Professional Documents

Culture Documents

JD 90 - 40 All Rows Except 3 - 6 On 8 Row

Uploaded by

alaynnastaabx786Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JD 90 - 40 All Rows Except 3 - 6 On 8 Row

Uploaded by

alaynnastaabx786Copyright:

Available Formats

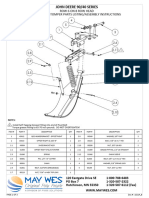

JOHN DEERE 90/40 SERIES

ALL ROWS EXCEPT ROW 6 ON 8 ROW HEAD

QD2 STALK STOMPER PARTS LISTING/ASSEMBLY INSTRUCTIONS

2.7

2.6

2.1

2.11 3

2.5

2.3

2.12

2.2

2.9

2.4

2.8

2.10

NOTES:

1 43016 - 14" Stalk Stomper Shoe Assy

2 41748 - 14" Stalk Stomper Shoe W/Poly

3 Install Self-Tapping Grease Fitting into end of Pivot Bolt

Torque grease fitting to 65-70 inch pounds. DO NOT OVERTIGHTEN!

ITEM # PART # DESCRIPTION QTY ITEM # PART # DESCRIPTION QTY

1 43010 QD2 HEADER BRACKET 1 2.6 01001 BOLT, CUSTOM (GREASEABLE) 1

1 2 43003 STALK STOMPER ASSY 9" 1 2.7 00213 NUT, 7/16"-14 HEX TOP LOCK 1

2.1 43004 SHOE BRACKET ASSY 1 2.8 00249 WASHER, 3/8" FLAT 2

2 2.2 41825 STALK STOMPER SHOE W/POLY 9" 1 2.9 00104 BOLT, 3/8"-16 X 1" HEX 2

2.3 01040 SPRING 1 2.10 00209 NUT, 3/8"-16 HEX 2

2.4 00691 PIN, 1/4" X 3" COTTER 1 2.11 01009 GREASE FITTING, 1/4"-28 STRAIGHT 1

2.5 00931 CHAIN 1 2.12 01046 CHAIN SLEEVE 1

120 Eastgate Drive SE 1-800-788-6483

PO Box 7 1-320-587-2322

Hutchinson, MN 55350 1-320-587-6112 (Fax)

WWW.MAYWES.COM

PAGE 1 OF 2 Doc #: 10197_A

JOHN DEERE 90/40 SERIES

ALL ROWS EXCEPT ROW 6 ON 8 ROW HEAD

STALK STOMPER INSTALLATION

Safety Procedure:

- Park Combine on level ground and engage the parking brake.

- Raise the head and lock in the upright position.

- Support all row units that stalk stompers will be installed on to ensure row units remain stationary during

installation.

Installation Procedure:

- Remove the gear box bolts and the eye bolts which secure the row unit to the main frame of the corn head.

Replace the eyebolts with Header Bracket (43010) by inserting the threaded rods thru the roller frame

mount. Insert the gear box bolts thru the header bracket into the gearbox and tighten to factory

recommended torque specifications. Secure the threaded rods reusing the factory hardware and tighten

to factory recommended torque specifications (Fig. 1).

- Lift the Stalk Stomper Assy (43003) into mating features in the Header Bracket (43010).

Pull Stalk Stomper Assembly back until lock pin assembly snaps into place.

Header Bracket

Roller Frame

(Corn Head Frame)

Pin

Assembly

Factory Hardware

Gear Box Bolts

Mount

Pin

Completed Installation

Stalk Stomper Assy

Figure 1

120 Eastgate Drive SE 1-800-788-6483

PO Box 7 1-320-587-2322

Hutchinson, MN 55350 1-320-587-6112 (Fax)

WWW.MAYWES.COM

PAGE 2 OF 2 Doc #: 10197_A

QD2 Stalk Stomper Instructions

Safety Recommendations:

Prior to installation, removal or maintenance of May Wes Stalk Stompers, please follow the safety steps listed

below, in addition to all safety recommendations listed in the OEM owner's manuals.

- Park implement on level ground and lock the brakes.

- Raise the head and lock in the upright position.

