Professional Documents

Culture Documents

Mathcad - LAS BALOK KE KOLOM KUDA DEPAN WF150.75 - ENDPLATE GUDANG

Uploaded by

Andre NovanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathcad - LAS BALOK KE KOLOM KUDA DEPAN WF150.75 - ENDPLATE GUDANG

Uploaded by

Andre NovanCopyright:

Available Formats

Disian Las EP Kuda kuda Miring Disain Pergudangan

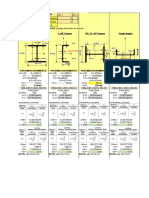

SAMBUNGAN LAS END PLATE BALOK KE KOLOM K.2

KUDA-KUDA KECIL DEPAN WF 150.75.5.7 SEGMEN GUDANG

Beban berfaktor Dari Analisa Struktur : Vu = 3.68kN M u = 5.28kN m Pu = 3.63kN

Sudut kemiringan Balok Kuda-kuda : αk = 14deg

Gaya Geser tambahan dari aksial : Vuad = Pu sin( αk) = 0.87818 kN

Disain Las Balok- End Plate :

Las yang digunakan SMAW E70XX

1

Mutu Flas = 400MPa

2

Las :

bwf = 75mm hwf = 275mm hwf1 = 155mm hwf2 = 120mm

3

tw = 5mm tf = 7mm

4

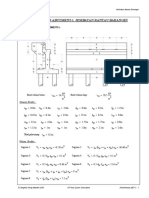

Mencari Titik Berat

Las :

5

Luas Penampang segmen las :

Alas2 = ( b wf - tw) 1 mm = 70 mm

2 2

6 Alas1 = bwf 1 mm = 75 mm

7

Alas3 = 2 ( hwf1 - 2tf ) 1 mm = 282 mm

2

8

Alas4 = ( b wf - tw) 1 mm = 70 mm

2

Alas5 = ( b wf - tw) 1 mm = 70 mm Alas6 = 2 ( hwf2 - tf ) 1 mm = 226 mm

2 2

Alas7 = ( b wf - tw) 1 mm = 70 mm

2 2

Alas8 = bwf 1 mm = 75 mm

Titik Berat individual segmen Las Terhadap Sisi Bawah Penampang sambungan :

ylas1 = 0.5mm + h wf + 1mm = 276.5 mm ylas2 = h wf - tf - 0.5mm + 1mm = 268.5 mm

h wf1 - tf

ylas3 = + h wf2 + 1mm = 195 mm ylas4 = 0.5mm + h wf2 + 1mm = 121.5 mm

2

h wf2 - tf

ylas5 = h wf2 - tf - 0.5mm + 1mm = 113.5 mm ylas6 = + 1mm = 57.5 mm

2

ylas7 = 0.5mm + tf + 1mm = 8.5 mm ylas8 = 0.5mm

Titik berat konfigurasi las gabungan :

ΣYA = ylas1 Alas1 + ylas2 Alas2 + ylas3 Alas3 + ylas4 Alas4 + ylas5 Alas5 + ylas6 Alas6 + ylas7 Alas7 + ylas8 Alas8

ΣA = Alas1 + Alas2 + Alas3 + Alas4 + Alas5 + Alas6 + Alas7 + Alas8

PT PPLI Area CMFT Arak Duri Las EP - Balok Ke Kolom K.2- 1

Disian Las EP Kuda kuda Miring Disain Pergudangan

ΣYA

Ycgblas = = 132.83582 mm

ΣA Ycgalas = ( h wf + 1mm + 1mm) - Ycgblas = 144.16418 mm

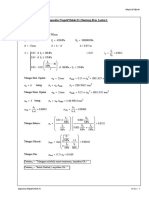

Inersia las :

