Professional Documents

Culture Documents

217810-Technical Proposal R0

Uploaded by

chida mohaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

217810-Technical Proposal R0

Uploaded by

chida mohaCopyright:

Available Formats

PLC with SCADA for Fertilizer Plant

End User Industries Chimiques du Senegal (I.C.S.)

Customer Industries Chimiques du Senegal (I.C.S.)

Proposal Ref #: 217810-R0

PLC with SCADA for Fertilizer Plant

Confidentiality Note: This proposal contains proprietary and confidential information of Yokogawa. This document shall not be used,

disclosed or reproduced, in whole or in part, for any purpose other than to evaluate this proposal, without the prior written consent

of Yokogawa.

For Internal Use Only

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

REVISION HISTORY

Revision Date Description Prepared Reviewed Approved

0 March 26, 2024 Issued for Review VM VS BD

Yokogawa Proprietary Information

Page 2 of 28

For Internal Use Only

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

TABLE OF CONTENT

1. INTRODUCTION .............................................................................................................................. 4

2. QUALITY ASSURANCE / QUALITY CONTROL ................................................................................... 8

3. STARDOM- RTU/PLC ....................................................................................................................... 9

3.1 Components of STARDOM ............................................................................................................. 9

3.1.1 FCN Autonomous Controllers ................................................................................................ 9

3.1.2 Application Portfolios .......................................................................................................... 10

3.1.3 STARDOM Operating Philosophy ......................................................................................... 10

3.1.4 STARDOM features and functionalities ............................................................................... 11

3.1.5 Standard Software tools ...................................................................................................... 11

3.1.6 Powerful Application Portfolio ............................................................................................ 12

3.1.7 Hot Swappable IO Modules ................................................................................................. 12

3.2 Benefits of Stardom Based Control System.................................................................................. 13

4 Visual DataServer (VDS) SCADA .................................................................................................... 15

5 BASIS OF PROPOSAL ..................................................................................................................... 17

5.1 SCOPE OVERVIEW.......................................................................................................................................17

6 Proposal Design Basis & Assumptions........................................................................................................18

6.1 VDS Operating System ........................................................................................................................ 18

6.2 Programmable Logic Controller (PLC) System. ................................................................................... 18

6.3 Exclusions. ..................................................................................................................................................19

7 Project Management Services....................................................................................................................20

7.1 Review Meetings ........................................................................................................................................20

7.2 Project Meetings ........................................................................................................................................20

7.3 Progress Reporting .....................................................................................................................................20

8 Documentation And Project Design Inputs ................................................................................................21

8.1 Project Drawings/Documents ....................................................................................................................21

8.2 Design Inputs for Execution .......................................................................................................................21

8.3 Design Deliverable......................................................................................................................................22

9 Scope Matrix...............................................................................................................................................23

10 Annexures...................................................................................................................................................25

Annexure 1: I/O SUMMARY ................................................................................................................................25

Annexure 2: BILL OF MATERIAL ..........................................................................................................................26

Annexure 3: Overall Architecture .......................................................................................................................28

Yokogawa Proprietary Information

Page 3 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

1. INTRODUCTION

Founded in 1915, Yokogawa is 100+ years old company with headquarters in Tokyo, Japan and is well regarded

in the global marketplace as a leading control automation and process instrumentation company and pioneer

in the development of control systems for the monitoring and control of processes in a broad range of facilities.

Based on Vigilant Plant, Yokogawa’s vision for realizing the ideal plant, Yokogawa are developing products and

services that enhance productivity, make maximum use of plant assets, ensure safety, and optimize operations

over the entire plant lifecycle. These solutions currently play vital supporting roles for our customers in the

oil, chemical, natural gas, electric power, iron and steel, pulp and paper, pharmaceutical, food, and other

industries.

Yokogawa is also providing solutions based on its measurement and control technologies that make more

efficient use of renewable energy and is devising new ways in which next-generation energy sources can be

utilized to achieve a sustainable society.

One Global Yokogawa

Yokogawa has close to 20,000 employees and operates in 54 countries.

Yokogawa has close to 24,624 System Installations, 7200 patents and has been a leader in Foundation

fieldbus and wireless technologies.

Yokogawa spends approximately 8-9% of its turnover on R&D to keep itself ahead with technological

advances. This is significantly high compared to the other companies in the Automation Industry.

Yokogawa total solution plays an important role helping customers to meet the challenges of reducing both

CAPEX and OPEX, while enhanced built-in technologies will increase the production. Yokogawa’s global

experience together with the rich local experience provides unique total solutions to meet the needs of this

industry. With experienced experts located in the offices, Yokogawa can provide quick and extensive support

to meet the day-by-day requests from the customers.

Yokogawa’s Global network along with regional headquarters is as shown below.

Yokogawa Proprietary Information

Page 4 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

Yokogawa’s manufacturing operations span globally across 13 countries and it has a very strong service

network including Middle East Africa working round the clock to meet the requirements of its esteemed

customer base.

Yokogawa Proprietary Information

Page 5 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

Yokogawa Middle East & Africa (YMA)

Yokogawa Middle East & Africa (YMA) is Yokogawa’s Regional Company for the Middle East Africa region.

YMA primary business activities are the sales, engineering, and servicing of industrial process

instrumentation, control systems, plant safety systems, plant information and management systems, PLC &

SCADA systems, measuring and analytical instruments, network security and communication networking.

The company workforce consists of engineers who are specialized in a variety of instrumentation fields.

Most projects are managed and executed by the staff locally, including the engineering, acceptance test,

commissioning, engineering, start-up, and training. To provide prompt after-sales support to customers, the

company maintains hot stand-by systems and products. At present, YMA have more than 1400+ employees.

Yokogawa Network in the Middle East Africa is as below.

Yokogawa Proprietary Information

Page 6 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

Yokogawa Network in the Middle East Africa is as below.

