Professional Documents

Culture Documents

SHEQ SYLLUBUS

Uploaded by

tarisai doro0 ratings0% found this document useful (0 votes)

4 views6 pagesRevision

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRevision

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views6 pagesSHEQ SYLLUBUS

Uploaded by

tarisai doroRevision

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

SYLLUBUS

SAFETY HEALTH EVIROMENTAL AND QUALITY MANAGEMENT

1.1.1 Identify hazards & risks associated with a task

Identify and demonstrate use of plant and equipment guards in accordance

with manufacturer’s specifications

-use of plant and equipment guards in accordance with manufacturer’s

-Plant and equipment manufacturers specifications

-Plant and equipment user manuals

Identify and implement safe manual handling procedures in line with

workplace procedures

-Different safe manual handling procedures

-Correct methods of manually lifting and moving loads

Apply the safety procedures for the use, handling and storage of

potentially hazardous substances in accordance with instructions and

legislation

Identify materials common to the electrical industry which can be

hazardous to the workers’ health

-Solvents

-Hydrogen and other gases

-Paints. Lead, isocyanates, polymers

-Coolants, PCBs. etc.

-Thermal laggings such as asbestos safety procedures for the use, handling and

storage of potentially hazardous substances

-Safe and correct handling, use, and storage of different types of hazardous

-Hazardous substances regulations

-Safe and correct disposal of hazardous substances

1.1.2 Adhere to relevant regulations & permits relevant legislation relating

to the health and safety of employees at work

-SHEQ rules and regulations

-Factories ACT

-Relevant sections of Occupational Health and Safety Regulations

-IEE Regulations

-Zimbabwe Institute of Electrical Engineers regulations

-Standards Associations of Zimbabwe (SAZ)

1.1.3 Investigate possible mitigatory measures.

Identify key features of relevant legislation relating to the health and safety

of employees at work and apply them in line with workplace procedures

relevant legislation relating to the health and safety of employees at work

-SHEQ rules and regulations

-Factories ACT

-Relevant sections of Occupational Health and Safety Regulations

-IEE Regulations

-Zimbabwe Institute of Electrical Engineers regulations

-Standards Associations of Zimbabwe (SAZ)

-Demonstrate awareness of the rights, duties and obligations of employers and

employees

-rights, duties and obligations of employers and employees

-Relevant sections of the Constitution

-Relevant sections of the Labour ACT and regulations

-Company safety policy and procedures

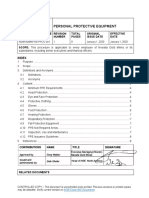

Demonstrate the selection, wearing and storage of Personal Protective

Equipment according to job requirements and workplace procedures.

Meaning of the term PPE

Importance of the wearing and using PPE

Different types of PPE and their uses

Headgear

Gloves

Safety glasses and goggles

Work suits, Coveralls and other body protective gear

Ear plugs and ear muffs

Safety boots

Respirator/Mask

Safety Belts

Safe and correct handling, use, maintenance and storage of different types of

PPE .

Demonstrate the usage, handling, maintenance and storage of safely tools,

equipment and materials according to manufacturer’s specifications and

relevant legislation.

Usage, handling, maintenance and storage of safely tools, equipment and

materials

Appropriate tools and equipment user manuals

Relevant safety manuals

Safe and correct handling, use, maintenance and storage of different types of

safely tools, equipment and materials

Demonstrate adherence to safe work procedures in line with workplace

procedures.

Good housekeeping practices safe work procedures Emergency and

evacuation procedures

Administering First aid to cuts, burns, abrasions etc.

1.1 Carry out tasks in a safe manner and in accordance with

workplace requirements, policies and procedures

Importance of workplace occupational and environmental health and safety

policies and procedures

Provisions of workplace occupational and environmental health and safety

policies and procedures

1.2 Identify and follow safety signs and symbols in line with

workplace procedures.

Purpose of safety signs and symbols .

