Professional Documents

Culture Documents

Home Assignment Chemistry

Uploaded by

Adithya Gulla0 ratings0% found this document useful (0 votes)

3 views2 pages1. Elucidate the role of Consumer behaviour in Marketing. 10 10

2. Explain the role of consumer research in marketing 10 10

3. Explain Freudian Theory of Personality. 10 10

Q.No Assignment Set – 2

Questions Marks Total Marks

4. Explain the consumer buying process. 10 10

5. Write Short Notes on the following:

a) Differential Threshold

b) Subliminal Perception 5*2 10

6. Discuss the Diffusion of Innovation with a suitable example. 5+5 10

Original Title

HOME ASSIGNMENT CHEMISTRY

Copyright

© © All Rights Reserved

Available Formats

ODT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. Elucidate the role of Consumer behaviour in Marketing. 10 10

2. Explain the role of consumer research in marketing 10 10

3. Explain Freudian Theory of Personality. 10 10

Q.No Assignment Set – 2

Questions Marks Total Marks

4. Explain the consumer buying process. 10 10

5. Write Short Notes on the following:

a) Differential Threshold

b) Subliminal Perception 5*2 10

6. Discuss the Diffusion of Innovation with a suitable example. 5+5 10

Copyright:

© All Rights Reserved

Available Formats

Download as ODT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesHome Assignment Chemistry

Uploaded by

Adithya Gulla1. Elucidate the role of Consumer behaviour in Marketing. 10 10

2. Explain the role of consumer research in marketing 10 10

3. Explain Freudian Theory of Personality. 10 10

Q.No Assignment Set – 2

Questions Marks Total Marks

4. Explain the consumer buying process. 10 10

5. Write Short Notes on the following:

a) Differential Threshold

b) Subliminal Perception 5*2 10

6. Discuss the Diffusion of Innovation with a suitable example. 5+5 10

Copyright:

© All Rights Reserved

Available Formats

Download as ODT, PDF, TXT or read online from Scribd

You are on page 1of 2

HOME ASSIGNMENT-2

2000080039

1. Chemical Theory of Corrosion:

- In addition to atmospheric oxygen, other environmental factors such as moisture, acids,

bases, and salts can also contribute to corrosion through direct chemical reactions with the

metal surface.

- The corrosion rate in the chemical theory is influenced by factors such as temperature,

humidity, and the chemical composition of the environment.

- Certain metals form protective oxide layers that can inhibit further corrosion. For

example, aluminum and stainless steel develop passive oxide layers that provide corrosion

resistance under normal conditions. However, these protective layers can be disrupted by

certain environmental factors, leading to localized corrosion.

2. Electrochemical Theory of Corrosion:

- In electrochemical corrosion, the metal surface contains regions known as anodes and

cathodes, where oxidation and reduction reactions occur, respectively.

- Anodic reaction: At the anode, metal atoms lose electrons and undergo oxidation,

releasing metal ions into the surrounding electrolyte solution.

- Cathodic reaction: At the cathode, reduction reactions take place, typically involving the

reduction of oxygen or hydrogen ions present in the electrolyte.

- The electrolyte serves as a medium for ion transport and completes the electrochemical

circuit by facilitating the movement of electrons from the anode to the cathode.

- Localized variations in environmental conditions or the presence of impurities on the

metal surface can create microenvironments that promote corrosion, leading to phenomena

such as pitting corrosion, crevice corrosion, and stress corrosion cracking.

- Electrochemical corrosion processes can be quantitatively analyzed using techniques such

as polarization curves, electrochemical impedance spectroscopy, and scanning

electrochemical microscopy.

3. Prevention and Control:

- Understanding the mechanisms of corrosion is essential for developing effective corrosion

prevention and control strategies.

- Measures to prevent corrosion include the use of corrosion-resistant materials, protective

coatings, corrosion inhibitors, cathodic protection, and proper design and maintenance

practices.

- Corrosion monitoring techniques such as corrosion rate measurements, visual inspection,

and non-destructive testing help assess the effectiveness of corrosion control measures and

identify potential corrosion issues before they cause significant damage.

