Professional Documents

Culture Documents

Adjustment Instructions: From WM No. 5044 Onwards

Uploaded by

Mohammedasif0 ratings0% found this document useful (0 votes)

2 views4 pagesOriginal Title

451_3R_e

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views4 pagesAdjustment Instructions: From WM No. 5044 Onwards

Uploaded by

MohammedasifCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

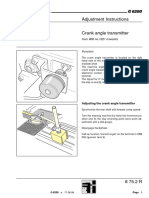

Adjustment Instructions

Pick finding device

from WM no. 5044 onwards

1 Function

The rear shaft, which in turn controls the shedding

motion, is driven by the creep speed motor via an

electromagnetic gear coupling. The shedding mech-

anism opens the weave shed in accordance with the

weave repeat, so that the broken pick is exposed.

Operation

Pick finding forward or reverse is initiated by pressing

control button 1 or 2. The weaving machine then

moves automatically into the pick finding position and

the shedding motion seeks the shed for the last weft

insertion.

2

4 51.3 R

G 6200 e 18.10.99 Page 1

Fitting coupling sensor

Screw clutch sensor 3 right into the drive housing,

then back approx. 3 turns.

Plug connector X111 into the appropriate socket (RGG

board in the control cabinet). Secure the sensor cable

with a cable binder over the main motor.

Set clutch sensor 3.

X111

X112

X113 X114

X111

X123

X124

X121 X122

4 51.3 R

Page 2 G 6200 e 18.10.99

Setting the clutch sensor

During this setting work the weaving

machine must be switched off, the

emergency stop button locked and the

notice "Machine stopped" displayed

prominently on this weaving machine.

Before starting with the setting, make sure that pick

finding clutch 4 is engaged.

4

Checking clutch position

7 Slacken nut 6 until screw 7 is no longer tight.

6

8 Turn screw 7 a quarter turn and remove cover 8.

Check clutch position.

Replace cover in reverse order, locking screw 7 with

a hexagon socket wrench.

Adjusting the clutch

– Screw clutch sensor into the drive housing until the

LED in the sensor holder lights up.

– Turn the clutch sensor another quarter to half turn

and secure with lock nut 9, making sure that the

clutch sensor does not turn as well.

9 Before starting weaving, replace all pro-

tective covers and place the control

cabinet so that the creep speed and

LED main drives are covered.

4 51.3 R

G 6200 e 18.10.99 Page 3

You might also like

- kiểm tra twistlocks (khó gù)Document5 pageskiểm tra twistlocks (khó gù)Nguyễn Văn HùngNo ratings yet

- Adjustment Instructions: From WM No.1021 OnwardsDocument4 pagesAdjustment Instructions: From WM No.1021 OnwardsMohammedasifNo ratings yet

- Timing ExerciceDocument12 pagesTiming Exercicehector eduardo moya benavidesNo ratings yet

- Adjustment Instructions: Jacquard MachineDocument2 pagesAdjustment Instructions: Jacquard MachineMohammedasifNo ratings yet

- Benchmark MC-12 - ManualDocument6 pagesBenchmark MC-12 - ManualWatch ShamsNo ratings yet

- DANequip 25SP - 27SP Manual PDFDocument18 pagesDANequip 25SP - 27SP Manual PDFKim SparkesNo ratings yet

- 4WNA & 4WFA Winch Operations ManualDocument14 pages4WNA & 4WFA Winch Operations Manualsukri arjunaNo ratings yet

- Repeat Back Unit (Type HE Wide Rudder Angle)Document1 pageRepeat Back Unit (Type HE Wide Rudder Angle)craponzelNo ratings yet

- Series 70 Electric Actuators: Quick Start GuideDocument2 pagesSeries 70 Electric Actuators: Quick Start GuideTrio Adi PamungkasNo ratings yet

- Proaim Spin 3 Axis Motorized Pan Tilt Head PT SPIN 3Document5 pagesProaim Spin 3 Axis Motorized Pan Tilt Head PT SPIN 3Ismael Morales HerreraNo ratings yet

- Speci-Mix Aliquot Mixer 26100Document11 pagesSpeci-Mix Aliquot Mixer 26100Rumy CascoNo ratings yet

- User Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesDocument12 pagesUser Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesTGM KalimantanNo ratings yet

- User Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesDocument12 pagesUser Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesIsaac Isaias AlvarezNo ratings yet

- Valve/Tappet Clearance Valve/Tappet Clearance: ! CautionDocument2 pagesValve/Tappet Clearance Valve/Tappet Clearance: ! CautionVenkatNo ratings yet

- CAT Compression Brake Lash - AdjustDocument2 pagesCAT Compression Brake Lash - Adjustbenge henrique100% (2)