1

b wf ( 1mm) + 1mm b wf ( ylas1 - Ycgblas ) = 1547960.97683 mm

3 2 4

Ix1 =

12

1 bwf tw bwf tw 2

- ( ylas2 - Ycgblas) 2 = 1288339.69778 mm

3 4

Ix2 = - ( 1mm) + 1mm

12 2 2 2 2

1 3

h wf h wf 2

- 2 tf ( ylas3 - Ycgblas ) 2 = 1268445.28128 mm

4

Ix3 = 1 mm - 2 tf + 1mm

12 2 2

1 bwf tw bwf tw 2

- ( ylas4 - Ycgblas) 2 = 9000.89181 mm

3 4

Ix4 = - ( 1mm) + 1mm

12 2 2 2 2

1 bwf tw bwf tw 2

- ( ylas5 - Ycgblas) 2 = 26177.01121 mm

3 4

Ix5 = - ( 1mm) + 1mm

12 2 2 2 2

1 h wf

3

h wf

Ix6 = 1 mm - 2 tf + 1mm

2

- 2 tf ( ylas6 - Ycgblas ) 2 = 1715787.1656 mm

4

12 2 2

1 bwf tw bwf tw 2

- ( ylas7 - Ycgblas) 2 = 1082163.57838 mm

3 4

Ix7 = - ( 1mm) + 1mm

12 2 2 2 2

1

b wf ( 1mm) + 1mm b wf ( ylas8 - Ycgblas ) = 1313463.96191 mm

3 2 4

Ix8 =

12

4

Ixtot = Ix1 + Ix2 + Ix3 + Ix4 + Ix5 + Ix6 + Ix7 + Ix8 = 8251338.5648 mm

Panjang Total las :

Llas = 2 b wf + 4 ( b wf - tw) + ( h wf - 3 tf ) = 684 mm

Gaya geser arah Y akibat Vp :

Vu + Vuad N

Ply = = 6.664

Llas mm

Gaya geser di titik sudut A akibat beban Mp :

1 mm M u Ycgalas N

Plz = = 92.25011

Ixtot mm

PT PPLI Area CMFT Arak Duri Las EP - Balok Ke Kolom K.2- 2

Disian Las EP Kuda kuda Miring Disain Pergudangan

Gaya geser gabungan akibat Vp dan Mp :

2 2 N

Ptot = Ply + Plz = 92.49049

mm

Tebal las yang dibutuhkan :

Ptot

tlas = = 0.72678 mm

0.75 0.707 0.6 Flas

Tebal maximum : tlasmax = tw if tw 6mm = 5 mm

tw - 1.6mm otherwise

Tebal minimum tlasmin = 3mm if tw 6mm = 3 mm

5mm if tw > 6mm tw 13mm

6mm if tw > 13mm tw 19mm

8mm otherwise

Tebal Las yang memenuhi Kriteria Disain : tlasd = tlasmin if tlas < tlasmin = 3 mm

tlasmax if tlas > tlasmax

tlas otherwise

Pakai las dengan tebal 5mm

PT PPLI Area CMFT Arak Duri Las EP - Balok Ke Kolom K.2- 3

You might also like

- Mathcad - Las Balok Kuda Ke Kolom - Endplate GudangDocument3 pagesMathcad - Las Balok Kuda Ke Kolom - Endplate GudangAndre NovanNo ratings yet

- Mathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-2Document3 pagesMathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-2Andre NovanNo ratings yet

- Mathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-1Document3 pagesMathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-1Andre NovanNo ratings yet

- Mathcad - LAS BALOK INDUK MEMANJANG - ENDPLATE KANTOR LT-1Document3 pagesMathcad - LAS BALOK INDUK MEMANJANG - ENDPLATE KANTOR LT-1Andre NovanNo ratings yet

- Mathcad - DISAIN STRINGER BEAM RANTAU SBG BALOK LENTURDocument4 pagesMathcad - DISAIN STRINGER BEAM RANTAU SBG BALOK LENTURAndre NovanNo ratings yet

- 52 Mathcad - BTG TENS TB9Document5 pages52 Mathcad - BTG TENS TB9Andre NovanNo ratings yet

- 11 Mathcad - BTG TENS BCM 01Document5 pages11 Mathcad - BTG TENS BCM 01Andre NovanNo ratings yet

