2024 at BE-66

• Next DROPS Inspection schedule:

- Weekly on 3 Apr 2024

- Monthly on 31 Mar 2024

- Every 3 month on 23 Jun 2024

- Every 6 month on 26 May 2024

• Sharing SSD:

- Sharing ARJ-11: WPF patah.

- Sharing AU-06, Truck Pusher ditemukan MD saat beristirahat

di yard AU dengan crew C.

- Sharing GBT-09 : Rig : Rig carier tergelincir dan mengenai pagar

pelindung pipa pada saat moving

- Sharing Airlangga-55 : Kaki Derrickman Terpeleset

di Area Mud Pump-1 dengan Crew A & C

- SSD Fatality accident at Zona 8 with Crew A, B & C

- SSD Flushby TMS-01: Jari telunjuk kiri Floorman terluka

dengan Crew A, B & C

- SSD Incident at RIG PDSI 52.2 when moved at Balam area with

Crew A, B, & C

==========================================================

28/03/2024 19.45 Rig Inspection [1] ECOL:

• Day Shift:

- N/A (Moving)

• Night Shift:

- N/A (Moving)

[2] Rig Action List (RAL)

• Internal finding (5 Open)

• HES Specialist finding (1 Open) Land, Original Hole, 29/03/2024

MD

[3] Running Hours & Rotating Hours DP-DC (ftKB Vertical schematic (actual)

(Last inspection on 25 May 2023) )

• Running Hours 3-1/2" DP : 343 Hrs

• Rotating Hours 4-3/4" DC : 182 Hrs 11,7

11,8

[4] R&C Visit, Mr. Edward PS (9 - 10 Mar 2024)

• 11 Items : 3 Critical, 8 Major, 0 Medium (0 Open)

11,9

• Initial Score : 92 % Final Score : 97 %. 12,1

105,0

Surface; 10 3/4 in; 12-409

[5] Last V&V visit on 25 Mar 2024 Mr. Antoni Irawan, Mr. Eko R. 419,0 ftKB

• 5 Protokol: IHE, Drops, Lifting & Rigging, MVS LV. MVS-TMC

. No Opportunity, Overall Score 100% 2.233,9

28/03/2024 20.00 Rig Inspection [6] CVVR LV & HV 2.325,1

• Tandem BM 9316 DU: Activate and Safe 2.330,1

• TMC BM 9406 EU: Activate and Safe 2.336,9

• Vacuum Truck BM 9844 DO: Activate and Safe

• Bus Crew BM 7047 TU: Activate and Safe 2.341,9

• LV Toolpusher BM 1885 QH: Activate and Safe 2.357,9

2.373,4

[7] QAQC Report on 17 Feb 2023, Conducted Final Inspection Production Casing; 7 in;

2.414,0

By QAQC Team (Mr. Ronny) due to Re-Operation Rig ARJ-15. Finding 12-2414 ftKB

Last QAQC Re-Operation Meeting: (details open on separate RAL) 2.497,0

Status Manpower Equipment 2.710,0

Meet contract spec 43 178 Land, Original Hole, 29/03/2024

Not meet contract spec 9 11 TVD Inc

Not Available 0 0 (ftK l Directional schematic (actual)

Total 52 189 B) (°)

Summary Inspection update 17 Feb 2023 1st Yearly Maintenance verification 14,1 0,0

Rig ARJ-15 WPF SLO (No. SPHR00250C) : 105,0 0,0

• Manpower : 98,65%

• Equipment : 98,84 % 409,1 0,0

• Pressure Test WCE : 100 % 2.157,2 0,0 1-1; Casing Joint; 10 3/4;

• Performance Test : 100% 10,063; 12-407,4; 395,40

• Function Test : 100 % 2.233,9 0,0 1-2; Float Shoe; 10 3/4;

10,050; 407,4-409; 1,60

2.324,1 0,0

[8] Leadership PHR visit on 17 Mar 2024 (Safari Ramadhan) 2-1; Casing Joint; 7; 6,340; 12-

Mr. Muhammad Malik Idris (Act Sr. Coordinator Rig WOWS No-2) and 2.341,9 0,0 2371,8; 2.359,80

Mr. Seno Pratomo 2.357,9 0,0

Total Finding : 0 Item

Total Closed Item : 0 items 2.371,7 0,0 2-2; Float Collar; 7; 6,340;

2371,8-2373,4; 1,60

Total Open Item : 0 item 2.404,9 0,0

2-3; Casing Joint; 7; 6,340;

2373,4-2412,4; 39,00

[9] Virtual Leadership engagement by i-CCTV on 26 Feb 2024 2.414,0 0,0

2-4; Float Shoe; 7; 6,340; 2412,4

-2414; 1,60

Mr. Malik Idris - Act Sr. Coordinator Rig WOWS Light Oil North-01 2.493,1 0,0

Leadership MK and Team

2.543,0 0,0

Note: Directional schematic does not correlate

2.710,0 0,0

to other tracks.

Company Confidential - Restricted Page 2/8 Report Printed: 28/03/2024

Workover Daily Report Report Date: 28/03/2024

Rig: Arjuna Petrogas Indonesia, PT. ARJ-15 Repot #: 7, DOL: 6,08

Sub Team NO2 DFS: 5,29

Safety/Inspections

Date Safety Check Com

28/03/2024 20.15 Rig Inspection [10] HES Engineer D&C visit: Mr. Darwin Marpaung, on 25 Mar 2024

Debrief:

- Pelaksanaan Onsite Safety Briefing oleh HFO

- Pelaksanaan Daily check-up oleh medic sebelum beraktifitas di lokasi

- Melakukan verifikasi pemahaman HFO berkaitan dengan materi NASIHAT

mampu menjelaskan dengan baik, Doktrin NASIHAT routine di sampaikan

kepada crew saat TGM

- Melakukan verifikasi dokumen GPTW dan JSA sudah tersedia, divalidasi

secara rutin

- Melakukan pengecekan ketersediaan Noise Mapping, Lux Mapping dan

Gas Mapping dilokasi

- Improvement:

Update untuk PWIW dari Januari s/d Maret 2024

[11] Management API visit on 17 Mar 2024 (Safari Ramadhan)

- Mr. Harri Mulyafid (District Manager),

- Ismail Salmi (Area Manager),

- Devrian (Assistant District Manager),

- Ananda Putra (HSE Coordinator) and

- Reynaldi (RE).

