Professional Documents

Culture Documents

47709019

Uploaded by

totoro2020202020Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

47709019

Uploaded by

totoro2020202020Copyright:

Available Formats

TAD570-572VE

5.13 liter, in-line 4 cylinder - 105, 129 & 160 kW

EU Stage IV / US EPA Tier 4 Final

TAD570-572VE is a powerful, reliable and economical off-road Diesel Engine range built on the Volvo Group in-line four concept.

Low cost of ownership

World class fuel efficiency combined with a reliable exhaust after-

treatment system gives high uptime as well as low cost of owner-

ship. No downtime for regeneration or decreased service intervals. • Proven and straight-forward design - built on

Compact & simple installation Volvo Group technology

SCR technology selected by Volvo does not increase amount of

cooling capacity needed. As optional equipment all material need- • Low cost of ownership and operation

ed in order to install the engine can be ordered from Volvo Penta.

Installation guidelines as well as drawings and CAD models are • High power and torque already at low engine speed

easy to access.The result is an engine and aftertreatment system

that is easy to install. • SCR and cooled EGR only - no DPF, DOC or regeneration

Durability & low noise

• Compact, simple installation and easy to service

Long experince with SCR systems in combination with base

engine development reduces risk of downtime. Well-balanced to

• Similar engine footprint for all emission standards

produce smooth operation with low noise.

Power & torque • Wide range of optional equipment

Maximum power and torque available at low rpm. As a result

noice as well as fuel consumption is very low. Useful engine speed

for the TAD570-572VE is due to power and torque layout very

flexible.

Low exhaust emission

Efficient injection as well as robust engine design in combination TAD570VE TAD571VE TAD572VE

with optimised SCR technology and a cooled EGR contributes to Power output, kW/hp

105/143 129/175 160/218

excellent combustion and low fuel consumption. at speed, rpm

2300 2300 2300

Easy service & maintenance

Max. torque, Nm/lb/ft

Easily accessible service and maintenance points contribute to 710/524 810/597 910/671

the ease of service of the engine. As optional equipment possible at speed, rpm

1200 1200 1450

to remote mount filters and service points. Up to 1000 hour oil

change interval.

TAD570-572VE

5.13 liter, in-line 4 cylinder - 105, 129 & 160 kW

EU Stage IV / US EPA Tier 4 Final

Technical data

Configuration and no. of cylinders.............................................in-line 4

Displacement, l (in³)................................................................ 5.13 (313)

Method of operation..................................................................4-stroke

Direction of rotation (viewed towards flywheel)...........anti-clockwise

Bore, mm (in.)..........................................................................110 (4.33)

Stroke, mm (in.)....................................................................... 135 (5.31)

Compression ratio...........................................................................17.5:1

Dry weight, engine only, kg (lb)............................................ 556 (1226)

Technical description

Engine and block

• Cast iron cylinder block

• Replaceable cylinder liners

• Replaceable valve guides and valve seats

• Overhead camshaft and four valves per cylinder

Lubrication system

• Full flow cartridge insert filter

• Gear type lubricating oil pump, gear driven

Fuel system

• Common rail

• Gear driven fuel feed pump

• Fuel prefilter with water separator and water-in-fuel indicator / alarm

• Fine fuel filter of cartridge, insert type

• Manual feed pump on pre filter

Cooling system

• Belt driven coolant pump with high degree of efficiency

Turbo charger

• Variable Geometry Turbo (VGT)

Electrical system

• Engine Management System (EMS) 2.3, an electronically controlled

processing system which optimizes engine performance. It also in-

cludes advanced features for diagnostics and fault tracing.

• The instruments and controls connect to the engine via the CAN SAE

J1939 interface. Options available for engine control equipment.

Exhaust aftertreatment system

• SCR and cooled EGR only

• Airless urea injection

• Wide range of options available, including different sized AdBlue® /

DEF tanks (also possible for OEM to design own tank)

• AdBlue/DEF Quality Level Temperature Sensor for US Market

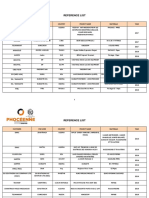

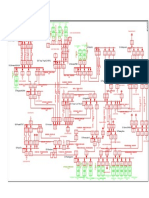

Main components - principal layout

Dimensions

Not for installation. Dimensions in mm.

992

1. Engine 5. AdBlue / DEF solution tank

2. Pump unit 6. NOx sensor

3. Solenoid valve, heating/ 7. Temperature sensor exhaust

cooling 8. Dosage Valve

English 02-2017. © 2017 AB Volvo Penta.