- Desain Batang Lentur (GP) : Elemen No. 379Document2 pagesDesain Batang Lentur (GP) : Elemen No. 379Refo AdityansyahNo ratings yet

- 08 Mathcad - DISAIN CROSS BEAM RANTAU SBG BALOK LENTURDocument4 pages08 Mathcad - DISAIN CROSS BEAM RANTAU SBG BALOK LENTURAndre NovanNo ratings yet

- 2 Side Beam To Column Connection Fin Plate Minor AxesDocument1 page2 Side Beam To Column Connection Fin Plate Minor Axessamon.itc2019No ratings yet

- 5 Metros MarceloDocument2 pages5 Metros Marcelomarcelo galarzaNo ratings yet

- Doubly Reinforced BeamDocument2 pagesDoubly Reinforced BeamG.DhanabalNo ratings yet

- Proiect Normativ P 118 1 Iunie 2016Document15 pagesProiect Normativ P 118 1 Iunie 2016Mihai AndreiasNo ratings yet

- Mathcad - Main Beam Design Opening2Document2 pagesMathcad - Main Beam Design Opening2mrnaeem76No ratings yet

- 3 1Document3 pages3 1Mark Arvin VelascoNo ratings yet

- Slab Manual CalculationDocument9 pagesSlab Manual CalculationArchana PoudelNo ratings yet

- 148841505-Verificare-StalpDocument50 pages148841505-Verificare-StalpkrmeenNo ratings yet

- Design of Beam To Column SpliceDocument1 pageDesign of Beam To Column SpliceAndro RebuyasNo ratings yet

- Bab 5 Perhitungan Balok BK2Document2 pagesBab 5 Perhitungan Balok BK2DickyArdianFelsaputraNo ratings yet

- Metal Heb 260Document3 pagesMetal Heb 260Ionela BaiesNo ratings yet

- Perhitungan Sambungan End Plate Terhadap Mini Kolom Dan Balok A. Data-DataDocument51 pagesPerhitungan Sambungan End Plate Terhadap Mini Kolom Dan Balok A. Data-DataAchmad Zaki ZulkarnainNo ratings yet

- GivenDocument4 pagesGivenMark Arvin VelascoNo ratings yet

- Bab 5 Perhitungan Balok BK1Document2 pagesBab 5 Perhitungan Balok BK1DickyArdianFelsaputraNo ratings yet

- As' Balok: Tul. Longitudinal Tul. SengkangDocument7 pagesAs' Balok: Tul. Longitudinal Tul. SengkangriandiNo ratings yet

- Shear Connection EC3Document15 pagesShear Connection EC3lucianduNo ratings yet

- Laterally UN-supported BeamDocument3 pagesLaterally UN-supported Beamhema kumarNo ratings yet

- Hasil Perhitungan Struktur Gudang Suzuki R 2Document57 pagesHasil Perhitungan Struktur Gudang Suzuki R 2SUKA SENIMANNo ratings yet

- PropertY Calculation 75CS40X10X1.2Document15 pagesPropertY Calculation 75CS40X10X1.2kingsuk1980No ratings yet

- EC3 - Fin Plate Connection Design ChecksDocument5 pagesEC3 - Fin Plate Connection Design Checkssuman_civilNo ratings yet

- Bridge Design v1 enDocument98 pagesBridge Design v1 enDjunedNo ratings yet

- TBeam To ACI318Document1 pageTBeam To ACI318dianfeng.envistaNo ratings yet

- Verify ASTM A992 W12 × 30Document29 pagesVerify ASTM A992 W12 × 30qgfytzvqabzqrxyilmNo ratings yet

- Verify ASTM A992 W12 × 30Document28 pagesVerify ASTM A992 W12 × 30ankhbayar batkhuuNo ratings yet

- H Beam Load Bearing CalculationDocument31 pagesH Beam Load Bearing CalculationMuhammad Attiq Ur RahmanNo ratings yet

- Beam To Col WebDocument10 pagesBeam To Col WebAlma M. LaraNo ratings yet

- Mathcad - KOLOM WF300.150.5.8Document8 pagesMathcad - KOLOM WF300.150.5.8Andre NovanNo ratings yet

