Professional Documents

Culture Documents

R2 ROTARY COMBINE

Uploaded by

alaynnastaabx7860 ratings0% found this document useful (0 votes)

2 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views3 pagesR2 ROTARY COMBINE

Uploaded by

alaynnastaabx786Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

ALMACO R2 ROTARY COMBINE SPECIFICATIONS

Contact us: www.almaco.com 515-382-3506

Engine and Drivetrain Package Threshing & Separation System Continued

Industry’s most powerful plot combine Rotor length - 99”

•

Digitally controllable from cab including reverse

•

Engine LED illumination operable even if system is locked out

•

• 275 HP Cummins QSB 6.7l turbo 6-cylinder diesel (Tier 4F) Large access panel for easy inspection/maintenance

•

Cooling package High torque 2 speed drive

•

• Radiator, Charge air coolers 200-750 RPM low range

• Integrated engine and hydraulic system cooler 750-1200 RPM high range

• Hydraulically driven reversible fan digitally adjustable from cab • Replaceable flighting edges & threshing elements

• Auto set or manual reverser • Tight clearance feed sump for effective cleanout

Multi-pad pump drive for efficient/compact hydraulic pump Concaves (per side)

mounting • Five removable/interchangeable sections

• Combination of gear & closed loop piston pumps • Standard bar spacing: 3/8”, 1/2”, 5/8”. Multiple alternative bar

• Manifold/cartridge style valves spacing configs available.

• Hydraulic reservoir – 35 gallons • Electric over hydraulic adjustable concave clearance from cab

Fuel tank – 160 gallons (average consumption ~8gph) 1/8” to 1-1/4” concave clearance

DEF Tank – 15 gallons (lasts 2 full fuel tanks) Multiple concave choices for all crops

Built-in air compressor • Auto open concaves upon threshing rotor reverse

Danfoss H1-100 Hydrostat • Internal conveyor system for fast seed delivery

Chassis Cleaning System

Chassis designed for simple transportation and safety Multiple sieve configurations (adjustable and fixed)

Machine dimensions Sieve (per side)

• Wheelbase - 132” Center to center • Single sieve - 72” long x 20.75”. Fixed size,4-22mm

• Length w/o header - 284” • Adjustable sieve (Gateway)

• Front wheel track - 109” Shaker/air lock/conveyor drive.

• Rear wheel track adjustable from 111” – 127” • Robust, compact, hydraulically driven mechanical drives to

• Transport Width – 132” improve efficiency & reliability.

• Ground clearance - 20” Transport height – 144” Cleaning slope fans

• Break-over angle - 16° • Hydraulically driven

• Gross vehicle weight with header and full fuel tank– 31,000 lbs • Electronic speed adjustment from cab

Steering • 400-1700 RPM

• Speed sensitive, hydraulic steering control Sieve fans

• Turning brakes • Hydraulically driven

• Turning radius – 23’ diameter (with turning brakes) • Electronic speed adjustment from cab

• John Deere steering components throughout • 400-1800 RPM

Structural weldment High capacity air compressor

• 45° weldment design throughout to prevent seed hang-up • Equipped with moisture removal system

• Total of 8 dedicated clean-out access points

Cab

Ground Drive System Industry’s largest and quietest cab: 106Cu.ft., 62dB noise rating

Wheel motors

• Poclain wheel motors front and rear Exterior features

• Two-wheel parking brakes • Curved glass windshield

• Three-step hydraulic transmission, digitally controlled from cab • Windshield wiper with washer fluid

Harvest speed: up to ~5mph • Fiberglass roof cap

Field speed: up to ~8mph • Integrated LED lighting package

Road speed: up to ~20mph • 3-Zone field lights

• Single hydraulic pump with electronic control • Folding/telescoping mirrors

Tires Interior Features

• 600/65R38 (Ag lug) front for minimal ground compaction • Increased glass surface area for maximized visibility

• 18.4-26 (Ag lug) rear for minimal ground compaction • Heated/cooled operator’s seat with air ride suspension optional

• Adjustable seat mounted console for operator comfort

Threshing & Separation System • Secondary seat with adjustable forward or rearward facing

Exclusive Patent Pending Top-Fed Rotor design provides 99.9% configurations; flip up for compact storage