[12] Dokter PHR visit: Dr Hendrik, on 25 Mar 2024

Improvement:

- Suhu ruangan yang panas berpotensi menyebabkan kerusakan pada

beberapa obat-obatan

- Cahaya lampu yang kurang terang

[13] QRA & Petrol Visit by Apriandi, Anggy on 13 Mar 2024

Campaign dan sosialisasi

1. Pre Record kill Sheet

2. Assessment Petrol

3. Check Document Well Control

[14] Function test GFCI

- Main genset : Working properly (08 Jan 2024)

- Genset Moving : Working properly (08 Jan 2024)

- Rig Office : Working properly (07 Jan 2024)

==========================================================

28/03/2024 21.30 Fire Drill Fire Drill with Crew-B (Simulation)

28/03/2024 22.45 PEKA of the Day Observer : Hendra Andreas (Tool pusher)

Ketika : Istirahat bekerja

Ditemukan : OP duduk sendirian di depan lokasi disekitar kebun sawit

dengan kurangnya penerangan

Sebab : Sambil mencari signal handphone

Saran : Op diminta untuk istirahat ditempat yang sudah disediakan

sesuai mini grouping dan jangan berada diarea yang gelap menghindari

bahaya biological

========================================================== Land, Original Hole, 29/03/2024

28/03/2024 23.00 Fuel Storage - Last fuel storage on 27 Mar 2024 = 4496 L MD

- New fuel storage on 28 Mar 2024 = - L (ftKB Vertical schematic (actual)

)

- Estimated fuel consumption on 28 Mar 2024 = 178 L

- Remaining fuel at location = 4318 L 11,7

========================================================== 11,8

Well Control Drill 11,9

Date Safety Check Tour Inspected By Des Result Com 12,1

19/03/20 Shut in Drill Crew A Charles F General Average Shut in Drill w/ Crew-A 105,0

24 19.15 Pakpahan while TOH ESP Surface; 10 3/4 in; 12-409

419,0 ftKB

28/03/20 Well Control Crew A Rifwanto General Average Non Routine with Crew-A

2.233,9

24 08.00 Drill for non- (Table Top)

routine 2.325,1

28/03/20 Well Control Crew B Abdul General Average Non Routine Drill with 2.330,1

24 20.30 Drill for non- Rasyid Crew-C (Table Top) 2.336,9

routine Amrin 2.341,9

26/03/20 Well Kill Drill Crew B Rifwanto General Average Well Kill Drill w/ Crew-B 2.357,9

24 14.30 (Table Top)

2.373,4

26/03/20 Well Kill Drill Crew C Abdul General Average Well Kill Drill with Crew-C Production Casing; 7 in;

24 20.30 Rasyid (Table Top) 2.414,0

12-2414 ftKB

Amrin 2.497,0

2.710,0

Land, Original Hole, 29/03/2024

TVD Inc

(ftK l Directional schematic (actual)

B) (°)

14,1 0,0

105,0 0,0

409,1 0,0

2.157,2 0,0 1-1; Casing Joint; 10 3/4;

10,063; 12-407,4; 395,40

2.233,9 0,0 1-2; Float Shoe; 10 3/4;

10,050; 407,4-409; 1,60

2.324,1 0,0

2-1; Casing Joint; 7; 6,340; 12-

2.341,9 0,0 2371,8; 2.359,80

2.357,9 0,0

2.371,7 0,0 2-2; Float Collar; 7; 6,340;

2371,8-2373,4; 1,60

2.404,9 0,0

2-3; Casing Joint; 7; 6,340;

2373,4-2412,4; 39,00

2.414,0 0,0

2-4; Float Shoe; 7; 6,340; 2412,4

-2414; 1,60

2.493,1 0,0

2.543,0 0,0

Note: Directional schematic does not correlate

2.710,0 0,0

to other tracks.

Company Confidential - Restricted Page 3/8 Report Printed: 28/03/2024

Workover Daily Report Report Date: 28/03/2024

Rig: Arjuna Petrogas Indonesia, PT. ARJ-15 Repot #: 7, DOL: 6,08

Sub Team NO2 DFS: 5,29

Daily Operations

Report Start Date Report End Date Recordable Incident? Days Since Rec. (days) Days Since LTI (days)

28/03/2024 00.00 29/03/2024 00.00 No 475 475

Operations Summary

78% MOMI from Benar-037 to Benar-013.

Status at Reporting Time

05:00 : WO Daylight due to low hanging cable

Projected Operations

100% MOMI from BNR-37 to BNR-13. R/U Rig. N/D ProductionTree. N/U BOP. R/U WPF.

Comments

I. Well Information Benar-13 (ACT03)

- Well type: Oil Producer (Vertical)

- MASP: 0 Psi

- GOR : 0.00 MSCF/STB

- Maximum Bullheading or Injection Pressure (Below Fract. Pressure) = 466 psi *use water

II. Completed Wells & Approved

1. BLSE-001 Completed 04 Mar 2024 @ 12:00, Post Job : Approved

2. BKO-095 Completed 12 Mar 2024 @ 22:00, Post Job : Approved

3. BKO-339 Completed 16 Mar 2024 @ 20:00, Post Job : Approved.

4. BNR-66 Completed 20 Mar 2024 @ 00:00, Post Job : Approved.

5. BNR-37 Completed 25 Mar 2024 @ 10:00, Post Job : N/Y.

III. Next Well Candidate (Update: 28 Mar 2024)

1. BO 168 (PMP09)

- LSC Status: Red

- Final Rig Assessment: NY

- Well program: NY, EAR: NY, WVD: NY, Handover: NY, RA: NY, MOC number: NR

- Wellpad Layout: NY, UGC: NY, CP-21: NR

- Issue: NY

IV. Preventive Maintenance Mar 2024

- Previous: 4 hrs

- Today: 0 hrs

- Cumulative: 4 hrs out of 16 hrs

- Rig Eng run hrs: 21278 hrs. last service: 21015 hrs on 2 Mar, 2024. Next service: 21365 hrs (Rem: 87 hrs)

- Rig Eng Trans run hrs: 21278 hrs. last service: 21290 hrs on 6 Mar, 2024. Next service: 22290 hrs (Rem: 1012 hrs)

- Mud Pump run hrs: 22370 hrs. last service: 22291 hrs on 19 Mar, 2024. Next service: 22641 hrs (Rem: 271 hrs)

- Mud Pump Trans run hrs: 22370 hrs. last srv: 22322 hrs on 22 Mar, 2024. Next service: 23322 hrs (Rem: 952 hrs)

- 325 kVA Genset run hrs: 18730 hrs. last srv: 18458 hrs on 5 Mar, 2024. Next service: 18808 hrs (Rem: 78 hrs)

V. Cutting Box:

- 5 filled box of congeal oil ex BLSE-23. Current position at BLSE-01.

- 15 filled box, total 15 box at BLSE-05. PPLI picked up on 13 Mar 2024.

VI. Others

- Ton Mile: 310.04 Next: 600. Last slack off on 21 Feb 2024 (cut +/- 150 ft drilling line)

- i-CCTV status: Offline (rig moving)

Time Log

UE

Dur Ref Land, Original Hole, 29/03/2024

Start Time End Time (hr) Phase Activity Com No.