- Support all row units that stalk stompers will be installed on to ensure row units stay stationary during

installation (corn head row unit mount application only).

Setup/Operating Recommendations:

May Wes stalk stompers are intended to be setup/operated with minimal to no ground contact and minimal

spring compression during field operation. To achieve the recommended operating setup, rotate spring to

reduce or increase down pressure per application requirements. Minimizing spring preload will allow for

maximum spring travel during operation. After operating position is established, adjust the chains so there

is no slack when the shoe is not in contact with the ground. This will help reduce shoe damage, premature

wear of the poly and accidental spring loss.

Note: As with all aftermarket product applications please maintain an awareness of the stalk stompers

during operation. The head/stalk stompers should always be raised prior to backing up to prevent damage

to the stalk stompers. The curved design of the shoe is intended to prevent or minimize damage if the

head/stalk stompers are inadvertently left down while backing up.

Maintenance Recommendations:

Your May Wes stalk stompers should require minimal maintenance during operation. During rountine

equipment maintenance, grease Stalk Stomper pivot point. Periodically check the pivot bolts connecting

the shoes and the mount brackets and replace when wear is present. The springs and chains should also

be checked periodically for proper adjustment/operation and to ensure the cotter pins are still in place.

This should be done along with other routine maintenance of the equipment.

Transport Recommendations:

If a header cart is used to transport head, stalk stomper shoes may need to be removed on rows that interfere

with the header cart. Follow the Safety Recommendations listed above prior to beginning the recommended

procedure listed below for transport. See page 2 for Transport Position (toolbar mount only).

Note: For ease of storage of Quick Disconnect 2 Stalk Stompers, optional Storage Brackets are available for

purchase. To order Storage Brackets per pair (set of two) use part number 43020.

Storage Recommendations:

It is recommended that stalk stompers be removed prior to storing the head. Please refer to the procedures

listed under Transport Recommendations for removal of Quick Disconnect 2 stalk stompers.

PLEASE VISIT WWW.MAYWES.COM FOR VIDEO INSTALLATION

120 Eastgate Drive SE 1-800-788-6483

PO Box 7 1-320-587-2322

Hutchinson, MN 55350 1-320-587-6112 (Fax)

WWW.MAYWES.COM

PAGE 1 OF 2 Doc #: 10206_A

QD2 Stalk Stomper Instructions

Operating Position Transporting Position

2) Transport

Position

3) Lock Pin

Snaps into

Location

1) Lock Pin

Assembly

Transport Position (Toolbar Mount Only):

1) Pull down on Lock Pin Assembly to release Stalk Stomper Shoe

2) Place front mounting pin in upright position

3) Pull up until Lock Pin Assembly snaps into place

120 Eastgate Drive SE 1-800-788-6483

PO Box 7 1-320-587-2322 WWW.MAYWES.COM

Hutchinson, MN 55350 1-320-587-6112 (Fax)

PAGE 2 OF 2 Doc #: 10206_A

You might also like

- JD 90 - 40 Rows 3 - 6 On 8 RowDocument7 pagesJD 90 - 40 Rows 3 - 6 On 8 Rowalaynnastaabx786No ratings yet

- Manual 46 STE SEDocument7 pagesManual 46 STE SEdautroc13No ratings yet

- Ulfm Butterfly ValveDocument7 pagesUlfm Butterfly ValveFranklin Esteban CárdenasNo ratings yet

- Current Revision Approved: USE AWS E309-17/E309L-17 CONSUMABLE Weld NoteDocument1 pageCurrent Revision Approved: USE AWS E309-17/E309L-17 CONSUMABLE Weld NoteRigobrertoNo ratings yet

- Hydro Trip Pressure SubsDocument5 pagesHydro Trip Pressure SubsyasirismNo ratings yet

- 9802/6220 E4-7-3 Ram, Bucket 8'4"Document2 pages9802/6220 E4-7-3 Ram, Bucket 8'4"Garcia CruzNo ratings yet

- Motor Cooling Catalogue Rev 1.0 SmallDocument25 pagesMotor Cooling Catalogue Rev 1.0 SmallnofriandiNo ratings yet

