Professional Documents

Culture Documents

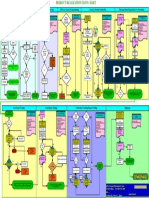

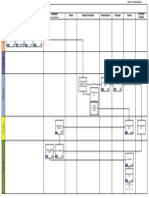

IPOM 7.5.5 Materials Process Map

Uploaded by

Thế PhongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IPOM 7.5.5 Materials Process Map

Uploaded by

Thế PhongCopyright:

Available Formats

IPOM 7.5.

5 Materials Management Process

Process Owner: Materials Manager Date:

Objective: 1. To Establish a systematic approach to ensure customer properties are identified, verified, stored and maintained for 5/10/2007

incorporation into products.

2. To Establish a system to maintain optimal inventory level.

Macro Matrices Date scheduled maintained to Material (GOOD)

Date Scheduled Met

Phase Input Resp

Process Resp

Output Objective/Measure

Sales

Forecast

Forecast

Service

ServiceParts

Partsrequirements

requirements

Slow Excess

Excess oror

SlowMoving

MovingInventory

Inventorylist

list Material Mgt

Available

Material Management Review Input

Optimum Available Mgt Obsolete

OptimumInventory

InventoryLevel

Level Vs Obsolete

Vs Inventory

Required Inventory

Inventory RequiredInventory

Inventory

InventoryReport

Report

Excess

Excess Or

Or

Obsolete

Obsolete

Inventory

Inventory Communication

Communication

With

WithCustomer

Customer Management Review Output

Communication

Communication

Plan

NCNR Material Mgt Material Mgt With

WithSuppliers

Suppliers

NCNR

Evaluate

Evaluateand

and

Disposition

Disposition eeCommerce

Commerce

Action

ActionItem

ItemReport

Report

Purchase

PurchaseOrder

Order

Receiving

ReceivingStatus

Status

Report 1-1-Organized

Report Organizedkit

kitcarts,

carts,While

While

Review waiting

waitingtotoreceive

receiveparts

Material ReviewthethePurchase

PurchaseOrder

Order Material 2-2-Organized

parts PAR

PAR Line of Sight

Status

StatusReport

Reportand

andEstablish:

Establish: OrganizedWarehouse

Warehouse

Material

MaterialHandling 1-1- Space

Equipment

Handling SpaceAllocation

Allocation

Equipmentand

and 2-2- Storage

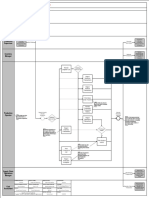

StorageBins

Binsand

andBox

Box

Storage For

Storage ForThe

TheKits

KitsPrior

Priortoto

Arrival.

Arrival.

1.1. Receive

ReceiveMaterial

MaterialFrom

FromCarrier

Carrier

2.2. Open

OpenBox

Box

3.3. Match

MatchPacking

PackingSlip

Slip

Material Verify

VerifyContent.

Content.

Receiving

Supplier Initiate

InitiateNCMR

NCMR

1- Kit Order

1- Kit Order Verify

Verify: :

2- AVL

2- AVL Notify

NotifyProgram

Program

3- Qty AVL

AVL

3- Qty Management

Managementandand

4- Expected Delivery Date Date

Date Requirement: Verification of purchased

4- Expected Delivery Date Purchasing

Purchasing

5- Part No

5- Part No Mfr

MfrP/N

P/N product that is per customer requirements

6- Manufacturing Part No, Qty

6- Manufacturing Part No, Qty

Packaging

Packaging

Doc./FAIR/Certs/CoF/etc. Non-Conforming Feedback to customer

Doc./FAIR/Certs/CoF/etc.

Feedback to purchasing

CAR

CAR

1- Work instruction Updated

Updated

1- Work instruction

2- NCMR instruction

2- NCMR instruction

Supplier

SupplierHistory

History

Material

File

File

Material

Receive

ReceiveParts

PartsInInThe

The

Material

Receiving

ReceivingReports

Reports

System

System

Kit

KitPlaced

Placedinindesignated

designatedarea

area

Custom

Customoror

Material Tooled Material

Tooledpart?

part? NO

A

Drawing

Drawing

Documentation

Documentation Non -Conforming Initiate

InitiateNCMR

NCMR CAR

Incoming CAR

IncomingQuality

CTQ list Doc Control Quality

CTQ list

Sampling Plan Quality

Sampling Plan Control

Control

Do

Notify

NotifyProgram

Program

Management

Managementandand

Purchasing

Purchasing

MRB

MRB MRB

Evaluation?

Evaluation?

