Professional Documents

Culture Documents

Adjustment Instructions: Jacquard Machine

Adjustment Instructions: Jacquard Machine

Uploaded by

Mohammedasif0 ratings0% found this document useful (0 votes)

1 views2 pagesOriginal Title

875_3R_e

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views2 pagesAdjustment Instructions: Jacquard Machine

Adjustment Instructions: Jacquard Machine

Uploaded by

MohammedasifCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Adjustment Instructions

Crank angle transmitter

Jacquard machine

Function

The crank angle transmitter is located on the right

hand side of the machine and is driven by the inter-

mediate shaft.

The machine angle values are transferred by the

crank angle transmitter to the computer (CPU) of the

electronic control and can be called up at the WM

terminal.

The signal for 0° machine angle must be given when

the sley is exactly in its frontmost position.

Adjusting the crank angle transmitter

Synchronize the rear shaft with forward creep speed.

Turn the weaving machine by hand into frontmost po-

sition and fix the sley reversing point (zero point ad-

justment) with a dial gauge.

Disengage handwheel.

Call up function "current angle" on the terminal in OB6

D02 (generic term 6).

8 75.3 R

G 6200 e 17.08.99 Page 1

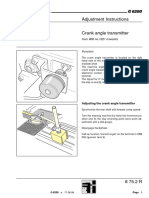

Remove plastic screw plug 1 from the crank angle

transmitter.

Loosen screw 2 of clutch ring 3.

3 5

Using a screw driver, turn the crank angle transmitter

until the function "current angle" on the terminal reads

0 degrees (increasing in counter-clockwise direc-

tion).

Position clutch ring 3 laterally so that clutch disc 5

∑ = 0,5 mm has an axial play of approx. 0.5 mm.

3 Tighten screw 2.

Check: Turn the weaving machine by hand, making

sure that the function "Current angle" always reads 0°

when the sley is in frontmost position.

2 Install plastic screw plug 1.

Remove dial gauge.

8 75.3 R

Page 2 G 6200 e 17.08.99

You might also like

- CAT c15 Ecm PinoutDocument13 pagesCAT c15 Ecm Pinoutmohamedfatoh87% (15)

- W211 Engine Wiring Diagram LegendDocument1 pageW211 Engine Wiring Diagram Legendnik50% (2)

- OM - 11594020 - NIRWise Plus Software - enDocument34 pagesOM - 11594020 - NIRWise Plus Software - enSamuel SuNo ratings yet

- ScaniaDocument6 pagesScaniaGustavo Paez100% (2)

- Securebasebook PDFDocument184 pagesSecurebasebook PDFMiyamoto MusashiNo ratings yet

- Briot 6000 Scanform III Maintenance ManualDocument153 pagesBriot 6000 Scanform III Maintenance ManualLeonardoNo ratings yet

- JUKI HZL-G Series Service ManualDocument34 pagesJUKI HZL-G Series Service Manualneotoxin100% (1)

- Sextant User's GuideDocument24 pagesSextant User's GuideHenrik Lindqvist100% (1)

- 20 A18 Terminal ID PDFDocument220 pages20 A18 Terminal ID PDFMohammedasif100% (2)

- Adjustment Instructions: From WM No.1021 OnwardsDocument4 pagesAdjustment Instructions: From WM No.1021 OnwardsMohammedasifNo ratings yet

- Adjustment Instructions: From WM No. 5044 OnwardsDocument4 pagesAdjustment Instructions: From WM No. 5044 OnwardsMohammedasifNo ratings yet

- Instruction Manual For Multi Head Drilling Machine LZD12-17Document22 pagesInstruction Manual For Multi Head Drilling Machine LZD12-17tommy.noelNo ratings yet

- LEYBOLD 554 831e GoniometerDocument4 pagesLEYBOLD 554 831e GoniometermsiarovNo ratings yet

- Adjustment Instructions: From WM No 5044 OnwardsDocument6 pagesAdjustment Instructions: From WM No 5044 OnwardsMohammedasifNo ratings yet

- G-5500 Im Eng E12901004Document12 pagesG-5500 Im Eng E12901004ampetreNo ratings yet

- Proaim Spin 3 Axis Motorized Pan Tilt Head PT SPIN 3Document5 pagesProaim Spin 3 Axis Motorized Pan Tilt Head PT SPIN 3Ismael Morales HerreraNo ratings yet