- Perhitungan Sambungan Baut Profil SikuDocument12 pagesPerhitungan Sambungan Baut Profil Sikuberangketr100% (1)

- Elastic Lateral Torsional BucklingDocument3 pagesElastic Lateral Torsional BucklingRuchit ParmarNo ratings yet

- Design of Steel I-Section (BS5950)Document3 pagesDesign of Steel I-Section (BS5950)gertjaniNo ratings yet

- Design of PurlinsDocument8 pagesDesign of PurlinsLa BeamNo ratings yet

- Spacing of Bolts in Built-Up BeamsDocument7 pagesSpacing of Bolts in Built-Up BeamsDAN MARK OPONDANo ratings yet

- Minimum Thickness of Two Way SlabDocument3 pagesMinimum Thickness of Two Way SlabWinston AdvinculaNo ratings yet

- D. Disain Tumpuan Base Plate Dan Angkur: Gaya Dalam Maksimum, Nu 171.39 KN, Vu 7.94 KN, Mu 1.753 KNM X MDocument2 pagesD. Disain Tumpuan Base Plate Dan Angkur: Gaya Dalam Maksimum, Nu 171.39 KN, Vu 7.94 KN, Mu 1.753 KNM X MMudiyaNo ratings yet

- Design of Connection (Rb2 With Column)Document14 pagesDesign of Connection (Rb2 With Column)adil_khan648No ratings yet

- 2B1.Connection Design (SH400)Document4 pages2B1.Connection Design (SH400)Agnes FerinnaNo ratings yet

- Baja UTS IrmaDocument69 pagesBaja UTS IrmaArjuna CrewNo ratings yet

- Design of Corbel - Workshop Cum Office BuildingDocument2 pagesDesign of Corbel - Workshop Cum Office BuildingMuhammad HasanNo ratings yet

- Bird Mesh Frame Main Beam Local Capacity CheckDocument7 pagesBird Mesh Frame Main Beam Local Capacity CheckChandru MohanNo ratings yet

- Moment Cap (With Initial Strain)Document15 pagesMoment Cap (With Initial Strain)Chong Wee LinNo ratings yet

- Steeltek ConnectionDocument5 pagesSteeltek ConnectioncadsultanNo ratings yet

- Bolted Splice DesignDocument8 pagesBolted Splice DesignAnonymous sfkedkymNo ratings yet

- Mathcad - Bab 9 Balok B1 25X50Document4 pagesMathcad - Bab 9 Balok B1 25X50Ananta Eka YudistiraNo ratings yet

- Mathcad - Bab 6 Balok BordesDocument2 pagesMathcad - Bab 6 Balok BordesAnanta Eka YudistiraNo ratings yet

- Verificare Grinda MetalicaDocument2 pagesVerificare Grinda MetalicaVirginia Elena IordacheNo ratings yet

- Base Plate - PenutupDocument15 pagesBase Plate - PenutupLaskharNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Pembatas BalokDocument1 pagePembatas BalokAndre NovanNo ratings yet

- Mathcad - ANALISA KAP SLOOF S2 BNIDocument14 pagesMathcad - ANALISA KAP SLOOF S2 BNIAndre NovanNo ratings yet

- Mathcad - BALOK ELEV 4 WF-200.100Document8 pagesMathcad - BALOK ELEV 4 WF-200.100Andre NovanNo ratings yet

- Mathcad - KOLOM WF300.150.5.8Document8 pagesMathcad - KOLOM WF300.150.5.8Andre NovanNo ratings yet

- Mathcad - SENGKANG SLOOF S-01 GUDANG CMTFDocument4 pagesMathcad - SENGKANG SLOOF S-01 GUDANG CMTFAndre NovanNo ratings yet

- Lamp Math Lembaga PDFDocument15 pagesLamp Math Lembaga PDFAndre NovanNo ratings yet

- Desain Spektra Indonesia Parit 16Document2 pagesDesain Spektra Indonesia Parit 16Andre NovanNo ratings yet