• Steering column - dual tilt & telescoping

cleanout

• Radio with AM/FM/WB/CD/USB/Bluetooth/Aux In

• Automatic climate control

Throat and header digitally adjusted from cab

• Integrated cup holders

• Forward and reverse

• Automatic dome lights

• Speed adjustment

• Storage bin

Rotors (per side)

• Rotor diameter - 15.5”

1 Product specifications are subject to change without prior notice 11.14.2017

ALMACO R2 ROTARY COMBINE SPECIFICATIONS

Contact us: www.almaco.com 515-382-3506

Controls & Sensory System • LOTO system

• Easy access to common service points

Near infinite expandability with six dedicated controllers • Powered rear ladder for safer/easy access to engine

compartment

Operator interface

• Engine oil, hydraulic oil and air compressor purge located at

• Danfoss Plus1 control package

operator level for easy access

• Digital interlocks built-in to prevent mechanical damage

• Multi-zone LED ground lighting system

• 7” high resolution color display with complete system diagnostics

• Digital interlock system to prevent accidental engagement

• Visual and audio alerts for all machine functions

• Push button digital controls of all machine functions

Operator console Infeed System: Throat and pinch belt

• Ergonomic Danfoss Joystick • Dual feeder drums

Friction hold for stable machine operation • Fixed throat with quick-attach header units

User definable hot keys for features frequently adjusted • Rubber feed belt and pinch belt for better cleanout

during harvest • Hydraulically driven infeed belt with forward and reverse,

• Encoder/button module electronically controlled/adjusted from cab

• Convenient/ergonomic access to HMI navigation

Sensory system Headers

• 40 sensor capacity system Auto header recognition – System resets to crop specific defaults

16 open sensor ports for future expandability based on header selection.

Control system

• Full electronic control with CAN bus communication

• Independent micro-controllers for cost effective/flexible Corn Header

expansion • Hydraulically adjustable

• Sensors provide real time feedback on all critical machine • Speed digitally adjustable from cab

functions • Single point, multiport connector

• Cameras • Reversible

Backup camera standard • Poly snouts

Up to 4 cameras per screen • 4/2 row, 30” row spacing

• Hydraulic stripper plates

Multiple screens available

• Stalk chopper available

Floating Row crop, Auger Header

Seed Delivery System • Speed digitally adjustable from cab

Industry’s largest and most efficient air-lock system – Precision • Pneumatic floating system with independent airbags on each row

machined by ALMACO • Reversible

• Single point, multiport connector

• Two units, 6-vane per unit with pressure sensors that • Dual auger flighting for optimal infeed control

communicate with operator interface for system monitoring • 4/2 row, 30” row spacing

• 18 lbs/sec (corn) per side • Gathering belts for fast, gentle seed conveyance

• Intake and exhaust silencer system to minimize noise • Hydraulically driven row units with variable speed control

• Digitally adjustable from cab • “Jackknife” tins for easy access to each row unit

Seed delivery blower

• Positive displacement seed delivery blower Grain Analysis

Transports grain to weigh system without the use of augers Multiple Data Capture Electronic Systems available

Lower velocity, higher pressure pneumatic conveying • Easy access to weigh buckets from cab platform

system moves higher volume of seed with less seed damage. • Electronics platform easily slides out for

Tubing/elbows inspection/maintenance

• 4” diameter for large capacity without excessive air velocity

• Equipped with quick-clamps for easy maintenance/inspection

Options:

Grain Tank • Automated packaging system ( APx )

• Straw chopper – Sliding design for easy access to

Grain tank is designed for optimal grain flow to low-point to concaves/sieves

eliminate kernel hang-up Digitally controlled from cab

• TorqueKing 4WD

• Grain tank full sensor • Subsampling/bagging in cab

• Up to 300-bushel capacity with extensions • Seed devitalization system

• Standard ~250-bushel capacity • Onboard cameras ( up to 4 cameras per screen )

• 13’ unload auger discharge height • Row vision system (row guidance) – offered in 2019

• Two access panels for easy inspection • Multiple data collection system options

• Unload time >2min (2.5 bu/sec) • Auto Steer

• Telematics

Safety / Maintenance • Electronically adjustable sieve system

• Entire system operates with only 4 belts (including engine • HarvestMax non-stop harvesting system

serpentine belt)

