Professional Documents

Culture Documents

Rayclean Imo and DNV GL Type Approval Certificate

Uploaded by

AHMED MOHAMMEDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rayclean Imo and DNV GL Type Approval Certificate

Uploaded by

AHMED MOHAMMEDCopyright:

Available Formats

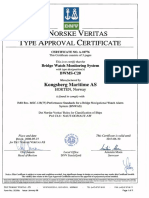

Certificate No:

P-14955

File No:

TYPE APPROVAL CERTIFICATE 771.91

Job Id:

262.1-014477-1

This is to certify:

That the Ballast Water Management System

with type designation(s)

RayClean™ BWTS

Issued to

DESMI Ocean Guard A/S

NØRRESUNDBY, Denmark

is found to comply with

Resolution MEPC.174(58)

Det Norske Veritas' Rules for Classification of Ships

DNV Type Approval Program No.771.91

Application :

This is to certify that the Ballast Water Management System listed above has been examined

and tested in accordance with the requirements of the specifications contained in Guidelines

contained in Resolution MEPC.174(58) and DNV Rules stated above. This Certificate is valid

only for the Ballast Water Management System referred to above.

This Certificate is issued on behalf of the Danish Maritime Authority and Danish Nature

Agency.

This Certificate is valid until 2018-12-31.

Issued at Høvik on 2014-09-05

for DNV GL

DNV GL local station: Aalborg Digitally Signed By: Sæle-Nilsen, Dag

Location: DNV GL Høvik, Norway

Approval Engineer: Ingrid Sigvaldsen Signing Date: 2015-02-06

Dag Sæle-Nilsen

Head of Section

This Certificate is subject to terms and conditions overleaf. Any significant change in design or construction may render this Certificate invalid.

The validity date relates to the Type Approval Certificate and not to the approval of equipment/systems installed.

If any person suffers loss or damage which is proven to have been caused by any negligent act or omission of the Society, then the Society shall

pay compensation to such person for his proven direct loss or damage. However, the compensation shall not exceed an amount equal to ten

times the fee charged for the service in question. The maximum compensation shall never exceed USD 2 million.

In this provision the “Society” shall mean DNV GL AS as well as all its direct and indirect owners, affiliates, subsidiaries, directors, officers,

employees, agents and any other person or entity acting on behalf of DNV GL AS.

Form code: TA 1411a Revision: 2014-05 www.dnvgl.com Page 1 of 4

© DNV GL 2014. DNV GL and the Horizon Graphic are trademarks of DNV GL AS.

Certificate No: P-14955

File No: 771.91

Job Id: 262.1-014477-1

Type and model designation

RayCleanTM BWTS, RayClean-300

Place of production: Nørresundby, Denmark

Equipment /assembly drawings

TYPE Description Drawing no. Rev.

Pipe and instrumentation BWTS 300 m3/h Non-EX RayClean BWTS 470460 A

diagram

Wiring diagram Master Control Panel MCP Project no. 17-7-

2000002 2014

Wiring diagram UV Control Panel UVCP Project no. 17-7-

200002 2014

Product description

The RayClean Ballast Water Management System description is given in “Operation Maintenance and

Safety Manual for RayClean by DESMI OceanGuard” approved by DNV.

Treatment sequence:

• Ballast water uptake: Filtration and UV Disinfection

• Ballast water discharge: Filtration and UV Disinfection

Application/Limitationi

Treatment rated Min UV- Intensity (W/cm2) Min. UV – Transmittance (%)

capacity (TRC)

ii

(m3/h)

300 iii 33-55

55-165

i. Verified through 15 tests meeting D-2 discharge standard on G8 land-based challenge water in fresh, brackish and marine water and 5

tests meeting D-2 discharge standard on G8 shipboard challenge water.

ii. TRC is defined as net flow out of the treatment system, a net flow exceeding the given value implies that the ballast water is not

treated in accordance with this certificate.

iii. When the UVI is between 55-165 W/m2, the flow will be regulated between 100-300m3/h to achieve the required dose. UV intensity

below the lower limit implies that the ballast water is not treated in accordance with this certificate.