- HRC Coupling PDFDocument8 pagesHRC Coupling PDFJorge Calderon RojasNo ratings yet

- Keyway Sizing ChartDocument1 pageKeyway Sizing Chartpstechnical_43312697No ratings yet

- Boxer 322D Parts ManualDocument40 pagesBoxer 322D Parts ManualAbdul RehmanNo ratings yet

- As-5 Packer: We Know DownholeDocument1 pageAs-5 Packer: We Know DownholeservicemenruNo ratings yet

- 3020-Plataforma 3020Document557 pages3020-Plataforma 3020Genival FaustinoNo ratings yet

- Rocker Shaft Assembly and Push RodsDocument3 pagesRocker Shaft Assembly and Push Rodsma.powersourceNo ratings yet

- 680 Series Lead-Free Brass Gate Valve IPS, Full PortDocument1 page680 Series Lead-Free Brass Gate Valve IPS, Full PortLuis D UrciaNo ratings yet

- W A U K E S H A: 44 FORM 6302 First EditionDocument2 pagesW A U K E S H A: 44 FORM 6302 First Editiondiego yecid millan mendozaNo ratings yet

- Vibration Damper and Pulley - Install - Pulley With Split Lock Rings (KENR6081-15)Document3 pagesVibration Damper and Pulley - Install - Pulley With Split Lock Rings (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- 7 CabinDocument48 pages7 CabinEmrah MertyürekNo ratings yet

- A500719 Buw Assy With Actuator Shell 650tDocument3 pagesA500719 Buw Assy With Actuator Shell 650tAndros SustersickNo ratings yet

- 204-01 Front Stabilizer Bar LinkDocument2 pages204-01 Front Stabilizer Bar LinkFerhan SerdarogluNo ratings yet

- Engine Complete 4Document41 pagesEngine Complete 4Garcia CruzNo ratings yet

- SAE J518 Split FlangesDocument1 pageSAE J518 Split Flangesmanh hung leNo ratings yet

- Bell430 MM CH07Document10 pagesBell430 MM CH07ame.venkyNo ratings yet

- HRC Couplings: Maryland MetricsDocument8 pagesHRC Couplings: Maryland MetricsnguyenhuanNo ratings yet

- Asi X Packer 105243965Document3 pagesAsi X Packer 105243965Esteban RochaNo ratings yet

- Axle AssemblysDocument24 pagesAxle AssemblysGarcia CruzNo ratings yet

- 9630 20 TSS MMB 7130.autoDocument1 page9630 20 TSS MMB 7130.autoDanielNo ratings yet

- Dhahran Home Ownership S/S # 2 Transformer Pad & Wing Wall Ser No Description No's Length Width Hight Transformer Pad WallsDocument2 pagesDhahran Home Ownership S/S # 2 Transformer Pad & Wing Wall Ser No Description No's Length Width Hight Transformer Pad WallsjunNo ratings yet

- Style 807NDocument7 pagesStyle 807NUmmes AhmedNo ratings yet

- Gof-1600-Ce - 3 601 F24 000Document10 pagesGof-1600-Ce - 3 601 F24 000Andre FilipeNo ratings yet

- Global LP-8971-I-AUT Parts, Service and Instruction ManualDocument133 pagesGlobal LP-8971-I-AUT Parts, Service and Instruction ManuallauzoNo ratings yet

- U-Pvc Sewage & Drainage Piping System: Plastic Pipes & Fittings Factory Yousif Khalid Al-Adasani EstDocument12 pagesU-Pvc Sewage & Drainage Piping System: Plastic Pipes & Fittings Factory Yousif Khalid Al-Adasani EstCarlos Benjamin BC100% (1)

- 9802/5530 B4-5-1 LINK, BUCKET: Item Part # Change No Description Usage Code QTYDocument2 pages9802/5530 B4-5-1 LINK, BUCKET: Item Part # Change No Description Usage Code QTYVictor Pescador AmorNo ratings yet

- Boxer 320 Parts ManualDocument34 pagesBoxer 320 Parts ManualAbdul RehmanNo ratings yet