4. AdBlue/DEF Level Tempera- 9. Muffler with catalytic converter

ture Sensor for EU Market 10. Aftertreatment control module

AdBlue/DEF Quality Level 11. NOx sensor

Temperature Sensor for US 12. Temperature sensor air

Market 946 870

Power standards Please note that products illustrated may differ from

production models.

The engine performance corresponds to ISO 3046,

BS 5514 and DIN 6271. The technical data applies to Not all models and accessories are available in all markets,

an engine without cooling fan and operating on a fuel and standard equipment may vary between different

with calorific value of 42.7 MJ/kg (18360 BTU/lb) markets. Every effort has been made to ensure that facts

and a density of 0.84 kg/liter (7.01 lb/US gal, 8.42 lb/ and figures are correct at the time of publication. However,

lmp gal), also where this involves a deviation from the Volvo Penta reserves the right to make changes without

standards. prior notice at any time.

AB Volvo Penta

Additional information SE-405 08 Göteborg, Sweden

For additional information, please contact your Volvo www.volvopenta.com

Penta representative or visit www.volvopenta.com.

You might also like

- 47709275Document2 pages47709275totoro2020202020No ratings yet

- 47709274Document2 pages47709274jamesNo ratings yet

- Tad572ve enDocument2 pagesTad572ve enPakito-sanNo ratings yet

- TAD870-873VE: Low Cost of OwnershipDocument2 pagesTAD870-873VE: Low Cost of OwnershipAaravGuptaNo ratings yet

- enDocument2 pagesenAlbertoNo ratings yet

- 47711515Document2 pages47711515totoro2020202020No ratings yet

- enDocument2 pagesenTTIBCCANo ratings yet

- TAD540-542VE: Low Cost of OwnershipDocument2 pagesTAD540-542VE: Low Cost of OwnershipHorea CordunianuNo ratings yet

- TAD1140-1142VE: Low Cost of OwnershipDocument2 pagesTAD1140-1142VE: Low Cost of OwnershipEmerson BatistaNo ratings yet

- TAD1140-1142VE: Low Cost of OwnershipDocument2 pagesTAD1140-1142VE: Low Cost of OwnershipRachid Smaili100% (1)

- TAD1150-1152VE: Low Cost of OwnershipDocument2 pagesTAD1150-1152VE: Low Cost of OwnershipTioNo ratings yet

- Tad1170ve-Tad1170ve 2Document2 pagesTad1170ve-Tad1170ve 2ARTMehr Eng. GroupNo ratings yet

- LEHH0551Document4 pagesLEHH0551Lore ChNo ratings yet

- Engine Volvo Penta Tad1641veDocument2 pagesEngine Volvo Penta Tad1641veRohit Om TiwariNo ratings yet

- D7C Ta: Volvo Penta Inboard DieselDocument2 pagesD7C Ta: Volvo Penta Inboard DieselAhmet GelisliNo ratings yet

- 1206e-E70tta Iopu PN1962Document4 pages1206e-E70tta Iopu PN1962dmitryiNo ratings yet

- SINOPEC TULUX T500 E7 CI-4 15W-40 Diesel Engine OilDocument3 pagesSINOPEC TULUX T500 E7 CI-4 15W-40 Diesel Engine OilYoong TanNo ratings yet

- 1106D E70ta Iopu PN3065Document3 pages1106D E70ta Iopu PN3065Luis JaimesNo ratings yet

- 1200 Series: 1206F-E70TTADocument4 pages1200 Series: 1206F-E70TTANo PersonNo ratings yet

- 5160DF PowerDocument7 pages5160DF PowerPankaj Kamble100% (1)

- Brochure 51 60DFDocument8 pagesBrochure 51 60DFSenol Seidali100% (1)

- 350KVA Diesel Generator CATDocument6 pages350KVA Diesel Generator CATAnonymous N0ZIvW100% (1)

- DEUTZ - CaracterísticasDocument2 pagesDEUTZ - CaracterísticasIkerNo ratings yet

- TULUX L1000 E4 E7 CI-4 10W-40 Diesel Engine OilDocument3 pagesTULUX L1000 E4 E7 CI-4 10W-40 Diesel Engine OilYoong TanNo ratings yet

- LEHW0175Document4 pagesLEHW0175حسين عبدالهاديNo ratings yet

- CAT 3406 C Heavy Duty Truck EngineDocument5 pagesCAT 3406 C Heavy Duty Truck EngineAS_865025438100% (1)

- TULUX T700 E9 CK-4 15W-40 Diesel Engine OilDocument3 pagesTULUX T700 E9 CK-4 15W-40 Diesel Engine OilYoong TanNo ratings yet

