Professional Documents

Culture Documents

Inspection and Test Plan Sanitary İnstallation Works

Uploaded by

Habib BagciCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection and Test Plan Sanitary İnstallation Works

Uploaded by

Habib BagciCopyright:

Available Formats

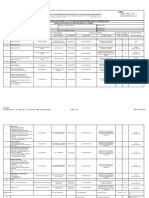

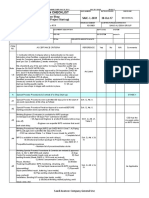

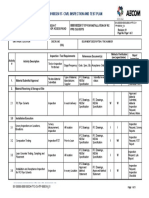

HUNGARY GLASS PACKAGING FACTORY INVESTMENT SANİTARY İNSTALLATİON

WORKS

Scope Sanitary İnstallation Works Document no HSCM-QC-ITP-013

BOQ no 14.03.000.0000 Inspection and Test Plan for Sanitary İnstallation Works Revision 00

ITP No ITP-004 Submittal Date

Control Category

Activity Inspection

Description Inspection Method References Acceptance Criteria

no Frequency Sub- Project

Contractor Employer

Contractor Director

1 MATERIALS

1.1 Control of pipes and insulation products to be used. 100% H Certificate Check Material Submittal,Project Specification Material Submittal,Project Specification

1.2 Pipe Fitting Equipment (Bolt, DObel, Rod, Profile, Clip). 100% H Certificate Check Material Submittal,Project Specification Material Submittal,Project Specification

1.3 Sanitary Equipment (Drainer, Closet, Armature, Accessories,Pump,Water tank). 100% H Certificate Check Material Submittal,Project Specification Material Submittal,Project Specification

2 INSTALLATİON

2.1 Pipe Installation as per approved drawings. 100% W Visual Check-Drawings Check Approved Drawing,DIN Standards Approved Drawing,DIN Standards

2.2 Valve and Accessory Assembly Control. 100% W Visual Check-Drawings Check Approved Drawing,DIN Standards Approved Drawing,DIN Standards

2.3 Hangers and support installation support spacing,ducting route,reinforcement & hangers. 100% Visual Check-Drawings Check DIN Standards,Project specification,Approved DIN Standards,,Project

W Drawing,MOS specification,Approved Drawing,MOS

2.4 In-wall pipe installation control. 100% W Visual Check-Drawings Check DIN Standards,Project specification,MOS DIN Standards,,Project specification,MOS

2.5 Control of in-wall equipment installation. 100% W Visual Check-Drawings Check DIN Standards,Project specification,MOS DIN Standards,,Project specification,MOS

2.6 PVC pipe slope control. 100% Visual Check-Drawings Check DIN Standards,Project specification,Approved DIN Standards,,Project

W Drawing,MOS specification,Approved Drawing,MOS

2.7 Pipe insulation installation as per drawing,check the insulation band spacing as per drawing. 100% W Visual Check-Drawings Check DIN Standards,Project specification,MOS DIN Standards,,Project specification,MOS

3 EQUIPMENT INSTALLATİON

3.1 Equipment Foundation Location Check as per Approved Drawing. 100% H Survey check-Drawings Check Approved Drawing,Project specification Approved Drawing,Project specification

3.2 Sanitary Equipment (Drainer, Closet, Armature, Accessories,Pump,Water tank) Check as per Approved Drawing. 100% W Visual Check-Drawings Check Approved Drawing,Project specification Approved Drawing,Project specification

3.3 Verify unit Installation is as per approved Drawing, Check Vibration pad Place Beneath the Package Equipment installation. 100% W Visual Check-Drawings Check Approved Drawing,Project specification Approved Drawing,Project specification

4 FINAL INSPECTION

4.1 Calibration of test equipment. 100% H Document Review Accredited Firm / Site Verification As Per Report

4.2 PVC pipe fullness test. 100% W Visual Check-Drawings Check Approved Drawing,Project specification,MOS Approved Drawing,Project

specification,MOS

4.3 PPRC ande Galvanize pipe check for leak test for pipe installation. 100% W Visual Check,Sealing Check Approved Drawing,Project specification,MOS Approved Drawing,Project

specification,MOS

4.4 Control of Tightness Tests of Pipes (Hydrostatic Test, 1.5 times the operating pressure 24 hours). 100% W Visual Check,Sealing Check Approved Drawing,Project specification Approved Drawing,Project specification

4.5 Insulation Control of Test Completed Pipes. 100% H Form Check,Visual Check Approved Drawing,Project specification Approved Drawing,Project specification

Preparared by Reviewed by Approved by

H= Hold Point

W= Witness point

S= Surveillance Point

T= Test point

R= Review of Records

_x000D_ Bu dokümanda HASSAS bilgi bulunmamaktadır. / This document does not contain SENSITIVE information.