- Pump Out Plug 674871Document1 pagePump Out Plug 674871kirankirkNo ratings yet

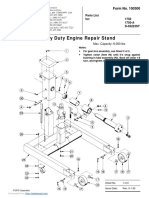

- Heavy Duty Engine Repair Stand: Form No. 100300Document4 pagesHeavy Duty Engine Repair Stand: Form No. 100300Mouayed TalbiNo ratings yet

- X510UA Service Guide-2Document42 pagesX510UA Service Guide-2dioskeyNo ratings yet

- Aquajack ManualDocument40 pagesAquajack ManualPanirChelvan RamanathanNo ratings yet

- Current Revision Approved: Eccentric Assy, 68H/SbsDocument1 pageCurrent Revision Approved: Eccentric Assy, 68H/Sbscapslive_001No ratings yet

- Bottom Plate Placement DiagramDocument2 pagesBottom Plate Placement DiagramJun Xian WaiNo ratings yet

- (I-00458) Ford Cam Castor 11-22Document12 pages(I-00458) Ford Cam Castor 11-229229113No ratings yet

- BG00870511 RD106 OMM32 D28 Water Flushing PDFDocument33 pagesBG00870511 RD106 OMM32 D28 Water Flushing PDFarmando rojo100% (2)

- Three-Phase Electric Motor Technical Catalogue - IEC MarketDocument44 pagesThree-Phase Electric Motor Technical Catalogue - IEC MarketNduP78No ratings yet

- Mission C PumpDocument15 pagesMission C PumpNarendra GaikwadNo ratings yet

- Proposal - Exhibit A: ESI - Edmond Security, IncDocument1 pageProposal - Exhibit A: ESI - Edmond Security, Incanon-767874No ratings yet

- Casing - DC-20150830-144606117Document39 pagesCasing - DC-20150830-144606117Jairo PuentesNo ratings yet

- SAMARIA 1081 CompletacionBHJDocument8 pagesSAMARIA 1081 CompletacionBHJjavicu_87No ratings yet

- Same 603 EngineDocument42 pagesSame 603 EngineNarek MinasyanNo ratings yet

- Three-Phase Electric Motor: Technical Catalog Nema MarketDocument48 pagesThree-Phase Electric Motor: Technical Catalog Nema MarketNduP78No ratings yet

- Manual Pala Case 580NDocument1,820 pagesManual Pala Case 580Nmabertovallejo04No ratings yet

- Sqt-007679 Rak Ghani Glass LLCDocument4 pagesSqt-007679 Rak Ghani Glass LLCShu MerNo ratings yet

- M (V) - 22 Expansion JointDocument22 pagesM (V) - 22 Expansion Jointerkan aksoyNo ratings yet

- Booklet Maker (BK5010) Parts Catalog: 25 April 2006Document33 pagesBooklet Maker (BK5010) Parts Catalog: 25 April 2006Алекс КNo ratings yet

- Design Flat PackDocument10 pagesDesign Flat PackwaquarstrNo ratings yet

- Cadenas PDFDocument45 pagesCadenas PDFVazquez Perez IvanNo ratings yet

- Parts Catalog Jeep Cherokee, Grand Cherokee y Wrangler 1994-1996Document1,045 pagesParts Catalog Jeep Cherokee, Grand Cherokee y Wrangler 1994-1996Guillermo MaluendaNo ratings yet

- Transformers and Ignitors: Engineered Solutions For Power and The EnvironmentDocument16 pagesTransformers and Ignitors: Engineered Solutions For Power and The EnvironmentDuile Blanco LopezNo ratings yet

- Offfset Final - Manzari - 1Document6 pagesOfffset Final - Manzari - 1Hari RamNo ratings yet

- Vermeer TD120Document29 pagesVermeer TD120Bernie PolegaNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- 630 Flex Cutting Platform - 630 Flex Cutting Platform: Features & SpecsDocument2 pages630 Flex Cutting Platform - 630 Flex Cutting Platform: Features & Specsalaynnastaabx786No ratings yet