Key features of safety signs and symbols

shape

colour

graphics

Types of signs

prohibitive signs and symbols

cautionary signs and symbols

mandatory signs and symbols

Meaning of safety signs and symbols

hazard identification

facility or location signs

directional

traffic warning signs and symbols

1.3 Identify and demonstrate use of plant and equipment guards in

accordance with manufacturer’s specifications use of plant and equipment

guards in accordance with manufacturer’s specifications

Plant and equipment manufacturers specifications

Plant and equipment user manuals

1.4 Identify and implement safe manual handling procedures

in line with workplace procedures

Different safe manual handling procedures

Correct methods of manually lifting and moving loads

1.5 Apply the safety procedures for the use, handling and

storage of potentially hazardous substances in accordance

with instructions and legislation

Identify materials common to the electrical industry which can be hazardous

to the workers’ health

Solvents

Hydrogen and other gases

Paints. Lead, isocyanates, polymers

Coolants, PCBs. etc.

Thermal laggings such as asbestos

Safety procedures for the use, handling and storage of potentially hazardous

substances

Safe and correct handling, use, and storage of different types of hazardous

substances

Hazardous substances regulations

Safe and correct disposal of hazardous substances

1.6 Manage waste in accordance with instructions and relevant legal

requirements

Manage waste according to instructions and relevant legal requirements

Different types of solid, liquid and gas waste

Waste management regulations

Safe and correct handling of waste Safe and correct disposal of waste

Assessment Tasks:

Written and/or oral assessment on the skills and knowledge required to conduct

appropriate :

Safety, Health, Environmental and quality management

1. As outlined in the assessment criteria and content above.

Practical assessment on the conducting the following of SHEQ requirements, the

consideration of environmental factors which affect Safety,

Health,Environmental and quality management Conditions/Context of

assessment

2 Written and/or oral assessment can be conducted in a classroom environment.

Oral assessment can also be conducted by the assessor during the performance

of the practical assessment by the trainees.

3The practical assessment will be conducted in the plant or simulated work

environment in the training institution.

4 The context of assessment should include the facilities, tools, equipment and

materials listed below:

1. Basic Electrician tool kit: Safety manuals

2. Reference materials

3. Emergency and evacuation procedures

4. Labour Act

5. Relevant sections of Occupational Health and Safety Regulations

6. Personal protective equipment and clothing

7. Common signs and symbol

8. Common chemicals

9. Firefighting equipment

10. Different types of scaffolding and work platforms

11. Different types of ladders

Learning Outcome 02

Guarantee SHEQ at workplace

Assessment Criteria:

1.2.1 Issue /wear appropriate PPE

1.2.2 Inspect suitability of PPE

1.2.3 Identify training needs

1.2.4 Do appropriate training

1.2.5 Monitor SHEQ Regulations adherence

Content:

1.2.1 Issue /wear appropriate PPE

Demonstrate the selection, wearing and storage of Personal Protective

Equipment according to job requirements and workplace procedures.

Meaning of the term PPE

Importance of the wearing and using PPE

Safe and correct handling, use, maintenance and storage of different types

of PPE

1.2.2 Inspect suitability of PPE

1. Different types of PPE and their uses

2. Headgear

3. Gloves

4. Safety glasses and goggles

5. Work suits, Coveralls and other body protective gear

6. Ear plugs and ear muffs

7. Safety boots

8. Respirator/Mask

9. Safety Belts

1.2.3 Identify training needs

SHEQ Requirements regarding

-workplace safety

-Housekeeping

-Protection of Equipment

1.2.4 Do appropriate training

SHEQ Training

1.2.5 Monitor SHEQ Regulations adherence

Monitor SHEQ Regulations adherence

-house keeping

-usage of appropriate PPE

-Protection of Equipment in accordance with set standards

-Usage of Signs and Symbols

-Availability of First Aid Equipment

Labour Act

Relevant sections of Occupational Health and Safety Regulations

Personal protective equipment and clothing

Common signs and symbol

Learning Outcome 03

Perform housekeeping

Assessment Criteria:

1.3.1 Classify materials to be sorted

1.3.2 Apply the 5 –S (sorting, setting, shining, standardize, sustain) as per

procedure.