YMA has the following staging facilities for Middle East Africa from where all its projects are staged.

o 5300 sq-metre in Abu Dhabi, UAE.

o 10,000 sq-metre in Bahrain.

o 16,573 sq-metre in Saudi Arabia.

Besides the above, Yokogawa also has its Response Center Middle East & Africa (RCMA) based in Bahrain,

wherein all customers can get ready support on any technical support/service issues.

Yokogawa has long established credentials in being the most reliable supplier in the process control industry.

With its large installed base and experienced engineers, Yokogawa shall be in the best position to deliver the

project up to total customer satisfaction.

Yokogawa Proprietary Information

Page 7 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

2. QUALITY ASSURANCE / QUALITY CONTROL

As an organization, Yokogawa is structured to provide complete engineering, integrated system solutions,

products including training and service with excellent quality.

Yokogawa’s policy is “Quality First” in all aspects - ensuring quality and reliable products, on-time delivery and

cost-effective solution. Yokogawa as an ISO 9001:2015, 14001:2015, 45001:2018 certified company is

committed to continuous improvement in areas such as customer service, features & benefits, quality,

delivering guaranteed service and cost of operation over long periods.

Yokogawa Proprietary Information

Page 8 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

3. STARDOM- RTU/PLC

Yokogawa STARDOM Control System has 15+ year’s proven experience in various industrial and process

applications including Oil & Gas Industry. More than 27,000+ Controllers are in successful operation

Worldwide.

STARDOM meets the emerging technology requirements and offers high flexibility to build a superior control

system, i.e., a system befitting each user’s purpose. Reliability, operability, flexibility, scalability are keys for

implementing functionality in an industrial control system and all of these are well-featured in STARDOM.

The STARDOM is a Commercial Off-The-Shelf (COTS) system. It brings the total cost of ownership down to a

very competitive level.

STARDOM Core Competence

The STARDOM consists of the following highly independent components:

• Field Control Node (FCN) autonomous controllers

• Application Portfolios

3.1 Components of STARDOM

3.1.1 FCN Autonomous Controllers

STARDOM’s autonomous controllers have a highly independent architecture for linking up distributed

controllers and devices in the control domain and autonomously transmitting information without relying

Yokogawa Proprietary Information

Page 9 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

on HMI software. The many benefits include the design for distributed installation to distribute functions

and risk hedge, and promotion for registration of reusable software parts, thus making engineering more

efficient, from purchase and operation to expansion and modification. The autonomous controller is

available in model FCN (Field Control Node) controller that can have a dual-redundant configuration.

3.1.2 Application Portfolios

Yokogawa has put its decades of expertise in configuring control functions into libraries of software parts

available as Application Portfolios. By using control logic parts from a portfolio that meet the specification

requirements, advanced functions can be implemented more quickly and reliably.

3.1.3 STARDOM Operating Philosophy

The FCN is a modular architecture controller assembled with CPU, I/O, and other modules as necessary. It

supports a variety of I/O modules, provides highly reliable system with options for duplex power supply, CPU

and control network. It is a highly scalable system.

Communications with the host system can be via the Redundant Ethernet Network. As the STARDOM system

is designed is to be autonomous, this implies that in situation when there is a loss of communication between

the host system and the STARDOM controllers, field data can be restored from the controllers upon recovery

of the communication network without any loss of critical data.

Yokogawa Proprietary Information

Page 10 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

3.1.4 STARDOM features and functionalities

Some unique features of STARDOM FCN are:

3.1.5 Standard Software tools

• Simple configuration and setup.

• Five (5) IEC61131-3 compliant programming languages supported.

• LD • ST / IL

• FB • SFC

• Simple configuration and setup

• Enhanced Programming Feature

Yokogawa Proprietary Information

Page 11 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

3.1.6 Powerful Application Portfolio

• Efficient development of control applications such as feedback and sequence control

• Intellectual property protection

• Yokogawa’s application expertise is packed, enable effortless creation of complex applications, such

as pipeline pump load control algorithm.

3.1.7 Hot Swappable IO Modules

Easy steps for IO modules replacement-

Remove terminal block/MIL Connector for

disconnecting field wirings.

(No need to disconnect each field wiring)

Replace New I/O module and

attach terminal block/MIL

Connector.

IO definition automatically copied

Reconfiguration NOT

required.

Yokogawa Proprietary Information

Page 12 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

3.2 Benefits of Stardom Based Control System

Features Benefits of STARDOM

Highly Reliable System • Risk diversification with by distributing independent STARDOM controllers

at remote sites and over any network infrastructure. Built-in data buffering

function ensures no data is loss when network goes down.

• Robust hardware suitable for harsh environment in case required and

specified. Compliant to Class 1 Div 2 FM Approval, ATEX Type n; Corrosion-

proof coating (option) and wide operating temperature range (FCN: -20 to

70°C)

• Highly reliable hardware design inherited from CENTUM DCS

• Advanced self-diagnosis on complete system and Error Check & Correct

(ECC) memory protects against transient memory errors.

• System availability is significantly improved with redundant configuration.

• Fan-less architecture and analog current input modules with surge

protection reduces downtime risk.

Openness & • Seamless integration with YOKOGAWA FAST/TOOLS, CI Server Web-based

Connectivity Supervisory System with dedicated communication driver and data buffer

function , CENTUM DCS via Universal Gateway Station, Plant Asset

Management, Plant Information Management System, and Safety

Instrumented System

• Common look-and-feel for graphic parts, system diagnostics, faceplates,

tuning panels, and trends.

• Utilizes standard TCP/IP based open network which allows STARDOM to

be easily integrated to any existing or available network infrastructure.

• Support open protocols (Modbus, OPC, DNP3) and Field Digital Networks

such as FOUNDATION™ fieldbus, HART, Profibus-DP, CANopen and ISA100

Wireless give you freedom to choose any open technology and take

advantage of the benefits of field digital networks.

