Professional Documents

Culture Documents

Calculation, Pump, Hydraulic, NPSH, Suction, Fluid, Water, Net

Uploaded by

Mohamed Abou El hassanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation, Pump, Hydraulic, NPSH, Suction, Fluid, Water, Net

Uploaded by

Mohamed Abou El hassanCopyright:

Available Formats

Mechanical energy provided to the fluid (Closed loop), mechanical energy in hydrostatic load (Fluid on open circuit) - degraded

Energy

(Power at the shaft of the pump) Pumps head, Pumps horsepower, Pumps Net Positive Suction Head.

French site | Home | Thematic | Tables | Programs | Library | Download | Links | Contact | Forum |

_You are in the heading Wed Dec 28 2022 08:41:13 GMT+0300 (Arabian Standard Time)

--

Pumps

Thematic

Quotation Energy provided by the pump

Margin

Hydraulic

In the hydraulic field, the load of a pump is expressed in theory in height of water.

Linear pressure

loss

The absorptive energy by the pump breaks up:

Local pressure

loss

Mechanical energy provided to the fluid (Closed loop)

Compressible

fluids

No circular duct

It is the hydraulic power communicated to the liquid of its passage through the pump.

Thermal

This mechanical power is given by the following formula:

Thermal fluid

flow

Pipe sizing

steam

Control valves With:

Orifice plate

Pumps P = Power transmitted to the fluid by the pump in Watt.

Ventilators Q = Flow in m3/s.

Gas Hm = Energy or pressure loss of the hydraulic network expressed in m.

Fuel gas

Mechanical energy in hydrostatic load (fluid on open circuit)

With:

P = Power transmitted to the fluid by the pump in Watt.

Q = Flow in m3/s.

p = Density of the liquid in kg/m3.

H = Piezometric height in meter of water.

9.81 = Average Intensity of gravity.

Mechanical energy provided to the liquid (For example, distribution network of drinking water):

With:

P = Power transmitted to the fluid by the pump in Watt.

Q = Flow in m3/s.

p = density of the liquid in kg/m3.

Hm = Hydraulic pressure loss network expressed in m.

H = Hydraulic load in meter of water.

9.81 = Average Intensity of gravity.

Degraded energy expressed by the output of the pump (Power at the shaft of the pump)

It is the power measured on the shaft of the pump.

Mechanical energy necessary to a pump is always higher than the energy transmitted to the fluid, following

various frictions of the bodies of rotation.

With:

Pmec = Mechanical power necessary to the pump.

Pfl = Power transmitted to the fluid.

Rv = Output of the ventilator.

Rt = Output of the transmission.

In the centrifugal pumps, the essence of degraded energy overheats is the pumped liquid.

In the reciprocating pumps, the essence of degraded energy is in the mechanical drives and is not

communicated to the liquid.

The outputs generally allowed are:

Piston pumps = 0.6 à 0.7

Centrifugal pumps = 0.4 à 0.8

Motorization

At the time of the choice of the engine, it is the absorptive power by the pump which determines the power

delivered by the engine and thus also the absorptive power at the network. It is necessary thus to take guard

so that the engine has a sufficient power to satisfy all the situations of operation of the installation.

Let us take the case of a pump having an absorptive power of 8.5 kW. The engine will provide these 8.5 kW,

independently owing to the fact that it is conceived for 7 kW or 10 kW. An engine of 7 kW, having to function at

40°C, would thus always be overloaded of 21.5 %.

The direct consequence of an overload of the engine is an increase in the temperature of winding. A overtaking

of the limiting temperature of 8-10°C, decreases the lifespan of the insulation of approximately half. Overtaking

beyond of 20°C mean shortening of 75 %.

The engines of standard construction are planned for a use at maximum ambient temperature of 40°C (and a

maximum altitude of the site of 1 000 m). Any variation requires a correction of the nominal output.