- CAT Engine Specifications: G3306B TA Gas Petroleum EngineDocument4 pagesCAT Engine Specifications: G3306B TA Gas Petroleum EngineSrija sagiNo ratings yet

- Cat 3406 Fuel ConsumptionDocument5 pagesCat 3406 Fuel Consumptionayman akrab100% (2)

- Industrial Engine Ratings Guide: EPA Tier 4 Interim/EU Stage IIIB/MLIT Step 4Document36 pagesIndustrial Engine Ratings Guide: EPA Tier 4 Interim/EU Stage IIIB/MLIT Step 4Balamurugan ArumugamNo ratings yet

- 3 Sinopec Tulux T600 15W 40Document3 pages3 Sinopec Tulux T600 15W 40arman chowdhuryNo ratings yet

- 1106D-E70TA PerkinsDocument2 pages1106D-E70TA PerkinsRuben Espinoza CruzNo ratings yet

- Cat® Engine SpecificationsDocument5 pagesCat® Engine SpecificationsadelabostatNo ratings yet

- D9 MG GensetDocument4 pagesD9 MG GensetAji HandokoNo ratings yet

- D5A-A T GensetDocument4 pagesD5A-A T Gensetknp2809No ratings yet

- Cat 3406 Genset Specs enDocument6 pagesCat 3406 Genset Specs enAndrei Bleoju80% (5)

- C9.3 Acert Industrial Power Unit: Tier 4 Final, Stage Iv Technology 224-298 Bkw/300-400 BHP at 1800-2200 RPMDocument4 pagesC9.3 Acert Industrial Power Unit: Tier 4 Final, Stage Iv Technology 224-298 Bkw/300-400 BHP at 1800-2200 RPMAditi DasNo ratings yet

- Mack T13 Engine Lubricant TestDocument2 pagesMack T13 Engine Lubricant TestFrank FareNo ratings yet

- GenSet Velvo Penta D7A TDocument4 pagesGenSet Velvo Penta D7A TPlingu Razvan100% (2)

- Portable Air Compressors Powerful Dependable GlobalDocument4 pagesPortable Air Compressors Powerful Dependable GlobalJamal HabbasNo ratings yet

- CAT C7.1 Stage VDocument5 pagesCAT C7.1 Stage VGoran MatovicNo ratings yet

- 9 Sinopec TULUX T500 Classic Diesel Engine Oil (CI-4SL)Document3 pages9 Sinopec TULUX T500 Classic Diesel Engine Oil (CI-4SL)Salman Ahmed PrinceNo ratings yet

- Lehh0022 Cat 6.6 PDFDocument4 pagesLehh0022 Cat 6.6 PDFRobinson GuanemeNo ratings yet

- DE12 Diesel Engine Shop ManualDocument165 pagesDE12 Diesel Engine Shop ManualkevUwUr93% (15)

- Mercedes - 560 SEC - Wiring Diagram - 1989 - 1989Document2,133 pagesMercedes - 560 SEC - Wiring Diagram - 1989 - 1989OudayNo ratings yet

- 5 Sinopec TULUX T600F LA 10W-40 Diesel Engine Oil (Low Ash) Full SynDocument3 pages5 Sinopec TULUX T600F LA 10W-40 Diesel Engine Oil (Low Ash) Full SynDavidNo ratings yet

- C15 Acert Petroleum Engine: Tier 4 Interim/Stage Iiib 354-433 Bkw/475-580 BHP at 1800-2100 RPMDocument4 pagesC15 Acert Petroleum Engine: Tier 4 Interim/Stage Iiib 354-433 Bkw/475-580 BHP at 1800-2100 RPMAbd Alkarem SalamhNo ratings yet

- 6100 Synergie+ 10W-40: Gasoline and Diesel Engine Oil TechnosyntheseDocument2 pages6100 Synergie+ 10W-40: Gasoline and Diesel Engine Oil TechnosyntheseDan AlecsandruNo ratings yet

- Sinopec TULUX T500 Plus 15W-40 Diesel Engine Oil (CI-4+)Document3 pagesSinopec TULUX T500 Plus 15W-40 Diesel Engine Oil (CI-4+)DavidNo ratings yet

- Perkins 1106C-70TADocument5 pagesPerkins 1106C-70TAHendra100% (1)

- Total Oil DetDocument2 pagesTotal Oil DetAwais A.No ratings yet

- Caterpillar 3412EDocument4 pagesCaterpillar 3412Esaftbond00733% (3)

- 3412 Fire Pump: CAT Engine SpecificationsDocument2 pages3412 Fire Pump: CAT Engine Specificationshector mauricioNo ratings yet

