Professional Documents

Culture Documents

6 Pdca

Uploaded by

2k18.russia.world.cupOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Pdca

Uploaded by

2k18.russia.world.cupCopyright:

Available Formats

PDCA

PLAN

Design or revise production/business process components to improve results. Define the

problem statement clearly & accurately. Use fish bone analysis, 5 why ? or Mind mapping to

find out the main causes and drill down to root cause. Understand clearly the back ground

and make scope specific (end of the tunnel) .A clear objective statement. Prepare a clear

action plan , where you want to go and how you want to go ?

DO

Implement the plan and measure its performance. Carrying out irreversible containment action

for all the root causes for a pilot size / proto sample and not full scale. During the process of

implementation, you will collect the data parallels, you will analyse the concluded solution and

start implementing it.

CHECK

Assess the measurements, monitor and evaluate the processes and results against objectives

and specifications and report the results to decision makers. Is there a way to check the

effectiveness of corrective action? What to do if your initial implementation is not successful.

You will repeat plan,do & check until desired results are achieved by considering lessons learnt.

ACT

Decide on changes needed to improve the process and apply actions to the outcome for

necessary improvement. This means reviewing all steps (Plan, Do, Check, Act) and modifying

the process to improve it before its next cycle of implementation. Standardize to full scale.

Since, it is done on a full scale you will once again do a Plan, Do & check giving weightage to

scale size.

You might also like

- Quality Tools Plan Do Check ActDocument4 pagesQuality Tools Plan Do Check ActAhmed M. HashimNo ratings yet

- When To Use Plan-Do-Check-ActDocument9 pagesWhen To Use Plan-Do-Check-ActRajesh NairNo ratings yet

- Pdca Process - PsDocument8 pagesPdca Process - PsGabby xxxNo ratings yet

- PDCA CycleDocument2 pagesPDCA CycleAaron Joshua VediaNo ratings yet

- CSS 12 WEEK 3 LMDocument7 pagesCSS 12 WEEK 3 LMJames John AgubanNo ratings yet

- What Is PDSA Cycle in Quality Management?Document6 pagesWhat Is PDSA Cycle in Quality Management?Free The SoulNo ratings yet

- Presented by Ritam Ghosh (CM14224) Arpit Garg (CM14205)Document13 pagesPresented by Ritam Ghosh (CM14224) Arpit Garg (CM14205)War Machine100% (2)

- Pdca Cycle Quality Storyboard TemplateDocument16 pagesPdca Cycle Quality Storyboard TemplateRoger T.No ratings yet

- What Is PDCA?: Continually Improving, in A Methodical Way Also Known As PDSA, The "Deming Wheel," and "Shewhart Cycle"Document10 pagesWhat Is PDCA?: Continually Improving, in A Methodical Way Also Known As PDSA, The "Deming Wheel," and "Shewhart Cycle"Gladys YaresNo ratings yet

- Kaizen: Concepts and System: Kai-ZenDocument4 pagesKaizen: Concepts and System: Kai-ZenPark ChanyeolNo ratings yet

- Lo3 Engage in Quality Improvement 1Document19 pagesLo3 Engage in Quality Improvement 1Jasmin OrielNo ratings yet

- PDCA Instructional TemplateDocument2 pagesPDCA Instructional TemplatevinayNo ratings yet

- Action PlanDocument21 pagesAction PlanYacine BENKHEROUFNo ratings yet

- Customer: Six Sigma Aims Maximise Satisfaction Minimise DefectsDocument5 pagesCustomer: Six Sigma Aims Maximise Satisfaction Minimise DefectsjesusNo ratings yet

- Continuous Process Improvement MethodsDocument76 pagesContinuous Process Improvement MethodsRahulNo ratings yet

- Monodzukuri Test Monodzukuri Test: Learning Textbook Learning TextbookDocument31 pagesMonodzukuri Test Monodzukuri Test: Learning Textbook Learning TextbookMani Rathinam Rajamani0% (2)

- PDCADocument10 pagesPDCAAvinashRaiNo ratings yet

- Computer Systems Servicing: Quarter 1 - Module 3Document12 pagesComputer Systems Servicing: Quarter 1 - Module 3Johny JohnsonsNo ratings yet