- Quantity Jembatan Bukit Condong 1 Juli 2022Document41 pagesQuantity Jembatan Bukit Condong 1 Juli 2022Andre NovanNo ratings yet

- MPMR Abt PendekDocument5 pagesMPMR Abt PendekAndre NovanNo ratings yet

- Quantity Jembatan Parit Gading 1 June 2022Document64 pagesQuantity Jembatan Parit Gading 1 June 2022Andre NovanNo ratings yet

- Grafik Lpile Abt-1 R 1 No MomDocument49 pagesGrafik Lpile Abt-1 R 1 No MomAndre NovanNo ratings yet

- Story Shear SemuaDocument13 pagesStory Shear SemuaAndre NovanNo ratings yet

- Quantity Jembatan Parit 16 31 Mei 2022Document58 pagesQuantity Jembatan Parit 16 31 Mei 2022Andre NovanNo ratings yet

- 10 Mathcad - SAMBUNGAN END PLATE CROSS BEAM KE JOINDocument10 pages10 Mathcad - SAMBUNGAN END PLATE CROSS BEAM KE JOINAndre NovanNo ratings yet

- Iterasi Spring Abt 1 R 1Document10 pagesIterasi Spring Abt 1 R 1Andre NovanNo ratings yet

- 52 Mathcad - BTG TENS TB9Document5 pages52 Mathcad - BTG TENS TB9Andre NovanNo ratings yet

- 04 Mathcad - PEMBEBANAN ABT 2 RANTAU BERANGINDocument11 pages04 Mathcad - PEMBEBANAN ABT 2 RANTAU BERANGINAndre NovanNo ratings yet

- 02 Mathcad - PEMBEBANAN PIER 1 2 RANTAU BERANGINDocument10 pages02 Mathcad - PEMBEBANAN PIER 1 2 RANTAU BERANGINAndre NovanNo ratings yet

- 03 Mathcad - PEMBEBANAN ABT RANTAU BERANGINDocument12 pages03 Mathcad - PEMBEBANAN ABT RANTAU BERANGINAndre NovanNo ratings yet

- 11 Mathcad - BTG TENS BCM 01Document5 pages11 Mathcad - BTG TENS BCM 01Andre NovanNo ratings yet

- 08 Mathcad - DISAIN CROSS BEAM RANTAU SBG BALOK LENTURDocument4 pages08 Mathcad - DISAIN CROSS BEAM RANTAU SBG BALOK LENTURAndre NovanNo ratings yet

- Mathcad - CEK SENGKANG BALOK BA2-MASJID Lt-1Document3 pagesMathcad - CEK SENGKANG BALOK BA2-MASJID Lt-1Andre NovanNo ratings yet

- Mathcad - ANALISA KAP NEG BALOK B-1 LT 1 MASJID AL HIJRAHDocument6 pagesMathcad - ANALISA KAP NEG BALOK B-1 LT 1 MASJID AL HIJRAHAndre NovanNo ratings yet

- BL201415Document27 pagesBL201415ezaza3108No ratings yet

- Case Study - Narrative Structure - RevisedDocument10 pagesCase Study - Narrative Structure - RevisedMatthew ButcherNo ratings yet

- Ghostbusters - The Card Game - Rulesheet-FINAL-loresDocument8 pagesGhostbusters - The Card Game - Rulesheet-FINAL-loreskruangNo ratings yet

- Bihar 202278890878907Document1 pageBihar 202278890878907Raushan RajNo ratings yet

- Brand-Brand Ambassador Quiz: Answer KeyDocument1 pageBrand-Brand Ambassador Quiz: Answer Keyrahul kumarNo ratings yet

- Updated Unique Rank List (PG)Document36 pagesUpdated Unique Rank List (PG)Vishu KushwahaNo ratings yet

- Primeira Proba Parte A-Opción ADocument9 pagesPrimeira Proba Parte A-Opción AVíctor BLNo ratings yet