- Panasonic Ey7440 Manual de Usuario Páginas 7 9Document3 pagesPanasonic Ey7440 Manual de Usuario Páginas 7 9Mr. Gonza M.No ratings yet

- Subaru Direct Ignition Operation and DiagnosisDocument4 pagesSubaru Direct Ignition Operation and DiagnosisJayNo ratings yet

- Windshield Wipers and WashersDocument10 pagesWindshield Wipers and WashersPelis CloneNo ratings yet

- WheelHorse Raider 12 Owners Manual 1-6231 - 357Document12 pagesWheelHorse Raider 12 Owners Manual 1-6231 - 357Kevins Small Engine and Tractor Service50% (4)

- Manual de Instalação WarnerDocument8 pagesManual de Instalação WarnerЭлектроника EletroeletrônicaNo ratings yet

- MCH Control Handle Addition or Replacement of PartsDocument8 pagesMCH Control Handle Addition or Replacement of PartsporitzNo ratings yet

- Windshield Wipers and WashersDocument6 pagesWindshield Wipers and WashersPelis CloneNo ratings yet

- Manual For Cen H v6000 v6500Document5 pagesManual For Cen H v6000 v6500Julio Daniel Melendez RazoNo ratings yet

- Tabla de Conversión de TorquesDocument2 pagesTabla de Conversión de TorquesLuis TorresNo ratings yet

- Renault 19 Dci Timing Belt GuideDocument1 pageRenault 19 Dci Timing Belt GuideLucian Elena IlcauNo ratings yet

- VibrodijagnostikaDocument20 pagesVibrodijagnostikaPerc AleksandarNo ratings yet

- Transpol 2Document46 pagesTranspol 2MarcusrezendejuniorNo ratings yet

- LC-04B Plus Tabletop Low Speed Centrifuge: Operation Manual Maintenance InstructionsDocument6 pagesLC-04B Plus Tabletop Low Speed Centrifuge: Operation Manual Maintenance InstructionsManuela OchoaNo ratings yet

- Kitchen Aid k45 Service Manual For Hobart Made Vintage Mixers CompressDocument30 pagesKitchen Aid k45 Service Manual For Hobart Made Vintage Mixers Compresshartfordmove9328100% (1)

- Bowens Illumitran 3Document22 pagesBowens Illumitran 3vicentolueNo ratings yet

- Instruction Manual For Multi Head Drilling Machine LZD12-17Document22 pagesInstruction Manual For Multi Head Drilling Machine LZD12-17tommy.noelNo ratings yet

- Cummins Jake BrakeDocument7 pagesCummins Jake BrakerowanNo ratings yet

- 103 Series - DS - EN - 04.2011 - V1.4Document4 pages103 Series - DS - EN - 04.2011 - V1.4rafael lalaNo ratings yet

- SectionalizersDocument30 pagesSectionalizersNoel DegonesNo ratings yet

- Creeping Speed G6200Document16 pagesCreeping Speed G6200muhammedasif100% (1)

- Advent X Rear Derailleur Installation VerRD002003Document30 pagesAdvent X Rear Derailleur Installation VerRD002003inoxsteelNo ratings yet

- NTC45LED Floodlight Operating ProcedureDocument9 pagesNTC45LED Floodlight Operating ProcedureDerrickNo ratings yet

- MV Switchgear Operation Procedure and Interlock Condition: Unit 4Document58 pagesMV Switchgear Operation Procedure and Interlock Condition: Unit 4sherifmoussaNo ratings yet

- Lift Chart: KR-20H-L KATO Rough Terrain Mobile CraneDocument7 pagesLift Chart: KR-20H-L KATO Rough Terrain Mobile CraneChristopher Ong100% (1)

- Service: SMCS - 1290 2009/02/17 Electronic Unit Injector - Adjust (SENR9888)Document2 pagesService: SMCS - 1290 2009/02/17 Electronic Unit Injector - Adjust (SENR9888)SyahdiNo ratings yet

- Kurimat Solar GTO - 601-700Document100 pagesKurimat Solar GTO - 601-700Mohamed AbdelbadieNo ratings yet

- Pub 8037 2 2019Document2 pagesPub 8037 2 2019Philippe LajoieNo ratings yet

- Pfaff - 72 Manual ENDocument45 pagesPfaff - 72 Manual ENTurtle LacrosseNo ratings yet

- D PwrView 001NHNA ENU SBData SB2 2392Document3 pagesD PwrView 001NHNA ENU SBData SB2 2392Alex CummingsNo ratings yet

- Interbrake AEBDocument6 pagesInterbrake AEBKarim BaddagNo ratings yet

- Escape Clock Spring Removal and Installation.Document5 pagesEscape Clock Spring Removal and Installation.Tom DunningNo ratings yet