1.3.3 Carry out appropriate waste disposal procedures

Content

1.3.1 Classify materials to be sorted

Apply the safety procedures for the use, handling and storage of potentially

hazardous substances in accordance with instructions and legislation

Identify materials common to the electrical industry which can be hazardous

to the workers’ health

Solvents

-Hydrogen and other gases

-Paints. Lead, isocyanates, polymers

-Coolants, PCBs. etc.

Thermal laggings such as asbestos safety procedures for the use, handling

and storage of potentially hazardous substances

Safe and correct handling, use, and storage of different types of hazardous

substances

Hazardous substances regulations

Safe and correct disposal of hazardous substances

1.3.2 Apply the 5 –S (sorting, setting, shining, standardize, sustain) as per

procedure.1.7

Manage waste in accordance with instructions and relevant legal

requirements

Manage waste according to instructions and relevant legal requirements

Different types of solid, liquid and gas waste

Waste management regulations

Safe and correct handling of waste

Safe and correct disposal of waste

1.3.3 Carry out appropriate waste disposal procedures

Identify appropriate waste disposal procedure.

- Implement plans for the disposal of waste

Importance of implementing plans for storage and disposal of waste

Importance of establishing working methods for the management of waste

Identify and complete records or documentation relating to the storage,

transport or disposal of waste.

Importance of identifying and completing records or documentation relating

to the storage, transport or disposal of waste.

Learning Outcome 04

Adhere to emergency preparedness procedures

Assessment Criteria:

1.4.1 Carryout pre -induction

1.4.2 Identify workplace dangers and appropriate mitigatory measures.

1.4.3 Adhere to emergency alarms

Content:

1.4.1 Carryout pre -induction

Emergency and evacuation procedures

-Identify appropriate personnel in line with communication channels in the

event of an emergency

-Demonstrate safe workplace procedures for dealing with accidents, fires and

emergencies within scope of responsibility.

- Carry out emergency and evacuation procedures in line with workplace

procedures.

1.4.2 Identify workplace dangers and appropriate mitigatory

measures.

Identify workplace dangers

-Identify the causes and effects of the hazards associated with the use of

electrical equipment

-Demonstrate the application of safety rules of checking cables, leads plugs and

earthing.

- Demonstrate the application of safety rules of working with portable and

reduced voltage.

-Demonstrate the application of measures for avoiding contact with live

connections.

Demonstrate Administration of First Aid victim of electric shock, treat burns.

1.4.3 Adhere to emergency alarms

Identify appropriate personnel in line with communication channels in the

event of an emergency

Demonstrate safe workplace procedures for dealing with accidents, fires and

emergencies within scope of responsibility.

-Importance of the application of safe workplace procedures for dealing with

accidents, fires and emergencies within scope of responsibility.

Use various types of fire extinguishers ,Firefighting methods and types of

firefighting equipment.

Carry out emergency and evacuation procedures in line with workplace

procedures.

-Importance of different workplace emergency and

evacuation procedures.

You might also like

- Peo2 001Document7 pagesPeo2 001Jimmy Gray0% (1)

- Qpeo2 001Document7 pagesQpeo2 001Daniel Cowie0% (1)

- Laboratory Safety HandbookDocument134 pagesLaboratory Safety HandbookBidhan RajkarnikarNo ratings yet

- Personal Protective EquipmentDocument3 pagesPersonal Protective EquipmentgagsvashNo ratings yet

- 1.1 Health and Safety Knowledge QuestionsDocument5 pages1.1 Health and Safety Knowledge QuestionsJack PetersNo ratings yet

- Practice Occupational Health and Safety ProceduresDocument4 pagesPractice Occupational Health and Safety ProceduresREYNALDO DONIONo ratings yet

- MODULES OF INSTRUCTION Commonsmawnc1Document51 pagesMODULES OF INSTRUCTION Commonsmawnc1KaJong JaclaNo ratings yet

- The Health and Safety at Work Act 1974Document52 pagesThe Health and Safety at Work Act 1974vrlbhavanisankaram3786No ratings yet