You might also like

- Industrial Materials and ProcessesDocument24 pagesIndustrial Materials and ProcessesJamie Christine0% (1)

- Corrosion Protection of SteelDocument9 pagesCorrosion Protection of SteelChristian D. OrbeNo ratings yet

- Composition and Formulation of Mineral Mixture For Dairy Animals.Document3 pagesComposition and Formulation of Mineral Mixture For Dairy Animals.Dr. MANOJ SHARMA80% (15)

- CorrosionDocument31 pagesCorrosionLyle Joseph Legaspi100% (1)

- CorrosionDocument176 pagesCorrosionFalfonso69100% (7)

- Wind Ananlysis Calculation For MR Pankaj Pachlore: 8.5 + 3 11.5 Between 1.5 & 10 MDocument9 pagesWind Ananlysis Calculation For MR Pankaj Pachlore: 8.5 + 3 11.5 Between 1.5 & 10 Mhitesh gandhiNo ratings yet

- Polarization CurveDocument9 pagesPolarization Curvefreeuser3No ratings yet

- Corrosion: 2/engr Leonardo C Cuerdo, MSCDocument43 pagesCorrosion: 2/engr Leonardo C Cuerdo, MSCJayvee MauricioNo ratings yet

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksFrom EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNo ratings yet

- Method To Prevent CorrosionDocument4 pagesMethod To Prevent CorrosionFaradilah Binti Ajma'inNo ratings yet

- Corrosion, Prevention and ControlDocument60 pagesCorrosion, Prevention and ControlCherry Obias100% (1)

- Corrosion Prevention and ControlDocument10 pagesCorrosion Prevention and ControlBensoyNo ratings yet

- Corrosion Prevention For MetalsDocument17 pagesCorrosion Prevention For Metalsabdul100% (1)

- Part 1 General EducationDocument8 pagesPart 1 General EducationGrimReaper20No ratings yet

- Unit 2 CorrosionDocument37 pagesUnit 2 CorrosionRohan PolNo ratings yet

- Ways To Control CorrosionDocument37 pagesWays To Control CorrosionKyle DugayoNo ratings yet

- Corrosion Minimizing ProceduresDocument5 pagesCorrosion Minimizing ProceduresCh. Muhammad UsamaNo ratings yet

- Corrosion Types - Real PicturesDocument3 pagesCorrosion Types - Real PicturesJaswant Singh ChauhanNo ratings yet

- Activity 2Document7 pagesActivity 2Ren RenNo ratings yet

- Corrosion Prevention and ControlDocument5 pagesCorrosion Prevention and ControlElyk TakataNo ratings yet

- Corrosion and Its Prevention: Presented by B.Chandaneswar Kumar 15001A0839 Iv Btech Chemical EngineeringDocument8 pagesCorrosion and Its Prevention: Presented by B.Chandaneswar Kumar 15001A0839 Iv Btech Chemical EngineeringChandaneswarkumar BoddaniNo ratings yet

- 53 - Cse - Vaibhav Rakesh Singh Report Chem CorrosionDocument8 pages53 - Cse - Vaibhav Rakesh Singh Report Chem Corrosion53 CS&E Vaibhav Rakesh SinghNo ratings yet

- Corrosion Prevention and Control: By: Patick James Pallo Ram Jun RegaladoDocument10 pagesCorrosion Prevention and Control: By: Patick James Pallo Ram Jun RegaladoBensoyNo ratings yet

- Dennis Wambua Corrosion in BruceDocument30 pagesDennis Wambua Corrosion in Brucedenniswambua10669No ratings yet

- CorrosionDocument5 pagesCorrosionsamyuldarosaNo ratings yet

- CorrosionDocument33 pagesCorrosionSherina Mae GonzalesNo ratings yet

- Laboratory 2 - Gutierrez 1Document3 pagesLaboratory 2 - Gutierrez 1John Michael MarianoNo ratings yet

- Corrosion and Its Types: Engineering Material AssignmentDocument6 pagesCorrosion and Its Types: Engineering Material AssignmentHasieb Alam KhanNo ratings yet

- CorrosionDocument1 pageCorrosionChandra mohith.V reddyNo ratings yet

- Unit 3 CorrosionDocument26 pagesUnit 3 CorrosionVasudev GuptaNo ratings yet

- Prevention and Control of Corrosion: Muhamed Musthafa Pulikkal M.Tech (NDT) Roll No.-213118015Document14 pagesPrevention and Control of Corrosion: Muhamed Musthafa Pulikkal M.Tech (NDT) Roll No.-213118015hadiNo ratings yet

- Welding CorrosionDocument36 pagesWelding CorrosionKe HalimunNo ratings yet

- Unit 3. Corrosion 2022Document31 pagesUnit 3. Corrosion 2022Rohit AgrawalNo ratings yet

- Unit VI Corrosion Science: Course Instructor-Dr. Shailesh DhokeDocument58 pagesUnit VI Corrosion Science: Course Instructor-Dr. Shailesh DhokeLadliNo ratings yet

- BCHES102 Module-3 Corrosion & Electrode System-1Document33 pagesBCHES102 Module-3 Corrosion & Electrode System-1svam81118No ratings yet