• Expanding front ladder access platform. Operator accessible

from left or right side

• Centralized grease locations (4 locations, 17 zerks)

• Operator presence system

2 Product specifications are subject to change without prior notice 11.14.2017

ALMACO R2 ROTARY COMBINE SPECIFICATIONS

Contact us: www.almaco.com 515-382-3506

3 Product specifications are subject to change without prior notice 11.14.2017

You might also like

- Liebherr R924 StageV en PI 2019 10Document24 pagesLiebherr R924 StageV en PI 2019 10Goran MatovicNo ratings yet

- Sennebogen Material Handlers Spec 2170beDocument12 pagesSennebogen Material Handlers Spec 2170bemarionabil998No ratings yet

- R926Document16 pagesR926equipment9278No ratings yet

- R926 - ManualDocument24 pagesR926 - ManualElena RomanNo ratings yet

- R 920 Compact Crawler Excavator Product DetailsDocument16 pagesR 920 Compact Crawler Excavator Product Detailspebi liveNo ratings yet

- R930Document16 pagesR930equipment9278No ratings yet

- R 920 Compact Litronic en (ff0) 1 PDFDocument28 pagesR 920 Compact Litronic en (ff0) 1 PDFNandaDS2709No ratings yet

- LIEBHERR R934-StageV-EN-PI-2021-01Document24 pagesLIEBHERR R934-StageV-EN-PI-2021-01ganendra santantikaNo ratings yet

- R924Document8 pagesR924equipment9278No ratings yet

- Paper Roll Special BrochureDocument8 pagesPaper Roll Special BrochurealbertoNo ratings yet

- O&k F206Document10 pagesO&k F206Foromaquinas100% (2)

- L1350Document4 pagesL1350RodrigoAndrésMondacaArriazaNo ratings yet

- R938Document20 pagesR938equipment9278No ratings yet

- Liebherr - R934 StageV EN PI 2019 10Document24 pagesLiebherr - R934 StageV EN PI 2019 10Goran MatovicNo ratings yet

- R945Document20 pagesR945equipment9278No ratings yet

- Excavator Liebherr R920Document16 pagesExcavator Liebherr R920ganendra santantikaNo ratings yet

- SpecificationsDocument4 pagesSpecificationsForomaquinas100% (3)

- R945 StageV en PI 2023 01 UnlockedDocument28 pagesR945 StageV en PI 2023 01 UnlockedMárton SzőkeNo ratings yet

- RH8.5+RH9.5 Prospekt PDFDocument20 pagesRH8.5+RH9.5 Prospekt PDFОливер Карески100% (1)

- 30 Ton Terex T 230 Specs and Load Chart Rev 5 - 06 - DLDocument16 pages30 Ton Terex T 230 Specs and Load Chart Rev 5 - 06 - DLDimi Jeri TriNo ratings yet

- Ficha TecnicaDocument4 pagesFicha TecnicaRodrigo LeónNo ratings yet

- Manual Book Forklift ToyotaDocument12 pagesManual Book Forklift ToyotaAnanta60% (5)

- 2021 - Box Car Special - Comprehensive - DigitalDocument8 pages2021 - Box Car Special - Comprehensive - DigitalMarcos SalazarNo ratings yet

- Baumann BGXDocument10 pagesBaumann BGXslawny77100% (1)

- Catalogo Barredora BroceDocument2 pagesCatalogo Barredora Brocesebastian sanabriaNo ratings yet

- Terex 860 SX, 860 EliteDocument2 pagesTerex 860 SX, 860 EliteYogan100% (1)

- Catalogo Ir 675-825Document4 pagesCatalogo Ir 675-825dany riversNo ratings yet

- Wheel Loader: 294 KW (394 HP) at 2100 RPM (Straight / Full Turn) 24.7 / 21.8 T 5.4 MDocument20 pagesWheel Loader: 294 KW (394 HP) at 2100 RPM (Straight / Full Turn) 24.7 / 21.8 T 5.4 MBilal VURALNo ratings yet

- Toyota 8FGU25 ForkliftDocument8 pagesToyota 8FGU25 ForkliftLance Zhengling Yin100% (1)