Minimum capacity is 30 m3/h.

Salinity and temperature are no limiting conditions for this system.

UV unit

The system is equipped with an UV-lamp power optimization control. UV-lamp power usage is reduced in

favouarble water conditions based on measured UV-intensity. Lamp power usage can be reduced by up

to 50%.

UV units can be installed in parallel configuration to achieve treatment rated capacities up to 3000m3/h

according to the RayClean document 1011 “Overview Main Comonents and Sizes – RayClean BWTS”

dated 06-06-2014 and the RayClean installation guide.

Filter

Filter(s) shall be installed that corresponds to the ballast flow capacity.

Boll & Kirch Filter, - 30µm wire mesh

Form code: TA 1411a Revision: 2014-05 www.dnvgl.com Page 2 of 4

Certificate No: P-14955

File No: 771.91

Job Id: 262.1-014477-1

The type approved system includes a Bollfilter Automatic Filter Selfclean type 6.18.3 BWT with 30µm

wire mesh. The filter is designed for 6 or 10 Bar. The maximum allowed filter differential pressure to

initiate backflush is 0.5 bar.

Boll & Kirch type Filter max flow (m3/h)

717687 (6.18.3.419) 220

717688 (6.18.3.521) 300

717689 (6.18.3.600) 450

717690 (6.18.3.750) 850

717691 (6.18.3.900) 1250

717692 (6.18.3.1000) 1500

717693 (6.18.3.1100) 2250

717694 (6.18.3.1200) 2500

717695 (6.18.3.1330) 3000

Operational specifications for the different components

Flow Meter and Control Valve

The type approved system must be installed with a flow meter and a means for regulating the flow

through each UV unit according to the approved control curve.

Information regarding the selected components shall be part of the documentation related to the specific

installation, either by a reference to valid type approval certificate or technical documentation.

Control Equipment

The type approved system includes the following control units and sensors:

Software

Name Model Revision

UV Control Panel UV CONTROL PANEL RayClean Non-EX UV CABLE OUT

RIGHT

UV CONTROL PANEL RayClean Non-EX UV CABLE OUT

LEFT

Master Control Panel MASTER CONTROL PANEL RayClean 300 Non-EX V01.08

MASTER CONTROL PANEL RayClean 600 Non-EX 05.09.2013

MASTER CONTROL PANEL RayClean 900 Non-EX

MASTER CONTROL PANEL RayClean 1200 - 3000 Non-EX

Power Distribution POWER DISTRIBUTION PANEL RayClean 1200 Non-EX -----

Cabinetiv POWER DISTRIBUTION PANEL RayClean 1500 Non-EX

POWER DISTRIBUTION PANEL RayClean 1800 Non-EX

POWER DISTRIBUTION PANEL RayClean 2100 Non-EX

POWER DISTRIBUTION PANEL RayClean 2400 Non-EX

POWER DISTRIBUTION PANEL RayClean 2700 Non-EX

POWER DISTRIBUTION PANEL RayClean 3000 Non-EX

UV Sensor ZED D-SiCONORM-LP -----

iv. Only for systems with TRC greater than 900 m3/h.

All changes in software are to be recorded as long as the system is in use onboard. The records of all

changes are to be forwarded to DNV for evaluation and approval.

Major changes to the software are to be approved before installed in the computer.

A Certification of Application Functions may be required for the particular vessel.

Documents approval

The following documentation is to be submitted for approval in each case.

Form code: TA 1411a Revision: 2014-05 www.dnvgl.com Page 3 of 4

Certificate No: P-14955

File No: 771.91

Job Id: 262.1-014477-1

• Piping and Instrumentation Diagram (P&ID) of the ballast system including the treatment system

installation

• Power supply arrangement

• An overview of all controlled and monitored points, (I/O list)

• Description confirming the arrangement of alarms for bypass of the BWMS

Type Approval documentation

• Biological efficacy performance evaluation of Ballast Water Management System,

QAPP/V2.1/2012.11

• Preliminary Land Based Test Plan for RayClean (BWTS), 2012-11-13, rev. 2.

