Professional Documents

Culture Documents

Northern Airplane

Uploaded by

Đoàn Thị Quỳnh0 ratings0% found this document useful (0 votes)

6 views2 pagesCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesNorthern Airplane

Uploaded by

Đoàn Thị QuỳnhCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

A B C D E F G H I J K

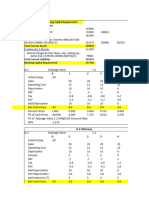

1 Northern Airplane Co. Production-Scheduling Problem

2

3 Production Cost Regular Storage Cost

4 ($millions) Time Overtime ($millions per month)

5 Month 1 1.08 1.10 0.015

6 Month 2 1.11 1.12

7 Month 3 1.10 1.11

8 Month 4 1.13 1.15

9

10

11 Unit Cost Month Installed

12 ($millions) 1 2 3 4

13 1 (RT) 1.08 1.10 1.11 1.13

14 1 (OT) 1.10 1.12 1.13 1.15

15 2 (RT) - 1.11 1.13 1.14

16 Month 2 (OT) - 1.12 1.14 1.15

17 Produced 3 (RT) - - 1.10 1.12

18 3 (OT) - - 1.11 1.13

19 4 (RT) - - - 1.13

20 4 (OT) - - - 1.15

21

22

23 Month Installed Maximum

24 Units Produced 1 2 3 4 Produced Production

25 1 (RT) 10 5 0 5 20 <= 20

26 1 (OT) 0 0 0 0 0 <= 10

27 2 (RT) 0 10 0 0 10 <= 30

28 Month 2 (OT) 0 0 0 0 0 <= 15

29 Produced 3 (RT) 0 0 25 0 25 <= 25

30 3 (OT) 0 0 0 10 10 <= 10

31 4 (RT) 0 0 0 5 5 <= 5

32 4 (OT) 0 0 0 0 0 <= 10

33 Installed 10 15 25 20

34 = = = = Total Cost

35 Scheduled Installations 10 15 25 20 ($millions)

36 77.4

L M N

1

2

3 Range Name Cells

4 Installed D33:G33

5 MaxProduction J25:J32

6 Produced H25:H32

7 ProductionCost D5:E8

8 ScheduledInstallationsD35:G35

9 StorageCost G5

10 TotalCost J36

11 UnitCost D13:G20

12 UnitsProduced D25:G32

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

You might also like

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- OM Part2Document6 pagesOM Part2KK PandeyNo ratings yet

- A Seminar On Earliest Dealine First Algorithm: Presented by Final Year Computer Science and EngineeringDocument16 pagesA Seminar On Earliest Dealine First Algorithm: Presented by Final Year Computer Science and Engineeringkaushal_bkscNo ratings yet

- EXCEL Modeli Upravljanja Troškovima - HP - XI - 2013Document16 pagesEXCEL Modeli Upravljanja Troškovima - HP - XI - 2013Ana MarkovićNo ratings yet

- Lbomgts Bip & NLPDocument6 pagesLbomgts Bip & NLPDenize Angela PinedaNo ratings yet

- Bandejas Sotano REV-JRVDocument10 pagesBandejas Sotano REV-JRVWallpaper TigerNo ratings yet

- 16 - LOB-Meeting A Deadline DurationDocument12 pages16 - LOB-Meeting A Deadline DurationMohammed QusayNo ratings yet

- A Novel Disk Scheduling Algorithm: Presented byDocument19 pagesA Novel Disk Scheduling Algorithm: Presented bykaushal_bkscNo ratings yet

- Revised Better ProductsDocument2 pagesRevised Better ProductsĐoàn Thị QuỳnhNo ratings yet

- Li - GENQEC Model For Stability Studies in PSSEDocument26 pagesLi - GENQEC Model For Stability Studies in PSSEpower systemNo ratings yet

- Orm CS MRPDocument12 pagesOrm CS MRPRahul DumawatNo ratings yet

- MTH 601 Assignment No 1Document3 pagesMTH 601 Assignment No 1umar altafNo ratings yet