- 1 Digital Precision Optical Dividing HeadDocument3 pages1 Digital Precision Optical Dividing HeadAnand Hariharan0% (1)

- Repeat Back Unit (Type HE Wide Rudder Angle)Document1 pageRepeat Back Unit (Type HE Wide Rudder Angle)craponzelNo ratings yet

- Meteorological Instruments: MODEL 05103-45Document11 pagesMeteorological Instruments: MODEL 05103-45Jay SanchaniyaNo ratings yet

- TORNADO 100, 200 AND 300 Z-Axis Reference Proceedure Before Commencement of This Procedure Remove Any Workshifts Set in Z-AxisDocument1 pageTORNADO 100, 200 AND 300 Z-Axis Reference Proceedure Before Commencement of This Procedure Remove Any Workshifts Set in Z-AxistonyNo ratings yet

- Machine Zero Point Setting BW209Document6 pagesMachine Zero Point Setting BW209Luis Angel Thirion PerezNo ratings yet

- Micro Optic TheodoliteDocument28 pagesMicro Optic TheodoliteVishal shingadeNo ratings yet

- Series 70 Electric Actuators: Quick Start GuideDocument2 pagesSeries 70 Electric Actuators: Quick Start GuideTrio Adi PamungkasNo ratings yet

- Manual Singer 518 538 TextDocument58 pagesManual Singer 518 538 TextGaby Zarabanda100% (1)

- FD QG Po 013 IntDocument36 pagesFD QG Po 013 Intherysyam1980No ratings yet

- ERROR E03 EngDocument3 pagesERROR E03 EngСергей Калихов100% (1)

- Angle DekkorDocument15 pagesAngle Dekkorarun elshaddaiNo ratings yet

- 944-950 Manual With PartsDocument27 pages944-950 Manual With PartsGabeNo ratings yet

- Pfaff - 72 Manual ENDocument45 pagesPfaff - 72 Manual ENTurtle LacrosseNo ratings yet

- RM Young 12102 ManualDocument8 pagesRM Young 12102 Manuallanjiao333No ratings yet

- EMG 2402 Metrology - Notes 2022 Lecture 4 11022022Document11 pagesEMG 2402 Metrology - Notes 2022 Lecture 4 11022022Harry DaviesNo ratings yet

- Service M Adjustm. Automatic Screen Exchange GD HM V02Document8 pagesService M Adjustm. Automatic Screen Exchange GD HM V02khaismaelsaNo ratings yet

- PE 2040 Automatic/Manual Turntable Service ManualDocument52 pagesPE 2040 Automatic/Manual Turntable Service ManualTSNo ratings yet

- Self Balancing RobotDocument5 pagesSelf Balancing RobotMuhammadHarisNo ratings yet

- Digital vs. Analog Control SystemsDocument33 pagesDigital vs. Analog Control SystemsAbril de Vera100% (1)

- April 2016 - Naarva S23 Length Measuring and Automatic Drive 2016Document26 pagesApril 2016 - Naarva S23 Length Measuring and Automatic Drive 2016notitle91No ratings yet

- Autorefractor RT 8000 PDFDocument28 pagesAutorefractor RT 8000 PDFSawit RuntuhNo ratings yet

- AnemometroyveletaDocument6 pagesAnemometroyveletaBruno RuartesNo ratings yet

- Autorefractor RT 8000 PDFDocument28 pagesAutorefractor RT 8000 PDFSawit RuntuhNo ratings yet

- ES400 F 21iMB Mag Zero Set 033007Document3 pagesES400 F 21iMB Mag Zero Set 033007Julián MorelosNo ratings yet

- Service Note 13Document4 pagesService Note 13Brezhnev AguilarNo ratings yet

- Sri986 Electro-Pneumatic Positioner: Quick Guide QG EVE0102 (En)Document6 pagesSri986 Electro-Pneumatic Positioner: Quick Guide QG EVE0102 (En)herysyam1980No ratings yet

- Windshield Wipers and WashersDocument6 pagesWindshield Wipers and WashersPelis CloneNo ratings yet

- Sextant User GuideDocument24 pagesSextant User GuideCharles Thompson100% (2)

- Air Damper Actuators GMA..1 - enDocument6 pagesAir Damper Actuators GMA..1 - enlucemiro2009No ratings yet

- Electric Actuator RHD250 ABBDocument20 pagesElectric Actuator RHD250 ABBQuốc BảoNo ratings yet