Record

Record

Concession

Concession MRB

Customer

Customer

Approval

Approval

(If(IfRequired)

Required)

Rework Reported

ReportedCost

Rework MRB

Cost

Sort Absorption

Absorptiontoto

Sort Accounting

Accounting

Scrap

Scrap

Sort/Rework

Sort/Rework MFG

Scrap

Scrap Notification

Notificationtoto

Quality Program

Program

Management

Managementand and Quality Verification

Verification Non-Conforming Purchasing

Verification Purchasing

Material

Conforming

Release

ReleaseMaterial

MaterialFor

For

Production

Production

Material Mgt Prog Mgt. Promise to customer Validation

Released Material For

Released Material For

Production

Production

Promised Delivery Date

Promised Delivery Date

Validation ( Δ Days)

Validationofof

Customer

Customer

Promised

PromisedDate

Date

Pareto Analysis

Notify

NotifyCustomer

Customer Trend Chart

Receiving Reports

Receiving Reports

Promised Delivery Date to

Promised Delivery Date to

Customer CAR

Customer CAR

Action

ActionItem

ItemReport

Report

Material Mgt Material Mgt

Released Kits

Released Kits

Assessment

Check

Assessment

NCMR Management

NCMR Management

Reports

Reports

CAR

CAR

Material Mgt Material Mgt

PAR Action Item Report Implement

PAR Action Item Report Implement Implement

Implement

Act

You might also like

- SMT Generic Control PlanDocument2 pagesSMT Generic Control Plansmtdrkd81% (21)

- Contoh Business Process MapDocument1 pageContoh Business Process MapIlham KasumaNo ratings yet

- 14 Days Demand Notice - 134385199Document2 pages14 Days Demand Notice - 134385199Gerry OmbaNo ratings yet

- Advance Account II MCQ FinalbsisjshDocument33 pagesAdvance Account II MCQ FinalbsisjshPranit Pandit100% (1)

- Our Solution": Your Customer RelationshipDocument28 pagesOur Solution": Your Customer RelationshipAjay SimonNo ratings yet

- Construction Organization Processes InteractionsDocument1 pageConstruction Organization Processes InteractionsfazalNo ratings yet

- Distribution ManagementDocument21 pagesDistribution ManagementMay AliceNo ratings yet

- Sistem Informasi Akuntansi - Minggu Ke 9 - Benny PrawiranegaraDocument28 pagesSistem Informasi Akuntansi - Minggu Ke 9 - Benny PrawiranegaraWikeu Ayu LestariNo ratings yet

- © Oxford University Press 2013. All Rights ReservedDocument26 pages© Oxford University Press 2013. All Rights ReservedakankshaNo ratings yet

- (VES) Flujo General Procesos Visual ERPDocument1 page(VES) Flujo General Procesos Visual ERPOSWALD ZAHIDNo ratings yet

- Warehouse Management SystemsDocument5 pagesWarehouse Management SystemsRidho AnjikoNo ratings yet

- Adobe Scan 01 Apr 2021Document1 pageAdobe Scan 01 Apr 2021Syafinah WahdahNo ratings yet

- SAP Business One Solution Model: Customer SupplierDocument11 pagesSAP Business One Solution Model: Customer SupplierMalu FlorendoNo ratings yet

- Introducing SAP Business OneDocument19 pagesIntroducing SAP Business OneSaiyed ShoyebNo ratings yet

- 1 Operations Management IntroductionDocument5 pages1 Operations Management Introduction208vaibhav bajajNo ratings yet

- Subcontracting (BMY) - Process DiagramsDocument1 pageSubcontracting (BMY) - Process DiagramsAnonymous s1zWy06ZDNo ratings yet

- Major Tables and Relationships For Costing April 2010Document50 pagesMajor Tables and Relationships For Costing April 2010karthik rNo ratings yet

- Major Tables and Relationships For Costing April 2010Document50 pagesMajor Tables and Relationships For Costing April 2010sastrylanka1980No ratings yet

- Oracle Applications User Group Discrete MFG SIG - Cost Group April 27 2010Document50 pagesOracle Applications User Group Discrete MFG SIG - Cost Group April 27 2010Conrad RodricksNo ratings yet

- Etengine-Erp Techno-Functional Information: ContentDocument14 pagesEtengine-Erp Techno-Functional Information: ContentHarshit VermaNo ratings yet

- INd As 2 by Jai ChawlasDocument2 pagesINd As 2 by Jai Chawlasvishnu tejaNo ratings yet

- You May Also Be Interested in Our Model System For DRP/MRP/Capacity SchedulingDocument40 pagesYou May Also Be Interested in Our Model System For DRP/MRP/Capacity Schedulinghasan7262No ratings yet

- SAP PP PresentationDocument45 pagesSAP PP Presentationassurance mashokoNo ratings yet

- GOLDENHORN ONEGRC Three Lines of Defence Mapping 1580023424Document1 pageGOLDENHORN ONEGRC Three Lines of Defence Mapping 1580023424Gurcan KarayelNo ratings yet