Last update: 12/28/2022 08:41:13

Copyright © 2003-2014 - ThermExcel - All Rights Reserved

You might also like

- HM Assingment 02Document7 pagesHM Assingment 02PradneshNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- A Virtual Laboratory For Understanding Hydraulic Hybrid TechnologyDocument11 pagesA Virtual Laboratory For Understanding Hydraulic Hybrid TechnologyfreemeonceNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- VDF Pumps Paper PDFDocument5 pagesVDF Pumps Paper PDFAnthony Flores ValeraNo ratings yet

- 4.2 Water PumpDocument8 pages4.2 Water PumpPRATIKNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Design of Hydropower Plant : Mohammed ADocument18 pagesDesign of Hydropower Plant : Mohammed AMymanNo ratings yet

- Introduction to Hydropower OutlineDocument45 pagesIntroduction to Hydropower Outlinekass00488_18085260975% (4)

- Energy and power transfer in hydraulic systemsDocument14 pagesEnergy and power transfer in hydraulic systemsMuhammed RazzaqueNo ratings yet

- Power System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)From EverandPower System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)No ratings yet

- 01 - Irrigation PumpsDocument47 pages01 - Irrigation PumpsJonesNo ratings yet

- Centrifugal PumpsDocument20 pagesCentrifugal PumpsPiccollo640780% (5)

- Exp 8 Turbo Centrifugal PumpDocument8 pagesExp 8 Turbo Centrifugal PumpChirag JainNo ratings yet

- A Ideal Approach of Designing Run Off River Plant: February 2014Document5 pagesA Ideal Approach of Designing Run Off River Plant: February 2014Janaisha Bai TitoNo ratings yet

- Turbine - 1Document80 pagesTurbine - 1Vineet Gupta100% (1)

- LESSON 7 Theory of TurbinesDocument12 pagesLESSON 7 Theory of TurbinesChandima K PriyamalNo ratings yet

- GPSA m12 PumpDocument20 pagesGPSA m12 PumpGift Piyapong88% (8)

- Hydraulic Machines TurbinesDocument137 pagesHydraulic Machines TurbinesKamlesh GuptaNo ratings yet

- Centrifugal Pump: Hardik Goswami Mechanical Engg. Department, SOT PDPU, GandhinagarDocument40 pagesCentrifugal Pump: Hardik Goswami Mechanical Engg. Department, SOT PDPU, GandhinagarDr Churamani Dev MishraNo ratings yet

- Activity 2: Hydroelectric Power Plants: Ee133L Power Plant Engineering Laboratory Learning OutcomesDocument8 pagesActivity 2: Hydroelectric Power Plants: Ee133L Power Plant Engineering Laboratory Learning OutcomesErica VillasNo ratings yet

- Design of Hydro Power by Using Turbines Kaplan OnDocument5 pagesDesign of Hydro Power by Using Turbines Kaplan Ondave chaudhuryNo ratings yet

- Mixing Fundamentals Terminology and FormulasDocument24 pagesMixing Fundamentals Terminology and FormulasJorge DiAlvearNo ratings yet

- Chapter4-Hydraulic MachinesDocument16 pagesChapter4-Hydraulic MachinesHeena MarziaNo ratings yet

- Narnarayan Shastri Institute of Technology: Prepared byDocument22 pagesNarnarayan Shastri Institute of Technology: Prepared byAdhanom G.No ratings yet

- Micro Hydro TestingDocument6 pagesMicro Hydro TestingSandip DeNo ratings yet

- CE-UG-2018 Spring FEB-JUN 2020Document43 pagesCE-UG-2018 Spring FEB-JUN 2020SalmanNo ratings yet

- Planta A Vapor Ciclo RankineDocument62 pagesPlanta A Vapor Ciclo Rankinelides fernandez saldivarNo ratings yet

- Hydraulic Turbine Selection and ClassificationDocument35 pagesHydraulic Turbine Selection and Classificationhabte gebreial shrashr100% (2)

- Centrifugal Pump Test RigDocument5 pagesCentrifugal Pump Test RigAlbert AinstineNo ratings yet

- B-Basic Information: MNFN 100 - GR2-Y18-T2Document26 pagesB-Basic Information: MNFN 100 - GR2-Y18-T2Mohamed SaeeDNo ratings yet

- Experiment #3 - Test of Series Connected Centrifugal PumpDocument8 pagesExperiment #3 - Test of Series Connected Centrifugal PumpRoi Vincent AnitNo ratings yet

- Thermodynamics Steam TurbineDocument8 pagesThermodynamics Steam TurbineidhammenderoNo ratings yet