- Tiger Heated GripsDocument9 pagesTiger Heated Gripschampion11311No ratings yet

- Operation Manual of Crimping MachineDocument14 pagesOperation Manual of Crimping Machinebinbaz29100% (1)

- Nikon ML-3Document36 pagesNikon ML-3Ренат РахматуллинNo ratings yet

- Sargent and Greenleaf Mechanical Safe Lock GuideDocument28 pagesSargent and Greenleaf Mechanical Safe Lock Guidecanuseemenow00100% (1)

- E S S O S M: Lectric Lideout Ystem Peration AND Ervice AnualDocument21 pagesE S S O S M: Lectric Lideout Ystem Peration AND Ervice AnualJuan ContrerasNo ratings yet

- CP2Document172 pagesCP2ahmedNo ratings yet

- 4in Chain-Vey - ManualDocument29 pages4in Chain-Vey - ManualRonald Barcia100% (1)

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceNo ratings yet

- WheelHorse WORKHORSE "700" TRACTOR Manual1-3745-3741Document12 pagesWheelHorse WORKHORSE "700" TRACTOR Manual1-3745-3741Kevins Small Engine and Tractor ServiceNo ratings yet

- Adjustment Instructions: From WM No 5044 OnwardsDocument6 pagesAdjustment Instructions: From WM No 5044 OnwardsMohammedasifNo ratings yet

- INSTALLATION Brake SwitchDocument2 pagesINSTALLATION Brake SwitchJose BaldomeroNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Adjustment Instructions: FunctionDocument4 pagesAdjustment Instructions: FunctionMohammedasifNo ratings yet

- Adjustment Instructions: From WM No 5044 OnwardsDocument6 pagesAdjustment Instructions: From WM No 5044 OnwardsMohammedasifNo ratings yet

- ATA Hard DriveDocument42 pagesATA Hard DriveMohammedasifNo ratings yet

- Adjustment Instructions: (WM With Race Board)Document4 pagesAdjustment Instructions: (WM With Race Board)MohammedasifNo ratings yet

- Information Electrical Installation: 1.1 Basic RequirementsDocument6 pagesInformation Electrical Installation: 1.1 Basic RequirementsMohammedasifNo ratings yet

- Textile Technology: From WM No. 5044Document24 pagesTextile Technology: From WM No. 5044MohammedasifNo ratings yet

- Manual PR90 en 2.0webDocument24 pagesManual PR90 en 2.0webMohammedasifNo ratings yet

- SS 9597333 18331799 061Document12 pagesSS 9597333 18331799 061MohammedasifNo ratings yet

- Encoder Buffer BoardDocument4 pagesEncoder Buffer BoardMohammedasifNo ratings yet

- Final Marine Engineering TestDocument13 pagesFinal Marine Engineering TestMohammedasifNo ratings yet

- Weft-Feeder Sper PartesDocument6 pagesWeft-Feeder Sper PartesMohammedasifNo ratings yet

- ROJ - GB-Luna X3Document43 pagesROJ - GB-Luna X3MohammedasifNo ratings yet

- GAL22V10Document29 pagesGAL22V10Jesus RodriguezNo ratings yet

- S.No Title OrginisationDocument3 pagesS.No Title OrginisationMohammedasifNo ratings yet

- Stepper EncoderDocument2 pagesStepper EncoderMohammedasifNo ratings yet

- Final Marine Engineering TestDocument12 pagesFinal Marine Engineering TestMohammedasifNo ratings yet

- Wiring Diagram ECU 2KD FTVDocument2 pagesWiring Diagram ECU 2KD FTVMohammedasifNo ratings yet

- Vendaxo - Sulzer Loom Machinery - Width - 153 InchDocument3 pagesVendaxo - Sulzer Loom Machinery - Width - 153 InchMohammedasifNo ratings yet

- 20 A18 Terminal IDDocument1 page20 A18 Terminal IDMohammedasifNo ratings yet

- Wiring Diagram ECU 2KD-FTVDocument13 pagesWiring Diagram ECU 2KD-FTVDam Nguyen87% (95)

- Circuit SDMDocument8 pagesCircuit SDMMohammedasifNo ratings yet

- Rotry Encoder LCDDocument3 pagesRotry Encoder LCDMohammedasifNo ratings yet

- ReadmerDocument79 pagesReadmersatyajtiNo ratings yet

- Stepper EncoderDocument2 pagesStepper EncoderMohammedasifNo ratings yet

- 20 A18 Terminal ID PDFDocument220 pages20 A18 Terminal ID PDFMohammedasif100% (2)

- Rotry Encoder LCDDocument3 pagesRotry Encoder LCDMohammedasifNo ratings yet

- 4 2pwrsply MSGDocument41 pages4 2pwrsply MSGjohn smithNo ratings yet

- 000-0293 LL3 Probe Install Quick Reference GuideDocument2 pages000-0293 LL3 Probe Install Quick Reference GuideMohamed BoumedieneNo ratings yet