- Jan Feb Ae50 WebDocument32 pagesJan Feb Ae50 Webalaynnastaabx786No ratings yet

- 1026 1882 1 PBDocument2 pages1026 1882 1 PBalaynnastaabx786No ratings yet

- USGC Harvest Report 14 15 FinalDocument58 pagesUSGC Harvest Report 14 15 Finalalaynnastaabx786No ratings yet

- Grain Harvesting To Minimize Losses and Maximize ProfitDocument40 pagesGrain Harvesting To Minimize Losses and Maximize Profitalaynnastaabx786No ratings yet

- Acs73 15Document7 pagesAcs73 15alaynnastaabx786No ratings yet

- Powerbloc50ang 21530Document1 pagePowerbloc50ang 21530alaynnastaabx786No ratings yet

- Jan Feb Ae50 WebDocument32 pagesJan Feb Ae50 Webalaynnastaabx786No ratings yet

- 02 Benes LDocument5 pages02 Benes Lalaynnastaabx786No ratings yet

- Fall 2018 PDF CatalogDocument376 pagesFall 2018 PDF Catalogalaynnastaabx786No ratings yet

- 603-1037-1-PB (Combine Harvesters - State-Of-Theart and Further Developments For The Improvement of Machine Settings)Document3 pages603-1037-1-PB (Combine Harvesters - State-Of-Theart and Further Developments For The Improvement of Machine Settings)alaynnastaabx786No ratings yet

- HP-NH CR With Factory Extensions InstructionsDocument12 pagesHP-NH CR With Factory Extensions Instructionsalaynnastaabx786No ratings yet

- Air Foil Sieve For 8010 - Small Grain CropsDocument11 pagesAir Foil Sieve For 8010 - Small Grain Cropsalaynnastaabx786No ratings yet

- Parts List Index: Row UnitDocument115 pagesParts List Index: Row UnitAlexey petrovichNo ratings yet

- f19 CatalogDocument396 pagesf19 Catalogalaynnastaabx786No ratings yet

- 3200 PartsDocument100 pages3200 Partsalaynnastaabx786No ratings yet

- Man 01018 CVS RSD RVS Ops Man N AmericaDocument116 pagesMan 01018 CVS RSD RVS Ops Man N Americaalaynnastaabx786No ratings yet

- Calmer Catalog 2016 WEBDocument21 pagesCalmer Catalog 2016 WEBalaynnastaabx786No ratings yet

- CORNSTARDocument6 pagesCORNSTARalaynnastaabx786No ratings yet

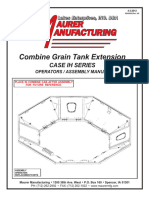

- Combine Grain Tank Extension: Case Ih SeriesDocument12 pagesCombine Grain Tank Extension: Case Ih Seriesalaynnastaabx786No ratings yet

- HP-NH CR With Big Top OFE InstructionsDocument14 pagesHP-NH CR With Big Top OFE Instructionsalaynnastaabx786No ratings yet

- Horst Header Carrier..Document22 pagesHorst Header Carrier..alaynnastaabx786No ratings yet

- Headertrailers AGCO EngDocument16 pagesHeadertrailers AGCO Engalaynnastaabx786No ratings yet

- Test-Report OptiMaxx Profi-International Harvest-2020Document5 pagesTest-Report OptiMaxx Profi-International Harvest-2020alaynnastaabx786No ratings yet

- 35 Series BrochureDocument2 pages35 Series Brochurealaynnastaabx786No ratings yet

- Multi-Crop HarvesterDocument6 pagesMulti-Crop Harvesteralaynnastaabx786No ratings yet

- Cosechadora CAse IH 7700Document20 pagesCosechadora CAse IH 7700Edwin Melendez100% (1)

- Sugar Cane Harvester 3520 BrochureDocument16 pagesSugar Cane Harvester 3520 Brochurealaynnastaabx786No ratings yet

- OXBO2460Document2 pagesOXBO2460alaynnastaabx786No ratings yet

- Flex GP Digital Imaging Plate Flex HR Digital Imaging Plate Flex XL Blue Digital Imaging PlateDocument2 pagesFlex GP Digital Imaging Plate Flex HR Digital Imaging Plate Flex XL Blue Digital Imaging PlateOriana Gabriela Amache RomanoNo ratings yet

