Professional Documents

Culture Documents

2024 03 13 SS26 OS Automation System Integration Flow Process

Uploaded by

ngoc tranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2024 03 13 SS26 OS Automation System Integration Flow Process

Uploaded by

ngoc tranCopyright:

Available Formats

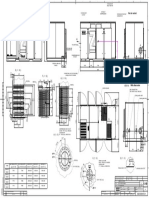

SS26 AUTOMATION (BASE & SPINE) PROCESS DESIGN

Process Plastic Outsole Injection Part Handling

Part SS26 P0/P1 FG MEN #8T (SAMPLE)

1st Injection Machine 2nd Injection Machine

Part Process

Stage BASE (Sub Part/Part 1) SPINE (Finished Part/Part 2)

Part Quantity 2 Pcs (1 Pair) 2 Pcs (1 Pair)

Area/ Station 1. Stud Transfer Table 2. Robot 1 3. Base Transfer 4. Robot 2 (Spine) 5.Conveyor

Table in Insert position Robot waits Mold Open Table in Insert position Robot waits Mold Open Conveyor give signal to Robot 2

Operator Inserting Stud to Jig Manually Robot get in Table give signal to Robot 1 Robot get in Robot 2 Put FG to conveyor

OPerator Push button Robot Insert Stud Robot 1 Insert Base to Base transfer table Robot Insert Base Conveyor get signal from Robot 2

Table Move to Fickup Position Robot Take-out Base Table get signal from Robot 1 Robot Take-out Finish Good(FG) conveyor swive/flip FG

Table give signal to Robot 1 Robot moving out Table swive/flip base and insert to Jig Robot moving out conveyor rotate

Table Waits Robot 1 to Pickup Stud Robot get Signal from Base transfer table Jig shrinking Robot putting FG to conveyor conveyor stop

Table get signal from Robot 1 Robot placing Base to Base transfer table Table move to pickup position Robot give signal to conveyor

Table Move back to insert Position Robot give signal to Base transfer table Table give signal to Robot 2 Robot move to Base transfer table

Robot get signal from Stud transfer table Table wait Robot 2 Pickup Base Robot get signal from Base transfer table

Process / Steps Robot move to Stud transfer table Table get signal from Robot 2 Robot Pickup Base

Robot Pickup stud Table move back to insert position Robot give signal to Base transfer table

Robot give signal to Stud transfer table

NB: see LayOut Draft for Refference

I/O DISTRIBUTION

DI (Digital Input) DO (Digital Output) Pneumatic Output LAYOUT DRAFT

Runner Detect Selenoid Runner chuck Runner Chuck In

Vac. Detect 1 Solenoid Chuck Prod. 1 Runner Chuck Out

Vac. Detect 2 Solenoid Chuck Prod. 2 Chuck Prod. In 1

Prod. Detect 1 Solenoid Vaccum 1 Chuck Prod. Out 1

Robot 1 (Base)

Prod. Detect 2 Solenoid Vaccum 2 Chuck Prod. In 2

Flip Action Position Product Insert/Eject(optional) Chuck Prod. Out 2

Flip Return Position Selenoid Blow (optional) Pneu. Vac. 1 (Flow: … lt/Min.)

Enable Pickup Stud (External Signal) Selenoid Flip Action Pneu. Vac. 1 (Flow: … lt/Min.)

Enabel Putting Base (External Signal) Selenoid Flip Return Sprue Chuck

Pickup Stud Confirm (External Signal) Runner Chuck

Putting Base Confirm (External Signal) Blow

Runner Detect Selenoid Runner chuck Runner Chuck In

Vac. Detect 1 Solenoid Chuck Prod. 1 Runner Chuck Out

Vac. Detect 2 Solenoid Chuck Prod. 2 Chuck Prod. In 1

Prod. Detect 1 Solenoid Vaccum 1 Chuck Prod. Out 1

Robot 2 (Spine)

Prod. Detect 2 Solenoid Vaccum 2 Chuck Prod. In 2

Flip Action Position Product Insert/Eject(optional) Chuck Prod. Out 2

Flip Return Position Selenoid Blow (optional) Pneu. Vac. 1 (Flow: … lt/Min.)