- Eal Qpeo2001 ADocument5 pagesEal Qpeo2001 A4612011No ratings yet

- Deped K To 12 Technology and Livelihood Education - Nail CareDocument6 pagesDeped K To 12 Technology and Livelihood Education - Nail Careyachiru12175% (4)

- Working Practices in Engineering: Unit 1Document40 pagesWorking Practices in Engineering: Unit 1Narendar SaggamNo ratings yet

- Occupational Health & Safety (OHS)Document36 pagesOccupational Health & Safety (OHS)MmeraKi100% (1)

- Engineering Health & Safety RegulationsDocument12 pagesEngineering Health & Safety RegulationsKeron BretalNo ratings yet

- Ethics in Safety Equipment BusinessDocument15 pagesEthics in Safety Equipment BusinessRevati WableNo ratings yet

- Learning Guide Learning Guide - 3: Vehicle Servicing Vehicle Servicing NTQF Level IDocument82 pagesLearning Guide Learning Guide - 3: Vehicle Servicing Vehicle Servicing NTQF Level Iabel assefaNo ratings yet

- Princ. Administration Workbook - (New SAMPLE)Document21 pagesPrinc. Administration Workbook - (New SAMPLE)Avram AlexandraNo ratings yet

- Contractor HSE InstructionsDocument24 pagesContractor HSE InstructionsLiyakathalikhan Shahjahan100% (1)

- Biosafety Test NotesDocument11 pagesBiosafety Test NotesWARDAH SHOAIBNo ratings yet

- Intro To Indus Arts - Midterm TopicDocument7 pagesIntro To Indus Arts - Midterm Topicjhayarangote473No ratings yet

- Engineering Health and SafetyDocument24 pagesEngineering Health and SafetyKobby BrineNo ratings yet

- Danut-Princ. Administration Workbook - V1.18 PDFDocument21 pagesDanut-Princ. Administration Workbook - V1.18 PDFsomyntNo ratings yet

- Safety Inspection Course (With Workshop)Document86 pagesSafety Inspection Course (With Workshop)YeddaMIlaganNo ratings yet

- General Safety Requirements Summary (39Document76 pagesGeneral Safety Requirements Summary (39Raja GuruNo ratings yet

- Safety SOP ProceduresDocument4 pagesSafety SOP ProceduresMarc GelacioNo ratings yet

- IADC Rig Crew SkillsDocument73 pagesIADC Rig Crew SkillsGoutam Manna100% (4)

- SOPs: Standard safety guidelinesDocument3 pagesSOPs: Standard safety guidelinesMarella surendraNo ratings yet

- Lecture Safety InspectionDocument43 pagesLecture Safety InspectionRose Mica AngelesNo ratings yet

- Applying Farm Safety MeasuresDocument6 pagesApplying Farm Safety MeasuresHernandez KeithNo ratings yet

- 11 04 2021 TTLM Monitor and Evaluate FireDocument63 pages11 04 2021 TTLM Monitor and Evaluate FireRafez JoneNo ratings yet

- 11 09 2021 TTLM Monitor and Evaluate FireDocument64 pages11 09 2021 TTLM Monitor and Evaluate FireRafez Jone100% (1)

- Health and Safety Program Consists of Eight Basic ComponentsDocument9 pagesHealth and Safety Program Consists of Eight Basic ComponentsNath SebastianNo ratings yet

- Michigan State University: Personal Protective Equipment GuidelinesDocument40 pagesMichigan State University: Personal Protective Equipment GuidelinessanpkaruNo ratings yet

- Lifting Equipment Inspection GuideDocument254 pagesLifting Equipment Inspection GuideChiheb Kaaniche100% (2)

- Safety 2 PpeDocument34 pagesSafety 2 PpeRamNo ratings yet

- Mod 2Document132 pagesMod 2Sudheesh SNo ratings yet

- EPP ManualDocument40 pagesEPP ManualAndyAlfonsNo ratings yet

- Reinstate Work Areas After Maintenance (40Document4 pagesReinstate Work Areas After Maintenance (40Abdulhameed HamadNo ratings yet