MD

00.00 06.00 6,00 PROD, WLKLBHD, OPSUS WO Daylight to continue moving due to low visibility of 2 (ftKB Vertical schematic (actual)

25/03/2024 10.00 PLN power low hanging cable (there are 4 spots). )

Note: 11,7

- PG&T crew there is no support at night 11,8

- Conduct housekeeping Rig and Equipment by Crew 11,9

Rig

- Kendala Operasi has been submitted 12,1

- OST "CLSR Hot Work" 105,0

Surface; 10 3/4 in; 12-409

06.00 18.00 12,0 PROD, WLKLBHD, OPSUS WO PLN / PG&T team to support rig equipment 3 419,0 ftKB

0 25/03/2024 10.00 moving activity by lifting 4 spot of PLN low hanging 2.233,9

cable 2.325,1

Note: 2.330,1

- PG&T crew there is no support full job. 2.336,9

- Conduct housekeeping Rig and Equipment by Crew 2.341,9

Rig

- Kendala Operasi has been submitted 2.357,9

- OST "Memorandum Pilar 3+1"with crew A 2.373,4

- Foco truck Pickup Cutting box from WDR 10 Box. 2.414,0

Production Casing; 7 in;

12-2414 ftKB

- Visit inspect by Rig Reability (Mr.Makmun Johan &

2.497,0

Deimy)

2.710,0

18.00 00.00 6,00 PROD, WLKLBHD, OPSUS WO Daylight to continue moving due to low visibility of 2

Land, Original Hole, 29/03/2024

25/03/2024 10.00 PLN power low hanging cable (there are 4 spots).

TVD Inc

(ftK l Directional schematic (actual)

Note: B) (°)

- PG&T crew there is no support at night

- Conduct housekeeping Rig and Equipment by Crew 14,1 0,0

Rig

- Kendala Operasi has been submitted 105,0 0,0

- Fire drill (simulation) with crew B 409,1 0,0

- OST " APAR"

1-1; Casing Joint; 10 3/4;

- Total WO PG&T Personnel = 29 hrs 2.157,2 0,0

10,063; 12-407,4; 395,40

- Total WO Daylight = 36 hrs 2.233,9 0,0 1-2; Float Shoe; 10 3/4;

10,050; 407,4-409; 1,60

=========== After Midnight =========== 2.324,1 0,0

2-1; Casing Joint; 7; 6,340; 12-

(00:00 - 05:00) 2.341,9 0,0 2371,8; 2.359,80

WO Daylight to continue moving due to low visibility of

PLN power low hanging cable (there are 4 spots). 2.357,9 0,0

2.371,7 0,0 2-2; Float Collar; 7; 6,340;

Note: 2371,8-2373,4; 1,60

- PG&T crew there is no support at night 2.404,9 0,0

2-3; Casing Joint; 7; 6,340;

2373,4-2412,4; 39,00

- Conduct housekeeping Rig and Equipment by Crew 2.414,0 0,0

2-4; Float Shoe; 7; 6,340; 2412,4

Rig -2414; 1,60

- Kendala Operasi has been submitted 2.493,1 0,0

- Fire drill (simulation) with crew B 2.543,0 0,0

- OST " APAR" Note: Directional schematic does not correlate

2.710,0 0,0

to other tracks.

Company Confidential - Restricted Page 4/8 Report Printed: 28/03/2024

Workover Daily Report Report Date: 28/03/2024

Rig: Arjuna Petrogas Indonesia, PT. ARJ-15 Repot #: 7, DOL: 6,08

Sub Team NO2 DFS: 5,29

Offline Activities

Start Date End Date Comment

06/03/2024 19.00 06/03/2024 20.00 - [WSEA 3-A]:

- Line up Return Line; from Tbg to Tank-1

- Check initial well pressure, SITP = 10 Psi; SICP = 0 Psi. Bleed

off to 0 psi.

- Line up Killing Line; from Mud Pump to Csg Valve-1 and from

Casing Valve-2 to Tank-1

- Fill up Well w/ 30 bbls, 3 bpm. initial pump press 50 psi

- Shut in. Observed Well for 30 mnts, SITP = SICP = 0. Confirm

Well is killed.

Detail Offline Activity

Start Date End Date Duration (hr) Activity Comment

06/03/2024 06/03/2024 1,00 WLKLBHD - [WSEA 3-A]:

19.00 20.00 - Line up Return Line; from Tbg to Tank-1

- Check initial well pressure, SITP = 10 Psi; SICP = 0 Psi.

Bleed off to 0 psi.

- Line up Killing Line; from Mud Pump to Csg Valve-1 and from

Casing Valve-2 to Tank-1

- Fill up Well w/ 30 bbls, 3 bpm. initial pump press 50 psi

- Shut in. Observed Well for 30 mnts, SITP = SICP = 0. Confirm

Well is killed.

Start Date End Date Comment

07/03/2024 10.00 28/02/2024 11.00 R/D ESP BHI Unit

Detail Offline Activity

Start Date End Date Duration (hr) Activity Comment

07/03/2024 07/03/2024 1,00 TBGR/D R/D ESP BHI Unit

10.00 11.00

Start Date End Date Comment

07/03/2024 03.30 07/03/2024 04.30 R/U ESP BHI Unit

Detail Offline Activity

Start Date End Date Duration (hr) Activity Comment

07/03/2024 07/03/2024 1,00 TBGR/U R/U ESP BHI Unit

03.30 04.30

Start Date End Date Comment

07/03/2024 17.15 07/03/2024 18.15 Spot & R/U BHI Cementing Unit

Detail Offline Activity

Start Date End Date Duration (hr) Activity Comment

07/03/2024 07/03/2024 1,00 CMTR/U Spot & R/U BHI Cementing Unit

17.15 18.15

Start Date End Date Comment

07/03/2024 22.15 07/03/2024 23.15 R/D BHI Cementing Unit

Detail Offline Activity

Start Date End Date Duration (hr) Activity Comment

07/03/2024 07/03/2024 1,00 CMTR/D R/D BHI Cementing Unit

22.15 23.15

UE Ref No. & Accountable Party:

Ref

ere Unsch Dur Est

nce Event Maj Unsch WC (Net) Cost Accountable

No. Start Date End Date Description Type Cat Detail Class (hr) (Cost) Party Contractor

2 28/03/2 28/03/2 WO Daylight to NPT WO DAYLI 6,00 783 Operator Pertamina Hulu Land, Original Hole, 29/03/2024

024 024 continue moving due GHT Rokan, Location-

MD

00.00 06.00 to low visibility of PLN Safety (ftKB Vertical schematic (actual)

power low hanging )

cable (there are 4

spots). 11,7

3 28/03/2 28/03/2 WO PLN / PG&T team NPT WO LOC 12,0 1.56 Operator Pertamina Hulu 11,8

024 024 to support rig 0 6 Rokan, Location- 11,9

06.00 18.00 equipment moving Safety

activity by lifting 4 spot

12,1

of PLN low hanging 105,0

Surface; 10 3/4 in; 12-409

cable. 419,0 ftKB

2 28/03/2 29/03/2 WO Daylight to NPT WO DAYLI 6,00 783 Operator Pertamina Hulu 2.233,9