- Sap SCM 5.0 Production Planning / Detailed SchedulingDocument68 pagesSap SCM 5.0 Production Planning / Detailed SchedulingTran Thanh Nam100% (2)

- MRP ExcelDocument38 pagesMRP ExcelALDAIR DANGELO HIDALGO GARRONo ratings yet

- MRP ExcelDocument35 pagesMRP ExcelMohamed FatehyNo ratings yet

- You May Also Be Interested in Our Model System For DRP/MRP/Capacity SchedulingDocument34 pagesYou May Also Be Interested in Our Model System For DRP/MRP/Capacity Schedulingdbbony 0099No ratings yet

- Fusion - Inventory ManagementDocument100 pagesFusion - Inventory ManagementFeNo ratings yet

- Period-End Closing - Plant (BEI) - Process DiagramsDocument2 pagesPeriod-End Closing - Plant (BEI) - Process DiagramsgobashaNo ratings yet

- Nterprise Esource Lanning (ERP)Document44 pagesNterprise Esource Lanning (ERP)Pankaj AttardeNo ratings yet

- Ahmad # 1Document3 pagesAhmad # 1nikhilpjagtap1996No ratings yet

- Sales: Submit Faulty Material To Quality DeptDocument1 pageSales: Submit Faulty Material To Quality DeptYash DudaniNo ratings yet

- You May Also Be Interested in Our Model System For DRP/MRP/Capacity SchedulingDocument37 pagesYou May Also Be Interested in Our Model System For DRP/MRP/Capacity SchedulingDamm GarciaNo ratings yet

- Operations ManagementDocument5 pagesOperations ManagementVAKUL SINGHNo ratings yet

- Contoh Proses Bisnis: Management ProcessDocument2 pagesContoh Proses Bisnis: Management ProcessSilvi KhoNo ratings yet

- Inbound Storage Tank Management - Process Manufacturing (3UK) - Process DiagramsDocument1 pageInbound Storage Tank Management - Process Manufacturing (3UK) - Process DiagramsEddy ChenNo ratings yet

- Inbound Storage Tank Management - Process Manufacturing (3UK) - Process DiagramsDocument1 pageInbound Storage Tank Management - Process Manufacturing (3UK) - Process DiagramsEddy ChenNo ratings yet

- Inbound Storage Tank Management - Process Manufacturing (3UK) - Process DiagramsDocument1 pageInbound Storage Tank Management - Process Manufacturing (3UK) - Process DiagramsEddy ChenNo ratings yet

- Complete Flow Chart - RevBDocument1 pageComplete Flow Chart - RevBanushaNo ratings yet

- 03fulfillment CostingDocument22 pages03fulfillment Costingsujit nayakNo ratings yet

- Customer Assets: Preventive MaintenanceDocument25 pagesCustomer Assets: Preventive MaintenanceSevNo ratings yet

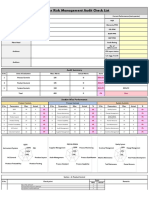

- Supplier Risk Management Audit Check ListDocument13 pagesSupplier Risk Management Audit Check ListPrakash kumarTripathiNo ratings yet

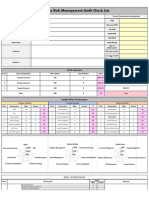

- Supplier Risk Management Audit Check ListDocument8 pagesSupplier Risk Management Audit Check ListPrakash kumarTripathiNo ratings yet

- SAp QM OverviewDocument80 pagesSAp QM OverviewAlfonso Herrera RojasNo ratings yet

- Bauxit Hauling Process DigitalizationDocument14 pagesBauxit Hauling Process DigitalizationfirmanNo ratings yet

- Value Stream VSM TemplateDocument4 pagesValue Stream VSM TemplateMiguel Valdivia ValenciaNo ratings yet

- InventoryControl ForecastingDocument7 pagesInventoryControl ForecastingME20BTECH11058No ratings yet

- MRP V4 PDFDocument32 pagesMRP V4 PDFRx DentviewNo ratings yet

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanNo ratings yet

- BM Work FlowDocument1 pageBM Work FlowKedir SeidNo ratings yet

- ERP ModulesDocument30 pagesERP ModulesBella BrymoraNo ratings yet

- P-Obj-01 - Qms Monitoring PlanDocument2 pagesP-Obj-01 - Qms Monitoring PlanAMRIT PAL SINGHNo ratings yet

- WEEK 6 Materials ManagementDocument29 pagesWEEK 6 Materials ManagementDKNo ratings yet

- EH - PM - Preventive Maintenance - Process FlowDocument1 pageEH - PM - Preventive Maintenance - Process FlowAbdelkader Ben SebgagNo ratings yet