- Vapour Cycle Thermodynamics TutorialDocument13 pagesVapour Cycle Thermodynamics TutorialDavid ChikuseNo ratings yet

- Pump NotesDocument10 pagesPump NotesSasmita SahooNo ratings yet

- Fluid Mechanics Chapter on Mechanical Energy and EfficiencyDocument43 pagesFluid Mechanics Chapter on Mechanical Energy and EfficiencyShazrel IzlanNo ratings yet

- Fluid MachineryDocument54 pagesFluid MachineryPadmanathan_Pa_719100% (2)

- Pump SizingDocument73 pagesPump SizingIsmael Llamelo PerezNo ratings yet

- Estimation of Water Power PotentialDocument30 pagesEstimation of Water Power PotentialNatnael SitotaNo ratings yet

- Reciprocating Pump Test RigDocument7 pagesReciprocating Pump Test RigPurtain MENo ratings yet

- Week 13 To 15 Hydroelectric Power PlantDocument11 pagesWeek 13 To 15 Hydroelectric Power PlantyellowP100% (1)

- Fluid Mechanics (Chapter 3, Lecture 7)Document10 pagesFluid Mechanics (Chapter 3, Lecture 7)Adel JamalNo ratings yet

- Hydraulic MachinesDocument64 pagesHydraulic MachinesInnocent RevocatusNo ratings yet

- Chapter - 3 - Hydraulic TurbinesDocument78 pagesChapter - 3 - Hydraulic TurbinesLauria LavdaNo ratings yet

- Polytechnic University of the Philippines Fluid Machinery ExamDocument4 pagesPolytechnic University of the Philippines Fluid Machinery ExamJohn David AnunciacionNo ratings yet

- HH Hydraulic MachinesDocument43 pagesHH Hydraulic MachinesTai Ching WongNo ratings yet

- PD Assi 3Document17 pagesPD Assi 3Abhay RajputNo ratings yet

- Recycled Hydro Power Plant Using Hydraulic Ram Pump Ijariie4588Document7 pagesRecycled Hydro Power Plant Using Hydraulic Ram Pump Ijariie4588Prakhar ChoureyNo ratings yet

- Formula Notes Power Systems - PDF 69Document26 pagesFormula Notes Power Systems - PDF 69Augustine Kwadjo GyeningNo ratings yet

- Trial On Steam Turbine Power PlantDocument4 pagesTrial On Steam Turbine Power PlantSr2152No ratings yet

- Chapter 5 Pump and Control Devices PDFDocument68 pagesChapter 5 Pump and Control Devices PDFRana G100% (2)

- PumpsDocument75 pagesPumpsmd junuNo ratings yet

- Fluid Mechanics Lab ManualDocument37 pagesFluid Mechanics Lab ManualMohith MarripatiNo ratings yet

- PumpsDocument75 pagesPumpsSurendra ReddyNo ratings yet

- Hydropower - Babak Rezapoor Exercise REV1 2016Document34 pagesHydropower - Babak Rezapoor Exercise REV1 2016RCNo ratings yet

- Bernoulli's TheoremDocument15 pagesBernoulli's TheoremRosmari Aquino PascualNo ratings yet

- Oil Color Chart Exercises For Artists (Master Your Paint Pallette)Document1 pageOil Color Chart Exercises For Artists (Master Your Paint Pallette)Mohamed Abou El hassanNo ratings yet

- Complete Guide on Color and the Effect of LightDocument1 pageComplete Guide on Color and the Effect of LightMohamed Abou El hassanNo ratings yet

- Elsweedy Alarm SystemDocument45 pagesElsweedy Alarm SystemMohab Mesho65No ratings yet

- What You Need to Know About Color Theory for PaintingDocument1 pageWhat You Need to Know About Color Theory for PaintingMohamed Abou El hassanNo ratings yet

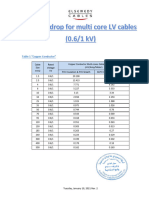

- Voltage Drop Rev. 2Document2 pagesVoltage Drop Rev. 2Mohamed Abou El hassanNo ratings yet

- Engineering Appendix Three Pumping Stations Version 12 November 2012Document16 pagesEngineering Appendix Three Pumping Stations Version 12 November 2012Mohamed Abou El hassanNo ratings yet