- Study of D-SCAN Algorithm: A Seminar ONDocument31 pagesStudy of D-SCAN Algorithm: A Seminar ONkaushal_bkscNo ratings yet

- DCS IO Segregation R1.1Document3 pagesDCS IO Segregation R1.1Arnel MorenoNo ratings yet

- 7814 - 6 - Material Requirement PlanningDocument36 pages7814 - 6 - Material Requirement PlanningorbansaNo ratings yet

- Chapter 10 Discounted DividendDocument5 pagesChapter 10 Discounted Dividendmahnoor javaidNo ratings yet

- Estimate & Staffing ModelDocument278 pagesEstimate & Staffing ModelDipesh DayamaNo ratings yet

- Production Planning Control AssignmentDocument13 pagesProduction Planning Control AssignmentdpksobsNo ratings yet

- Week 6 Extra Problems SolutionDocument7 pagesWeek 6 Extra Problems SolutionAbby HactherNo ratings yet

- MGT 3121 Chapter 16Document6 pagesMGT 3121 Chapter 16AmandaNo ratings yet

- StaticDocument3 pagesStaticnarendra29000No ratings yet

- Chan. EBTM3103 20200220Document7 pagesChan. EBTM3103 20200220Meha RajNo ratings yet

- Analyst Presentation June10Document30 pagesAnalyst Presentation June10Ubaid Muneer RajaNo ratings yet

- Enoncé Gps D MRP CBNDocument27 pagesEnoncé Gps D MRP CBNFerchichi HatemNo ratings yet

- Etabs ModelingDocument39 pagesEtabs ModelingHemal Mistry100% (10)

- Grocery GatewayDocument5 pagesGrocery GatewayPiyush SharmaNo ratings yet

- Running Head: Inventory Management: Inventory Management Student's Name Professor's Name Course Title Institution DateDocument5 pagesRunning Head: Inventory Management: Inventory Management Student's Name Professor's Name Course Title Institution DateHw SolutionNo ratings yet

- 3.2 Time Value of Money Inflation EscalationDocument10 pages3.2 Time Value of Money Inflation EscalationPrime ShineNo ratings yet

- Steel Manufacturing: Group Number - 10Document16 pagesSteel Manufacturing: Group Number - 10Somya ShrivastavaNo ratings yet

- DLF Announces Annual Results For FY10: HistoryDocument7 pagesDLF Announces Annual Results For FY10: HistoryShalinee SinghNo ratings yet

- CF TTR Quiz-1 SolutionDocument5 pagesCF TTR Quiz-1 SolutionNitesh BurnwalNo ratings yet

- Master of Commerce Term-End Examination December, 2019: No. of Printed Pages: 12Document12 pagesMaster of Commerce Term-End Examination December, 2019: No. of Printed Pages: 12Rohit GhuseNo ratings yet

- 1000 2000 Full Result 20230227Document19 pages1000 2000 Full Result 20230227Contra Value BetsNo ratings yet

- P - Scan: A Seminar OnDocument16 pagesP - Scan: A Seminar Onkaushal_bkscNo ratings yet

- RTS Unit 2 NotesDocument9 pagesRTS Unit 2 NotesSAROJ RAJANo ratings yet

- Perlakuan Ulangan 1 2 3 4 5 6Document7 pagesPerlakuan Ulangan 1 2 3 4 5 6Lalu awang AwangNo ratings yet

- Manea Elena Valeria Grupa 8301-A: Tot TotDocument2 pagesManea Elena Valeria Grupa 8301-A: Tot TotelisabetaNo ratings yet

- Lab 1Document2 pagesLab 1elisabetaNo ratings yet

- Tugas Pertemuan 7 - Gasal 23-24Document5 pagesTugas Pertemuan 7 - Gasal 23-24Feri Adi SaputraNo ratings yet