Fully Autonomous • STARDOM autonomous controllers realize all-in-one solution with Java

Technology* (if specified and required) including control functions, real-

time monitoring using web browser, logging functions and alarm & events

notification by email. Such intelligent PLC embedded functions enable

remote site operation & monitoring without any dedicated software or PC,

and information is easily acquired anywhere, anytime. * Apply for Simplex

CPU

Yokogawa Proprietary Information

Page 13 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

Features Benefits of STARDOM

Ease of Engineering & • Supports high quality software parts or templates that reduces

Maintenance engineering efforts and improved reusability. Utilizes global standard IEC

61131-3 (five programming languages1). Tag-based definitions simplify

engineering and re-mapping of tags or memory address assignments are

not required.

• Embedded specialized libraries, Application Portfolios (APPFs), provide

reliable control function including DCS regulatory control functions

cultivated from YOKOGAWA’s long DCS history; communication libraries

and application specific libraries such as gas flow calculation, boiler control

etc.

• Supports target-less debugging using a simulator which helps to test

modifications before downloading.

• Hot swappable hardware and online application modifications including

control programs, I/O allocation etc. can be updated to the controllers

without stopping control.

• Boot project saved on controller allows easy recovery & backup

• Easily upgrade & auto conversion of logics to the latest revision minimizes

total cost of ownership. Improvements in hardware do not affect logic nor

require download to controllers.

Compact Design • Compact footprint of STARDOM controllers gives significant cost reduction

especially in remotely distributed and hazardous locations.

• Additional cost savings in duplexed configuration where CPUs are

mounted on the same base plane thus does not require separate racks or

panels.

Long Term Stable • The reliability of STARDOM makes it an ‘Install-and-Forget’ system even in

Operation & Reliable harsh environment and contributes to long-term stable operation.

After-Sales Service • Expect Yokogawa’s strong commitment and support throughout the plant

Support lifecycle and rely on our extensive service network for support.

Long Product Lifecycle • High R&D investment and consistent long term migration policy protects

your investments

1

Supports Function Block Diagram, Ladder Diagram, Structured Text, Instruction List and Sequential Function Chart

Yokogawa Proprietary Information

Page 14 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

4 Visual DataServer (VDS) SCADA

Yokogawa has proposed Visual Data Server SCADA for this project. VDS is a software package that runs under

a Windows operating system and implements a Web-based human machine interface, OPC server functions,

data acquisition from a variety of controllers and devices, and historical data management.

VDS Viewer is required as the platform to run operation and monitor windows implemented as Java

application, offering platform- and scale-independent HMI clients.

All window data are created on and stored in a single HMI server and HMI clients do not contain window

files, namely, they are thin clients. Changes to window files only require work at the server; there is no need

for modifications at each client.

Integrated monitoring of data of multiple data servers is possible from an HMI client

Integrated information of multiple VDSs can be viewed at a personal computer using HMI client functions.

Allows operation and monitoring via the Internet, an intranet, and/or a private LAN; even if located beyond

a firewall.

Yokogawa Proprietary Information

Page 15 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

VDS consists of following functions:

• Data server functions

A data server acquires data from controllers and I/O devices such as autonomous controllers FCN/FCJ and

programmable logic controllers, saves them, and passes them to HMI servers and Visual Basic applications.

A data server manages sets of data as control objects (tags).

• HMI server functions

An HMI server delivers, to HMI clients, operation and monitoring window data for data residing in data

servers. An HMI server can access any data servers running on the same computer or a different computer

on the network.

• HMI client functions

An HMI client accesses an HMI server via VDS Viewer to display operation and monitoring windows.

An HMI client can exist on the same computer as an HMI server or a different computer on the network.

Yokogawa Proprietary Information

Page 16 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

5 BASIS OF PROPOSAL

5.1 SCOPE OVERVIEW

Yokogawa proposal includes following solutions comprise as a package along with project management

services including application development, documentation, testing (FAT/IFAT).

Sl. No. Description Make/Supplier

1 STARDOM FCN System as PLC. Yokogawa

2 Visual Data Server (VDS) SCADA Yokogawa

The proposed system is based on the following referenced documents:

Sl. No. Document Description Document No.

1 Mail received from customer on 14th March -

Refer to the following sections for proposed solutions and bill of material.

Annexure 1: IO Summary

Annexure 2: Bill of Material

Annexure 3: Overall Architecture

Yokogawa Proprietary Information

Page 17 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

6 Proposal Design Basis & Assumptions

6.1 VDS Operating System

• Engineering workstations with monitor – 1 nos.

• Operator workstations with monitor – 1 nos.

• 10 graphics & 5 reports considered.

6.2 Programmable Logic Controller (PLC) System.

• Supply of fully engineered programmable logic controller (PLC) Panels suitable for indoor, climate-

controlled environment.

• Panels are assumed to install in Control Room.

• PLC panel houses controller, IO Cards and termination.

• PLC Cabinet with Front/Rear Door IP-42, Cabinet Dimension: (H 2100 x W 800 x D 800) mm Control

Room.

• Cabinet with Side termination is considered.

• Refer to annexure 2 detail bill of material for proposed quantity.

• Refer to annexure 3 for architecture with proposed solution.

• Commissioning Spare are proposed as Optional scope.

• All Site activity shall be on per diem basis.

• The redundancy is considered as following:

1. Controller-Redundant

2. Network Switch- Redundant

3. IO Modules- Non-Redundant

• IO Modules

Following are the IO modules channel density proposed.

Module Type Model Number Description

Analog Input Module NFAI143H AI- 4-20mA, 16 Channel, Isolated with G3

Analog Output Module NFAI543H AO- 4-20mA, 16 Channel, Isolated with G3

Digital Input Module NFDV151 DI- 32 Channel, 24VDC, Isolated with G3

NFDR541 DO- 16 Channel, 24VDC, Isolated with G3 with

Digital Output Module current rating 2A for resistive load.