024 024 continue moving due GHT Rokan, Location- 2.325,1

18.00 00.00 to low visibility of PLN Safety

power low hanging 2.330,1

cable (there are 4 2.336,9

spots). 2.341,9

Well Control 2.357,9

Operations at 2.373,4

Kick Date Kick Depth (ftKB) P SIDP (psi) P SIC (psi) Time of Kick Well Kill Method / Notes Production Casing; 7 in;

2.414,0

12-2414 ftKB

Phases 2.497,0

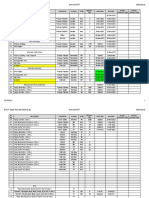

Actual Duration Actual 2.710,0

Well Pl AFE Cost Phase Field (AFE) Dur Land, Original Hole, 29/03/2024

Phase Phase 1 Phase 2 Actual Start Date Actual End Date (Cost) Est (Cost) (days) (days) systag

TVD Inc

LOCN DEMOB RD 06/03/2024 06/03/2024 504 325 0,08 0,08 Data (ftK l Directional schematic (actual)

04.00 06.00 Loader B) (°)

Add-In

LOCN MOB MOVEON 06/03/2024 06/03/2024 3.017 2.440 0,50 0,63 Data 14,1 0,0

06.00 21.00 Loader 105,0 0,0

Add-In

409,1 0,0

LOCN MOB RU 06/03/2024 06/03/2024 755 325 0,13 0,08 Data

21.00 23.00 Loader 2.157,2 0,0 1-1; Casing Joint; 10 3/4;

10,063; 12-407,4; 395,40

Add-In 2.233,9 0,0 1-2; Float Shoe; 10 3/4;

WO PRODTREE TREE 06/03/2024 06/03/2024 30.604 81 0,08 0,02 Data 10,050; 407,4-409; 1,60

23.00 23.30 Loader 2.324,1 0,0

2-1; Casing Joint; 7; 6,340; 12-

Add-In 2.341,9 0,0 2371,8; 2.359,80

WO PROD BOP 06/03/2024 07/03/2024 1.258 1.650 0,21 0,21 Data 2.357,9 0,0

23.30 04.30 Loader

Add-In 2.371,7 0,0 2-2; Float Collar; 7; 6,340;

2371,8-2373,4; 1,60

WO PROD PRODTBG 07/03/2024 07/03/2024 4.022 1.918 0,67 0,23 Data 2.404,9 0,0

2-3; Casing Joint; 7; 6,340;

04.30 10.00 Loader 2373,4-2412,4; 39,00

Add-In

2.414,0 0,0

2-4; Float Shoe; 7; 6,340; 2412,4

-2414; 1,60

COMP PROD CSGCLNOUT 07/03/2024 08/03/2024 5.028 7.761 0,84 1,08 Data 2.493,1 0,0

10.00 12.00 Loader 2.543,0 0,0

Add-In Note: Directional schematic does not correlate

2.710,0 0,0

to other tracks.

Company Confidential - Restricted Page 5/8 Report Printed: 28/03/2024

Workover Daily Report Report Date: 28/03/2024

Rig: Arjuna Petrogas Indonesia, PT. ARJ-15 Repot #: 7, DOL: 6,08

Sub Team NO2 DFS: 5,29

Phases

Actual Duration Actual

Well Pl AFE Cost Phase Field (AFE) Dur

Phase Phase 1 Phase 2 Actual Start Date Actual End Date (Cost) Est (Cost) (days) (days) systag

COMP PRODTBG TBG 08/03/2024 08/03/2024 4.022 840 0,67 0,15 Data

12.00 15.30 Loader

Add-In

COMP PRODTREE TREE 08/03/2024 08/03/2024 1.509 120 0,25 0,02 Data

15.30 16.00 Loader

Add-In

WO PROD WLKLBHD 25/03/2024 504 12.116 0,08 3,58 Data

10.00 Loader

Add-In

COMP PROD LOG 10.770 0,67 Data

Loader

Add-In

COMP PROD PERF 17.519 0,67 Data

Loader

Add-In

RESE PRODCSG EVAL 8.044 1,34 Data

VAL Loader

Add-In

Daily Fixed Costs

AFE Code Contract Field Est Field Est

Allocation Code Sub-Code Detail Des Detail Company Number/ID Cost (IDR) (Cost) Note

2202C 1080 25300 0800 Mob/demob fees Arjuna Petrogas SPHR0 469592 3.131 Standby with

C23014 0 1 (incl rig up and Indonesia, PT 0250C 50 Crews Rate

2A/CW rig down) (65%) = 24 hrs

12

2202C 1090 25200 0900 Drilling & Matra SPHR0 150000 10 Killing Fluid, Mud

C23014 0 0 Completion Unikatama, Pt 0136A Engineer, Packer

2A/CW Fluids - All Fluid, Corrosion

12 Inhibitor, etc

2202C 1142 25500 1400 Equipment Patra Drilling SPHR0 221588 148 Jr. Well Site

C23014 0 0 Rentals - All Contractor, PT 0582A 9 Representative =

2A/CW 1 person

12

Tubing Strings

Tubing

Run Date Run Job Set Depth (M… Top Depth (M… Pull Date Pull Job

01/12/2019 Pump Repair, 28/11/2019 2.300,8 13 07/03/2024 Return to Production,

17.00 06.30 05.00 06/03/2024 04.00

Cut/Pull Note Comment Reason Cut/Pull

Pump Set @ 2281.7' & BOM @ 2300.75'

Top Btm

Item Des SN OD (in) ID (in) Wt (lb/ft) Grade Jts Len (ft) Typ Thread Thread

Tubing Hanger 7 3,000 1 0,55 Tubing EUE EUE

Hanger

Tubing Pup 3 1/2 2,992 9,30 J-55 2 14,00 Tubing EUE EUE

Joint Land, Original Hole, 29/03/2024

Tubing 3 1/2 2,992 9,30 J-55 68 2.108,7 Tubing EUE EUE MD

9 (ftKB Vertical schematic (actual)

)

Valve 3 1/2 2,992 1 0,55 Other EUE EUE

Tubing 3 1/2 2,992 9,30 J-55 2 63,20 Tubing EUE EUE 11,7

Valve 3 1/2 2,992 1 0,55 Other EUE EUE 11,8

Tubing 3 1/2 2,992 9,30 J-55 2 63,20 Tubing EUE EUE 11,9

Tubing Pup 3 1/2 2,992 9,30 J-55 1 7,80 Tubing EUE EUE 12,1

Joint

105,0

ESP - Pump 5,4 4,813 1 8,60 ESP Pump Benoit Benoit Surface; 10 3/4 in; 12-409

ftKB

BTS8 BTS8 419,0

ESP - Intake 5,4 4,501 1 1,10 ESP Intake Benoit Benoit 2.233,9

BTS8 BTS8 2.325,1

Seal 5,4 4,500 1 6,90 Other Benoit Benoit 2.330,1

BTS8 BTS8 2.336,9

ESP - Motor 5,4 5,065 1 12,15 ESP Motor & Benoit Benoit 2.341,9

Cable BTS8 BTS8

2.357,9

Tubing 2.373,4

Run Date Run Job Set Depth (M… Top Depth (M… Pull Date Pull Job Production Casing; 7 in;