- Brochure Komatsu Hd785-7Document20 pagesBrochure Komatsu Hd785-7peterNo ratings yet

- Cat 972M XE: Wheel LoaderDocument2 pagesCat 972M XE: Wheel LoaderCapacitaciones RutasNo ratings yet

- RT 300 Series: Rough Terrain CranesDocument8 pagesRT 300 Series: Rough Terrain CranesJerome YangNo ratings yet

- R914Compact Tier4Final US PI 2020 12Document16 pagesR914Compact Tier4Final US PI 2020 12izael jesusNo ratings yet

- XG958 Wheel Loader Offers Powerful Performance and Low Operating CostsDocument8 pagesXG958 Wheel Loader Offers Powerful Performance and Low Operating CostsJohn JohnNo ratings yet

- Motor GraderDocument8 pagesMotor GraderEbied YoussefNo ratings yet

- R934Document24 pagesR934udoverNo ratings yet

- Aexq3623 01Document4 pagesAexq3623 01claudio santosNo ratings yet

- R954 Crawler Excavator Offers Powerful Digging & DemolitionDocument12 pagesR954 Crawler Excavator Offers Powerful Digging & Demolitionequipment9278No ratings yet

- VI-BROP Viking+Model+Brochure V6 10122021-WebsiteDocument4 pagesVI-BROP Viking+Model+Brochure V6 10122021-WebsiteConsultoria CientificaNo ratings yet

- AP 240 Pneu Tyred Roller: MachinesDocument6 pagesAP 240 Pneu Tyred Roller: MachinesBilal VURALNo ratings yet

- LIEBHERR R934-Tier4Final-US-PI-2021-01Document16 pagesLIEBHERR R934-Tier4Final-US-PI-2021-01ganendra santantikaNo ratings yet

- AC3 Specification SheetDocument4 pagesAC3 Specification SheetWiwa Hernandez DonosoNo ratings yet

- Esm 350renkDocument4 pagesEsm 350renkManivannan ManikamNo ratings yet

- Ac-3 Anfo Charger EspDocument4 pagesAc-3 Anfo Charger EspWiwa Hernandez DonosoNo ratings yet

- Catálogo Excavadora Hidráulica PC600LC 8 in WebDocument24 pagesCatálogo Excavadora Hidráulica PC600LC 8 in WebnachoNo ratings yet

- Mechanical TrucksDocument97 pagesMechanical TrucksGustavo Rathgeb100% (1)

- K-Winch Landline D CHDocument1 pageK-Winch Landline D CHeddy hariyadieNo ratings yet

- Cat Advantage - Cat 242D - 262D Skid Steer Loaders Vs Deere 320E - 324E - N Am (English)Document2 pagesCat Advantage - Cat 242D - 262D Skid Steer Loaders Vs Deere 320E - 324E - N Am (English)Fulkan HadiyanNo ratings yet

- Brochure Dx480lca Hd500lca HD enDocument12 pagesBrochure Dx480lca Hd500lca HD enPutra DesandraNo ratings yet

- EH DX420LC DemolitionDocument8 pagesEH DX420LC DemolitionCopemaq CopemaqNo ratings yet

- Komatsu Hd785-7 Rigid Dump TrucksDocument20 pagesKomatsu Hd785-7 Rigid Dump Truckswahyu100510No ratings yet

- Powerful 172HP excavator with hydraulic and electrical detailsDocument2 pagesPowerful 172HP excavator with hydraulic and electrical detailsSunil BhatiaNo ratings yet

- Case WX 210 BrochureDocument12 pagesCase WX 210 BrochureW Morales100% (1)

- Catalogo RTC-8050 IIDocument2 pagesCatalogo RTC-8050 IISara Sarmiento EcheverryNo ratings yet

- K-WINCH SlimLine PDFDocument1 pageK-WINCH SlimLine PDFAngela ogbajieNo ratings yet

- enDocument2 pagesenCan CanaydinNo ratings yet

- Engine Hydraulic System: Main PumpDocument2 pagesEngine Hydraulic System: Main PumpSunil BhatiaNo ratings yet

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsFrom EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNo ratings yet