NFAR181 Resistance Temperature Detector MODULE -12

RTD Input Modules Channel, Isolated

• Spare considered for PLC are as follows:

Spares Percentage

Wired I/O Spares 0%

Overall PLC Rack Spare 0%

Yokogawa Proprietary Information

Page 18 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

6.3 Exclusions.

a. The Field cables of any type

b. Fiber optic (FO) cable supplying, laying, termination, and testing.

c. FOPP is excluded from Yokogawa Scope.

d. The Earthing system of the proposed RTU systems at the respective locations are excluded from

Yokogawa scope. An earthing strip shall be provided in the proposed RTU cabinets.

e. All field instruments, field wiring, supply, lying, and termination including cable glands to proposed

RTU panels are excluded.

f. All civil, mechanical, demolishing, mounting and installation activities.

g. Supply and termination of Communication Cables between proposed RTU systems and other Third-

Party Systems (if any) are excluded from Yokogawa scope.

h. Unloading, Unpacking, Erection and Installation of RTU systems are excluded from Yokogawa scope.

Yokogawa shall provide necessary supervision assistance on per diem basis.

i. GPS antenna and SNTP server are excluded from Yokogawa scope.

j. Operator Consoles and Chairs are excluded from Yokogawa scope.

k. Any item which is not mention in bill of material.

Yokogawa Proprietary Information

Page 19 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

7 Project Management Services

7.1 Review Meetings

• Monthly Progress Meeting

Monthly Progress Review Meetings will be through teleconference/video conference and will be attended by

Project Manager/Lead Engineer, Key Members of Customer/End-User Project Team. The meeting will focus

on the progress and issues that affect the project work. The work done in the previous month and planned

work for the month ahead will also be reviewed and an action plan will be issued for problems envisaged.

Yokogawa will issue the agenda for the progress meeting one week in advance for EPC Project Team’s review

and finalization.

7.2 Project Meetings

KOM, Hardware design review, Software design review Meetings and all other meetings as required shall be

in Yokogawa facility and will be attend by Project Manager/Lead Engineers, and EPC CONTRACTOR’s

/COMPANY Project Team. We have proposed for all the meetings for review including HDR / SDR Etc.

The following meetings considered in our estimate.

a. Kick of Meeting – 1 no (In Yokogawa Bahrain)

b. Design Review Meetings (Hardware Design/Software Design Review)– 2 Meeting (In Yokogawa

Bahrain Facility)

All other review meetings are considered at our facility or Teleconference/Video conference at mutually

agreed timelines.

7.3 Progress Reporting

Progress reporting will be weekly and monthly. The weekly progress report will be submitted on every Monday

before the close of business and will report on the progress and activities of the week past and the activities

in the coming week. Formats for weekly and monthly report are to be finalized at the beginning of the Project.

The Monthly Progress report shall include as minimum the following:

a. Project Executive Summary

b. Project Schedule(s)

c. Project Progress Summary

d. Areas of Concern

e. Planned Activities

f. One month look ahead activities.

g. Action Item List with comments

Yokogawa Proprietary Information

Page 20 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

8 Documentation And Project Design Inputs

8.1 Project Drawings/Documents

List of documents and timeline for submission shall be mutually agreed during KOM.

As shipped documentation will be provided after successful completion of FAT, during System delivery.

Any further modification/updation of these documentations will be done through red line mark up at site

based on per diem rates. The actual updation in the softcopy can be done by Contractor based on the as-

shipped softcopy submitted to Contractor. If Contractor need vendor to do this updation same can performed

on per diem rates of back-office rates as per Commercial Proposal.

Yokogawa considered as two sets of documents submission, if any additional revision shall be chargeable.

8.2 Design Inputs for Execution

EPC Contractor shall provide all necessary configuration/design data in accordance with responsibility Matrix,

however key documents / inputs required preferably in softcopy during various stages of the project are listed

below.

Design Inputs to be provided by End-user /Customer for Hardware Design Review (HDR)

P&I Diagrams (progressive)

I/O Database in MS-EXCEL/MS-Access format containing RTU & I/O details

with area/sub area segregations and Field Cable Schedule along with JB details

TAG Philosophy

Control Room/IER Equipment Layout

Design Inputs to be provided by End-user /Customer for Software Design Review (SDR)

I/O Database in MS-EXCEL/MS-Access format containing RTU I/O details – Final for SDR

Mapping list in MS-EXCEL containing Sub-system I/O details

Field oops – List of critical loops/valves

Graphic Display Sketches (Progressive)

Logic Diagrams including all logics & Sequence Narratives

Functional logic diagram (FLD)

Log Report Details

Graphics Design Inputs required from End-user /Customer

Mark-up P&ID's for Graphics generation

Process Overview Graphics Display Sketches

Tag Grouping for Area Deviation Overview Graphics

Area alarm schematic grouping Sketches

Yokogawa Proprietary Information

Page 21 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

8.3 Design Deliverable

At Engineering stage with two review cycle progressively

Nestlaoding Document

Cabinet GA/IA drawings

System Architecture Drawings

Typical Loop drawing

Power and Heat Load calculation

Functional Design Specification

Bill Of Material

FAT Procedure

Configuration and Graphics Guideline

Yokogawa Proprietary Information

Page 22 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

9 Scope Matrix

Sr Activity Description Yokogawa Customer

No Scope Scope

1. Provide all engineering / detailed design inputs at the time of √

contract

2. Submission of design documentation for the scope of RTU √

System

3. Review and Approval of design √

4. Supply of material as per approved design including staging, √

internal testing, and FAT

5. Supply of suitable fully assembled System & Marshalling √

cabinets for RTU

6. Supply and laying of Fiber Optic cables between two locations √

7. Provide all regulated & stable power supply feed as required to √

respective locations for powering the offered systems.

8. Provide power distribution within cabinets for offered √

Yokogawa RTU Equipment.