08/03/2024 Return to Production, 105,0 14 2.414,0

12-2414 ftKB

12.30 06/03/2024 04.00 2.497,0

Cut/Pull Note Comment Reason Cut/Pull 2.710,0

3.5 OE at 90 ft Land, Original Hole, 29/03/2024

Top Btm

Item Des SN OD (in) ID (in) Wt (lb/ft) Grade Jts Len (ft) Typ Thread Thread TVD Inc

(ftK l Directional schematic (actual)

Tubing Hanger 7 3,000 1 0,55 Tubing EUE EUE B) (°)

Hanger

Tubing 3 1/2 2,992 9,30 J-55 3 90,50 Tubing EUE EUE 14,1 0,0

Rod Strings 105,0 0,0

<Rod Description?> 409,1 0,0

Run Date Run Job In Tubing String Set Depth (ftKB) Pull Date Pull Job

2.157,2 0,0 1-1; Casing Joint; 10 3/4;

10,063; 12-407,4; 395,40

Comment 2.233,9 0,0 1-2; Float Shoe; 10 3/4;

10,050; 407,4-409; 1,60

Item Des SN OD (in) Jts Len (ft) Top (ftKB) Btm (ftKB) Type 2.324,1 0,0

2-1; Casing Joint; 7; 6,340; 12-

2.341,9 0,0 2371,8; 2.359,80

Other In Hole 2.357,9 0,0

Description OD (in) ID (in) Top (ftKB) Btm (ftKB) Run Date Run Job Pull Date Pull Job

2.371,7 0,0 2-2; Float Collar; 7; 6,340;

Other Strings 2371,8-2373,4; 1,60

2.404,9 0,0

2-3; Casing Joint; 7; 6,340;

String Description Run Date Pull Date Set D… Wellbore Tubing String Run Job Pull Job 2373,4-2412,4; 39,00

2.414,0 0,0

2-4; Float Shoe; 7; 6,340; 2412,4

Other String Components -2414; 1,60

2.493,1 0,0

Item Des Icon OD (in) ID (in) Len (ft) Cum Len (ft) Top (ftKB) Btm (ftKB)

2.543,0 0,0

Note: Directional schematic does not correlate

2.710,0 0,0

to other tracks.

Company Confidential - Restricted Page 6/8 Report Printed: 28/03/2024

Workover Daily Report Report Date: 28/03/2024

Rig: Arjuna Petrogas Indonesia, PT. ARJ-15 Repot #: 7, DOL: 6,08

Sub Team NO2 DFS: 5,29

Casing/Liner String

<Casing Description?>

Run Date Run Job Set Depth (M… Pull Date Pull Job

Item Des OD (in) ID (in) Grade Len (ft)

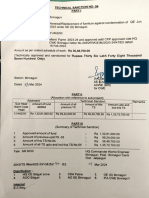

Cementing

Return to Production, 06/03/2024 04.00

Description Type Plan… String Cementing Start Date Cementing End Date Wellbore Technic…

Cement Squee N Production Casing, 07/03/2024 07/03/2024 Original Hole Succe

Squeeze ze Planned?-N, 2414ftKB 20.15 22.15 ss

Pump Start Date Pump End Date Top (ftKB) Btm (ftKB) Dens (lb/gal) Vol Pumped (bbl) Quantity (sacks)

07/03/2024 20.15 07/03/2024 22.15 2.157,0 2.358,0 15,80 8,9 42

Perforation (New Shot)

Date Perforatio… Top (ftKB) Btm (ftKB) Zone Wellbore Shot Dens (sh… Calcula…

String Perforated Job Gun Si… Conveyan… Carrier Tool Description Phasin…

Current Status Current Status Date

Perforation Status Info

Cur Stat Date Top (ftKB) Btm (ftKB) Current Status

21/05/2018 10.00 2.322,0 2.327,0 Squeezed-Cement (2.325,0 - 2.327,0 ftKB)

21/05/2018 10.00 2.322,0 2.331,0 Squeezed-Cement (2.322,0 - 2.331,0 ftKB)

21/05/2018 10.00 2.322,0 2.331,0 Squeezed-Cement (2.322,0 - 2.331,0 ftKB)

07/03/2024 20.15 2.324,0 2.328,0 Squeezed-Cement (2.324,0 - 2.328,0 ftKB)

21/05/2018 10.00 2.325,0 2.331,0 Squeezed-Cement (2.325,0 - 2.331,0 ftKB)

07/03/2024 20.15 2.326,0 2.342,0 Squeezed-Cement (2.324,0 - 2.330,0 ftKB)

21/05/2018 10.00 2.327,0 2.331,0 Squeezed-Cement (2.327,0 - 2.331,0 ftKB)

21/05/2018 10.00 2.337,0 2.340,0 Squeezed-Cement (2.337,0 - 2.340,0 ftKB)

30/06/1991 00.00 2.338,0 2.346,0 Squeezed-Cement (2.338,0 - 2.346,0 ftKB)

07/03/2024 20.15 2.338,0 2.342,0 Squeezed-Cement (2.336,0 - 2.340,0 ftKB)

12/11/2001 00.00 2.340,0 2.342,0 Squeezed-Cement (2.340,0 - 2.342,0 ftKB)

21/05/2018 10.00 2.342,0 2.346,0 Squeezed-Cement (2.342,0 - 2.346,0 ftKB)

Swabs

Date Job Completion/Zone Swab Company Comment

Swab Pull Depth Swab Time Vol Recov Q Oil

# Start Date Fdl Lvl (ftKB) (ftKB) (hr) (bbl) BS&W (%) Oil (bbl) BSW (bbl) (bbl/day)

Logs

Logging Depth Top

Date Type Company (MD) (ftKB) Btm (ftKB) Com

Wellhead/Tree

Wellhead

Install Date Type Sub-Type Make Service WP (psi) Size (in) Set Depth (ftKB)

11/11/1975 Wellhead Conventional Cameron NFLOW 2.000,0 7,063 12,0 Land, Original Hole, 29/03/2024

Comment MD

Non mandrel type tubing hanger (ftKB Vertical schematic (actual)

Description OD Nominal (in) ID Nominal (in) Length (in) )

Master Valve 3 1/2 3 4,00

WSEA 2: Pre-Spud/Operation Meeting 11,7

Date Safety Check Com 11,8

06/03/2024 Pre-Spud Meeting [WSEA 2-A] 11,9

21.00 Conducted Pre-Spud meeting before job execution with all rig Crews: 12,1

• Discuss well program ACT03 asessment, well control hazard, and safeguards

• Be aware of pressure trap & toxic gas when bleed of pressure, use blower and 105,0

Surface; 10 3/4 in; 12-409

personal gas detector. 419,0 ftKB

• Ensure well was killed and surface pressure was 0 psi before spud in. 2.233,9

• Benar-013 is Oil Producer Well, Vertical

• MASP: 0 psi, GOR: 0.00 MSCF/STB

2.325,1

• MGS will not be installed due to this well is Oil Producer & as per MOM Pre- 2.330,1

Spud 2.336,9

• There is no experienced killing problem in this well 2.341,9

• All materials and tools required to be prepared.