#

You might also like

- AAMA WDMA CSA 101 I S 2 A440 11 (Standard Specification For Windows, Doors and Skylights)Document8 pagesAAMA WDMA CSA 101 I S 2 A440 11 (Standard Specification For Windows, Doors and Skylights)siddique27No ratings yet

- KON 8.2 QA PRO 0020 C1 Welding Control ProcedureDocument15 pagesKON 8.2 QA PRO 0020 C1 Welding Control ProcedureAlizamin Salmanov100% (1)

- Itp - Refrigerant Pipe & Ac Split InstallationDocument9 pagesItp - Refrigerant Pipe & Ac Split InstallationGultom Juliana LiliesNo ratings yet

- Diy Tiling GuideDocument6 pagesDiy Tiling GuidenextreaderNo ratings yet

- KON 8.2 QA PRO 0024 C1 Certification ProcedureDocument8 pagesKON 8.2 QA PRO 0024 C1 Certification ProcedureAlizamin SalmanovNo ratings yet

- 1.SRO-QPITP - Mechanical WorksDocument2 pages1.SRO-QPITP - Mechanical Worksachusanachu100% (1)

- ITP - Conduit Metal (GI) & PVC InstallationDocument5 pagesITP - Conduit Metal (GI) & PVC InstallationGultom Juliana LiliesNo ratings yet

- ASME B31.1 QuestionsDocument13 pagesASME B31.1 Questionsabdo50% (2)

- Qa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Document3 pagesQa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Ali Haider100% (1)

- Reference Document. Inspection / Testing Frequency Testing Requirement/ Surveillance Points Disc Oneic AawDocument3 pagesReference Document. Inspection / Testing Frequency Testing Requirement/ Surveillance Points Disc Oneic AawPresanna Rajasekaran100% (2)

- ITP & Checklist FOR Excavation & Backfilling and CompactionDocument7 pagesITP & Checklist FOR Excavation & Backfilling and CompactionAmran Hossain100% (4)

- Inspection and Test Plan 2Document3 pagesInspection and Test Plan 2EdNo ratings yet

- Inspection and Test Plan: Cement Stucco (Exterior Plastering)Document3 pagesInspection and Test Plan: Cement Stucco (Exterior Plastering)Alvene TagocNo ratings yet

- Itp For SanitaryDocument4 pagesItp For SanitaryDebesh Chaudhary100% (1)

- Al Qunfudah New City Feeder Water Transmssion SystemDocument9 pagesAl Qunfudah New City Feeder Water Transmssion SystemLouis Clark100% (1)

- ITP For Plumbing & Drainage SystemDocument97 pagesITP For Plumbing & Drainage Systemmagdi badran100% (7)

- Tins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)Document4 pagesTins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)achusanachuNo ratings yet

- Attach-1 ITP For Belt Conveyor InstallationDocument7 pagesAttach-1 ITP For Belt Conveyor InstallationSukalyan BasuNo ratings yet

- Design Manual For Roads and BridgesDocument60 pagesDesign Manual For Roads and BridgesIon PusculitaNo ratings yet

- Inspection & Test PlanDocument1 pageInspection & Test PlanRonNo ratings yet

- M Storm Drainage System IC M SDS 00Document2 pagesM Storm Drainage System IC M SDS 00achusanachuNo ratings yet

- Erection Procedure For Preacast Pipe Rack (HGU-EPCC-06) 2 ReveivewedDocument15 pagesErection Procedure For Preacast Pipe Rack (HGU-EPCC-06) 2 Reveivewedpawankumar100% (2)

- Itp Installation of FcuDocument4 pagesItp Installation of FcuAkmaldeen AhamedNo ratings yet

- IQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFDocument11 pagesIQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFAli MajeedNo ratings yet

- Itp For Piping QPDocument4 pagesItp For Piping QPRejoy baby100% (2)

- Construction Procedures and Internal Quality ControlDocument17 pagesConstruction Procedures and Internal Quality ControlbienndcNo ratings yet

- SA04C2-00-WG-I-00111-A - ITP Steel Structure - ErectionDocument4 pagesSA04C2-00-WG-I-00111-A - ITP Steel Structure - ErectionABAID ULLAHNo ratings yet