9. Making of field cable schedule & Junction box Schedule as per √

data supplied by customer

10. Supply, installation and commissioning junction boxes, and √

over-head cable trays

11. Supply, installation, and commissioning of field instruments √

12. Supply all signal and power cables up to offered Yokogawa √

system and Marshalling cabinet at all locations

13. Supply of accessories like trays, glands, conduits etc. required √

for system cables at all locations.

14. Any hardware/software supply required for interfacing 3rd √

party devices with offered Yokogawa Systems, at 3rd Party

system, if any.

15. Services required for interfacing 3rd party devices with offered √

Yokogawa Systems, at 3rd Party system, if any.

16. Provide trenching, traying, laying and termination for all signal / √

communication (serial & FO) / power / cables up to Yokogawa

system provided in the respective locations.

17. Terminate all hardwired I/Os onto the terminal blocks of √

Yokogawa offered system.

18. Transportation to site. √

19. Transit & Storage Insurance. √

20. Unloading of system to the storage area/site. √

21. Provide proper earthing system as per required standards. √

22. Carry out all civil, mechanical, piping and modification works at √

site.

23. Carry out RTU panel/cabinet erection and installation. √

24. Provide supervision services during the installation stage on per √

diem basis.

Yokogawa Proprietary Information

Page 23 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

Sr Activity Description Yokogawa Customer

No Scope Scope

25. Carry out loop checking on the offered Yokogawa systems, on √

per diem basis.

26. Carry out loop checking at the field end. √

27. Commissioning of the offered Yokogawa System, on per diem √ √

basis. (Please refer commercial proposal for the per diem rates)

28. Site Acceptance Test, on per diem basis. √ √

29. Training requirements (Optional) √

30. Documentation √

31. Handing Over the systems to customer √ √

32. Commercial Closure for Yokogawa scope of work. √ √

Yokogawa Proprietary Information

Page 24 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

10 Annexures

Annexure 1: I/O SUMMARY

Proposed RTU system as per the Below IO count, any change in IO points will be subject to technical and

commercial implications.

Total Hardwired IO with 0% Installed Spares

Sr No Item Description AI AO DI DO RTD

4-20 mA 4-20 mA 24V DC 24V DC Ω

Hardwaired

1 PLC-01 64 28 96 80 12

Note:

▪ Panel diagnostic signals considered in above table (1 DI signal for Panel Door Open

Alarm and 1 AI signal for Cabinet Temperature.)

▪ All IO signals are considered as Non-IS signals.

Yokogawa Proprietary Information

Page 25 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

Annexure 2: BILL OF MATERIAL

Item BILL OF MATERIALS - STARDOM (FCN) Quantity

1 STARDOM SOFTWARE - R4

1.1 NT203AJ-PC11E FCN/FCJ Software media (CD-ROM) - R4.20 2

NT205AJ-PC11E APPF Media - R4.20 2

1.2 NT751FJ-LW11A Logic Designer Tool - R4 2

2 STARDOM HARDWARE

220-240VAC with no explosion with G3

2.1 NFPW442-51 Coating 6

FCN CPU MODULE( ETHERNET 4

2.2 PORTS)

NFCP502-S06 Standard with G3 Coating 2

2.3 FCN E2 BUS INTERFACE MODULE

N2EB100-S51 with no explosion with G3 Coating 6

2.4 FCN Base Module

NFBU200-S05 FCN Module - Long with no explosion 3

2.5 ANALOGUE INPUT MODULE

Terminal Block(without Surge) with no

NFAI143-S51/A4S00 explosion with G3 Coating 4

2.6 ANALOGUE OUTPUT MODULE

Terminal Block(without Surge) with no

NFAI543-S51/A4S00 explosion with G3 Coating 2

2.7 DIGITAL INPUT MODULE

Terminal Block(without Surge) with no

NFDV151--P61/B5S00 explosion with G3 Coating 3

2.8 DIGITAL OUTPUT MODULE

Terminal Block(with relay) with no explosion

NFDR541-T with G3 Coating 5

RTD Input Module (12 Channel,

2.9 Isolated)

Terminal Block(without Surge) with no

NFAR181-S51/R8S00 explosion with G3 Coating 1

3 RESALE/BUYOUTS ITEMS

PLC Cabinet

3.1 1

IP-42, Cabinet Dimension: ( H 2000 x W 800 x D 800 ) mm. Dual Door

3.2 Weidmuller/Eqvt 230VAC/24 VDC PS Unit with Diode module 2

3.3 Belden/Eqvt Ethernet UTP cable (1meter) 30

Ethernet Switch 8 port with 1 SFP module

3.4

Yokogawa std (DIN rail mounted?) 2

Yokogawa Proprietary Information

Page 26 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

Item BILL OF MATERIALS - SCADA SYSTEM Quantity

1 SCADA SOFTWARE

1.1 VDS software Licence NT610FJ-LS05E 1

1.2 Report Package NT301AJ-LW11A 1

2 RESALE/BUYOUTS ITEMS

2.1 Workstation With Monitor 24” Yokogawa Std. 2

2.2 Antivirus 2

2.3 MS Office 2

Yokogawa Proprietary Information

Page 27 of 28

Project Name: PLC with SCADA for Fertilizer Plant

End User: Industries Chimiques du Senegal (I.C.S.) Proposal Ref #: 217810-R0

Customer: Industries Chimiques du Senegal (I.C.S.)