• Keep tank full of fluid and enough during operation by supplying water thru VT 2.357,9

• Conduct PJMS for initial killing & N/D Tree 2.373,4

WSEA 3: Well Control Safeguards 2.414,0

Production Casing; 7 in;

12-2414 ftKB

Date Safety Check Com 2.497,0

06/03/2024 WSEA 3-A - [WSEA 3-A]:

2.710,0

19.00 - Line up Return Line; from Tbg to Tank-1

Land, Original Hole, 29/03/2024

- Check initial well pressure, SITP = 10 Psi; SICP = 0 Psi. Bleed off to 0 psi.

- Line up Killing Line; from Mud Pump to Csg Valve-1 and from Casing Valve-2 TVD Inc

(ftK l Directional schematic (actual)

to Tank-1 B) (°)

- Fill up Well w/ 30 bbls, 3 bpm. initial pump press 50 psi

- Shut in. Observed Well for 30 mnts, SITP = SICP = 0. Confirm Well is killed. 14,1 0,0

08/03/2024 WSEA 3-B [WSEA 3-B] 0,0

105,0

15.45 - Maintained primary well control barrier.

- Conducted hole monitoring at all times. 409,1 0,0

- Keep conduct hole monitoring during the job. 0,0 1-1; Casing Joint; 10 3/4;

- Ensured continuity of supply water into S. tank to maintain formation water

2.157,2

10,063; 12-407,4; 395,40

volume at least 300 bbl. 2.233,9 0,0 1-2; Float Shoe; 10 3/4;

10,050; 407,4-409; 1,60

- Vacuum truck is available to supply water. 2.324,1 0,0

WSEA 6: Casing Test 2-1; Casing Joint; 7; 6,340; 12-

2.341,9 0,0 2371,8; 2.359,80

Applied

Densit Surface 2.357,9 0,0

y Pressur

Date Job Test Type Item Tested (lb/gal) e (psi) Com 2.371,7 0,0 2-2; Float Collar; 7; 6,340;

2371,8-2373,4; 1,60

2.404,9 0,0

2-3; Casing Joint; 7; 6,340;

WSEA 8 : BOP Configuration 2373,4-2412,4; 39,00

Start Date End Date Description Class 2.414,0 0,0

2-4; Float Shoe; 7; 6,340; 2412,4

06/03/2024 23.30 08/03/2024 14.00 11" 3M BOPE on well head III 0,0

-2414; 1,60

2.493,1

Type Pressure Rating (psi) ID Nom (in) Fixed Ram Size (in)

Annular 3.000,0 11 2.543,0 0,0

Note: Directional schematic does not correlate

Blind Ram 3.000,0 11 2.710,0 0,0

to other tracks.

Company Confidential - Restricted Page 7/8 Report Printed: 28/03/2024

Workover Daily Report Report Date: 28/03/2024

Rig: Arjuna Petrogas Indonesia, PT. ARJ-15 Repot #: 7, DOL: 6,08

Sub Team NO2 DFS: 5,29

Type Pressure Rating (psi) ID Nom (in) Fixed Ram Size (in)

Pipe Ram-Fixed Bore 3.000,0 11 3 1/2

Spool/Outlet 2.000,0 7 1/16

WSEA 9: BOP Test

Applied

Surface

Density Pressure

Date Job Test Type Item Tested (lb/gal) (psi) Com

07/03/20 Return to BOP 11" 3M BOPE 8,33 400 [WSEA-9A]

24 03.30 Production, on well head, Performed function test on all BOP elements

06/03/2024 06/03/2024 (Annular, Blind Ram & Pipe Ram), followed with

04.00 23.30, III Accumulator drawdown test:

Charging the accumulator system to 3,000 psi

in 3.06 minutes with both Air Pump & Electric

Pump.

Verified pressure in Accumulator system:

- Precharge: 1000 psi

- Annular: 1100 psi

- Manifold: 1500 psi

- Accumulator: 3000 psi

Switched-off pump system.

Checked BOP element closing system as

follows:

• Close Pipe Ram: 4.2 sec, remaining pressure:

2500 psi

• Open Pipe Ram: 4.9 sec, remaining pressure:

2150 psi

• Close Annular: 28 sec, final remaining

pressure: 1350 psi.

WSEA 9-B

Performed BOP Shell test against Annular +

Valve #5, #6, #7, #8 with Low/High pressure:

300 psi/400 psi, each test hold for 5 mnts.

Recorded result on Barton chart.

Note:

- Last full test BOP 11" 3M at 27 Feb 2024

- Next full test BOP 11" 3M no later than 19

March 2024

- Last function test of mud pump PRV on 27

Feb 2024

WSEA 10: Barrier Test

Applied

Densit Surface

WSEA y Pressur

Date Job Number Test Type Item Tested (lb/gal) e (psi) Com

08/03/2 Return to 10-J Tubing 6 3/8in, 8,33 0 [WSEA-10-J]

024 Production, Hanger Tubing No ESP run

12.15 06/03/2024 with Hanger

04.00 Seal

08/03/2 Return to 10-I Tubing 6 3/8in, 8,33 0 [WSEA-10-I]

024 Production, Hanger Tubing - The existing tubing hanger is non Land, Original Hole, 29/03/2024

12.15 06/03/2024 with Hanger mandrell and to be reused MD

04.00 Seal - Pressure test of tubing hanger is not (ftKB Vertical schematic (actual)

required per MOCP-18-001D2: )

- MASP = 0 psi

- Non gas producer well, GOR<400 11,7

SCF/BBl 11,8

- No Loc/HES Issues with adjacent wells 11,9

08/03/2 Return to 10-K Tubing 6 3/8in, 8,33 0 [WSEA-10-K] 12,1

024 Production, Hanger Tubing Changed out tubing hanger seal with new

105,0

12.15 06/03/2024 with Hanger one Surface; 10 3/4 in; 12-409

04.00 Seal 419,0 ftKB

08/03/2 Return to 10-L Producti Upper 8,33 500 [WSEA-10L] 2.233,9

024 Production, on Tree Master Including Pressure test Production master 2.325,1

15.45 06/03/2024 Valve, valve with 500 psi, held 5 mins, Good 2.330,1

04.00 Master Valve

2.336,9

2.341,9

2.357,9

2.373,4

2.414,0

Production Casing; 7 in;

12-2414 ftKB

2.497,0

2.710,0

Land, Original Hole, 29/03/2024

TVD Inc

(ftK l Directional schematic (actual)

B) (°)

14,1 0,0

105,0 0,0

409,1 0,0

2.157,2 0,0 1-1; Casing Joint; 10 3/4;

10,063; 12-407,4; 395,40

2.233,9 0,0 1-2; Float Shoe; 10 3/4;

10,050; 407,4-409; 1,60

2.324,1 0,0

2-1; Casing Joint; 7; 6,340; 12-

2.341,9 0,0 2371,8; 2.359,80

2.357,9 0,0

2.371,7 0,0 2-2; Float Collar; 7; 6,340;

2371,8-2373,4; 1,60

2.404,9 0,0

2-3; Casing Joint; 7; 6,340;

2373,4-2412,4; 39,00

2.414,0 0,0

2-4; Float Shoe; 7; 6,340; 2412,4

-2414; 1,60

2.493,1 0,0

2.543,0 0,0

Note: Directional schematic does not correlate

2.710,0 0,0

to other tracks.

