Professional Documents

Culture Documents

Operation Procedure & FO Changeover

Operation Procedure & FO Changeover

Uploaded by

winmyintzaw0 ratings0% found this document useful (0 votes)

10 views12 pagesOriginal Title

operation procedure & FO Changeover

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views12 pagesOperation Procedure & FO Changeover

Operation Procedure & FO Changeover

Uploaded by

winmyintzawCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

GEY 18LW EEE

[Engine operation

Pre-operation procedure

1 = If priming stops for 2 hours or more, do a new priming for 20 minutes or more.

NOTICE

Priming pressure: 0.02 to 0.20 MPa

4-Releasing air from the lubricating oil filter

NOTICE

Release the air from the lubricating oil fier after:

+ The lubricating oil priming pump has stopped for 2 hours or more.

+ You disassemble and clean the lubricating oil fiter.

+ You change the lubricating oil. You disassemble the lubricating oil system.

1- Operate the lubricating oll priming pump.

2- Loosen the lubricating oil air vent plug.

3 Release the air.

4 Tighten the air vent plug.

5 Doan air running 5 times for about 3 seconds,

6 - Release the air again.

3. Cooling water system (the freshwater system has blue coating and the

seawater system has green coating)

1 Inspect the cooling water tank and check if the cooling water is contaminated. If the cooling water is

very dirty, change it.

2.- Fill the cooling water tank with cooling water. Fill it to the upper limit of the water level gauge. Add a

proper amount of corrosion inhibitor.

Selecting and controlling the corrosion inhibitor 30-0000-000-076

3 Open and close each valve of the cooling water pipe system according to the operation conditions.

4-- Open the cock on the top part of the charge air cooler to release the air.

NOTICE

If you replaced the cylinder liner or removed it for servicing, remove the cylinder side cover and make

sure that there are no water leaks inside the cylinder.

4. Fuel oil system (red coating)

1 = Drain the fuel oil fier and the fue! oil tank

2 Fill the fuel oll tank with fue! cil

3- Check the fue! level

4. Open or close each valve according to the operation conditions.

YANMAR.

a 8) ERIE MEIRO

[Engine operation

Pre-operation procedure

6-

7.

8-

NOTICE

+ (Pretreatment) Clean the heavy fuel oil thoroughly in pretreatment.

+ Ifyou use an engine with marine diesel oil start/stop specifications, turn on the heater for the heavy

fuel oll pipeline and continue heating the heavy fuel oil until it has the correct viscosity. Then switch

from marine diesel oil to heavy fuel oil.

M.D.0. CHANGE OVER 30-0000-000-131

+ For engine specifications that use heavy fuel oll for the engine start and stop, make sure that the fuel

oll temperature (viscosity) at the engine inlet is correct.

H.F.O. DIRECT START 30-0000-000-151

Properties of the fuel oil at engine inlet 30-0000-000-374

+ The seal potis at the fuel oil pressure gauge inlet. At the first start, fill ethylene glycol before you start

the engine,

Servicing the fuel oil seal pot 39-5009-000-271

Fully turn the handle of the bypass valve of the fuel feed pump counterclockwise to open the bypass

valve.

Open the air vent cock of the fuel oll fier to release the air.

Loosen the air vent cock of the fuel injection pump to release the alr.

Fully turn the bypass valve handle clockwise to close it.

Disassembly and assembly of the fuel feed pump and how to adjust the fuel oil pressure

'39-5002-000-280

Start air system (yellow coating)

1.

2-

6-

7.

8-

9o-

Drain the air tank.

Make sure that the pneumatic pressure in the air tank is high enough to start the engine (1.5 MPa or

higher),

Open the drain cocks at the charge air cooler outlet and the cylinder block of the supply air chamber to

drain the water.

Open the pressure indicator cocks,

AXCAUTION

If you start the engine without preparation, water hammer can occur and cause damage to the

connecting rod joint.

It is possible that fuel, water or lubricating oll collects in the cylinder.Check for unusual

amounts and turn the flywheel with the electric motor. Fuel, water and lubricating oil will blow

from the pressure indicator cocks. Do not bring your face near the pressure indicator cock.

Move the start/stop handle to STOP.

Let the pressure indicator cock stay open.

Do an air running for 2 to 3 seconds.

Release the air from the lubricating oil filter.

6. Protective device and governor (white coating)

1

Make sure the turning gear is in the GEAR OUT position.