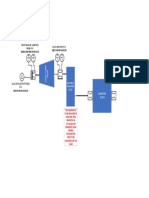

Annexure 3: Overall Architecture

CONTROL ROOM

24" 24"

EWS OWS-1

ESW-1

ESW-2

PROCESS PLC-1

RTU PLC

----------------END of Document---------------

Yokogawa Proprietary Information

Page 28 of 28

You might also like

- TIA Portal V19 Technical Slides ENDocument197 pagesTIA Portal V19 Technical Slides ENsklee0730No ratings yet

- CS 1026 Assignment 4Document5 pagesCS 1026 Assignment 4Jessica Li0% (3)

- Soar Pant O&M Practice PPT by LancoDocument30 pagesSoar Pant O&M Practice PPT by Lancoஇராஜ கணபதி100% (1)

- Detailed Project Report On Solar Module Manufacturing (60 MW)Document13 pagesDetailed Project Report On Solar Module Manufacturing (60 MW)sandeep devabhaktuniNo ratings yet

- 02 Hot Air GeneratorDocument60 pages02 Hot Air Generatorsk314650% (2)

- GATE UsersGuide - v5.0.0 PDFDocument225 pagesGATE UsersGuide - v5.0.0 PDFAlejandraGomezNo ratings yet

- HP Qfiniti 10.x Web Access User Guide enDocument696 pagesHP Qfiniti 10.x Web Access User Guide enSimón CamposNo ratings yet

- M4 Inline - Software User Manual 1.1Document47 pagesM4 Inline - Software User Manual 1.1Ignacio Granados33% (3)

- ETSE Zeiss Simply MeasureDocument17 pagesETSE Zeiss Simply MeasureDragu StelianNo ratings yet

- Systems, Roles, and Development Methodologies ReviewDocument3 pagesSystems, Roles, and Development Methodologies ReviewTasmim DishaNo ratings yet

- AlAzizyah Villa (12.1kW) - Indicative OfferDocument28 pagesAlAzizyah Villa (12.1kW) - Indicative OffershoaibNo ratings yet

- Socomec 2013Document660 pagesSocomec 2013thinewill_bedone8055No ratings yet

- CE2393 R2 CompaniadeMinasBuenaventura UnidadTambomayo ILR2000BA 160111Document29 pagesCE2393 R2 CompaniadeMinasBuenaventura UnidadTambomayo ILR2000BA 160111jcNo ratings yet

- lp33 User ManualDocument94 pageslp33 User ManualAndrew SisonNo ratings yet

- Valve Actuation News From RotorkDocument8 pagesValve Actuation News From RotorkIñaki EseberriNo ratings yet

- Haiwell Industry Application CaseDocument38 pagesHaiwell Industry Application CaseAlexander Diaz AlvarezNo ratings yet

- PLC Tender - R2 - 17.11.22Document34 pagesPLC Tender - R2 - 17.11.22SUSOVAN BISWASNo ratings yet

- 215122T001 JSM 6001 Instructions - To - Bidders Rev.0Document16 pages215122T001 JSM 6001 Instructions - To - Bidders Rev.0Paul KIMNo ratings yet

- Powerful Senses To Avoid MishapsDocument72 pagesPowerful Senses To Avoid Mishapsrajpre1213No ratings yet

- Viewsonic: Va1912W/Va1912Wb LCD DisplayDocument23 pagesViewsonic: Va1912W/Va1912Wb LCD DisplayJnaneshNo ratings yet

- GE SecoVac LineDocument56 pagesGE SecoVac LineRicardo MorenoNo ratings yet

- Irl Ce2393-R1-Cianuracion Intensiva PDFDocument39 pagesIrl Ce2393-R1-Cianuracion Intensiva PDFjcNo ratings yet

- Absolyte GP I&O ManualDocument35 pagesAbsolyte GP I&O ManualincobarNo ratings yet

- 5.1 Project Design Basis - NewDocument22 pages5.1 Project Design Basis - Newandrieysyah2525No ratings yet

- Aixtron - Phase I - Update - L2Document13 pagesAixtron - Phase I - Update - L2extortionchloride610No ratings yet

- CV - Isaac Saddek - Rowad Modern EngineeringDocument2 pagesCV - Isaac Saddek - Rowad Modern Engineeringisaacsaddek17No ratings yet

- RZQ 100-140 B8W1 Technical DataDocument31 pagesRZQ 100-140 B8W1 Technical DataJurutera Perunding Elektel Sdn BhdNo ratings yet

- BD000351U01 Araucaria 6 (San Pedro) RTSTGPRMS299.22 (12.21-02.22)Document30 pagesBD000351U01 Araucaria 6 (San Pedro) RTSTGPRMS299.22 (12.21-02.22)Hernan WaldbilligNo ratings yet

- Internship Report of BycoDocument17 pagesInternship Report of BycoSyed Faizan Ali0% (1)

- Raghu ReportDocument42 pagesRaghu ReportTyrone MichaelsNo ratings yet

- Applying A Single Rosemount 5900S 2-In-1 Radar Level Gauge As The Sensor in Two Independent Protection Layers (I.e. BPCS and Sis)Document48 pagesApplying A Single Rosemount 5900S 2-In-1 Radar Level Gauge As The Sensor in Two Independent Protection Layers (I.e. BPCS and Sis)iptusNo ratings yet

- 2022 03 07alcad CleverwatchDocument2 pages2022 03 07alcad CleverwatchhhelectronicsbdNo ratings yet

- Portable Gas Monitor: Operating ManualDocument58 pagesPortable Gas Monitor: Operating ManualRavindraNo ratings yet

- SM 52961Document29 pagesSM 52961p-nicoNo ratings yet

- 2 1 SecoGear PDFDocument64 pages2 1 SecoGear PDFMuhammad NomanNo ratings yet

- Kehua UPSDocument38 pagesKehua UPSArslan ShafqatNo ratings yet

- 1SQC173004D0201 - PEP - ABB ReliaGear Lighting Panelboards - Cu BusDocument14 pages1SQC173004D0201 - PEP - ABB ReliaGear Lighting Panelboards - Cu BusKidzoy ShopNo ratings yet

- Catalog Modicon M241 Programmable Logic Controller For Performance Demanding Applications English June2019Document21 pagesCatalog Modicon M241 Programmable Logic Controller For Performance Demanding Applications English June2019NgonzalezMagañaNo ratings yet