Company Confidential - Restricted Page 8/8 Report Printed: 28/03/2024

You might also like

- Itinerary For 3days and 2nights in Pangasinan, PhilippinesDocument5 pagesItinerary For 3days and 2nights in Pangasinan, PhilippinesKathleen Gail Arguelles ArcegaNo ratings yet

- Cqi-8 LpaDocument32 pagesCqi-8 LpaMonica AvanuNo ratings yet

- 16 University of Mindanao v. BSP (Dos Santos)Document3 pages16 University of Mindanao v. BSP (Dos Santos)Tippy Dos SantosNo ratings yet

- Workover Daily Report - PHR - Benar-066 - 2024-03-18Document7 pagesWorkover Daily Report - PHR - Benar-066 - 2024-03-18maikelmareaNo ratings yet

- Workover Daily Report SummaryDocument6 pagesWorkover Daily Report SummaryAldri CandraNo ratings yet

- Job Information: Engineer Checked Approved Name: Date: Project IDDocument8 pagesJob Information: Engineer Checked Approved Name: Date: Project IDwaweng22No ratings yet

- Restricted EP Wells Daily Operations Report SummaryDocument5 pagesRestricted EP Wells Daily Operations Report Summarymohamed gadallahNo ratings yet

- Shift-Wise Production Report (Under Ground) Form 1 - ADocument2 pagesShift-Wise Production Report (Under Ground) Form 1 - Aagrawalharshit27No ratings yet

- Summary of Capital Cost: DWSS (Gravity Flow)Document5 pagesSummary of Capital Cost: DWSS (Gravity Flow)Mohsin ShahzadNo ratings yet

- Daily Completion and Workover (Schematic) : Well Name: Sample 11 - Full Data Report # 18.0, Report Date: 2000-06-02Document1 pageDaily Completion and Workover (Schematic) : Well Name: Sample 11 - Full Data Report # 18.0, Report Date: 2000-06-02Souvik SenguptaNo ratings yet

- Daily Meeting Production 20220920Document50 pagesDaily Meeting Production 20220920lalanNo ratings yet

- TG3070Document815 pagesTG3070Jason SecretNo ratings yet

- RESTRICTED EP Wells Daily Operations ReportDocument3 pagesRESTRICTED EP Wells Daily Operations ReportCarlos SuárezNo ratings yet

- COB 114 Well SummaryDocument6 pagesCOB 114 Well Summaryichi ezzahraNo ratings yet

- Pipe Log Book: Integrated Field Plan Execution Services in Satellite Field in Rj-On-90/1 Block ProjectDocument2 pagesPipe Log Book: Integrated Field Plan Execution Services in Satellite Field in Rj-On-90/1 Block ProjectPRAKASH PANDEYNo ratings yet

- Pipebook ADocument2 pagesPipebook APRAKASH PANDEYNo ratings yet

- Ep Wells Daily Operation ReportDocument5 pagesEp Wells Daily Operation ReportMohammed HamzaaliNo ratings yet

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDocument7 pagesKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- Kahraman C-181 (ST-1)Document3 pagesKahraman C-181 (ST-1)Islam AtifNo ratings yet

- Ep Wells Daily Operation ReportDocument5 pagesEp Wells Daily Operation ReportMohammed HamzaaliNo ratings yet

- 003, SDLG G9290 SN 630027 Scarifier (Revised)Document1 page003, SDLG G9290 SN 630027 Scarifier (Revised)IhsanNo ratings yet

- 8D Front Map Pocket Short MoldDocument10 pages8D Front Map Pocket Short MoldNirmal polyplastic100% (1)

- Ep Wells Daily Operation ReportDocument4 pagesEp Wells Daily Operation ReportMohammed HamzaaliNo ratings yet

- Update DES Pit 9 Per Jam 10Document2 pagesUpdate DES Pit 9 Per Jam 10Tomi Ananda PradistyNo ratings yet

- Daily Breakdown Monitoring & Backlog-4Document1 pageDaily Breakdown Monitoring & Backlog-4Prasetyo BudiNo ratings yet

- Boiler 20210227Document4 pagesBoiler 20210227Syahrial KotoNo ratings yet

- GTL GS RobDocument15 pagesGTL GS Robajay kumar battaNo ratings yet

- S001032-14 (Datalogger Specification)Document2 pagesS001032-14 (Datalogger Specification)akramhomriNo ratings yet

- NDT Request for Butt WeldsDocument3 pagesNDT Request for Butt WeldsFiras AlbaweiNo ratings yet

- Daily Drilling Report: Well DataDocument4 pagesDaily Drilling Report: Well DataHamedNo ratings yet

- Ep Wells Daily Operation ReportDocument5 pagesEp Wells Daily Operation ReportMohammed HamzaaliNo ratings yet

- Site InstructionDocument17 pagesSite InstructionElezer BatchoNo ratings yet

- Test Report For: Gas Purity & Dew Point TestDocument2 pagesTest Report For: Gas Purity & Dew Point TestAhmed FathyNo ratings yet

- Daily Welding Chamber Skirt AssemblyDocument1 pageDaily Welding Chamber Skirt AssemblyMa'ruf firmansyahNo ratings yet

- Da14 DDR N2 14000103 175 0Document3 pagesDa14 DDR N2 14000103 175 0Hamed NazariNo ratings yet

- viewNitPdf 4288069Document26 pagesviewNitPdf 4288069Mohit AgarwalNo ratings yet

- Daily Breakdown Monitoring - DMPDocument1 pageDaily Breakdown Monitoring - DMPAhmat RamadaniNo ratings yet

- Equipment ErectionDocument5 pagesEquipment ErectionrohitNo ratings yet

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- FAR D6R LH Final Drive FailureDocument9 pagesFAR D6R LH Final Drive Failurealisa alainaNo ratings yet

- Daily Monitoring BD (DMBD) Tanggal 02 Feb 2022 DRMDocument1 pageDaily Monitoring BD (DMBD) Tanggal 02 Feb 2022 DRMTheo AnggaraNo ratings yet