- 27 05 00 Common Work Results For CommunicationsDocument16 pages27 05 00 Common Work Results For CommunicationsMohamed Abou El hassanNo ratings yet

- Choosing Between 3-Pole and 4-Pole Transfer Switches - Consulting - Specifying EngineerDocument1 pageChoosing Between 3-Pole and 4-Pole Transfer Switches - Consulting - Specifying EngineerMohamed Abou El hassanNo ratings yet

- MOS for the Installation of Water Supply SystemDocument16 pagesMOS for the Installation of Water Supply SystemMohamed Abou El hassanNo ratings yet

- Alworood - Power - Lighting-ModelDocument1 pageAlworood - Power - Lighting-ModelMohamed Abou El hassanNo ratings yet

- Chapter 16 Design of Pumping StationsDocument23 pagesChapter 16 Design of Pumping StationsNam SanchunNo ratings yet

- NK 125315326 Aa1f2besbaqerw3Document11 pagesNK 125315326 Aa1f2besbaqerw3Mohamed Abou El hassanNo ratings yet

- Collection Chamber Structural-Rev4Document1 pageCollection Chamber Structural-Rev4Mohamed Abou El hassanNo ratings yet

- 27 41 32 Ip-Based Television System (Iptv)Document30 pages27 41 32 Ip-Based Television System (Iptv)Mohamed Abou El hassanNo ratings yet

- 2" SS PIPING COMPONENTSDocument3 pages2" SS PIPING COMPONENTSMohamed Abou El hassanNo ratings yet

- 2 2 2 Electrical In-FillDocument14 pages2 2 2 Electrical In-FillMohamed Abou El hassanNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- CATL Battery Datasheet FinalDocument2 pagesCATL Battery Datasheet FinalMohamed Abou El hassan100% (1)

- ID1000 Underground Tank 1 10m3 - ENDocument1 pageID1000 Underground Tank 1 10m3 - ENMohamed Abou El hassanNo ratings yet

- ArtsDocument2 pagesArtsMohamed Abou El hassanNo ratings yet

- IWS STRONG Small Pumping Stations ENGDocument12 pagesIWS STRONG Small Pumping Stations ENGMohamed Abou El hassanNo ratings yet

- FIRE PUMP MINIMUM FLOW REQUIREMENTS - LinkedInDocument1 pageFIRE PUMP MINIMUM FLOW REQUIREMENTS - LinkedInMohamed Abou El hassanNo ratings yet

- ID700 Small Pumping Station Wilo MTC40 Plastic Cover ENGDocument1 pageID700 Small Pumping Station Wilo MTC40 Plastic Cover ENGMohamed Abou El hassanNo ratings yet

- Fire Pump Settings - NFPA 20 - Fire Protection SpecialistsDocument1 pageFire Pump Settings - NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- NFPA 13 - SELECTING AND SETTING PRESSURE CONTROL VALVES - LinkedInDocument1 pageNFPA 13 - SELECTING AND SETTING PRESSURE CONTROL VALVES - LinkedInMohamed Abou El hassanNo ratings yet

- Water Hammer - What Is It and How Does It Impact FirefightingDocument1 pageWater Hammer - What Is It and How Does It Impact FirefightingMohamed Abou El hassanNo ratings yet

- 22-Light ColorDocument12 pages22-Light ColorMohamed Abou El hassanNo ratings yet

- Tm-90-21-Ul (R-03/30/22)Document20 pagesTm-90-21-Ul (R-03/30/22)Mohamed Abou El hassanNo ratings yet

- Relief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsDocument1 pageRelief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- Conectores Rele Arranque Aveo 2005Document3 pagesConectores Rele Arranque Aveo 2005Jose Luis Velasquez RomeroNo ratings yet

- Climate Change Is A Change in The Statistical Distribution What Makes The Climate Change?Document4 pagesClimate Change Is A Change in The Statistical Distribution What Makes The Climate Change?Khriestal BalatbatNo ratings yet

- Module3 Besck104bDocument13 pagesModule3 Besck104bDivya Shrinidhi MaiyaNo ratings yet