- Versa V, B & C Series Solenoid IEC 61508 AssessmentDocument14 pagesVersa V, B & C Series Solenoid IEC 61508 AssessmentSilo LibraNo ratings yet

- Technical and Commercial Offer - Honeywell Ref GES-ES-2022-42 - Rev 3 - 300123Document13 pagesTechnical and Commercial Offer - Honeywell Ref GES-ES-2022-42 - Rev 3 - 300123Hamza ISSAOUINo ratings yet

- AssignmentDocument11 pagesAssignmentMoney MilkingNo ratings yet

- Flexibility Project at MOT - Technical Offer - Rev02 - ALTRADDocument8 pagesFlexibility Project at MOT - Technical Offer - Rev02 - ALTRADGhouse MohammedNo ratings yet

- 00 - ArtículoDocument7 pages00 - Artículoheidy pintoNo ratings yet

- Atg SPRL 01 PDFDocument25 pagesAtg SPRL 01 PDFMuhammad Faiez AfzaalNo ratings yet

- Amity University Rajasthan: A Training Report On PLC and ScadaDocument37 pagesAmity University Rajasthan: A Training Report On PLC and ScadaAshu SharmaNo ratings yet

- GCHK-100: Mining RelayDocument20 pagesGCHK-100: Mining RelayCasilda Mamani JuchazaraNo ratings yet

- Multi Diag Heavy Duty Tool Set Up InstructionDocument31 pagesMulti Diag Heavy Duty Tool Set Up InstructionLakbirNo ratings yet

- Mird G Issue2Document19 pagesMird G Issue2lbzuNo ratings yet

- New SPC Code Support For China Telecom (CR662522) : Technical MemoDocument9 pagesNew SPC Code Support For China Telecom (CR662522) : Technical Memoburdun777No ratings yet

- 屏规格书7626 CE200L T001Document29 pages屏规格书7626 CE200L T001LuisMiguelCalvoNo ratings yet

- WinCC Sugar and Biog-Ethanol enDocument12 pagesWinCC Sugar and Biog-Ethanol enAynen JohnWaynenNo ratings yet

- 4 Reasons The Right Controller Is Vital in AGVDocument5 pages4 Reasons The Right Controller Is Vital in AGVDavid GomezNo ratings yet

- Manual GX-8000Document52 pagesManual GX-8000Darbs DarbsNo ratings yet

- Internship ReportDocument71 pagesInternship ReportKrushnasamy SuramaniyanNo ratings yet

- DRP001-OUF-SPE-K-000-006-B1 - PLC SystemsDocument23 pagesDRP001-OUF-SPE-K-000-006-B1 - PLC SystemsSakthi venkateshNo ratings yet

- RE5VL42ADocument29 pagesRE5VL42AroozbehxoxNo ratings yet

- The Use of 3D Scanning in The Turbine Blade Industry.....Document1 pageThe Use of 3D Scanning in The Turbine Blade Industry.....MohanrajRajangamNo ratings yet

- Rs1483 - Genius1022-1023-Nm32la User Manual Rev 12 PN Um-0001 Rsid 1483 enDocument33 pagesRs1483 - Genius1022-1023-Nm32la User Manual Rev 12 PN Um-0001 Rsid 1483 enHieu LeNo ratings yet

- " Looking at The Future": Customer: Atlas Copco REFERENCE: 126-ATC-001-2021 Project: Compas Fitting & Bracket DevicesDocument10 pages" Looking at The Future": Customer: Atlas Copco REFERENCE: 126-ATC-001-2021 Project: Compas Fitting & Bracket DevicesMeño LaurelNo ratings yet

- Product Manual: Switchmode Power SupplyDocument12 pagesProduct Manual: Switchmode Power SupplyBurcin KarabacakNo ratings yet

- Diac / Difc / DSFC: Instruction ManualDocument46 pagesDiac / Difc / DSFC: Instruction ManualAnkur LadNo ratings yet

- NOJA-5005-02 IEC 61850 IED Definition and Conformance Statement - 0Document23 pagesNOJA-5005-02 IEC 61850 IED Definition and Conformance Statement - 0astorzeroNo ratings yet

- Number 66 2021Document108 pagesNumber 66 2021Mariano Salomon PaniaguaNo ratings yet

- H99-SA-E-0053916 - 00 - SCF - Wireless FATDocument37 pagesH99-SA-E-0053916 - 00 - SCF - Wireless FATയുവ കോമളൻNo ratings yet

- SmartGrid vs MicroGrid; Energy Storage Technology: Energy, #2From EverandSmartGrid vs MicroGrid; Energy Storage Technology: Energy, #2No ratings yet

- Waste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesFrom EverandWaste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesRating: 5 out of 5 stars5/5 (1)

- H07V-U / - R: Low Voltage Cables ( 750V)Document2 pagesH07V-U / - R: Low Voltage Cables ( 750V)chida mohaNo ratings yet

- CovidDocument1 pageCovidchida mohaNo ratings yet

- CV - Adarsh Anand AcharyaDocument1 pageCV - Adarsh Anand Acharyachida mohaNo ratings yet

- Software Used To Program S7Document1 pageSoftware Used To Program S7chida mohaNo ratings yet

- UntitledDocument2 pagesUntitledchida mohaNo ratings yet

- JustificationDocument1 pageJustificationchida mohaNo ratings yet

- ArchitectureDocument1 pageArchitecturechida mohaNo ratings yet

- Matrix - SPARSH VP510E - BrochureDocument2 pagesMatrix - SPARSH VP510E - Brochurechida mohaNo ratings yet

- Matrix Solutions - : Ics SenegalDocument48 pagesMatrix Solutions - : Ics Senegalchida mohaNo ratings yet

- VOIP Network Pre RequisitesDocument5 pagesVOIP Network Pre Requisiteschida mohaNo ratings yet

- Comments R1Document1 pageComments R1chida mohaNo ratings yet

- Queries Confirmation Matrix 31.10.22Document22 pagesQueries Confirmation Matrix 31.10.22chida mohaNo ratings yet