• RayClean Land-based testing -Final report, dated April 2014.

• RayClean - Shipboard test -Final report, dated May 2014.

• Operation Maintenance and Safety manual for RayClean, doc no. 10089, rev. 17, dated 2014-07-

04.

• Piping and instrumentation diagram with drawing number 470442 and 470458.

• Drawing Package Ballast Water Treatment (BWT)

• DELTA Test report, DANAK-19/14301, dated 2014-07-02

• Factory Acceptance Test

Tests carried out

• Land-based testing in accordance with Resolution MEPC.174 (58) witnessed by DNV

• Shipboard testing in accordance with Resolution MEPC.174 (58) witnessed by DNV

• Factory Acceptance Test of the control and automation system witnessed by DNV

• Environmental testing in accordance with Environmental test specification for instrumentation and

automation

equipment, DNV Standard for Certification No. 2.4 (April 2006) and Resolution MEPC.174 (58)

Marking of product

For traceability of this Type Approval, each treatment system is to be marked with:

• Manufacturer’s name or trade mark

• Type designation

• Serial number

Periodical assessment

For retention of the Type Approval, DNV Surveyor shall perform periodical assessments to verify that the

conditions of the TA are not altered since the certificate was issued.

The scope of periodical assessment includes:

Review of the TA documentation and verification that the documentation is still used as basis for

the production.

Review of possible changes in design, material and performance of the product.

Verification of the conpanys production and quality systems ensuring continued consistent

production of the type approved products to the required quality.

Verification that the product marking for identification and traceability to the TA Certificate is not

altered.

Copy of type approval certificate

A copy of this type approval certificate should be carried onboard a vessel fitted with this ballast water

management system at all times. An annex containing the summary reports of the test results of

landbased

and shipboard tests should be available for inspection onboard the vessel.

Form code: TA 1411a Revision: 2014-05 www.dnvgl.com Page 4 of 4

You might also like

- A0705260-Taa00001ne - 200512 Re17 Re17sDocument3 pagesA0705260-Taa00001ne - 200512 Re17 Re17saelbaroudy390No ratings yet

- MED (Module B)Document3 pagesMED (Module B)yucai.chenNo ratings yet

- Nexto Series Declaration of Conformity (DNV)Document3 pagesNexto Series Declaration of Conformity (DNV)Leandro OliveiraNo ratings yet

- Gea Westfalia - BallastDocument5 pagesGea Westfalia - BallastNorbertoNo ratings yet

- 99 157055 B Sailor 6120 Ssa System Type Approval Certificate DNVDocument3 pages99 157055 B Sailor 6120 Ssa System Type Approval Certificate DNVAnıl KahyaNo ratings yet

- ET Orske Eritas: Type Approval CertificateDocument2 pagesET Orske Eritas: Type Approval CertificateaseNo ratings yet

- DNV Type ApprovalDocument2 pagesDNV Type ApprovalPillai S KumarNo ratings yet

- Coc 064Document4 pagesCoc 064Ahmed ZidanNo ratings yet

- BW1350 DNVDocument4 pagesBW1350 DNVharmvdwNo ratings yet

- Taf00000jm 3Document3 pagesTaf00000jm 3Will SohNo ratings yet

- ET Orske Eritas: Type Approval CertificateDocument3 pagesET Orske Eritas: Type Approval CertificateJesus AguilarNo ratings yet

- DNV Liquid Mud ValveDocument3 pagesDNV Liquid Mud ValveVesna NikolicNo ratings yet

- Cavotec Micro-Control AS Coc-048Document4 pagesCavotec Micro-Control AS Coc-048Mohammad SholichudinNo ratings yet

- DNV GL Tae000045v UkDocument3 pagesDNV GL Tae000045v Ukpowerabsolut myanmarNo ratings yet

- Gunnebo Masterlink PDFDocument3 pagesGunnebo Masterlink PDFJason RobertsNo ratings yet