- t530 - Electrotechnics n4 QP Nov 2018Document8 pagest530 - Electrotechnics n4 QP Nov 2018Petro Susan BarnardNo ratings yet

- Surge Protector and Filter Specifications: Technical DataDocument16 pagesSurge Protector and Filter Specifications: Technical DataJuan Esteban Benjumea BenjumeaNo ratings yet

- Photo Electric EffectDocument19 pagesPhoto Electric EffectAbdullah ZafarNo ratings yet

- Database FanyDocument35 pagesDatabase Fanyimam17No ratings yet

- FT1800 Service ManualDocument33 pagesFT1800 Service Manualnebiyu mulugetaNo ratings yet

- Physics: Pearson Edexcel Level 1/level 2 GCSE (9-1)Document28 pagesPhysics: Pearson Edexcel Level 1/level 2 GCSE (9-1)Chari1No ratings yet

- KarnalDocument148 pagesKarnaladv.sonal8No ratings yet

- Datasheet 2020 Dryers DTT-11-18-23-HP - Dynamic - enDocument2 pagesDatasheet 2020 Dryers DTT-11-18-23-HP - Dynamic - enRodolfo L, CorrêaNo ratings yet

- SemiconductorDocument8 pagesSemiconductorritamnath337No ratings yet

- Psi Mud Agitators Product SheetDocument2 pagesPsi Mud Agitators Product SheetPRASHANT KANTENo ratings yet

- Part A: Thermal Energy: Name Elisabeth Albert Class General Science Page 1Document11 pagesPart A: Thermal Energy: Name Elisabeth Albert Class General Science Page 1RHEAMAE GALLEGO50% (2)

- Bi-Directional Single-Stage Grid-Connected Inverter For Battery Energy Storage SystemDocument9 pagesBi-Directional Single-Stage Grid-Connected Inverter For Battery Energy Storage SystemKirn ZafarNo ratings yet

- Energy AuditDocument145 pagesEnergy Auditparthasarothi_sikder79No ratings yet

- Evapco Maintenance Checklist Coolers & Condensers OM Bulletin 116-E - 0417Document3 pagesEvapco Maintenance Checklist Coolers & Condensers OM Bulletin 116-E - 0417Rudy HerreraNo ratings yet

- Grade 9 Physics worksheetDocument4 pagesGrade 9 Physics worksheetKassahun100% (1)

- The Van Conversion Bible - The Ultimate Guide To Converting A CampervanDocument170 pagesThe Van Conversion Bible - The Ultimate Guide To Converting A CampervanPil100% (3)

- Armada Spinning Ltd. 1KVA Online UPS QuotationDocument4 pagesArmada Spinning Ltd. 1KVA Online UPS QuotationhhelectronicsbdNo ratings yet

- 1-1. Safety HintsDocument25 pages1-1. Safety Hintsmargotsilva96No ratings yet

- Class 11 PaperDocument7 pagesClass 11 PaperUsha SherkhaneNo ratings yet

- Product Catalogue 188 192Document5 pagesProduct Catalogue 188 192Anand PuntambekarNo ratings yet

- Secrets of Gravity AbridgedDocument20 pagesSecrets of Gravity Abridgeddeadtree34100% (1)

- Oxygen Sensor Diagnose ReplaceDocument13 pagesOxygen Sensor Diagnose ReplaceStefanNo ratings yet

- Portable Compressors (Diesel) MDVN RangeDocument29 pagesPortable Compressors (Diesel) MDVN RangeRotair spaNo ratings yet

- TWX1 Flyer ENUDocument2 pagesTWX1 Flyer ENUJoão Márcio JorgeNo ratings yet

- Techrite Controls Eclipse Eclipse RHT Indirect Air Heating Burner 1392Document2 pagesTechrite Controls Eclipse Eclipse RHT Indirect Air Heating Burner 1392Yasin YILDIZNo ratings yet

- New 2024 Hyundai N Vision 74Document2 pagesNew 2024 Hyundai N Vision 74luxury life wishesNo ratings yet

- Model Lp3: Installation and Service Instructions For Streamline™ Lp3 Strobe LightsDocument20 pagesModel Lp3: Installation and Service Instructions For Streamline™ Lp3 Strobe LightsRogers Hermann Olivares CuevaNo ratings yet