YANMAR.

GEY18LW STI

[Engine operation

Pre-operation procedure

2- Set the power switch of the protective devices and the alarm devices to the ON position.

outers

‘The protective devices and the alarm devices do not operate if the power switch is not set to ON.

3 Check that the devices operate.

4- Move the start/stop handle from STOP to START and back.

5- Make sure that the rack of the fuel injection pump, the first lever shaft of the governor link and the

connector move easily.

6- Make sure that the pointer of that speed control shaff of the governor p

scale,

NOTICE

After you replace or service the governor or the fuel injection pump, check that the linkage device is

properly connected.

How to operate the speed control lever 3A-6003-000-271

's between 1 and 2 on the

Requirements after task completion

‘ier starting the engine, release the air from the lubricating oi fiter again.

YANMAR.

CIS OES Eee

lEngine operation

Normal operation procedures

No conditions

REQUIRED PERSONNEL

Person Categonyirade Skill level Trade Estimated time

SUPPORT EQUIPMENT

Nomenclature Identification code ‘Quantity

No support equi

SUPPLIES

Nomenclature Identification code Quantity

No supplies

SPARES.

Nomenclature Identification code ‘Quantity

No spares

SAFETY CONDITIONS

WARNING

Moving part hazard

DO NOT touch or come close to moving parts with your hands, body or clothing.

NEVER touch a moving part.

Noise hazard

Wear ear protection (ear plugs) In the engine room to prevent hearing loss.

ACAUTION

High temperature hazard

NEVER touch the following parts with your bare hands when the engine is running or when the engine has just

stopp

Ther

a risk of burns.

+ Turbocharger, exhaust piping, supply air piping

+ Indicator cock

+ Flue and funnel

Make sure that the room has good alrflow because the turbocharger needs a lot of air (oxygen).

Keep the control air valve open during engine operation.

If you close it, the protective devices do not oper

1. Engine start

AXCAUTION

Do not bring your face close to the air starter when you start the engine. Dirt on the exhaust port

YANMAR.

GEY1SLW 30-0000-000-131-00

|Engine operation

Normal operation procedures

of the air starter can enter your eye and cause injury.

NOTICE

If someone is present, give a signal and make sure that the person is safe before you start the engine.

Check the amount of fuel oil, lubricating oil and air.

Make sure that you remove the turning bar. Store it in its designated place.

‘Turn on the power supply of the engine protection device before you start the engine.

After a long engine stop or servicing, make sure that you start the engine on the engine side.

In case of an unusual increase of engine rotation, unusual sounds or smoke, immediately move the start!

stop handle to STOP and stop the engine.

This engine is started by an air-starter.

Press the START switch. The battery-powered pilot-air solenoid valve on the air starter will open and start

the engine.

4-Air running

ACAUTION

Before the first start after installation, servicing or a long engine stop, do an air running and

obey the following procedures. Make sure that there are no defects. Then start the engine on

the engine side. A large amount of fuel oll, cooling water or lubricating oil in the cylinders can

cause water hammering.

1 Set the turning gear to GEAR OUT.

2- Set the control position switch on the engine or the operation mode switch on the remote panel to

the ENGINE position.

3~ Open the pressure indicator cocks on all cylinders.

4- Move the start/stop handle to STOP.

5- Press the START switch for 2 to 3 seconds to start the air running.

2.-How to start the engine

1 Set the turning gear to GEAR OUT

2- Make sure that the pressure indicator cocks on all cylinders are closed.

3 Set the control position switch on the engine or the operation mode switch on the remote panel to

ENGINE or REMOTE, depending on the control position.

4- Set the start/stop handle to RUN.

5- Check that the needle of the governor speed control shaft indicates the correct (specified) speed.

6- Open the startup air reservoir and control air valve

7 = Press the start switch for 2 to 3 seconds. Release the switch after ignition.

YANMAR.

C= EE Rie)

Engine operation

Normal operation procedures

‘Start swith

.

‘StarStop lever —_

Operating select switch —

Fig.1. How to start the engine

3 «In case of start failure

A CAUTION

Do not restart the engine immediately after a failed start. Unburned combustion gas in the flue

can ignite and cause an explosion.

If you try to start the engine without pause, the starter can become too hot and malfunction.

1.- Do an air running and discharge the gas from the exhaust gas system. Then restart the engine.