- Taf00000xv 1Document2 pagesTaf00000xv 1Will SohNo ratings yet

- TAF00000WS - 1 (1) DFDDocument2 pagesTAF00000WS - 1 (1) DFDWill SohNo ratings yet

- TAK00001S2Document3 pagesTAK00001S2Will SohNo ratings yet

- BWMS-C20 A-10776Document3 pagesBWMS-C20 A-10776IulianIonutRaduNo ratings yet

- Grinnell DNV Certificate PDFDocument3 pagesGrinnell DNV Certificate PDFAna Carolina SantosNo ratings yet

- TAF000012NDocument3 pagesTAF000012NNavaneeth PurushothamanNo ratings yet

- 181-SSRS AM AlphaSSRS MED-B Cert 5-7-2021Document2 pages181-SSRS AM AlphaSSRS MED-B Cert 5-7-2021Costin CaraimanNo ratings yet

- Radar Trem MEDBDocument2 pagesRadar Trem MEDBRoman BabaevNo ratings yet

- Type Approval Certificate: Schneider Electric SADocument3 pagesType Approval Certificate: Schneider Electric SAJorge Armando Astorayme MansillaNo ratings yet

- DNV-GL CertificateDocument3 pagesDNV-GL CertificateRafael ReisNo ratings yet

- Det Norske Veritas Atex en Us 4189176Document2 pagesDet Norske Veritas Atex en Us 4189176Anitta TiburciaNo ratings yet

- Procedure Cum Check List: Gujarat State Petroleum Corporation LimitedDocument17 pagesProcedure Cum Check List: Gujarat State Petroleum Corporation LimitedDanny BoysieNo ratings yet

- DNV Certificate TAA00000U5 For WMT700 PDFDocument3 pagesDNV Certificate TAA00000U5 For WMT700 PDFaseNo ratings yet

- Tap000010x 3Document3 pagesTap000010x 3NorbertoNo ratings yet

- Emergency Evacuation Breathing Device ESCAPE-15Document2 pagesEmergency Evacuation Breathing Device ESCAPE-15faroNo ratings yet

- DNV 06atex0425qDocument3 pagesDNV 06atex0425qLuiz AssisNo ratings yet

- ECG-CE Comen PDFDocument3 pagesECG-CE Comen PDFTehoptimed SA0% (1)

- RM2B3B12V Medb000061fDocument2 pagesRM2B3B12V Medb000061fzaldymagbuhos0217No ratings yet

- 153A PMS System - DNV CertificateDocument3 pages153A PMS System - DNV CertificateJosephNo ratings yet

- 153A PMS System - DNV CertificateDocument3 pages153A PMS System - DNV CertificateJosephNo ratings yet

- EC Certificate: Full Quality Assurance SystemDocument3 pagesEC Certificate: Full Quality Assurance SystemДелян МилчевNo ratings yet

- TAF00001RJDocument2 pagesTAF00001RJNavaneeth PurushothamanNo ratings yet

- ABB-ACS880-01-VFD-DNV-GL-Type-Approval-Certificate AsdavxcvDocument3 pagesABB-ACS880-01-VFD-DNV-GL-Type-Approval-Certificate AsdavxcvassfgdfNo ratings yet

- DNV Taa000015hDocument2 pagesDNV Taa000015hLuiz AssisNo ratings yet

- MCS2Document3 pagesMCS2ABOUDHNo ratings yet

- Deck SocketDocument2 pagesDeck Socketbabis lionakisNo ratings yet

- Medb00001sh 2Document2 pagesMedb00001sh 2NorbertoNo ratings yet

- Terasix 10388-2017-CE-CZS-NA-PS Rev. 1.0 .PDF - 20200515 PDFDocument3 pagesTerasix 10388-2017-CE-CZS-NA-PS Rev. 1.0 .PDF - 20200515 PDFserofcaNo ratings yet

- Dantec LTD: This Is To CertifyDocument2 pagesDantec LTD: This Is To Certifypo truongNo ratings yet

- DNV Accesory Approval 2023 02Document3 pagesDNV Accesory Approval 2023 02Jorge JuanNo ratings yet