- Dozer: Engine WeightsDocument28 pagesDozer: Engine WeightssafvafNo ratings yet

- CAT Engine Specifications: 3508B Land Mechanical EngineDocument4 pagesCAT Engine Specifications: 3508B Land Mechanical Enginemehdi kamaliNo ratings yet

- 1200 Series: 1204E-E44TA/TTA IOPUDocument4 pages1200 Series: 1204E-E44TA/TTA IOPUyorgo7002100% (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- K21 06 10enDocument2 pagesK21 06 10enNIKINo ratings yet

- Accident Avoidance Drivers - Power Point PresentationDocument54 pagesAccident Avoidance Drivers - Power Point PresentationLydia VinalesNo ratings yet

- R7 AuraMarine Preheating UnitDocument4 pagesR7 AuraMarine Preheating UnitRodrigo CastroNo ratings yet

- Y 0720Document260 pagesY 0720Oscar Gálvez IglesiasNo ratings yet

- Final Drawing & Manual of Air DryerDocument16 pagesFinal Drawing & Manual of Air Dryerjin shodanNo ratings yet

- Selec 800 Xu Timer CatalogDocument1 pageSelec 800 Xu Timer CatalogfarooquesherinNo ratings yet

- Study Simple Steam Engine ModelDocument3 pagesStudy Simple Steam Engine ModelPradyot DeoliaNo ratings yet

- TC 10 19 PDFDocument159 pagesTC 10 19 PDFamare addisNo ratings yet

- Corporate Master List - Minera - LinkDocument762 pagesCorporate Master List - Minera - LinkMid Autum100% (2)

- Calculate Power FactorDocument2 pagesCalculate Power FactorbhadreshNo ratings yet

- Experiment 3 - KineticsDocument7 pagesExperiment 3 - Kineticsdiyana a.fNo ratings yet

- Flowserve Control ValvesDocument84 pagesFlowserve Control Valvesantony nirmalaNo ratings yet

- Equest For Leed Training: Proposed Building SetupDocument4 pagesEquest For Leed Training: Proposed Building SetupmasoodaeNo ratings yet

- 220kv GSSDocument46 pages220kv GSSAnkit KumarNo ratings yet

- GTD - Generation Transmission and Distribution Exam QuestionsDocument3 pagesGTD - Generation Transmission and Distribution Exam QuestionsKarunakaran M,47No ratings yet

- President SpeechDocument14 pagesPresident SpeechManish JaiswalNo ratings yet

- 13-Ref List Phoceenne Rev.1 (2010-2017)Document25 pages13-Ref List Phoceenne Rev.1 (2010-2017)Jawad BasraNo ratings yet

- Instruction Manual for Wine Chiller Models EWC801 and EWC1201Document16 pagesInstruction Manual for Wine Chiller Models EWC801 and EWC1201josue1965No ratings yet

- NCERT Physics Class 6-10 CompilationDocument119 pagesNCERT Physics Class 6-10 Compilationvishal tiwari100% (1)

- Adafruit Mics5524 Gas Sensor BreakoutDocument12 pagesAdafruit Mics5524 Gas Sensor BreakoutWerliock MorlorumNo ratings yet

- No Load Characteristic of DC Motors: ObjectivesDocument4 pagesNo Load Characteristic of DC Motors: ObjectivesYasser MohammedNo ratings yet

- Wind Turbines by UJJWAL NAUTIYALDocument14 pagesWind Turbines by UJJWAL NAUTIYALUjjwal NautiyalNo ratings yet

- CHE 110: Environmental Studies: Unit: 1 - Lecture: 5 - CHE110 - VKDocument17 pagesCHE 110: Environmental Studies: Unit: 1 - Lecture: 5 - CHE110 - VKAditya SajjaNo ratings yet

- Bronzeystrainer - Kvs 200 TDocument1 pageBronzeystrainer - Kvs 200 TTiến Lý NhậtNo ratings yet

- SLD Bali NormalDocument1 pageSLD Bali NormalHamam PrigelNo ratings yet

- JET 30 Multipurpose Single Pump UnitsDocument116 pagesJET 30 Multipurpose Single Pump UnitsAlberto VelásquezNo ratings yet

- Arduino Control Relay - Tutorial #5Document6 pagesArduino Control Relay - Tutorial #5Denaiya Watton LeehNo ratings yet

- Solution Combustion Synthesis, Energy and Environment: Best Parameters For Better MaterialDocument39 pagesSolution Combustion Synthesis, Energy and Environment: Best Parameters For Better MaterialBFCNo ratings yet

- Pompa Submersibila Lorentz Ps200 HRCDocument4 pagesPompa Submersibila Lorentz Ps200 HRCginghinacNo ratings yet