- acs73_15Document7 pagesacs73_15alaynnastaabx786No ratings yet

- POWERBLOC50ANG_21530Document1 pagePOWERBLOC50ANG_21530alaynnastaabx786No ratings yet

- 630FDocument2 pages630Falaynnastaabx786No ratings yet

- 603-1037-1-PB(Combine harvesters — state-of-theart and further developments for the improvement of machine settings )Document3 pages603-1037-1-PB(Combine harvesters — state-of-theart and further developments for the improvement of machine settings )alaynnastaabx786No ratings yet

- Jan Feb Ae50 WebDocument32 pagesJan Feb Ae50 Webalaynnastaabx786No ratings yet

- Air foil sieve for 8010 - small grain cropsDocument11 pagesAir foil sieve for 8010 - small grain cropsalaynnastaabx786No ratings yet

- 1026-1882-1-PBDocument2 pages1026-1882-1-PBalaynnastaabx786No ratings yet

- Jan Feb Ae50 WebDocument32 pagesJan Feb Ae50 Webalaynnastaabx786No ratings yet

- Fall 2018 PDF CatalogDocument376 pagesFall 2018 PDF Catalogalaynnastaabx786No ratings yet

- USGC Harvest Report 14 15 FinalDocument58 pagesUSGC Harvest Report 14 15 Finalalaynnastaabx786No ratings yet

- 02_Benes_LDocument5 pages02_Benes_Lalaynnastaabx786No ratings yet

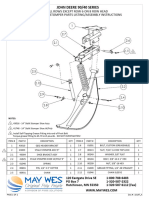

- JD 90_40 All Rows Except 3_6 on 8 RowDocument4 pagesJD 90_40 All Rows Except 3_6 on 8 Rowalaynnastaabx786No ratings yet

- f19 CatalogDocument396 pagesf19 Catalogalaynnastaabx786No ratings yet

- Grain Harvesting to Minimize Losses and Maximize ProfitDocument40 pagesGrain Harvesting to Minimize Losses and Maximize Profitalaynnastaabx786No ratings yet

- 3200partsDocument100 pages3200partsalaynnastaabx786No ratings yet

- HP-NH CR with Big Top OFE InstructionsDocument14 pagesHP-NH CR with Big Top OFE Instructionsalaynnastaabx786No ratings yet

- Parts List Index: Row UnitDocument115 pagesParts List Index: Row UnitAlexey petrovichNo ratings yet

- Calmer_Catalog_2016_WEBDocument21 pagesCalmer_Catalog_2016_WEBalaynnastaabx786No ratings yet

- Horst Header Carrier..Document22 pagesHorst Header Carrier..alaynnastaabx786No ratings yet

- 8E000005_AEDocument12 pages8E000005_AEalaynnastaabx786No ratings yet

- Test-report_OptiMaxx_profi-international_Harvest-2020Document5 pagesTest-report_OptiMaxx_profi-international_Harvest-2020alaynnastaabx786No ratings yet

- Sugar-Cane-Harvester-3520-BrochureDocument16 pagesSugar-Cane-Harvester-3520-Brochurealaynnastaabx786No ratings yet

- MAN-01018-CVS-RSD-RVS-OPS-MAN-N-AMERICADocument116 pagesMAN-01018-CVS-RSD-RVS-OPS-MAN-N-AMERICAalaynnastaabx786No ratings yet

- HP-NH CR with Factory Extensions InstructionsDocument12 pagesHP-NH CR with Factory Extensions Instructionsalaynnastaabx786No ratings yet

- Headertrailers_AGCO_engDocument16 pagesHeadertrailers_AGCO_engalaynnastaabx786No ratings yet

- CORNSTARDocument6 pagesCORNSTARalaynnastaabx786No ratings yet

- OXBO2460Document2 pagesOXBO2460alaynnastaabx786No ratings yet

- 35SeriesBrochureDocument2 pages35SeriesBrochurealaynnastaabx786No ratings yet

- Cosechadora CAse IH 7700Document20 pagesCosechadora CAse IH 7700Edwin Melendez100% (1)

- 2560-21v2Document6 pages2560-21v2alaynnastaabx786No ratings yet

- Chap 011Document90 pagesChap 011ainymughal100% (1)