- Prey (2022 Film) : Science Fiction Action Horror Film Dan Trachtenberg Prequel Predator HuluDocument6 pagesPrey (2022 Film) : Science Fiction Action Horror Film Dan Trachtenberg Prequel Predator HuluEndhy Wisnu Novindra0% (1)

- Ria Thanouli, Post-Classical NarrationDocument15 pagesRia Thanouli, Post-Classical NarrationmentamentaNo ratings yet

- Localization: Moana Frozen 2Document3 pagesLocalization: Moana Frozen 2marvinNo ratings yet

- FccnotDocument69 pagesFccnotBALASRINIVASAN RNo ratings yet

- List-3 17032023 PDFDocument15 pagesList-3 17032023 PDFraja babuNo ratings yet

- Attachment 1Document6 pagesAttachment 1Nữ HoàngNo ratings yet

- National Board of Examinations ResultDocument16 pagesNational Board of Examinations ResultSunny4288No ratings yet

- Television (TV) : Read The Passage and Highlight The Words You Don't UnderstandDocument2 pagesTelevision (TV) : Read The Passage and Highlight The Words You Don't UnderstandDuru Ergin100% (1)

- Fdocuments - in - List of Faculties For Aicte Approved Institutions Ay 2015 16 2015 05 29 ListDocument176 pagesFdocuments - in - List of Faculties For Aicte Approved Institutions Ay 2015 16 2015 05 29 ListSkillytek ServiceNo ratings yet

- Chittoor Dt. CAS and Staff Nurse ParticuarsDocument20 pagesChittoor Dt. CAS and Staff Nurse ParticuarsSivakumar AkkariNo ratings yet

- B ADocument6 pagesB ANagaraju EllandulaNo ratings yet

- Electrical Shift Duty Chart For The Crushing Season 2019-20Document3 pagesElectrical Shift Duty Chart For The Crushing Season 2019-20singhshubhamNo ratings yet

- Name of The Student Roll No Branch CompanyDocument2 pagesName of The Student Roll No Branch CompanyRaghuvaranNo ratings yet

- Zulqurnain Ali Abbas - The Shadow in The Rose GardenDocument2 pagesZulqurnain Ali Abbas - The Shadow in The Rose GardenNauman RazaNo ratings yet

- SGT To BT Maths Panel Final As On 01-01-2014Document6 pagesSGT To BT Maths Panel Final As On 01-01-2014edwin_prakash75No ratings yet

- MBBS - 2020 - 2021 - SESSION List of Candidates Allotted - On 01.12.2020Document31 pagesMBBS - 2020 - 2021 - SESSION List of Candidates Allotted - On 01.12.2020Charles Murgasan Charles MurgasanNo ratings yet

- Brahmastra Movie Review Despite Its Razzle-Dazzle, Ranbir Kapoor-Alia Bhatt Film Fails To Entertain Entertainment News, The inDocument1 pageBrahmastra Movie Review Despite Its Razzle-Dazzle, Ranbir Kapoor-Alia Bhatt Film Fails To Entertain Entertainment News, The inATUL SINGHNo ratings yet

- Script - Food Bank 2Document1 pageScript - Food Bank 2RoxanneMeatsNo ratings yet

- DownloadDocument7 pagesDownloadvishnuNo ratings yet

- 08 - 05 - 2022 - Result of FT (OYM&CF) - 2223 - T01Document4 pages08 - 05 - 2022 - Result of FT (OYM&CF) - 2223 - T01Løne WølfNo ratings yet

- Visual Perception and Cultural Memory: Typecast and Typecast (E) Ing in Malayalam CinemaDocument32 pagesVisual Perception and Cultural Memory: Typecast and Typecast (E) Ing in Malayalam CinemaDarshana Sreedhar MiniNo ratings yet

- Tentative Seniority List in Respect of Lecturers School New W.E.F. 1.1.14. To 31.12.17Document200 pagesTentative Seniority List in Respect of Lecturers School New W.E.F. 1.1.14. To 31.12.17ajay bhatiaNo ratings yet

- Celebrities PDFDocument14 pagesCelebrities PDFrominaandraNo ratings yet