- Section 22 - Sulfur RecoveryDocument145 pagesSection 22 - Sulfur RecoveryCHANADAS100% (1)

- MEYCO SupremaDocument4 pagesMEYCO SupremaRoberto ConchaNo ratings yet

- 00 LSPU Stage 2 Audit Report 2018 PDFDocument21 pages00 LSPU Stage 2 Audit Report 2018 PDFRolando Cruzada Jr.No ratings yet

- GX1000 B Quick Reference ManualDocument26 pagesGX1000 B Quick Reference ManualRafał KwaśnyNo ratings yet

- Actuator Controls Ac 01.2/acexc 01.2: Operation and Setting ManualDocument160 pagesActuator Controls Ac 01.2/acexc 01.2: Operation and Setting ManualJorge Antonio Lovera CastroNo ratings yet

- QuickRide LogcatDocument117 pagesQuickRide LogcatThala VetrivelNo ratings yet

- PN 218Document10 pagesPN 218Adnan KaraahmetovicNo ratings yet

- Smart Card NikkiDocument17 pagesSmart Card NikkimaheshfbNo ratings yet

- Subsurface Ventilation Systems MVS-SVE - Chapter04Document36 pagesSubsurface Ventilation Systems MVS-SVE - Chapter04Ghita Noerma GuphitaNo ratings yet

- SRV OldDocument24 pagesSRV OldAlvin PeraltaNo ratings yet

- JKR Manual On Pavement DesignDocument29 pagesJKR Manual On Pavement DesignWilfred Abraham100% (9)

- Kemparc Syn 300 (Digital) Gas Cooled Packages: Catalog - Nodescription en Sales - Pricdiscount Net PriceDocument11 pagesKemparc Syn 300 (Digital) Gas Cooled Packages: Catalog - Nodescription en Sales - Pricdiscount Net PricegtcweldNo ratings yet

- Administration Guide-NCC v2 6Document40 pagesAdministration Guide-NCC v2 6timucin.yalcinkayaNo ratings yet

- VoxStudio ManualDocument59 pagesVoxStudio ManualhmeyoyanNo ratings yet

- Dingli - Pilot PioneerDocument2 pagesDingli - Pilot PioneermalamontagneNo ratings yet

- 206L4 MM CH75 PDFDocument4 pages206L4 MM CH75 PDFRaisa RabeyaNo ratings yet

- Amity University Rajasthan: Amity School of EngineeringDocument15 pagesAmity University Rajasthan: Amity School of EngineeringRewa ShankarNo ratings yet

- Subsea Pipeline StabilityDocument9 pagesSubsea Pipeline StabilityJhy MhaNo ratings yet

- ReleaseNote FileList of G701VI WIN10 64 V3.01Document2 pagesReleaseNote FileList of G701VI WIN10 64 V3.01Sheik Mohamed ImranNo ratings yet

- Especificações SS CHS6 5Document2 pagesEspecificações SS CHS6 5kirlaniano@gmail.comNo ratings yet

- SiH4 N2 and NH3 Plasma ALDDocument2 pagesSiH4 N2 and NH3 Plasma ALDVikrant RaiNo ratings yet

- Siemens ET200M Systems ManualDocument240 pagesSiemens ET200M Systems ManualAndrey ZimnitskiyNo ratings yet

- MECH5 GETTING STARTEDv3Document6 pagesMECH5 GETTING STARTEDv3Justin JacksonNo ratings yet

- Research ProposalDocument6 pagesResearch Proposalapi-549913053No ratings yet

- RF Backhual Engineer ResumeDocument5 pagesRF Backhual Engineer ResumemadhubaddapuriNo ratings yet

- Test Bank For Equipment Theory For Respiratory Care 5th Edition by WhiteDocument28 pagesTest Bank For Equipment Theory For Respiratory Care 5th Edition by WhiteJohn Smoldt100% (29)

- Codex ExoditesDocument28 pagesCodex ExoditesPier Alexandre Champagne100% (1)

- Social Media Course SyllabusDocument9 pagesSocial Media Course Syllabusanthony_coccioloNo ratings yet