2- If the engine does not start in 30 seconds or less, stop the starter. Let the starter rest and cool for

2.5 minutes or more. Then try again.

4 - Starting without control power

ACAUTION

‘At manual start, the control module Is not in operation. This can cause overspeed of the air

starter. Use the manual start only in emergencies.

1 Ifthe battery for the START switch is empty (in case of emergency), push the manual button of the

air starter to start the engine.

2- Return the button to its original position immediately after the engine starts,

YANMAR.

GEY 18SLW ET

Engine operation

Normal operation procedures

Fig.2 Air starter manual button

5 -Checks after engine start

Do these checks. If you find any problems, stop the engine and do the necessary repairs.

+ Check that the pressure values on the gauge panel are normal

+ Check all pipes for leaks.

+ Check for unusual sounds and unusual heat.

6 - Automatic and remote starts

Refer to the respective sections.

2. Switching to heavy fuel oil

1 -M.D.0. CHANGE OVER

1 Start the engine on M.0.0. and run it for at least 15 minutes in the M.D.O. setting

2 Heat the heavy fuel oll Check that the fuel oll in the circulating line has the specified viscosity (14

to 14 mm 4s at engine inlet) and pressure. This prevents clogging of the fuel oil filter and an

irregular increase of pressure in the fuel injection pipe.

3- Make sure that the turning gear is in GEAR OUT.

‘Opn AFO.oatet valve

Giese M1D.0. aulot vane

‘Open WFO. et valve

Close MD.O. nie vane

Fig.3 Change-over switch

4 Switch to heavy fuel operation when the engine reaches a load factor of 20% or more.

5 If you switch to heavy fuel operation, check that the fuel oil viscosity and pressure are in the

specified range.

2 -H.F.O. DIRECT START

4 Heat and circulate the heavy fuel oil until it has a viscosity at engine inlet of 11 to14 mm %/s.

2- Circulate jacket cooling water of 65 °C to 70 °C and warm the engine.

3- Start the engine, if the above conditions are met.

YANMAR.

Sara Eee

[Engine operation Page

Normal operation procedures 5i5

3. Checks during operation

ene

Carefully examine the pressure and temperature. Check that there are no unusual sounds or unusual

heat.

Ifyou find a defect, immediately stop the engine and make the necessary repairs.

When the engine starts and increases rotation speed, it can momentarily rotate at a very high speed. This

is caused by torsional vibration of the camshaft. In that case, let the engine quickly increase speed to the

specified rotation setting. When it rotates at the specified speed, the torsional vibration will go away.

‘1~ Run the engine without load for about 10 minutes to warm it up,

2- If you run the engine at low load for more than 3 hours, the combustion worsens and fouling of the

‘combustion chamber, the exhaust pipe and the turbocharger increases. Obey these instructions:

If you use marine diese! oil, run the engine at a load factor of 15 % or higher.

If you use heavy fuel oil:

+ -Run the engine at a load factor of 15 % or more, if the engine has an al temperature control device

that heats the supply air.

+ = Run the engine at a load factor of 20 % or more, if the cooling water in the supply alr cooler and the

lubricating oil cooler is from a seawater cooling assembly.

NOTICE

When running at a low load factor, switch to M.D.O. operation.

3- If humidity is high, the air moisture can condense and result in a large amount of drainage. This is

normal

In this case, run the engine with an open drain cock of the supply air cooler.

4- Measure the engine performance at least once a day. Record the results.

Refer to the Factory Test Table and record the results in the engine log.

‘Measuring Engine Performance 30-0000-000-320

Requirements after task completion

No conditions

YANMAR.

GEY 18LW SETTER

Engine operation

Post-operation procedures

No conditions

REQUIRED PERSONNEL

Person Catagoryirade __Skililevel Trade Estimated time

SUPPORT EQUIPMENT

Nomenclature Identification code Quantity

No support equipment

SUPPLIES

Womenciature Teenification code Quantity

Wo supplies

SPARES

Nomenclature Taenication code Guantiy

‘No spares

SAFETY CONDITIONS

No safety conditions

1. Checks at engine stop

1- Donot stop the engine at the same time as the load shutoff. Only do so in emergencies.

2- Alter load shutoff, run the engine without load, then shut it off

3- Make sure that the engine is always ready to start.

AWARNING?