- MANUAL PARTES Y SERVICIO SD100sDocument58 pagesMANUAL PARTES Y SERVICIO SD100sAlberto LimónNo ratings yet

- List of Companies in MalaysiaDocument35 pagesList of Companies in MalaysiaBoskkurr GamingNo ratings yet

- Pegasus Spare PartsDocument54 pagesPegasus Spare PartsAndy LNo ratings yet

- Carrier and Midea Price List On 7th December 2023Document5 pagesCarrier and Midea Price List On 7th December 2023mostafa mahmoudNo ratings yet

- R1600G Load Haul Dump Operator Familiarization Student MaterialsDocument14 pagesR1600G Load Haul Dump Operator Familiarization Student Materialspaul heberth areche conovilcaNo ratings yet

- MG ZS Brochure Jul 2022Document13 pagesMG ZS Brochure Jul 2022James SmithNo ratings yet

- Rotary Joint: DR Pp1Document2 pagesRotary Joint: DR Pp1Phomma KhinphommavongNo ratings yet

- ZF Transmission ZF s5 47 Troubleshooting GuideDocument22 pagesZF Transmission ZF s5 47 Troubleshooting GuideManuel Acuña HernandezNo ratings yet

- Cat. Parker Pradifa Dirt SealsDocument2 pagesCat. Parker Pradifa Dirt SealsAlejandro GilNo ratings yet

- Big Blue - High Performance Fireproofing Pump and MixerDocument2 pagesBig Blue - High Performance Fireproofing Pump and MixerJonathan MendozaNo ratings yet

- OPERATIONDocument98 pagesOPERATIONvictor laraNo ratings yet

- 6.hydraulic Pressure SpesificationDocument3 pages6.hydraulic Pressure SpesificationTLK ChannelNo ratings yet

- Forklift - Battery - Ebook FINALDocument18 pagesForklift - Battery - Ebook FINALLuis GarridoNo ratings yet

- Datasheet LFU119XDocument2 pagesDatasheet LFU119XMohammed Tausif AhmedNo ratings yet

- 2022 09 22 Draft Wbs Si Unit 2 Pltu BanjarsariDocument77 pages2022 09 22 Draft Wbs Si Unit 2 Pltu BanjarsariMuhamad JemadiNo ratings yet

- L4400F (2wd) : VENDOR: Kubota Section: Engine Diagram: 010200 Piston and CrankshaftDocument5 pagesL4400F (2wd) : VENDOR: Kubota Section: Engine Diagram: 010200 Piston and CrankshaftMilton Quispe ChillitupaNo ratings yet

- Catálogo RexrothDocument228 pagesCatálogo RexrothJard CarvalhoNo ratings yet

- Door Lock Control System: DescriptionDocument2 pagesDoor Lock Control System: DescriptionMaxi SardiNo ratings yet

- Vehicle Surveillance - Basic Tactics, Part 1 PDFDocument15 pagesVehicle Surveillance - Basic Tactics, Part 1 PDFZoltán CserneiNo ratings yet

- HDS01Document3 pagesHDS01Sylvain AguedaNo ratings yet

- Classification of Production SystemDocument7 pagesClassification of Production SystemRahul BanerjeeNo ratings yet

- Vertical Transportation SystemDocument14 pagesVertical Transportation Systempassionpropel100% (3)

- Retreaded Tyres: Quality, Economy and Eco-EfficiencyDocument20 pagesRetreaded Tyres: Quality, Economy and Eco-EfficiencyLucky TraderNo ratings yet

- 1. Cẩm Nang Sửa Chữa Hệ Thống Điện Xe Honda Civic 2012Document138 pages1. Cẩm Nang Sửa Chữa Hệ Thống Điện Xe Honda Civic 2012Ngọc NamNo ratings yet

- (AC Drive) Electric Stand-On Straddle Stacker (1500/1700 KG.)Document2 pages(AC Drive) Electric Stand-On Straddle Stacker (1500/1700 KG.)Sai UrjaNo ratings yet

- The Oriental Insurance Company Limited: Particulars of Insured VehicleDocument2 pagesThe Oriental Insurance Company Limited: Particulars of Insured VehicleAnkit SinghNo ratings yet

- Enerpac Hydratight Powergen CapabilitiesDocument81 pagesEnerpac Hydratight Powergen CapabilitiesAhmed El TayebNo ratings yet

- Type AxleDocument17 pagesType AxleazroyNo ratings yet

- Yamaha Yzf-R15 CatalogueDocument59 pagesYamaha Yzf-R15 CatalogueAnonymous KoA00wXXD85% (60)