- Gma Sei̇emensDocument7 pagesGma Sei̇emensİbrahim UzunNo ratings yet

- Rmyoung PDFDocument11 pagesRmyoung PDFAldrine Dela CruzNo ratings yet

- WT901BLECL Attitude Angle Sensor Specification: Update Content Author Date V1.0 Release Sharlene 20180620Document18 pagesWT901BLECL Attitude Angle Sensor Specification: Update Content Author Date V1.0 Release Sharlene 20180620Константин БондаренкоNo ratings yet

- GDB 1e-Id-2834016Document10 pagesGDB 1e-Id-2834016Hamza AslamNo ratings yet

- Receiver REC 300 Digital: Operating InstructionsDocument8 pagesReceiver REC 300 Digital: Operating InstructionsbejanNo ratings yet

- Different Ways To Mount Travel TransducerDocument14 pagesDifferent Ways To Mount Travel TransducerIsa SolakNo ratings yet

- Practical Report-2: Analytical Photogrammetry Plotter AND Photogrammetry Stereo PlotterDocument9 pagesPractical Report-2: Analytical Photogrammetry Plotter AND Photogrammetry Stereo PlotterPablo CooperNo ratings yet

- Ysc 8320Document32 pagesYsc 8320flaudemir aparecidoNo ratings yet

- Gma161 9eDocument6 pagesGma161 9eElvirModricNo ratings yet

- Air Damper Actuators: Openair™Document10 pagesAir Damper Actuators: Openair™RAMESH RAMASAMYNo ratings yet

- M9930lu SM Sanyo en TextDocument15 pagesM9930lu SM Sanyo en TextgoNo ratings yet

- Sadoun Dg240 User ManualDocument11 pagesSadoun Dg240 User ManualANNA DOWENo ratings yet

- Atmos: The Perpetual Motion ClockDocument10 pagesAtmos: The Perpetual Motion ClockJayakrishna100% (2)

- MatildaDocument34 pagesMatildaPouya KarimiNo ratings yet

- Operating Manual of FRE203Document8 pagesOperating Manual of FRE203davidsongomesbhzNo ratings yet

- To Decrease Arc:: Gear Driven SprinklersDocument2 pagesTo Decrease Arc:: Gear Driven SprinklersBernianuNicoletaNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Order Decisions Import Export Committee 04Document5 pagesOrder Decisions Import Export Committee 04MohammedasifNo ratings yet

- T16 1 eDocument22 pagesT16 1 eMohammedasifNo ratings yet

- Textile Technology: From WM No. 5044Document24 pagesTextile Technology: From WM No. 5044MohammedasifNo ratings yet

- Adjustment Instructions: FunctionDocument4 pagesAdjustment Instructions: FunctionMohammedasifNo ratings yet

- T17 1 eDocument8 pagesT17 1 eMohammedasifNo ratings yet

- 731 2R eDocument2 pages731 2R eMohammedasifNo ratings yet

- T21 1 eDocument2 pagesT21 1 eMohammedasifNo ratings yet

- 731 3R eDocument2 pages731 3R eMohammedasifNo ratings yet

- 722 5R eDocument4 pages722 5R eMohammedasifNo ratings yet

- Adjustment Instructions: (WM With Race Board)Document4 pagesAdjustment Instructions: (WM With Race Board)MohammedasifNo ratings yet

- Information Electrical Installation: 1.1 Basic RequirementsDocument6 pagesInformation Electrical Installation: 1.1 Basic RequirementsMohammedasifNo ratings yet

- 851 1R eDocument2 pages851 1R eMohammedasifNo ratings yet

- Adjustment Instructions: From WM No 5044 OnwardsDocument6 pagesAdjustment Instructions: From WM No 5044 OnwardsMohammedasifNo ratings yet

- Manual PR90 en 2.0webDocument24 pagesManual PR90 en 2.0webMohammedasifNo ratings yet

- Weft-Feeder Sper PartesDocument6 pagesWeft-Feeder Sper PartesMohammedasifNo ratings yet

- ATA Hard DriveDocument42 pagesATA Hard DriveMohammedasifNo ratings yet

- ROJ - GB-Luna X3Document43 pagesROJ - GB-Luna X3MohammedasifNo ratings yet

- 22V10 PDFDocument11 pages22V10 PDFMohammedasifNo ratings yet

- Encoder Buffer BoardDocument4 pagesEncoder Buffer BoardMohammedasifNo ratings yet