- Chapter 10 - Profitability AnalysisDocument41 pagesChapter 10 - Profitability AnalysisSyafiq IzzuddinNo ratings yet

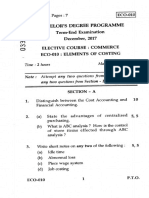

- Bachelor'S Degree Programme Term-End Examination December, 2017 C'R) CD Elective Course: Commerce Eco-010: Elements of CostingDocument7 pagesBachelor'S Degree Programme Term-End Examination December, 2017 C'R) CD Elective Course: Commerce Eco-010: Elements of CostingUjjval TrivediNo ratings yet

- CM P RepetitiveDocument12 pagesCM P RepetitiveAhmedNo ratings yet

- CAPCOST ProjectDocument16 pagesCAPCOST ProjectJonathanNo ratings yet

- Review Guide W/ Tables For Depreciation & TaxesDocument29 pagesReview Guide W/ Tables For Depreciation & Taxesjer7313No ratings yet

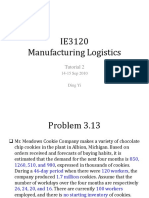

- IE3120 Manufacturing Logistics: Tutorial 2Document27 pagesIE3120 Manufacturing Logistics: Tutorial 2Joli SmithNo ratings yet

- Contoh Perhitungan Data Uji Sondir: Kedalaman 2,0 M R 25 KG/CM R 16 KG/CM QC R 25 KG/CM 0,4 KG/CMDocument8 pagesContoh Perhitungan Data Uji Sondir: Kedalaman 2,0 M R 25 KG/CM R 16 KG/CM QC R 25 KG/CM 0,4 KG/CMYoga PriyantNo ratings yet

- Mem671 Individual Assignment August 2023Document12 pagesMem671 Individual Assignment August 2023AIMAN ASYRAAF BIN ROSLANNo ratings yet

- Part 2 Homework AssignmentDocument6 pagesPart 2 Homework AssignmentGene Mark MillerNo ratings yet

- PERTDocument7 pagesPERTPrajaktaNo ratings yet

- Monthly & Annual Activities Plan (Estimate)Document2 pagesMonthly & Annual Activities Plan (Estimate)Mohammad IsraNo ratings yet

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument19 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsBIJAY KRISHNA DASNo ratings yet

- FN-230615-TWP Function SettingDocument6 pagesFN-230615-TWP Function SettingОлег ЕфимовNo ratings yet

- Enclosure Heat DissipationDocument4 pagesEnclosure Heat DissipationBlessingNo ratings yet

- Example On CPM and PERTDocument8 pagesExample On CPM and PERTGelantuNo ratings yet

- Capcost 2012Document15 pagesCapcost 2012Amanda Araujo RamosNo ratings yet

- Mpcproblems Institute of TechnologyDocument39 pagesMpcproblems Institute of TechnologyvundavilliravindraNo ratings yet

- NTN CVJDocument42 pagesNTN CVJLorena BakerNo ratings yet

- Multicore DSP: From Algorithms to Real-time Implementation on the TMS320C66x SoCFrom EverandMulticore DSP: From Algorithms to Real-time Implementation on the TMS320C66x SoCNo ratings yet

- Better ProductsDocument2 pagesBetter ProductsĐoàn Thị QuỳnhNo ratings yet

- P&T Co. Distribution Problem: Unit CostDocument2 pagesP&T Co. Distribution Problem: Unit CostĐoàn Thị QuỳnhNo ratings yet

- Revised Better ProductsDocument2 pagesRevised Better ProductsĐoàn Thị QuỳnhNo ratings yet

- MetroDocument2 pagesMetroĐoàn Thị QuỳnhNo ratings yet

- MiddletownDocument2 pagesMiddletownĐoàn Thị QuỳnhNo ratings yet

- NiftyDocument2 pagesNiftyĐoàn Thị QuỳnhNo ratings yet

- IFM - Chapter 6Document36 pagesIFM - Chapter 6Đoàn Thị QuỳnhNo ratings yet