Enabel Pickup Base (External Signal) Selenoid Flip Action Pneu. Vac. 1 (Flow: … lt/Min.)

Enabel Putting Base (External Signal) Selenoid Flip Return Sprue Chuck

Pickup Base Confirm (External Signal) Runner Chuck

Putting Base Confirm (External Signal) Blow

1 Emergency Stop 1 Servo Motor

Stud Transfer

2 Door/Safety Fence 2 Lamp Indicator (Auto)

3 Switch Auto / Manual 3 Lamp Indicator (Standby)

Table

4 Pushbutton forward 4 Enable Pickup Stud (for Input Robot 1)

5 Pushbutton Backward

6 Pickup Stud Confirm (From output Robot 1)

7 Sensor Position 1.1 (Backward)

8 Sensor Position 1.2 (Forward)

Base Transfer

1 Emergency Stop 1 Servo Motor

2 Door/Safety Fence 2 Lamp Indicator (Auto)

3 Switch Auto / Manual 3 Lamp Indicator (Standby)

Table

4 Pushbutton forward 4 Enable Putting Base (For input Robot 1)

5 Pushbutton Backward 5 Enable Pickup Base ( For input Robot 2)

6 Putting Base Confirm (From output Robot 1) 6 Vacuum

7 Pickup Base Confirm (From output Robot 2) 7 Swivel/flip

8 Sensor Position 2.1 (Backward) 8 Jig movement

9 Sensor Position 2.2 (Forward)

10 Vacuum Sensor

Conveyor

1 Emergency Stop 1 Servo Motor

Station

2 Switch Auto / Manual

3 Enable Conveyor Run

Total I/O

NB: I/O Needed for the system is closing or same with Robot I/O Capacity. For spare & future precaution, use External I/O (External PLC) 2024 01 15

Production Automation Dept.

You might also like

- DET-2 Service ManualDocument105 pagesDET-2 Service Manualkriotron50% (2)

- PDF - Inverter Operation InstructionsDocument16 pagesPDF - Inverter Operation InstructionsOmed Elind100% (3)

- Sharp J. Exam Ref AI-900 Microsoft Azure AI Fundamentals 2022 PDFDocument366 pagesSharp J. Exam Ref AI-900 Microsoft Azure AI Fundamentals 2022 PDFKoos SerfonteinNo ratings yet

- PI150 Series Frequency Inverter Operation Manual: 1.forewordDocument15 pagesPI150 Series Frequency Inverter Operation Manual: 1.forewordсергей100% (3)

- 21C Manual CBF PDFDocument218 pages21C Manual CBF PDFjorge erazo92% (26)

- Treinamento STEC-360A (NC Program) E PDFDocument107 pagesTreinamento STEC-360A (NC Program) E PDFArmando Rivera100% (2)

- Toy Robot SimulatorDocument3 pagesToy Robot Simulatorbreakfree210% (1)

- 01 Manual de Mantenimiento Del RobotDocument10 pages01 Manual de Mantenimiento Del RobotCarlos Eduardo Segura VillarrealNo ratings yet

- Ace III Service ManualDocument46 pagesAce III Service Manualosiris israely100% (1)

- Minecraft Redstone: 70 Top Minecraft Redstone Ideas Your Friends Wish They KnowFrom EverandMinecraft Redstone: 70 Top Minecraft Redstone Ideas Your Friends Wish They KnowRating: 3 out of 5 stars3/5 (10)

- 2024 01 10 SS26 OUTSOLE Automation - Intro For VendorsDocument8 pages2024 01 10 SS26 OUTSOLE Automation - Intro For Vendorsngoc tranNo ratings yet

- Sefac Bogie Drop TablesDocument3 pagesSefac Bogie Drop TablesKhhg AgddsNo ratings yet

