Professional Documents

Culture Documents

PWHT Annexure

Uploaded by

Sam RajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWHT Annexure

Uploaded by

Sam RajaCopyright:

Available Formats

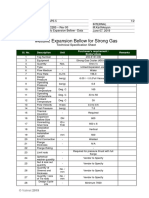

PWHT CALCULATION

Tag no: 24 V006A

SR. NO: PT/052

CS‐03 (Cirm.Seam

JOINT / NOZZLE NO Repair) Max depth is N9, N11 N10 N1 Remarks

8mm

ID: 1957 MM/ 12 2" / 8.74, 12, 10

SIZE / Nominal thick 4"/ 11.13, 12MM 10"/ 15.09MM

MM THK MM

TYPE OF JOINT BW BW & FW BW & FW BW

MINIMUM NOZZLE OUTWARD

NA 203 MM 203 MM 304 MM

PROJECTION

t or 50 mm

WIDTH OF SOAKING

whichever is 8 MM 12 MM 12 MM 15.09 MM

BAND (SB) less

WIDTH OF HEATING 2.5√ RT for

SB + 4√ RT 420 MM Req: 362 200 MM Req:88 200 MM Req:117 200 MM Req:117 attachment weld

BAND (HB)

GRADIENT CONTROL HB+ 4√ RT 800 MM Req:716 400 MM Req:164 400 MM Req:222 400 MM Req:222

BAND (GCB)

SELECTION OF CERAMIC PAD CP10 CP21 CP10, CP21 CP10, CP21

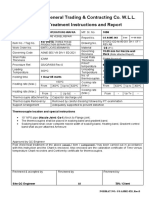

Note:

1, Thermpcouples shall be placed along the centerline of the weld in the middle of the center heater of the control

zone.

2, The local PWHT temperature shall be monitored by a suitable number of thermocouples at least two.

3, The required PWHT temperature shall be maintained for a distance of not less than two times the basemetal

thickness measured from the weld as per NBIC part.3 ED‐2023 and AWS D10.10 ED‐2021.

You might also like

- Fixed Normal 575Document8 pagesFixed Normal 575mohanNo ratings yet

- CK Tourqe CalculationDocument7 pagesCK Tourqe Calculationamit amity100% (1)

- 2/2 Way Direct Acting Solenoid Valve: Uflow AutomationDocument4 pages2/2 Way Direct Acting Solenoid Valve: Uflow AutomationkarthikNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- RC Beam - CantileverDocument2 pagesRC Beam - CantilevermayphyoNo ratings yet

- Pt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)Document2 pagesPt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)Solikhul HarisNo ratings yet

- Tbe For Osbl (SBS)Document5 pagesTbe For Osbl (SBS)benidbb100% (3)

- Calculation Noozle - Heat ExchangerDocument6 pagesCalculation Noozle - Heat Exchangercalinvasco190670No ratings yet

- Moment ConnectionsDocument16 pagesMoment Connectionsankit kadam0% (1)

- 02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Document117 pages02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Asaru Deen100% (1)

- PD5500 - 133 - RectangularFlange CalculationDocument9 pagesPD5500 - 133 - RectangularFlange CalculationDarshan PanchalNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Asme B31.8 Nozzles CalcDocument16 pagesAsme B31.8 Nozzles CalcSAMER OSMANNo ratings yet

- Call - Off - mp023 - 248 - x12-0055 - Pile Cap (Grid D To E) #2 OffDocument2 pagesCall - Off - mp023 - 248 - x12-0055 - Pile Cap (Grid D To E) #2 OffEmon SahNo ratings yet

- SL No Tower Numbers Tower Type No. of Locations Descriptio Nofbar Dia of Bar (MM)Document9 pagesSL No Tower Numbers Tower Type No. of Locations Descriptio Nofbar Dia of Bar (MM)PrabhakarNo ratings yet

- Heat ExchangerDocument11 pagesHeat ExchangerMangesh MandgeNo ratings yet

- MSCL-SEC-ME-ISO-002 Rev.BDocument2 pagesMSCL-SEC-ME-ISO-002 Rev.BMohd Sami UddinNo ratings yet

- Strong Gas Cooler - Metallic Expansion Bellow - Data Sheet - Rev 00Document2 pagesStrong Gas Cooler - Metallic Expansion Bellow - Data Sheet - Rev 00Anonymous Ywevve5HNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Quo12039 Wbh-BoguraDocument1 pageQuo12039 Wbh-BoguraMD. MAHMUDUL HASAN 39-044No ratings yet