- Begotti Donato-Il Volo Del Moscardone 2 PDFDocument6 pagesBegotti Donato-Il Volo Del Moscardone 2 PDFLeonardo BalzoniNo ratings yet

- Alliance Electronics Truck Electronic & Electrical Parts Catalogue 2018Document36 pagesAlliance Electronics Truck Electronic & Electrical Parts Catalogue 2018Alliance Transport Technologies Ltd100% (3)

- Questions and answers on multiplexersDocument2 pagesQuestions and answers on multiplexersGopikaNo ratings yet

- 2018 Beach Grove Amateur ResultsDocument3 pages2018 Beach Grove Amateur ResultsVGT - Vancouver Golf TourNo ratings yet

- A Night in Tunisia For Eb InstrumentsDocument5 pagesA Night in Tunisia For Eb InstrumentsmiccmaccNo ratings yet

- Exalted Cheat SheetDocument1 pageExalted Cheat SheetClete CollumNo ratings yet

- Beyma Speakers Data Sheet Low Mid Frequency 18G550Document2 pagesBeyma Speakers Data Sheet Low Mid Frequency 18G550Al JannahNo ratings yet

- Audio Pro April 2010Document53 pagesAudio Pro April 2010leo1507No ratings yet

- Books and Articles about Southwest Airlines CultureDocument24 pagesBooks and Articles about Southwest Airlines CultureManan SukiyantoNo ratings yet

- Actividad 2. Condicionales: Zero ConditionalDocument3 pagesActividad 2. Condicionales: Zero ConditionalHELLS PRIUX50% (2)

- Unmanaged Gigabit Ethernet Fiber Optic SwitchDocument1 pageUnmanaged Gigabit Ethernet Fiber Optic SwitchMohamed NaserNo ratings yet

- American Optical Series 110 MicroStar Parts ListDocument12 pagesAmerican Optical Series 110 MicroStar Parts Listservice iyadMedicalNo ratings yet

- Sony MZ-R30 Service ManualDocument62 pagesSony MZ-R30 Service Manualkong2550No ratings yet

- Modul 1 Bahasa InggrisDocument45 pagesModul 1 Bahasa InggrisFermanto FermantoNo ratings yet

- Annual CircularDocument9 pagesAnnual CircularToufique KaziNo ratings yet

- Chitra Sutra 14Document7 pagesChitra Sutra 14Prantik GuptaNo ratings yet

- User Manual of HikCentral Professional Web ClientDocument203 pagesUser Manual of HikCentral Professional Web ClientnanoleoNo ratings yet

- STAR WARS: LAST SHOT - 50 Page FridayDocument55 pagesSTAR WARS: LAST SHOT - 50 Page FridayRandom House Publishing GroupNo ratings yet

- The RAKE by Georgina DevonDocument5 pagesThe RAKE by Georgina Devongdosman370% (1)

- Physical Education and Health 3 Grade 12 Module 4Document20 pagesPhysical Education and Health 3 Grade 12 Module 4Dame Iris Zamora80% (5)

- Group 2 - Salad and SandwichesDocument5 pagesGroup 2 - Salad and SandwichesZyra Gwyneth Santos LazaroNo ratings yet

- Cheddar Bay BiscuitsDocument2 pagesCheddar Bay BiscuitsMaggie CavanaughNo ratings yet

- Nero Video Log AnalysisDocument55 pagesNero Video Log AnalysisSalvador Quezada de LeónNo ratings yet

- Reasoning Practice Questions 01Document28 pagesReasoning Practice Questions 01cuteprincess.mistyNo ratings yet

- Nokia 9500 MPR MPT Short-Haul R6-1 ANSI Data Sheet enDocument2 pagesNokia 9500 MPR MPT Short-Haul R6-1 ANSI Data Sheet enSiva KumarNo ratings yet

- Multiple Choice Questions: Techno India Batanagar Computer Science and Engineering Model QuestionsDocument10 pagesMultiple Choice Questions: Techno India Batanagar Computer Science and Engineering Model QuestionsSuvayan MohantyNo ratings yet

- Open TuningsDocument17 pagesOpen TuningsRonald OttobreNo ratings yet

- Movement AnalysDocument4 pagesMovement AnalysDanNo ratings yet