- Essay On Corrosion - Baimourne BournebeDocument4 pagesEssay On Corrosion - Baimourne BournebeBAIMOURNE BOURNEBENo ratings yet

- Chemistry Unit - 2 NotesDocument13 pagesChemistry Unit - 2 Notesjoshinihar19No ratings yet

- Experiment 2 Electroplating and Galvanic Protection Objectives: Experiment To Demonstrate Electroplating and Galvanic Protection TheoryDocument9 pagesExperiment 2 Electroplating and Galvanic Protection Objectives: Experiment To Demonstrate Electroplating and Galvanic Protection Theoryboatcom100% (1)

- Corrosion Prevention and ControlDocument22 pagesCorrosion Prevention and ControlMobile LegendsNo ratings yet

- Corrosion (Study Material)Document8 pagesCorrosion (Study Material)SANDEEP NAYAKNo ratings yet

- Environmental Degradation PDFDocument10 pagesEnvironmental Degradation PDFMuhammad UsmanNo ratings yet

- Project P 1 CLGG AhsbhDocument16 pagesProject P 1 CLGG Ahsbhpranav mahajanNo ratings yet

- DAFLOU BATIS VpCI - 2Document6 pagesDAFLOU BATIS VpCI - 2Wr ArNo ratings yet

- Cathodic ProtectionDocument14 pagesCathodic ProtectionnazirulhakimNo ratings yet

- Pages From Electrochemistry Encyclopedia: ElectroplatingDocument5 pagesPages From Electrochemistry Encyclopedia: ElectroplatingJeebee Logroño AloNo ratings yet

- 12 - Corrosion and Its Control - (I)Document32 pages12 - Corrosion and Its Control - (I)Anushka SahuNo ratings yet

- Metal Corrosion and Its Prevention: Material ScienceDocument49 pagesMetal Corrosion and Its Prevention: Material Sciencedr nfNo ratings yet

- Unit 2 Corrosion - 2019Document31 pagesUnit 2 Corrosion - 2019Abhay hNo ratings yet

- Corrosion: CH 109: Applied Chemistry Dr. Aneeqa Noor Date: 5.12.22Document20 pagesCorrosion: CH 109: Applied Chemistry Dr. Aneeqa Noor Date: 5.12.22Abdul Rehman Khan TareenNo ratings yet

- Cathodic ProtectionDocument36 pagesCathodic ProtectionMasood KhanNo ratings yet

- Effect of Anodization On The Corrosion Behavior of Aluminium Alloy in HCL Acid and NaohDocument5 pagesEffect of Anodization On The Corrosion Behavior of Aluminium Alloy in HCL Acid and NaohGabriel DevaNo ratings yet

- Chemisrty Digital Assignment - 2: Topic: Corrosion TechnologyDocument5 pagesChemisrty Digital Assignment - 2: Topic: Corrosion TechnologyUsha UshasreeNo ratings yet

- Corrosion - JUDocument32 pagesCorrosion - JUSWAGATAM BAZNo ratings yet

- Two Corrosion Protection MethodsDocument5 pagesTwo Corrosion Protection MethodsShukry AmiryNo ratings yet

- SIandA11 Introduction To Corrosion MechanismsDocument22 pagesSIandA11 Introduction To Corrosion MechanismsmahendranmaheNo ratings yet

- Chemistry Informatory ProjectDocument7 pagesChemistry Informatory ProjectGaming WorldNo ratings yet

- Corrosion Module 4Document106 pagesCorrosion Module 4sk10000067No ratings yet

- Corrosion BasicsDocument35 pagesCorrosion BasicsAbdul Wajid AliNo ratings yet

- Corrosion Protection of SteelDocument3 pagesCorrosion Protection of Steelbenandy2018No ratings yet

- Corrosion: Corrosion Is A Natural Process That Converts A Refined Metal Into ADocument15 pagesCorrosion: Corrosion Is A Natural Process That Converts A Refined Metal Into AWaqas LuckyNo ratings yet

- WINSEM2018-19 - CHY1701 - ETH - SJT304 - VL2018195004125 - Reference Material I - EC - Module-4-Corrosion ProtectionDocument61 pagesWINSEM2018-19 - CHY1701 - ETH - SJT304 - VL2018195004125 - Reference Material I - EC - Module-4-Corrosion ProtectionkumarklNo ratings yet

- CorrosionDocument81 pagesCorrosionsureshs83No ratings yet

- EP 1649950A2 Method For Manufacturing Copper AlloysDocument7 pagesEP 1649950A2 Method For Manufacturing Copper AlloysNut AssanaiNo ratings yet

- Alkaloids Chemistry and BiologyDocument108 pagesAlkaloids Chemistry and BiologyChiến NguyễnNo ratings yet