- MIV From JAN - 2023 To APR-2023Document12 pagesMIV From JAN - 2023 To APR-2023chida mohaNo ratings yet

- 8640 16 ValveDocument1 page8640 16 Valvechida mohaNo ratings yet

- Log BookDocument1 pageLog Bookchida mohaNo ratings yet

- Drop Test Report Tower B 22112022Document1 pageDrop Test Report Tower B 22112022chida mohaNo ratings yet

- Modbus ManualDocument11 pagesModbus Manualchida mohaNo ratings yet

- Drop Test Report Tower B 22112022Document1 pageDrop Test Report Tower B 22112022chida mohaNo ratings yet

- EEP8 v2.3 Licensing OverviewDocument3 pagesEEP8 v2.3 Licensing Overviewchida mohaNo ratings yet

- Darou-1 Instrumentation Proposed Capex 2023Document1 pageDarou-1 Instrumentation Proposed Capex 2023chida mohaNo ratings yet

- Existing ProbeDocument1 pageExisting Probechida mohaNo ratings yet

- AWW Gradation List FINALDocument18 pagesAWW Gradation List FINALchida mohaNo ratings yet

- ProductOverview 2022 en LowDocument294 pagesProductOverview 2022 en Lowchida mohaNo ratings yet

- V1 Tour B 220317Document6 pagesV1 Tour B 220317chida mohaNo ratings yet

- Cpe Xomox XLB Iom en A4 2016-11-30 WebDocument10 pagesCpe Xomox XLB Iom en A4 2016-11-30 Webchida mohaNo ratings yet

- Worksheet Predicts Hydrodynamic NoiseDocument3 pagesWorksheet Predicts Hydrodynamic Noisechida mohaNo ratings yet

- Gas Compressibility InTech FocusDocument10 pagesGas Compressibility InTech Focuschida mohaNo ratings yet

- Using Installed Gain CalcsDocument7 pagesUsing Installed Gain Calcschida mohaNo ratings yet

- New Io List-1 - Address SynchronizationDocument760 pagesNew Io List-1 - Address Synchronizationchida mohaNo ratings yet

- Mad Lab ManualDocument67 pagesMad Lab ManualVîkrâm VêlûNo ratings yet

- ZM1 Low Amperage Line Sensor: BenefitsDocument2 pagesZM1 Low Amperage Line Sensor: BenefitsArun JosephNo ratings yet

- Precision 3660 Tower: Setup and SpecificationsDocument23 pagesPrecision 3660 Tower: Setup and SpecificationsLộc HuỳnhNo ratings yet

- Multiple Choice Questions: Eecs 183 Fall 2014 Exam 2Document12 pagesMultiple Choice Questions: Eecs 183 Fall 2014 Exam 2Madhu CkNo ratings yet

- Agile Customer ExperiencesDocument5 pagesAgile Customer ExperiencesIntense Technologies LimitedNo ratings yet

- A Packet Is The Unit of Data That Is Routed Between An Origin and A Destination On The Internet or Any OtherDocument9 pagesA Packet Is The Unit of Data That Is Routed Between An Origin and A Destination On The Internet or Any OtherYeoh YoungNo ratings yet

- Linux Command Cheat Sheet Simple VersionDocument9 pagesLinux Command Cheat Sheet Simple VersionbelopezpNo ratings yet

- Computer Organization & Assembly Language: Conditional and Unconditional Jump Instructions Loop InstructionDocument23 pagesComputer Organization & Assembly Language: Conditional and Unconditional Jump Instructions Loop InstructionAbdul RahmanNo ratings yet

- Symantec DLP 14.6 Server FlexResponse Platform Developers GuideDocument54 pagesSymantec DLP 14.6 Server FlexResponse Platform Developers Guidedbf75No ratings yet

- DC190 ManualDocument66 pagesDC190 ManualcôngNo ratings yet

- Beginners Guide To Massive Open Online Courses (Moocs)Document8 pagesBeginners Guide To Massive Open Online Courses (Moocs)Teri OsaNo ratings yet

- Exp ManualDocument66 pagesExp ManualMahmoudwaked100% (1)

- Of 18 MMDocument469 pagesOf 18 MMToma KuckovNo ratings yet

- Net102 Midterm Lab-Activity-1Document2 pagesNet102 Midterm Lab-Activity-1John Carlo Mesina GomezNo ratings yet

- 4Gls Sap R/2: Sap Systems and LandscapesDocument19 pages4Gls Sap R/2: Sap Systems and LandscapesBenoitNo ratings yet

- Reference Configuration For The Avaya S8720 or S8730 Server Using Software DuplicationDocument9 pagesReference Configuration For The Avaya S8720 or S8730 Server Using Software DuplicationMahmoud AbdallahNo ratings yet

- Resume 1Document2 pagesResume 1api-336360984No ratings yet

- Creation of Query Report With Additional Calculated FieldDocument11 pagesCreation of Query Report With Additional Calculated FieldAnil KumarNo ratings yet

- A Systematic Literature Review On The Security Attacks and Countermeasures Used in Graphical PasswordsDocument15 pagesA Systematic Literature Review On The Security Attacks and Countermeasures Used in Graphical Passwordsmahendrarm2112No ratings yet

- Onepager: What Is FTEC?Document3 pagesOnepager: What Is FTEC?Виталий МельникNo ratings yet

- Effective Windows PowerShellDocument50 pagesEffective Windows PowerShellAbby LiuNo ratings yet

- LTE CONCEPT & TDD COMPARISON With FDD PDFDocument173 pagesLTE CONCEPT & TDD COMPARISON With FDD PDFbagus mardaniNo ratings yet

- Ditf301 Unit 1Document25 pagesDitf301 Unit 1Pratibha BhadauriyaNo ratings yet

- Cisco SD WanDocument2 pagesCisco SD WanKurabiye CanavarıNo ratings yet