- DNV TAP000003C Rev1-60GAA Valid-until15Sep19Document4 pagesDNV TAP000003C Rev1-60GAA Valid-until15Sep19Arif AyubNo ratings yet

- Seven Oceans 90001 - CERTDocument2 pagesSeven Oceans 90001 - CERTCarloNo ratings yet

- Din-Dvgwtype Examination Certificate: Din-Dvgw-BaumusterprüfzertifikatDocument2 pagesDin-Dvgwtype Examination Certificate: Din-Dvgw-BaumusterprüfzertifikatRicardo BarrosNo ratings yet

- Kistler Instrumente AG - DNVDocument3 pagesKistler Instrumente AG - DNVMukund IndianNo ratings yet

- Rti Certificate Med Steel Bulkhead A-60 Searox SL 620-60 25mmDocument3 pagesRti Certificate Med Steel Bulkhead A-60 Searox SL 620-60 25mmchayan.anandagroupNo ratings yet

- Qs - Certificate of Assessment - Ec (Module D) : Awg Fittings GMBHDocument2 pagesQs - Certificate of Assessment - Ec (Module D) : Awg Fittings GMBHsailbirdNo ratings yet

- Lifebuoy Ring SOLAS MED 2.5Kg and 4 KG W-Retroreflective TapeDocument2 pagesLifebuoy Ring SOLAS MED 2.5Kg and 4 KG W-Retroreflective TapeyoganveildesantosNo ratings yet

- DNV 3xxx Taa00001rwDocument4 pagesDNV 3xxx Taa00001rwtom7132414No ratings yet

- Medb0000726-Afff 3% MedDocument2 pagesMedb0000726-Afff 3% MedDinesh KhatiNo ratings yet

- Taf0000044 1Document2 pagesTaf0000044 1Canberk KarahanNo ratings yet

- Aoss0000h9m 0Document2 pagesAoss0000h9m 0JuanRamosNo ratings yet

- MESPAS Type Approval CertificateDocument2 pagesMESPAS Type Approval CertificateSergiy BelenkoNo ratings yet

- 153E FiFi Pump Motor - DNV Certificate 2Document2 pages153E FiFi Pump Motor - DNV Certificate 2JosephNo ratings yet

- SIKADocument5 pagesSIKAMukund IndianNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- 2021 Small Cruise Ship Wastewater ReportDocument24 pages2021 Small Cruise Ship Wastewater ReportAHMED MOHAMMEDNo ratings yet

- Rayclean Imo and DNV GL Type Approval CertificateDocument4 pagesRayclean Imo and DNV GL Type Approval CertificateAHMED MOHAMMEDNo ratings yet

- CaseStudy Dairy-The True Value of Wastewater enDocument3 pagesCaseStudy Dairy-The True Value of Wastewater enAHMED MOHAMMEDNo ratings yet

- BEMA BW Commisioning Testing Guidance - Dec2020Document16 pagesBEMA BW Commisioning Testing Guidance - Dec2020AHMED MOHAMMEDNo ratings yet

- DistillationDocument89 pagesDistillationjokish33% (3)

- HP Bypass System and Reheater Protection LogicDocument11 pagesHP Bypass System and Reheater Protection LogicPrathamesh Gangal80% (5)

- B018-933-80-42-SP-3002 - Rev.B-Job SpecificationsDocument67 pagesB018-933-80-42-SP-3002 - Rev.B-Job Specificationssumit kumarNo ratings yet

- DPSB-CMS-002 Project Specific Handover ProcedureDocument23 pagesDPSB-CMS-002 Project Specific Handover ProcedureSyahroslizam SuhaimiNo ratings yet

- Gate Books For Electrical EngineeringDocument2 pagesGate Books For Electrical EngineeringMichael FosterNo ratings yet

- DR Asad Abidi - June Workshop FlyerDocument2 pagesDR Asad Abidi - June Workshop Flyerahmadusman123No ratings yet