4- Do not open the side cover of the crankcase for at least 10 minutes after the engine stops. Fresh

air that rushes in can cause an explosion

AXCAUTION

High temperature hazard

Immediately after the engine stops, the whole engine is hot. Do not burn yourself.

Make sure that your hands, your body or your clothing do not touch the turbocharger, the

exhaust manifold, the exhaust pipes or the engine body.

When you drain oil from the hot engine, make sure that you do not come in contact with the

including splashes of oil.

When you disassemble the cooling water system while the engine is still hot, vapor or hot water

can spurt out and burn you. Wait until the engine becomes cool, then wrap the part that you

want to remove with cloth and slowly loosen it.

Immediately repair any defects of the running engine.

2. Preparing the engine stop

1/- Run the engine without load for about 10 minutes.

2- M.D.0. CHANGE OVER

OE ai Emenee

lEngine operation

Post-operation procedures

For the start/stop specifications for marine diesel oll on heavy fuel oil engines, switch from heavy fuel

oil to marine diesel oll. This prevents heavy fuel oil from staying inside the fuel oil pipes, fiters and

pumps when the engines stops.

Run the engine with marine diese! oil for about 20 to 30 minutes. The time can change depending on

the load at the time of the switch and the capacity of the ship pipes. Confirm with the dockyard where

the engine was installed

3- H.F.O, DIRECT START

For heavy fuel oil, after the engine stopped, continue to heat and circulate the fuel oil to maintain the

specified viscosity. Make sure that the heavy fuel oll and the jacket cooling water meet the engine

stand-by conditions at least 2 hours before you start the engine

Before you stop the engine for a long time, switch to marine diesel oil operation. Make sure that no

heavy fue! oil is left in the piping and that it is completely replaced by marine diesel oil

Riven from the strainer]

Open MD. inlet valve

Coxe HF. inet vave

Leaveinhia sage 2 3 minds, end ern he

FEES. amsning inte man pp eb HF Oth

‘Depending cn the leg of he boon,

the wating re may ba one

‘Open M.D 0. outa valve

Close HO. oulot vawve

ano es RAFAT] te

Fig.1 Change-over switch

3. Stopping the engine

1 Move the start/stop handle to STOP.

2- Run the standby lubricating oll pump or the electric lubricating oil priming pump for 1 minutes or more

to cool the piston and the turbocharger.

3- Open the pressure indicator cock. Do an air running to release gas from the combustion chambers.

4 Open or close the valves of all circuits as itis specified for engine stops.

5 - Drain the cooling water from the cylinder block side and the cooler side if the cooling water can freeze

due to cold weather or before a long engine stop.

Requirements after task completion

No conditions

YANMAR.

aha ERIE TSE

[Engine operation

Emergency procedure

1.Emergency stop

ACAUTION

If any of the following problems arise:

stop the engine.

NOTICE

Ifyou set the start/stop handle to STOP or press the STOP switch and the engine does not stop, close the

fuel oil inlet valve.

immediately set the start/stop lever in the STOP position to

The lubricating oil pressure decrease alarm operates.

‘The lubricating oil pressure increase alarm operates.

‘The cooling water temperature increase alarm operates,

The overspeed alarm operates.

Irregular noise

Irregular heat

‘Smoke from a bearing or other moving part

‘A broken pipe of the fuel oil system, lubricating oil system or cooling water system

The supply of cooling water has stopped, and itis impossible to supply it immediately.

A loose or broken bolt or setscrew of a moving part.

Water in the lubricating oil

‘The intake air pressure decreases and the exhaust temperature increases a lot.

‘The rack of the fuel injection pump is stuck.

+ The exhaust temperature of one cylinder is 40 °C higher or lower than the average temperature of all

cylinders,

+ (There is tisk of misfiring and torsional vibration.)

2. After an emergency stop

When repairing the engine or investigating the cause of problem, observe the following items:

a AWARNING

Do not open the side cover of the cylinder block for 10 minutes or more after engine stop.

Fresh alr that enters the engine can ignite oll mist and result in an explosion.

NOTICE

If the engine stopped while running on heavy fuel oil, immediately bleed the fuel oil pipes, fuel cil filter and

fuel injection pumps. Switch to marine diesel cil

If the residual H.F.O. is cooled and its viscosity rises, it becomes impossible to restart the engine.

Set the fuel oil changeover valves at the engine inlet and outlet to marine diesel ol

Open the bypass valve of the fuel feed pump.