- S.No Title OrginisationDocument3 pagesS.No Title OrginisationMohammedasifNo ratings yet

- Vendaxo - Sulzer Loom Machinery - Width - 153 InchDocument3 pagesVendaxo - Sulzer Loom Machinery - Width - 153 InchMohammedasifNo ratings yet

- Circuit SDMDocument8 pagesCircuit SDMMohammedasifNo ratings yet

- Edit CF QSDocument46 pagesEdit CF QSsanjithr619No ratings yet

- Swe Mid Term - ExampleDocument4 pagesSwe Mid Term - Exampleanas mazenNo ratings yet

- Radio TV Experimenter 1965-02-03 Regen 80 10m Muy Bueno Dos TubosDocument132 pagesRadio TV Experimenter 1965-02-03 Regen 80 10m Muy Bueno Dos TubosNestor Alberto EscalaNo ratings yet

- Essai Kontribusi Dan PrestasiDocument2 pagesEssai Kontribusi Dan PrestasiRuly TonapaNo ratings yet

- Informatica Developer - MuraliDocument3 pagesInformatica Developer - MuraliraamanNo ratings yet

- Mrtu6202204 210909aDocument37 pagesMrtu6202204 210909aGhulam ZakyNo ratings yet

- 8DA CatalogDocument64 pages8DA Catalogivan_marquez_82No ratings yet

- Siemens Hearing Aid Price List 2017-18 DownloadDocument14 pagesSiemens Hearing Aid Price List 2017-18 DownloadrukiNo ratings yet

- Lista Grupo 77 Import Ca 17-01-19Document82 pagesLista Grupo 77 Import Ca 17-01-19Alejandro GarciaNo ratings yet

- CarPark CodeDocument16 pagesCarPark CodeMansi PatelNo ratings yet

- My - Bill - 11 Apr, 2023 - 10 May, 2023 - 300886936899-1Document2 pagesMy - Bill - 11 Apr, 2023 - 10 May, 2023 - 300886936899-1Abhijnyan ChandraNo ratings yet

- Distributed Wireless Communication SystemDocument28 pagesDistributed Wireless Communication SystemArjunhunts007No ratings yet

- Yale YDM3109 Digital Lock User ManualDocument32 pagesYale YDM3109 Digital Lock User Manualinspace2036No ratings yet

- System Board User's Manual: 935-X48T26-000G 03810809EDocument106 pagesSystem Board User's Manual: 935-X48T26-000G 03810809EHrvoje Placko MacekNo ratings yet

- Milestone 2Document6 pagesMilestone 2Akhil VinnakotaNo ratings yet

- Password Recovery Procedure For Catalyst 4500Document12 pagesPassword Recovery Procedure For Catalyst 4500Getachew MekonnenNo ratings yet

- How Do I Hide and Show A Menu Item in The Android ActionBarDocument4 pagesHow Do I Hide and Show A Menu Item in The Android ActionBarHawaz BeyeneNo ratings yet

- DS670-001 - Exp. Proof SpeakerDocument2 pagesDS670-001 - Exp. Proof SpeakerRidho Saputro HutomoNo ratings yet

- Aerzen Biogas Solutions: Compressors For Biogas and BiomethaneDocument7 pagesAerzen Biogas Solutions: Compressors For Biogas and BiomethaneCorneliu MateeviciNo ratings yet

- 8D CT Interchnaged - NNLDocument10 pages8D CT Interchnaged - NNLAbhinav SinghNo ratings yet

- WF - Hytera MD65X Mobile Radio U1&v Service Manual V00Document207 pagesWF - Hytera MD65X Mobile Radio U1&v Service Manual V00A&A LABORATORIO100% (1)

- CamJam EduKit - Worksheet 2 - LEDsDocument5 pagesCamJam EduKit - Worksheet 2 - LEDsmbozhoNo ratings yet

- STS - MODULE2 - STS in Philippine ContextsDocument19 pagesSTS - MODULE2 - STS in Philippine Contextsbea punongbayanNo ratings yet

- GUI Lab Programs 1 To 4Document33 pagesGUI Lab Programs 1 To 4ananthalaxmiNo ratings yet

- Tatra t815 7n0r99 8x8 Cargo Carrier With Crane - enDocument2 pagesTatra t815 7n0r99 8x8 Cargo Carrier With Crane - enHarish Kumar0% (1)

- STK350 030Document5 pagesSTK350 030tthutchNo ratings yet