- ResumeDocument2 pagesResumeyagneshshetty2012No ratings yet

- Docslide - Us - 41 Ovation Dcs 2007 PDFDocument52 pagesDocslide - Us - 41 Ovation Dcs 2007 PDFtriplbingazi100% (1)

- C InstrumentationDocument12 pagesC InstrumentationabyzenNo ratings yet

- EEPC 119 Module 2Document7 pagesEEPC 119 Module 2Chandria CalipNo ratings yet

- 30a100dbqb23150 - Exde03 - 100 (08-10-2023) - Quality Control Plan For InstrumentationDocument100 pages30a100dbqb23150 - Exde03 - 100 (08-10-2023) - Quality Control Plan For Instrumentationsamuel madisonNo ratings yet

- Experiment 1 WLF Water Flow MeasurementDocument4 pagesExperiment 1 WLF Water Flow MeasurementYi Ling GohNo ratings yet

- CATIA - Piping & Instrumentation Diagrams 2 (PID) BROUCHEDocument5 pagesCATIA - Piping & Instrumentation Diagrams 2 (PID) BROUCHECarlos PregoNo ratings yet

- TE-419895-001 - 863-U-3001 - Gas Corrosion Inhibitor Injection Package - Rev.BDocument16 pagesTE-419895-001 - 863-U-3001 - Gas Corrosion Inhibitor Injection Package - Rev.Brizwan.zamanNo ratings yet

- 31 Series SPP Projects Compendium PDFDocument0 pages31 Series SPP Projects Compendium PDFKabil Raj100% (1)

- An Automatic Maintenance System For Nuclear Power Plants InstrumentationDocument5 pagesAn Automatic Maintenance System For Nuclear Power Plants InstrumentationcaptainrajneeshNo ratings yet

- CUAHSI Annual Report 2013Document11 pagesCUAHSI Annual Report 2013Consortium of Universities for the Advancement of Hydrologic Science, Inc.No ratings yet

- List of IEC Standards - Wikipedia, The Free EncyclopediaDocument14 pagesList of IEC Standards - Wikipedia, The Free EncyclopediaSundaresan SabanayagamNo ratings yet

- Control System Engineering Reference ManualDocument144 pagesControl System Engineering Reference ManualKaleem Ullah96% (25)

- Saudi Arabian Engineering Standards Saes J 9021Document30 pagesSaudi Arabian Engineering Standards Saes J 9021sarvesh14111984100% (1)

- HimanshuParihar NITAllahabad SemesterTransriptDocument2 pagesHimanshuParihar NITAllahabad SemesterTransriptgarvit pariharNo ratings yet

- PaccarServiceManual2005 2010Document189 pagesPaccarServiceManual2005 2010Eric Porter100% (19)

- Chart Recorder - Rototherm - Clearscan - ManualDocument26 pagesChart Recorder - Rototherm - Clearscan - Manualshahulkms100% (1)

- Ds ct9110 en CoDocument6 pagesDs ct9110 en CoJoby JacobNo ratings yet

- IEC 60063 Preferred Number Series For Resistors and CapacitorsDocument52 pagesIEC 60063 Preferred Number Series For Resistors and CapacitorsFernando SanchezNo ratings yet

- Basic Engineering Package: Equipment List Line List Piping Service Index Instrument ListDocument17 pagesBasic Engineering Package: Equipment List Line List Piping Service Index Instrument Listjenish parekhNo ratings yet

- Sep 09Document24 pagesSep 09c_nghia50% (2)

- Measurement and Instrumentation AnalysisDocument13 pagesMeasurement and Instrumentation AnalysisYinka Ajinaja0% (1)

- Ee8511 Control and Instrumentation Laboratory PMCDocument73 pagesEe8511 Control and Instrumentation Laboratory PMCILYAS BASHA100% (1)

- Bulk Storage Transfer Equipment PsDocument1 pageBulk Storage Transfer Equipment Psalvaro netoNo ratings yet

- 1.engineering & Commissioning Manager (ECM)Document7 pages1.engineering & Commissioning Manager (ECM)harrisvasNo ratings yet