0% found this document useful (0 votes)

1K views13 pagesThumb Rule for Brickwork Calculation

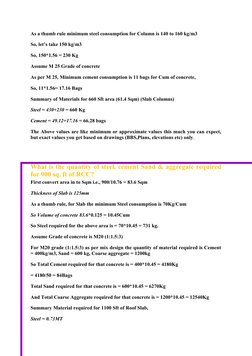

The document provides guidance on estimating quantities of materials needed for various concrete construction projects. It explains how to calculate the steel, cement, sand and aggregate required for slabs, beams, columns and other structural elements. Approximate quantities per cubic meter are given as thumb rules for different members like slabs needing 60-65 kg/m3 of steel on average.

Uploaded by

lokeshCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views13 pagesThumb Rule for Brickwork Calculation

The document provides guidance on estimating quantities of materials needed for various concrete construction projects. It explains how to calculate the steel, cement, sand and aggregate required for slabs, beams, columns and other structural elements. Approximate quantities per cubic meter are given as thumb rules for different members like slabs needing 60-65 kg/m3 of steel on average.

Uploaded by

lokeshCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

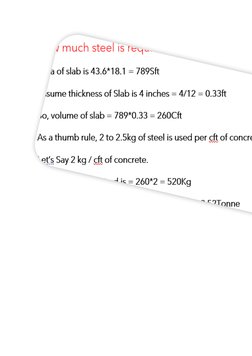

- Steel Requirements for Slabs

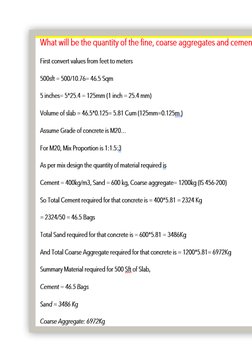

- Material Quantity Calculations

- Conversion and Estimation Techniques

- Steel and Aggregate Calculations for Roof Slabs

- Brick and Mortar Volume Calculations

- Cement Requirements for Plastering

- Cost Estimation for Concrete Slabs

- General Steel Requirements

- Shuttering and Formwork Details

- Concrete Volume Ratios

![For 1m2, Volume of Plaster required is [ 1*1*(12/1000)] = 0.012m3

(0.012 m3, which includes both cement and sand)

So

Cement r](https://screenshots.scribd.com/Scribd/252_100_85/356/718469347/8.jpeg)