- HulkScratch Instruction For 6.0Document57 pagesHulkScratch Instruction For 6.0Alay camilo lopezNo ratings yet

- General Timing Chart / General Circuit Diagram: Ir5075/5065/5055 SeriesDocument38 pagesGeneral Timing Chart / General Circuit Diagram: Ir5075/5065/5055 SeriesAnonymous T8I5K1nNh100% (2)

- Function Junction ManualDocument12 pagesFunction Junction ManualshadesforgrayNo ratings yet

- National University of SingaporeDocument8 pagesNational University of Singaporerub786No ratings yet

- FDJ 040 CDocument13 pagesFDJ 040 Cpratik.udeNo ratings yet

- Specs For RobotDocument1 pageSpecs For RobotAjay SuryavanshiNo ratings yet

- Busbar B90 Engg ApprovedDocument20 pagesBusbar B90 Engg ApprovedSandeep sahuNo ratings yet

- Integral Starter With Motorized Valve Programmable Logic Controller (PLC) or Remote I/O Unit (RIO)Document11 pagesIntegral Starter With Motorized Valve Programmable Logic Controller (PLC) or Remote I/O Unit (RIO)BasabRajNo ratings yet

- Work DataDocument5 pagesWork DatashivarajNo ratings yet

- 12 ExampleDocument10 pages12 ExampleCamilo HerreraNo ratings yet

- Topic 9Document24 pagesTopic 9bsmaldeniyaNo ratings yet

- 1465270-Ir6570 SeriesDocument36 pages1465270-Ir6570 SeriesandiNo ratings yet

- Let's Play Ball!: PLC IIP Roje CTDocument11 pagesLet's Play Ball!: PLC IIP Roje CTALEXDRIVERA27No ratings yet

- Origin Search (REAL) : MD - CPU050 - Home - REAL: 0'BCPU 050 Basic Function SymbolDocument2 pagesOrigin Search (REAL) : MD - CPU050 - Home - REAL: 0'BCPU 050 Basic Function SymbolSUPPANAT CHAISAWATNo ratings yet

- TR - Dif 7ut612Document4 pagesTR - Dif 7ut612Abo Abdullah MohamedNo ratings yet

- Tutorial On The Double Balanced Mixer: Enrico RubiolaDocument52 pagesTutorial On The Double Balanced Mixer: Enrico Rubiolafaroo28No ratings yet

- General Timing Chart-General Circuit DiagramDocument38 pagesGeneral Timing Chart-General Circuit DiagramWillian S.100% (1)

- 12 MCM3320 Hardware IO Block DiagramDocument1 page12 MCM3320 Hardware IO Block DiagramJuan CarlosNo ratings yet

- Manual Pi150Document16 pagesManual Pi150REYNo ratings yet

- Tanggal: 21 Oktober 2013: Rangkuman Pekerjaan M.E.P & Hvac Proyek G3Tv - Kebon Jeruk - Jakarta Barat Stc-Multikon JoDocument16 pagesTanggal: 21 Oktober 2013: Rangkuman Pekerjaan M.E.P & Hvac Proyek G3Tv - Kebon Jeruk - Jakarta Barat Stc-Multikon Joiwd_smNo ratings yet

- Toy Robot SimulatorDocument3 pagesToy Robot SimulatorDiane RiveraNo ratings yet

- Report 2 RobotikDocument10 pagesReport 2 RobotikMr AloneNo ratings yet

- Electrix - Tweaker: DJ Product 1Document1 pageElectrix - Tweaker: DJ Product 1USER58679No ratings yet

- Fanuc TrainingDocument42 pagesFanuc TrainingCarlos Musella100% (4)

- AB Mannual ProgrammingDocument37 pagesAB Mannual Programmingle chauNo ratings yet

- Installation and Operating Instructions For Avid Eazical Ir PositionerDocument9 pagesInstallation and Operating Instructions For Avid Eazical Ir PositionerFlavioNo ratings yet