- Inspection and Test Plan: Tile WorksDocument2 pagesInspection and Test Plan: Tile WorksAlvene Tagoc100% (2)

- ITP Ducting Work Include Insulation Work (Rev.3)Document9 pagesITP Ducting Work Include Insulation Work (Rev.3)Researcher100% (2)

- Specification Shinso PileDocument1 pageSpecification Shinso PileAjay Kumar Sinha80% (5)

- ITP - Blockwork R0 - HKHDocument2 pagesITP - Blockwork R0 - HKHabdou89% (9)

- ITP - 031 (Earthing)Document2 pagesITP - 031 (Earthing)mohamed wahebNo ratings yet

- Forte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationDocument2 pagesForte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationfrancisbautistaNo ratings yet

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Itp For Plumbing Amp Drainage SystemDocument98 pagesItp For Plumbing Amp Drainage Systemtristan guarinoNo ratings yet

- Inspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Document3 pagesInspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Researcher0% (1)

- ITP Check List HVAC Piping WorksDocument5 pagesITP Check List HVAC Piping WorksResearcherNo ratings yet

- S-000-1676-0001V - 11 - ITP For Piping WorkDocument47 pagesS-000-1676-0001V - 11 - ITP For Piping WorkVO DINH TRI100% (2)

- Method Statement For The Installation of Power and Lighting System WiringDocument4 pagesMethod Statement For The Installation of Power and Lighting System Wiringsamsunglover0% (1)

- Process Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesFrom EverandProcess Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesKatherine A. BakeevNo ratings yet

- Low Cost HousingDocument15 pagesLow Cost HousingIPSITA SWAINNo ratings yet

- X6 Structural Steel Erection Inspection Test PlanDocument11 pagesX6 Structural Steel Erection Inspection Test PlanNoor A Qasim100% (1)

- Inspection and Test Plan Heating and Cooling Installation WorksDocument1 pageInspection and Test Plan Heating and Cooling Installation WorksHabib BagciNo ratings yet

- Inspection and Test Plan Fire Installation WorksDocument1 pageInspection and Test Plan Fire Installation WorksHabib BagciNo ratings yet

- Inspection and Test Plan Ventılatıon Installatıon Works 21 MarchDocument1 pageInspection and Test Plan Ventılatıon Installatıon Works 21 MarchHabib BagciNo ratings yet

- ITP - 028 (Lighting Fixtures)Document2 pagesITP - 028 (Lighting Fixtures)mohamed wahebNo ratings yet

- Itp - 029 (CCTV)Document2 pagesItp - 029 (CCTV)mohamed wahebNo ratings yet

- ITP - 030 (Fire Alarm)Document4 pagesITP - 030 (Fire Alarm)mohamed wahebNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- Inspection and Test Plan 2 PDF FreeDocument3 pagesInspection and Test Plan 2 PDF FreeaefNo ratings yet

- ITP Ducting Work Include Insulation Work (Rev.3)Document9 pagesITP Ducting Work Include Insulation Work (Rev.3)ResearcherNo ratings yet

- HSCM-BRL-ITP-004 Sanitary İnstallation WorksDocument1 pageHSCM-BRL-ITP-004 Sanitary İnstallation WorksHabib BagciNo ratings yet

- Method Statement For Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMethod Statement For Installation of Electric PVC Conduits and AccessoriessamsungloverNo ratings yet

- Curriculum Vitae: 9789115962 Ramesh - gr87Document5 pagesCurriculum Vitae: 9789115962 Ramesh - gr87Amul PontingNo ratings yet

- ITP - Installation of Chilled Water PipesDocument2 pagesITP - Installation of Chilled Water Pipessheik.rasith.anvarNo ratings yet

- Inspection 4 Industry LLC: GeneralDocument31 pagesInspection 4 Industry LLC: GeneralKaliya PerumalNo ratings yet

- Project Quality Plan (ITP)Document2 pagesProject Quality Plan (ITP)SuresharNo ratings yet

- Saudi Aramco Typical Inspection Plan: Powered In-Plant Communication Systems SATIP-T-481-01 30-Oct-17 TelecommunicationsDocument12 pagesSaudi Aramco Typical Inspection Plan: Powered In-Plant Communication Systems SATIP-T-481-01 30-Oct-17 TelecommunicationsAsif ShareefNo ratings yet