- PL_CS0137_D_M_2103_REV-FDocument4 pagesPL_CS0137_D_M_2103_REV-FSilvio Veragua GallardoNo ratings yet

- Test Report For: Gas Purity & Dew Point TestDocument2 pagesTest Report For: Gas Purity & Dew Point TestAhmed FathyNo ratings yet

- 000 Analisa Design Spreader Beam H200Document18 pages000 Analisa Design Spreader Beam H200Gennady FahmiNo ratings yet

- TS No 04 GE SDocument3 pagesTS No 04 GE SDinesh KumarNo ratings yet

- 61.AISDocument3 pages61.AISLUU QUANG HOANo ratings yet

- Lanea E-2 TCP-GR Invoice 2019-01-18Document2 pagesLanea E-2 TCP-GR Invoice 2019-01-18DIEUDONNE MBAIKETENo ratings yet

- 062.A Deck Stores Requisition Gresik 25.10.2021Document1 page062.A Deck Stores Requisition Gresik 25.10.2021Keysha RaissaNo ratings yet

- (C) F0032-00022 - Ad Instrument List (Including Vibration Sensor) For CCW PUMPDocument7 pages(C) F0032-00022 - Ad Instrument List (Including Vibration Sensor) For CCW PUMPTrong Nguyen VanNo ratings yet

- WD CS 01 BFNS22.9 2018Document15 pagesWD CS 01 BFNS22.9 2018Dipanjan chakrabortyNo ratings yet

- Wo 3594725Document1 pageWo 3594725minh nhat leNo ratings yet

- Daily Chamber Cone Assembly (BELUM DILAS)Document6 pagesDaily Chamber Cone Assembly (BELUM DILAS)Ma'ruf firmansyahNo ratings yet

- Method Statement for Tree Felling (Excluding Portion A) I05Document44 pagesMethod Statement for Tree Felling (Excluding Portion A) I05Jacky TamNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- BlankGLdata 3Document2 pagesBlankGLdata 3Jay SadNo ratings yet

- ABC Engineering Production RecordsDocument12 pagesABC Engineering Production RecordsNnandkishoreNo ratings yet

- EP Wells Daily Operation Report SummaryDocument4 pagesEP Wells Daily Operation Report SummaryMohammed HamzaaliNo ratings yet

- 17.11.2020 Day & Night ShiftDocument1 page17.11.2020 Day & Night ShiftLakmal JayashanthaNo ratings yet

- Pipe Rack Design Summary PDFDocument64 pagesPipe Rack Design Summary PDFNathan PattersonNo ratings yet

- Daily Report Status Unit Site Pt. Kpb/IpDocument1 pageDaily Report Status Unit Site Pt. Kpb/IpWahyu SriharjaNo ratings yet

- 2021-0395-MWCI-ICC-2022-T-0029_NGRDocument30 pages2021-0395-MWCI-ICC-2022-T-0029_NGRLeo TabitaNo ratings yet

- Package Cover Sheet Line Maintenance: Certificate of Release To ServiceDocument6 pagesPackage Cover Sheet Line Maintenance: Certificate of Release To ServiceFemi AgbanaNo ratings yet

- How To Knit SocksDocument10 pagesHow To Knit SocksHolly Robles100% (1)

- How Historians Seek Historical TruthDocument30 pagesHow Historians Seek Historical Truthlezier Padilla SumagangNo ratings yet

- Wolf Marshall's Guide To C A G E DDocument1 pageWolf Marshall's Guide To C A G E Dlong_tu02No ratings yet

- Bank TellerDocument3 pagesBank Tellerapi-3701112No ratings yet

- Level 3 Repair: 8-1. Components LayoutDocument50 pagesLevel 3 Repair: 8-1. Components LayoutManuel BonillaNo ratings yet

- Combined Orders (SAP Library - Production Planning and Control)Document3 pagesCombined Orders (SAP Library - Production Planning and Control)Rashid KhanNo ratings yet

- Oscilloscope TutorialDocument32 pagesOscilloscope TutorialEnrique Esteban PaillavilNo ratings yet

- Newton Interviews Aton Resources On RodruinDocument38 pagesNewton Interviews Aton Resources On RodruinPeter BellNo ratings yet

- RBT-25/B Spec SheetDocument2 pagesRBT-25/B Spec SheetSrpskiNo ratings yet

- Sample ProposalDocument22 pagesSample Proposalbrynzky100% (1)

- How To Remove Letters From Stringsnumberscells in ExcelDocument1 pageHow To Remove Letters From Stringsnumberscells in ExcelharshilNo ratings yet

- Burj Khalifa Case StudyDocument4 pagesBurj Khalifa Case StudyJATINKUMAR CHAUDHARINo ratings yet

- Cortisol II 2020-03 v6Document5 pagesCortisol II 2020-03 v6Parishan SaeedNo ratings yet

- 9 Counter-Drone Technologies To Detect and Stop Drones TodayDocument1 page9 Counter-Drone Technologies To Detect and Stop Drones TodayNikolaiTihinovNo ratings yet

- Customer Guide Electrical Service Information FormDocument2 pagesCustomer Guide Electrical Service Information FormRyder BergerudNo ratings yet

- Circuit Breaker GalilioDocument34 pagesCircuit Breaker GalilioMoaz KhursheedNo ratings yet

- Tutorial: Creating A Middleware Application Using CMSIS ComponentsDocument25 pagesTutorial: Creating A Middleware Application Using CMSIS ComponentsJose Romero MurilloNo ratings yet

- ml350p g8.Document57 pagesml350p g8.Aboubacar N'dji CoulibalyNo ratings yet

- MT Dbp-hcp-1000 Series ManualDocument54 pagesMT Dbp-hcp-1000 Series ManualNguyễn Thế PhongNo ratings yet

- Characteristics: EXPERIMENT 08: SPICE Simulation of and Implementation For MOSFETDocument11 pagesCharacteristics: EXPERIMENT 08: SPICE Simulation of and Implementation For MOSFETJohnny NadarNo ratings yet

- Difference between net profit and gross returnsDocument2 pagesDifference between net profit and gross returnsSue VenidaNo ratings yet

- SL 78r CK FRNC Lv2.0Document2 pagesSL 78r CK FRNC Lv2.0Huế Đà NẵngNo ratings yet

- Stability and Development StrategyDocument34 pagesStability and Development StrategySudan North-South Border InitiativeNo ratings yet

- S141 Advanced DSP-based Servo Motion ControllerDocument8 pagesS141 Advanced DSP-based Servo Motion ControllersharkeraNo ratings yet

- Change-oriented leadership impacts team climate & potencyDocument17 pagesChange-oriented leadership impacts team climate & potencyAkhwand Abdur Raffi SaulatNo ratings yet

- Letter From Empower Oversight and Nixon Peabody To CongressDocument3 pagesLetter From Empower Oversight and Nixon Peabody To CongressThe FederalistNo ratings yet

- Chapter 3Document2 pagesChapter 3RoAnne Pa Rin100% (1)