- ExecuteDiscreteProduction Fusion1.0.12 BPEApprovedDocument1 pageExecuteDiscreteProduction Fusion1.0.12 BPEApprovedDybbuk OTNo ratings yet

- WEEK 3 Tech and Business Architecture 2014Document46 pagesWEEK 3 Tech and Business Architecture 2014DKNo ratings yet

- Erp Infor LXDocument6 pagesErp Infor LXMaria Rita RagusaNo ratings yet

- Powerful Odoo For ManufacturingDocument18 pagesPowerful Odoo For ManufacturingCanh BescoNo ratings yet

- ITIL Poster 2018Document1 pageITIL Poster 2018szaros logeci100% (1)

- Service-Oriented Modeling: Service Analysis, Design, and ArchitectureFrom EverandService-Oriented Modeling: Service Analysis, Design, and ArchitectureNo ratings yet

- Chapter 7 Solved Booklet Page 72 and 83Document3 pagesChapter 7 Solved Booklet Page 72 and 83Rumana AliNo ratings yet

- Oriflame Interim Report H1 2020 PDFDocument24 pagesOriflame Interim Report H1 2020 PDFMichael JohnNo ratings yet

- BOIUPIDocument231 pagesBOIUPIchauhan0124urwanNo ratings yet

- Ia Eco121Document10 pagesIa Eco121Quach Hai My (K17 CT)No ratings yet

- GST 311 PQ Ca-1Document15 pagesGST 311 PQ Ca-1Muhammed UmarNo ratings yet

- Analisis Penentuan Harga Jual Apartemen - CompressDocument14 pagesAnalisis Penentuan Harga Jual Apartemen - Compressriko andreanNo ratings yet

- BA 211 Midterm 2Document6 pagesBA 211 Midterm 2Gene'sNo ratings yet

- History of Strategic Management:: Alfred Chandler Recognized The Importance of Coordinating The Various AspectsDocument32 pagesHistory of Strategic Management:: Alfred Chandler Recognized The Importance of Coordinating The Various AspectsQasirUrRehmanKashifNo ratings yet

- Where Lifestyle Meets LogisticsDocument10 pagesWhere Lifestyle Meets LogisticssalmanNo ratings yet

- Delivery Hero SE Q2 2019 Presentation VFFFDocument26 pagesDelivery Hero SE Q2 2019 Presentation VFFFGiang NguyenNo ratings yet

- Lekan Poultry Farm Business - PlanDocument29 pagesLekan Poultry Farm Business - PlanMAVERICK MONROENo ratings yet

- Financial Statements: Balance SheetDocument237 pagesFinancial Statements: Balance SheetPramod VasudevNo ratings yet

- Lesson 1.2 Fundamental Economic Problems and Economic SystemDocument7 pagesLesson 1.2 Fundamental Economic Problems and Economic SystemPhrexilyn PajarilloNo ratings yet

- Lesson Two:: Prepared and Compiled by Gerry S. PeñaDocument22 pagesLesson Two:: Prepared and Compiled by Gerry S. PeñawonuNo ratings yet

- Work & Money (مفردات العمل والمال)Document6 pagesWork & Money (مفردات العمل والمال)Armylova OfficialNo ratings yet

- Artificial Intelligence, Fintech, and Financial Inclusion 2023Document179 pagesArtificial Intelligence, Fintech, and Financial Inclusion 2023cerohad333No ratings yet

- Adam SmithDocument18 pagesAdam SmithNesma HusseinNo ratings yet

- E StatementDocument6 pagesE Statementfislam1631No ratings yet

- Appendix B, Profitability AnalysisDocument97 pagesAppendix B, Profitability AnalysisIlya Yasnorina IlyasNo ratings yet

- SOIC-My JourneyDocument24 pagesSOIC-My JourneyPrateekNo ratings yet

- MoneyDocument2 pagesMoney09-Nguyễn Hữu Phú BìnhNo ratings yet

- The Kingsmen IIM B VFDocument19 pagesThe Kingsmen IIM B VFSupriya MurdiaNo ratings yet

- M&a 2021Document76 pagesM&a 2021Tarek OsmanNo ratings yet

- Key Features: A Oke9Wjwm36Onlmr&Redirect Signup A Oke9Wjwm36OnlmrDocument5 pagesKey Features: A Oke9Wjwm36Onlmr&Redirect Signup A Oke9Wjwm36OnlmrVicard GibbingsNo ratings yet

- SbaDocument4 pagesSbaahyenn cabello100% (1)

- Le 1 Answer KeyDocument8 pagesLe 1 Answer KeyApril NaidaNo ratings yet

- Google Finance Investment TrackerDocument13 pagesGoogle Finance Investment TrackerSwaraj NayseNo ratings yet

- Quiz 1Document8 pagesQuiz 1Kurt dela TorreNo ratings yet