- Spinach As DyeDocument39 pagesSpinach As DyeKearl MandaoNo ratings yet

- Iso 08502-1Document12 pagesIso 08502-1Hassan FekiNo ratings yet

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document4 pagesTable of Material Properties For Structural Steel S235, S275, S355, S420Mouhssine BrahmiaNo ratings yet

- Lecture Planner - Chemistry PDF OnlyDocument1 pageLecture Planner - Chemistry PDF OnlyJai ChandNo ratings yet

- Diffraction 2Document18 pagesDiffraction 2kalozira123No ratings yet

- Product Overview Vinnapas Dispersions: Adhesives I Polymer Binders I EuropeDocument5 pagesProduct Overview Vinnapas Dispersions: Adhesives I Polymer Binders I EuropeSaad AzzouniNo ratings yet

- Experimental Investigations On Mechanical Properties of Jute Fiber Reinforced Composites With Polyester and Epoxy Resin MatricesDocument12 pagesExperimental Investigations On Mechanical Properties of Jute Fiber Reinforced Composites With Polyester and Epoxy Resin MatricesSayan RakshitNo ratings yet

- Solubilidad Del Florfenicol Con Diferentes SolventesDocument4 pagesSolubilidad Del Florfenicol Con Diferentes Solventesrafael wadniparNo ratings yet

- SKF Chumaceras y Grado Alimentició.Document108 pagesSKF Chumaceras y Grado Alimentició.Maria Isabel MagañaNo ratings yet

- Topic - 13 - Test (Organic Chemistry A Level Aqa)Document11 pagesTopic - 13 - Test (Organic Chemistry A Level Aqa)afivealeNo ratings yet

- Test Bank For Biochemistry 8th Edition by Berg Tymoczko Gatto and Stryer ISBN 1464126100 9781464126109Document36 pagesTest Bank For Biochemistry 8th Edition by Berg Tymoczko Gatto and Stryer ISBN 1464126100 9781464126109jamesarmstrongcmzxgbqedw100% (25)

- f2 Chemistry TopicalsDocument36 pagesf2 Chemistry TopicalsEvansOmoiNo ratings yet

- Method Verification Protocol For USP Method For Assay of Ratio of Alkyl Components in BZK-CL Solution 50 % RMDocument5 pagesMethod Verification Protocol For USP Method For Assay of Ratio of Alkyl Components in BZK-CL Solution 50 % RMmohsenNo ratings yet

- Us9598594 PDFDocument16 pagesUs9598594 PDFAPEX SONNo ratings yet

- TracersInTheSea SearchableDocument705 pagesTracersInTheSea SearchableAvan AngelNo ratings yet

- 9 - Class Notes (CH-101 &CH-201) Module-3 - Electro Chemistry-5Document3 pages9 - Class Notes (CH-101 &CH-201) Module-3 - Electro Chemistry-5antony2288No ratings yet

- Union Technical AlertDocument4 pagesUnion Technical AlertSantosh Kumar AlpeteNo ratings yet

- Total Internal Reflect-InteractiveDocument25 pagesTotal Internal Reflect-InteractiveRodel VerzosaNo ratings yet

- Verifying The Alignment of X-Ray Diffraction Instrumentation For Residual Stress MeasurementDocument4 pagesVerifying The Alignment of X-Ray Diffraction Instrumentation For Residual Stress MeasurementGina f AlmeidaNo ratings yet

- ASTM D2697 Standart Test Method For Volume Nonvolatile Matter in ClearDocument3 pagesASTM D2697 Standart Test Method For Volume Nonvolatile Matter in ClearCristian Garcia GuzmanNo ratings yet

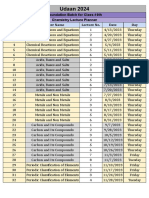

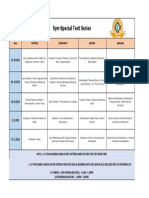

- Special Test Series ScheduleDocument1 pageSpecial Test Series SchedulehuguioNo ratings yet

- Granular Urea PssDocument1 pageGranular Urea PssChandan JstNo ratings yet

- Grade 10 Chemistry Week 3 Lesson 2Document2 pagesGrade 10 Chemistry Week 3 Lesson 2Nikoli MajorNo ratings yet

- Y7 Homework BookletDocument17 pagesY7 Homework BookletSarah KKCNo ratings yet

- Kinetics of Soybean Oil Epoxidation in A Semibatch Reactor: AccessDocument12 pagesKinetics of Soybean Oil Epoxidation in A Semibatch Reactor: AccessCinthia Sierra LgarsNo ratings yet