- Canon Ir2016 Block DiagramDocument20 pagesCanon Ir2016 Block DiagrampotatoNo ratings yet

- General Timing Chart / General Circuit Diagram: Imagepress C1 SeriesDocument240 pagesGeneral Timing Chart / General Circuit Diagram: Imagepress C1 SeriesElonaHoxhaNo ratings yet

- Robot Sequence SheetsDocument6 pagesRobot Sequence Sheetsjitap52882No ratings yet

- TIA PRO1 06 Binary Operations 2 enDocument19 pagesTIA PRO1 06 Binary Operations 2 endikiNo ratings yet

- Manual Shifting Test: Automatic TransmissionDocument2 pagesManual Shifting Test: Automatic TransmissionMayobanex Moya MartinezNo ratings yet

- Guide 8 - RAPID Programming LanguageDocument44 pagesGuide 8 - RAPID Programming LanguageAna Julia AndradeNo ratings yet

- WDM Lab Pe Aristo RobotDocument8 pagesWDM Lab Pe Aristo Robotfkmal28569No ratings yet

- Main Panel Manual Ample Bass Upright: Beijing Ample Sound Technology Co. LTDDocument18 pagesMain Panel Manual Ample Bass Upright: Beijing Ample Sound Technology Co. LTDMaxiMoralesNo ratings yet

- XB4 / ZB4: Control and Signaling Diameter 22mmDocument64 pagesXB4 / ZB4: Control and Signaling Diameter 22mmSebastian EspinozaNo ratings yet

- 400V LV SWGR Protective Setting RelayDocument3 pages400V LV SWGR Protective Setting Relaywidionosucipto29No ratings yet

- Lab SessionsDocument14 pagesLab SessionshamzatariqmirzaNo ratings yet

- Main Panel Manual-AMHDocument19 pagesMain Panel Manual-AMHkalichexNo ratings yet

- Stylus - Pro - 4400 101 200 (042 100)Document59 pagesStylus - Pro - 4400 101 200 (042 100)Joso CepuranNo ratings yet

- Melco EP1BDocument49 pagesMelco EP1BAlex PerexNo ratings yet

- Robot Motion Planning Presentation 13-12-12Document63 pagesRobot Motion Planning Presentation 13-12-12Stephen WigginsNo ratings yet

- Main Panel Manual Ample Ethno Ukulele: Beijing Ample Sound Technology Co. LTDDocument19 pagesMain Panel Manual Ample Ethno Ukulele: Beijing Ample Sound Technology Co. LTDRivaldo KrimadiNo ratings yet

- Name: Date/Time: Daily Plant Inspection Tour: False FalseDocument1 pageName: Date/Time: Daily Plant Inspection Tour: False FalsemohammadNo ratings yet

- Main Panel Manual Ample Ethno Ukulele: Beijing Ample Sound Technology Co. LTDDocument19 pagesMain Panel Manual Ample Ethno Ukulele: Beijing Ample Sound Technology Co. LTDElkin EscorciaNo ratings yet

- Semiconductor - RF Device - Tray To Tape N Reel SystemDocument1 pageSemiconductor - RF Device - Tray To Tape N Reel SystemAnthony FajardoNo ratings yet

- High Efficiency RF and Microwave Solid State Power AmplifiersFrom EverandHigh Efficiency RF and Microwave Solid State Power AmplifiersRating: 1 out of 5 stars1/5 (1)

- Family Emergency PlanDocument4 pagesFamily Emergency PlanShaira C. AdralesNo ratings yet

- WebSphere Portal Family Wiki - Database Configuration For WebSphere Portal - Steps To Configure WebSphere Portal 6.1Document7 pagesWebSphere Portal Family Wiki - Database Configuration For WebSphere Portal - Steps To Configure WebSphere Portal 6.1Parameshwara RaoNo ratings yet

- CSC Job Portal: Mgo Plaridel, Misamis Occidental - Region XDocument1 pageCSC Job Portal: Mgo Plaridel, Misamis Occidental - Region XDnrxsNo ratings yet