- SITXWHS001 Assessment 1 - Short AnswersDocument15 pagesSITXWHS001 Assessment 1 - Short AnswersAnkit BhattraiNo ratings yet

- NTPC 2004 Safety ManualDocument287 pagesNTPC 2004 Safety ManualHari Krishna.M100% (2)

- Albofera Manufacturers SEAMDocument10 pagesAlbofera Manufacturers SEAMALBOFERA, PRAISE GEE L.No ratings yet

- Aeng 513 Easa Part 66 Module 7Document70 pagesAeng 513 Easa Part 66 Module 7Charbel SayyarNo ratings yet

- 1 HLTWHS002 PPSlides V1.0.pptx (Autosaved)Document145 pages1 HLTWHS002 PPSlides V1.0.pptx (Autosaved)Leanne EvansNo ratings yet

- CPCCPB3026 PresentationDocument85 pagesCPCCPB3026 PresentationAbdul HaseebNo ratings yet

- IntroductionDocument8 pagesIntroductionArokiaraj AmalrajNo ratings yet

- نموذج خطة السلامة والصحة المهنية3Document4 pagesنموذج خطة السلامة والصحة المهنية3أحمد سالمNo ratings yet

- National Occupation Standards: Vehicle Damage AssessorsDocument24 pagesNational Occupation Standards: Vehicle Damage Assessorsibrahim Aref ibrahimNo ratings yet

- Deped K To 12 Technology and Livelihood Education - Bread and Pastry Production - 001Document7 pagesDeped K To 12 Technology and Livelihood Education - Bread and Pastry Production - 001yachiru12183% (6)

- Electronic Products Assembly and Servicing Grade 11: 1 Semester - Quarter 1 Module 1 Week 1-2Document42 pagesElectronic Products Assembly and Servicing Grade 11: 1 Semester - Quarter 1 Module 1 Week 1-2CHESTER ALLAN MENDEZNo ratings yet

- OSH Industrial SafetyDocument21 pagesOSH Industrial SafetyMuhammad Syahir BadruddinNo ratings yet

- MSU PPE GuidelinesDocument40 pagesMSU PPE GuidelinesRuby SmithNo ratings yet

- Manual HSE Empresa Metal MecanicaDocument36 pagesManual HSE Empresa Metal Mecanicacz99No ratings yet

- Whmis Review HandbookDocument46 pagesWhmis Review HandbookAzabou SlehNo ratings yet

- Standards & CodesDocument15 pagesStandards & Codeseetua86% (7)

- Mechanical Drafting Quarter 4Document45 pagesMechanical Drafting Quarter 4kristine dor caprichoNo ratings yet

- Drafting Report 2 - Safety PracticesDocument11 pagesDrafting Report 2 - Safety Practicesgatchalianwarren30No ratings yet

- Safety in the Chemical Laboratory and Industry: A Practical GuideFrom EverandSafety in the Chemical Laboratory and Industry: A Practical GuideNo ratings yet

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- Hybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesFrom EverandHybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesNo ratings yet

- Presentation1Document20 pagesPresentation1tarisai doroNo ratings yet

- Right Triangle Definitions, Where 0 /2: MVCC Learning Commons IT129Document1 pageRight Triangle Definitions, Where 0 /2: MVCC Learning Commons IT129Bianca Christine AgustinNo ratings yet

- 2850 256 Sample Questions v1 0 PDF.ashxDocument7 pages2850 256 Sample Questions v1 0 PDF.ashxtarisai doroNo ratings yet

- Power Generation SyllubusDocument9 pagesPower Generation Syllubustarisai doroNo ratings yet

- Communications and Computers SyllubusDocument6 pagesCommunications and Computers Syllubustarisai doroNo ratings yet

- Nass SyllubusDocument9 pagesNass Syllubustarisai doroNo ratings yet

- 140198Document73 pages140198KhanzadaRajputNo ratings yet

- Notes On The Field Effect Transistor (Fet)Document5 pagesNotes On The Field Effect Transistor (Fet)tarisai doroNo ratings yet