Open the drain cock of the fuel oll fiter and the drain valve of the fuel oil main pipe.

Turn the flywheel to drain the heavy fuel cil from the fuel injection pipes and fuel injection valves.

(The nozzles will spray fuel if you move the start/stop handle to RUN and turn the flywheel.)

YANMAR.

CS

ja

Emergency procedure

Fuel oll ter

Drain cock

=

Normal "CLOSE

Discharge OPEN

Fig. 1 Draining locations for heavy fuel oil

YANMAR.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MC Iccp SystemDocument1 pageMC Iccp SystemwinmyintzawNo ratings yet

- EY26 From Operation ManualDocument1 pageEY26 From Operation ManualwinmyintzawNo ratings yet

- MC Galley EquipmentDocument1 pageMC Galley EquipmentwinmyintzawNo ratings yet

- MC Life Boat DavitDocument1 pageMC Life Boat DavitwinmyintzawNo ratings yet

- Q26946 (ASL Shipyard - in Situ Machining of AFT & FWD Stern Tube Housin...Document3 pagesQ26946 (ASL Shipyard - in Situ Machining of AFT & FWD Stern Tube Housin...winmyintzawNo ratings yet

- New Doc 2023-07-11 10.35.03Document12 pagesNew Doc 2023-07-11 10.35.03winmyintzawNo ratings yet

- Stern Cast - AFCDocument1 pageStern Cast - AFCwinmyintzawNo ratings yet

- 铸钢件焊补工艺Document6 pages铸钢件焊补工艺winmyintzawNo ratings yet

- VSCC 2023-04-25 09.52.17Document5 pagesVSCC 2023-04-25 09.52.17winmyintzawNo ratings yet

- VSCC 2023-04-27 09.56.36Document5 pagesVSCC 2023-04-27 09.56.36winmyintzawNo ratings yet

- AC Equipments (Ceiling Cassette, Non-Inverter)Document1 pageAC Equipments (Ceiling Cassette, Non-Inverter)winmyintzawNo ratings yet

- 3084 001Document3 pages3084 001winmyintzawNo ratings yet

- AC Installation (Non-Inverter)Document2 pagesAC Installation (Non-Inverter)winmyintzawNo ratings yet

- J12432020 LS - Ko Win Myint Zaw, Digicom Co - LTDDocument5 pagesJ12432020 LS - Ko Win Myint Zaw, Digicom Co - LTDwinmyintzawNo ratings yet

- LMA) ေဇာ္ဂ်ီ-A Study of the Rise of the Burmese NovelDocument8 pagesLMA) ေဇာ္ဂ်ီ-A Study of the Rise of the Burmese NovelwinmyintzawNo ratings yet

- LMA) ေဇာ္ဂ်ီ-ပုဂံေခတ္ မဟာယာနပန္းခ်ီDocument5 pagesLMA) ေဇာ္ဂ်ီ-ပုဂံေခတ္ မဟာယာနပန္းခ်ီwinmyintzawNo ratings yet

- LMA) ေဇာ္ဂ်ီ-ပုဂံေခတ္ ဗုဒၶဝင္ ပန္းခ်ီDocument7 pagesLMA) ေဇာ္ဂ်ီ-ပုဂံေခတ္ ဗုဒၶဝင္ ပန္းခ်ီwinmyintzawNo ratings yet

- ASGM Toolkit Eguide en 180216.compressedDocument196 pagesASGM Toolkit Eguide en 180216.compressedwinmyintzawNo ratings yet

- Fuel Consumption (Diesel Engine Driven Generator) : DCA-220SPK3Document1 pageFuel Consumption (Diesel Engine Driven Generator) : DCA-220SPK3winmyintzawNo ratings yet

- Clean Pro Professional Cleaning Services: Company ProfileDocument17 pagesClean Pro Professional Cleaning Services: Company ProfilewinmyintzawNo ratings yet

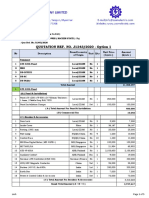

- Mark Two Seven Co., LTD.: QuoteDocument1 pageMark Two Seven Co., LTD.: QuotewinmyintzawNo ratings yet

- DCA-220SPK3 STD SpecDocument8 pagesDCA-220SPK3 STD SpecwinmyintzawNo ratings yet