- SerDes - WikipediaDocument3 pagesSerDes - WikipediaPronadeep BoraNo ratings yet

- Seat BeltDocument56 pagesSeat BeltMirceaNo ratings yet

- ITB 2021-22 - Session 5-6 - Cybersecurity and PrivacyDocument54 pagesITB 2021-22 - Session 5-6 - Cybersecurity and Privacyriya lakhotiaNo ratings yet

- Dyna 320M Test Program-V2.1Document8 pagesDyna 320M Test Program-V2.1JorgeZelayaNo ratings yet

- Algebra TestDocument12 pagesAlgebra TestHazel De Castro PanaliganNo ratings yet

- Crowdsourcing and Social Engagement:: Potential, Power and Freedom For Libraries and UsersDocument73 pagesCrowdsourcing and Social Engagement:: Potential, Power and Freedom For Libraries and Usersjaypee pengNo ratings yet

- Web Technology Lesson PlanDocument4 pagesWeb Technology Lesson PlanBhavana VenkatNo ratings yet

- E-Mail Spam Detection Using Machine Lear PDFDocument7 pagesE-Mail Spam Detection Using Machine Lear PDFTrending this yearNo ratings yet

- Fujitsu Ten 86120 Pinout New in 2023 - Car Stereo Systems, Car Stereo, Car AudioDocument1 pageFujitsu Ten 86120 Pinout New in 2023 - Car Stereo Systems, Car Stereo, Car AudiosvezxboxNo ratings yet

- Canon Pixma IP3000 Part ListDocument22 pagesCanon Pixma IP3000 Part ListlftrevNo ratings yet

- Design of Power-Transmitting Shafts: Reference Publication 1123Document30 pagesDesign of Power-Transmitting Shafts: Reference Publication 1123Rodrigo MachadoNo ratings yet

- Digital ForensicsDocument23 pagesDigital ForensicsMunagala Sai SumanthNo ratings yet

- Manual Casio Te 2400Document240 pagesManual Casio Te 2400Fran AbadNo ratings yet

- Operating System (17CS64)Document3 pagesOperating System (17CS64)Pranove ABNo ratings yet

- Certificate of Candidacy For Member, Sangguniang Bayan: Commission On ElectionsDocument2 pagesCertificate of Candidacy For Member, Sangguniang Bayan: Commission On ElectionsPiagapo Lanao del SurNo ratings yet

- ZA6VSD RysDocument1 pageZA6VSD RysDanielNo ratings yet

- Document From Sfere Electric23 AbcDocument29 pagesDocument From Sfere Electric23 AbcMuhammad SaleemNo ratings yet

- NF - Apple EUADocument2 pagesNF - Apple EUAgustavogko01100% (1)

- List of Thesis Title Proposal For It StudentsDocument7 pagesList of Thesis Title Proposal For It StudentsHelpWritingCollegePapersSavannah100% (2)

- Ee6602 Embedded Systems LT P C 3 0 0 3Document94 pagesEe6602 Embedded Systems LT P C 3 0 0 3Jebas ManovaNo ratings yet

- Ps2 3 KHDocument14 pagesPs2 3 KHBranden933No ratings yet

- Flydat Control Operator'S Manual: Aircraft EnginesDocument16 pagesFlydat Control Operator'S Manual: Aircraft EnginesNickNo ratings yet

- TYBCA Cyber Security Notes 1Document99 pagesTYBCA Cyber Security Notes 1pradneshshinde29No ratings yet

- Technology and Society Unit 3Document21 pagesTechnology and Society Unit 3me niksyNo ratings yet

- Manual IFQ Monitor en Rev 08-2022Document50 pagesManual IFQ Monitor en Rev 08-2022Gerald StiflerNo ratings yet

- PoN Servcie Container - WARTSILADocument5 pagesPoN Servcie Container - WARTSILAIgnacio BartchNo ratings yet