- Occupational Health and SafetyDocument8 pagesOccupational Health and Safetygroup oneNo ratings yet

- Ferrolix 8353 (GB-en)Document14 pagesFerrolix 8353 (GB-en)danielNo ratings yet

- GC 2 Element 7Document25 pagesGC 2 Element 7vidya sagar boddetiNo ratings yet

- Install Habitat JSADocument3 pagesInstall Habitat JSAEprizal lNo ratings yet

- MSDS Addmix 700Document6 pagesMSDS Addmix 700Sam WitwickyNo ratings yet

- Copra MSDDocument1 pageCopra MSDStephanie AcuzarNo ratings yet

- Questionnaire For Stress Management in An OrganizationDocument8 pagesQuestionnaire For Stress Management in An OrganizationTapassya Giri33% (3)

- for Fixwool Coating 130 SDSDocument6 pagesfor Fixwool Coating 130 SDSSaleh AlTamimiNo ratings yet

- Excavation and TrenchingDocument28 pagesExcavation and TrenchingParth PatelNo ratings yet

- Personal Protective Equipment: IndexDocument9 pagesPersonal Protective Equipment: IndexNat OffeiNo ratings yet

- Safety Data Sheet - Pearl Liquid Hand Soap 1Document5 pagesSafety Data Sheet - Pearl Liquid Hand Soap 1Shingi MameNo ratings yet

- Warehouse RECEIVINGDocument1 pageWarehouse RECEIVINGamalinaNo ratings yet

- JHA For Brush Painting UpdatedDocument3 pagesJHA For Brush Painting UpdatedNawadip Rai100% (1)

- C&C-EHS-P-017 Legal and Other RequirementDocument17 pagesC&C-EHS-P-017 Legal and Other RequirementNajman HamdiNo ratings yet

- Grade 7 Tle April 1 15Document2 pagesGrade 7 Tle April 1 15Angela HidalgoNo ratings yet

- Co SHDocument4 pagesCo SHJomz YatnimNo ratings yet

- Employer'S Work Accident Illness Report: Dole/Bwc/Ohsd/Ip-6Document1 pageEmployer'S Work Accident Illness Report: Dole/Bwc/Ohsd/Ip-6ellaNo ratings yet

- Fit Small Business Sample Break Lunch PolicyDocument2 pagesFit Small Business Sample Break Lunch PolicySajid IqbalNo ratings yet

- HIRA Insullation URCDocument12 pagesHIRA Insullation URCsyed khaja misbhuddinNo ratings yet

- Accident Investigation ReportDocument3 pagesAccident Investigation ReportKhan Mohammad Mahmud HasanNo ratings yet

- CleanbladeDocument9 pagesCleanbladeNikolay OngoyNo ratings yet

- Iso VG46Document5 pagesIso VG46joyli22No ratings yet

- MSDS Sunlight LemonDocument4 pagesMSDS Sunlight LemonEgiya GoldarosaNo ratings yet

- Monthly Employee Schedule TemplateDocument2 pagesMonthly Employee Schedule TemplateMuhamad QaddafiNo ratings yet

- Department of Labor: 2007 VOSH Conf BrochureDocument6 pagesDepartment of Labor: 2007 VOSH Conf BrochureUSA_DepartmentOfLaborNo ratings yet

- TLE-FOS Mod 6Document31 pagesTLE-FOS Mod 6Vicente VicenteNo ratings yet

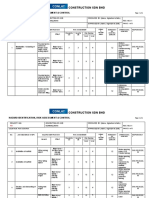

- Construction SDN BHD: Hazard Identification, Risk Assessment & ControlDocument4 pagesConstruction SDN BHD: Hazard Identification, Risk Assessment & Controlsafety_hunterNo ratings yet

- Abate MSDSDocument10 pagesAbate MSDS缪忠琴No ratings yet

- Fall Protection PPT v-03!01!17Document31 pagesFall Protection PPT v-03!01!17Mustafa AdelNo ratings yet

- aDVANCE rEGISTERDocument1 pageaDVANCE rEGISTERdsujit2000100% (2)