- Act 2-22Document2 pagesAct 2-22CYNDRILLE JOHN BRAGATNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- SnugDocument26 pagesSnugNur KholifahNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Pin Li-Cqa-104-F-02Document11 pagesPin Li-Cqa-104-F-02MOHD SUHAILNo ratings yet

- Newly Prepared BbsDocument5 pagesNewly Prepared BbsMOHD SUHAILNo ratings yet

- Quo12039 Wbh-IshwardiDocument1 pageQuo12039 Wbh-IshwardiMD. MAHMUDUL HASAN 39-044No ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- Calculation For Moment Connection - Type ADocument15 pagesCalculation For Moment Connection - Type ANitesh SinghNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 4373898-a-ZWI-SDR06-Needle Valve With Reverse Flow CheckDocument2 pages4373898-a-ZWI-SDR06-Needle Valve With Reverse Flow CheckGaneshkumar Enkili SundarvasanNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Iqwq Ce1091 VPWLD D7 4556 - 0Document7 pagesIqwq Ce1091 VPWLD D7 4556 - 0jacksonbello34No ratings yet

- Base Plate DesignDocument14 pagesBase Plate Designsoumi bhattacharyaNo ratings yet

- Calculation Sheet: Design PhilosophyDocument18 pagesCalculation Sheet: Design PhilosophyrammohanNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- All Final DimensionDocument6 pagesAll Final Dimensionshailesh deshmukhNo ratings yet

- Slip StreamDocument1 pageSlip StreamvietsdsNo ratings yet

- "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Document4 pages"Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNo ratings yet

- Belt Data Sheet - PhoenixDocument2 pagesBelt Data Sheet - PhoenixSeshuNo ratings yet

- SAP FILTER-May-2020-1200Dia-Rev - PDocument4 pagesSAP FILTER-May-2020-1200Dia-Rev - PHasmukh DaveNo ratings yet

- Condensate Tank - For 250Document3 pagesCondensate Tank - For 250Sakthi VelNo ratings yet

- Os SPM CVX19001 1245 042Document5 pagesOs SPM CVX19001 1245 042DarshAwadNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEnokarajuNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEBayu AjiNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- REDUCER TEE 3x3x2 S10sx40s - OKDocument2 pagesREDUCER TEE 3x3x2 S10sx40s - OKJovianto PrisilaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Project: Jobno: Description: DateDocument2 pagesProject: Jobno: Description: DateJONAS NGNo ratings yet

- Drill Pipe Tool JointDocument1 pageDrill Pipe Tool JointJosh SabimanNo ratings yet

- Scantling CalculationDocument16 pagesScantling Calculationfadelrifqi8No ratings yet

- Weld Stress CalculationsDocument19 pagesWeld Stress CalculationsMichael WaltersNo ratings yet

- KUWAIT TAMIL CHURCHDocument1 pageKUWAIT TAMIL CHURCHSam RajaNo ratings yet

- Binder 1Document3 pagesBinder 1Sam RajaNo ratings yet

- Mrir 036Document17 pagesMrir 036Sam RajaNo ratings yet

- Jo RT Request-13Document6 pagesJo RT Request-13Sam RajaNo ratings yet

- HT 001Document1 pageHT 001Sam Raja100% (1)

- 5.4 Faculty RetentionDocument1 page5.4 Faculty RetentionSam RajaNo ratings yet

- Fabrication and Welding General Requirements 103188871Document18 pagesFabrication and Welding General Requirements 103188871Sam RajaNo ratings yet

- DWR S 036Document1 pageDWR S 036Sam RajaNo ratings yet

- DPT 166Document1 pageDPT 166Sam RajaNo ratings yet

- Nde Request - Thickness SurveyDocument1 pageNde Request - Thickness SurveySam RajaNo ratings yet

- Nde Request - RTDocument1 pageNde Request - RTSam RajaNo ratings yet

- Nde Request - DPTDocument1 pageNde Request - DPTSam RajaNo ratings yet

- Nde Request - HTDocument1 pageNde Request - HTSam RajaNo ratings yet

- DPT 171Document1 pageDPT 171Sam RajaNo ratings yet

- HT 003Document1 pageHT 003Sam RajaNo ratings yet