- Application of Proprietary Cementitious Fireproofing Minimum Requirement ITP Template - Rev 001Document6 pagesApplication of Proprietary Cementitious Fireproofing Minimum Requirement ITP Template - Rev 001Adam FarhanNo ratings yet

- Itp-22!11!1 Rev.0 en 10219-Bare Pipe Somatm SaDocument12 pagesItp-22!11!1 Rev.0 en 10219-Bare Pipe Somatm Samahmut gelNo ratings yet

- Saic L 2031Document25 pagesSaic L 2031Mohamed ThasimNo ratings yet

- Site Acceptance Testing (S.A.T) : Quality Control DepartmentDocument2 pagesSite Acceptance Testing (S.A.T) : Quality Control Departmentefmartin21No ratings yet

- 0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxDocument1 page0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxMeshaal ALBalharithNo ratings yet

- Sarfaraz Khan CV SubmissionDocument4 pagesSarfaraz Khan CV SubmissionSarfaraz khanNo ratings yet

- Door & WindowDocument1 pageDoor & WindowAMIT KUMARNo ratings yet

- Diamond Star White TdsDocument3 pagesDiamond Star White TdsManoj DoshiNo ratings yet

- Molly Maid ChecklistDocument1 pageMolly Maid ChecklistYessNo ratings yet

- Module 1 - Civil Engineering Disciplines and Building ScienceDocument30 pagesModule 1 - Civil Engineering Disciplines and Building SciencePavan KumarNo ratings yet

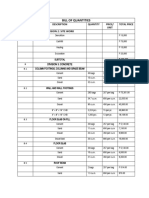

- Bill of Quantities: Division 2: Site WorkDocument2 pagesBill of Quantities: Division 2: Site WorkCristine ArponNo ratings yet

- Summarize Notes Rule 9 - 20Document12 pagesSummarize Notes Rule 9 - 20John Carlo LosolosoNo ratings yet

- G81-Design and Planning Rev 0.5Document25 pagesG81-Design and Planning Rev 0.5radulescuandrei100No ratings yet

- Masterflow 150 v1Document2 pagesMasterflow 150 v1vinayNo ratings yet

- Merritt Morning Market 3925 - Feb 14Document2 pagesMerritt Morning Market 3925 - Feb 14Kim LeclairNo ratings yet

- Investor: Municipality of Devoll, Undp Object: Multifunctional Social Centre - Bilisht, Devoll Works Cost EstimateDocument6 pagesInvestor: Municipality of Devoll, Undp Object: Multifunctional Social Centre - Bilisht, Devoll Works Cost EstimateGezim GezimNo ratings yet

- Climate Responsive School at RautahatDocument10 pagesClimate Responsive School at Rautahatkalpit chaulagainNo ratings yet

- Criteria and Technologies For The Structural Repair and Strengthening of Architectural HeritageDocument17 pagesCriteria and Technologies For The Structural Repair and Strengthening of Architectural HeritageScribd2015No ratings yet

- Masterseal NP 472 TdsDocument2 pagesMasterseal NP 472 TdsŠhehabAlŠhǻrnobiNo ratings yet

- Thesis Final - JYOTI KANDELDocument49 pagesThesis Final - JYOTI KANDELAbhishek AcharyaNo ratings yet

- Earthquake Safety MeasuresDocument37 pagesEarthquake Safety MeasuresJohn Robert GabrielNo ratings yet

- Grinding MachinesDocument74 pagesGrinding MachinesRandy EsoleNo ratings yet

- Xperion Aerospace GMBH: Continuous Compression Moulding MachineDocument25 pagesXperion Aerospace GMBH: Continuous Compression Moulding MachinefaradaiNo ratings yet

- Tunis Village & UttarkashiDocument22 pagesTunis Village & Uttarkashiyxb6tnwgcwNo ratings yet

- Speckled BandDocument14 pagesSpeckled BandSushil1998No ratings yet

- Competency-Based Learning MaterialDocument49 pagesCompetency-Based Learning MaterialClaire CabactulanNo ratings yet

- Architect Drawing Titiwangsa ModelDocument1 pageArchitect Drawing Titiwangsa ModelAin NasirNo ratings yet

- 1.0 Abstract: Cultural Influences of Baba-Nyonya On Eclectic Style ShophouseDocument18 pages1.0 Abstract: Cultural Influences of Baba-Nyonya On Eclectic Style ShophouseArcade PlayerNo ratings yet

- Hardware Auto & Machinery May22Document86 pagesHardware Auto & Machinery May22Gustavo BritoNo ratings yet