- The Easy Guide To Developing An Effective Action PlanDocument6 pagesThe Easy Guide To Developing An Effective Action PlanResa Consigna Magusara100% (1)

- Plan Do Check ActDocument2 pagesPlan Do Check ActElo JTNo ratings yet

- PDCADocument24 pagesPDCARaju DesaiNo ratings yet

- Continuous Improvement 230221Document15 pagesContinuous Improvement 230221minh hoangNo ratings yet

- CHP 5 - Business PlanningDocument32 pagesCHP 5 - Business PlanningAbdullah :No ratings yet

- You Exec - Process Improvement FreeDocument9 pagesYou Exec - Process Improvement Freecarlo ViverosNo ratings yet

- Tools To Achieve Performance ExcellenceDocument43 pagesTools To Achieve Performance ExcellenceVinayNo ratings yet

- SAP S/4HANA Cloud Test Management:: Guide and Best PracticesDocument24 pagesSAP S/4HANA Cloud Test Management:: Guide and Best PracticesAlison MartinsNo ratings yet

- Week 9 Continuous Improvement Quality ToolsDocument39 pagesWeek 9 Continuous Improvement Quality Toolsleila DNo ratings yet

- 6.quality Control CircleDocument16 pages6.quality Control Circlegrace mwenjeNo ratings yet

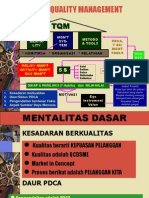

- Total Quality Management: Basic Menta-Lity MGN'T Sys - TEM Metodo & ToolsDocument25 pagesTotal Quality Management: Basic Menta-Lity MGN'T Sys - TEM Metodo & ToolsFaried Kurniawan100% (1)

- Development of Quality Management 14-11Document38 pagesDevelopment of Quality Management 14-11Rochak VyasNo ratings yet

- Pdca ConversionDocument53 pagesPdca ConversionJose Ortega100% (1)

- Lean Six SigmaDocument2 pagesLean Six SigmaAkash RathodNo ratings yet

- Plan Do Check Act FINALDocument2 pagesPlan Do Check Act FINALFaisalNo ratings yet

- Process Improvement Cycle: Identify RedesignDocument9 pagesProcess Improvement Cycle: Identify RedesignsandinoNo ratings yet

- What Is The PDCA Cycle and How Can It Improve Your ProcessDocument5 pagesWhat Is The PDCA Cycle and How Can It Improve Your ProcessHSE AmlaakNo ratings yet

- Module 50. Rapid Improvement Event (RIE)Document85 pagesModule 50. Rapid Improvement Event (RIE)taghavi1347No ratings yet

- Kaizen: Concepts and SystemsDocument76 pagesKaizen: Concepts and SystemsLastine AdaNo ratings yet

- 8D Methodology and Line BalancingDocument4 pages8D Methodology and Line BalancingMd Nayeemur RahmanNo ratings yet

- Group 4 TQM PresentationDocument70 pagesGroup 4 TQM PresentationDonabell RapiNo ratings yet

- Larc TemplateDocument21 pagesLarc TemplateSemeeeJuniorNo ratings yet

- DCIPS Performance Management Job AidsDocument21 pagesDCIPS Performance Management Job AidsAndreeaMare1984No ratings yet

- Training Programme On 7 QC Tools: A Quality Improvement ProcessDocument75 pagesTraining Programme On 7 QC Tools: A Quality Improvement ProcessVinod VahinipatiNo ratings yet

- MBM 101Document40 pagesMBM 101divya gambhirNo ratings yet

- Sec 08 - Problem Solving PDFDocument4 pagesSec 08 - Problem Solving PDFAmali LakmaliNo ratings yet

- PDCA (Plan Do Check Act)Document2 pagesPDCA (Plan Do Check Act)SnakeNo ratings yet

- Content/Uploads/2011/12/Info Improvingresourceefficiency PDFDocument3 pagesContent/Uploads/2011/12/Info Improvingresourceefficiency PDFNATALIA MARCELA PICON ANGARITANo ratings yet

- The Deming Cycle - AsdiDocument2 pagesThe Deming Cycle - AsdiEder Julinho Calanche SotomayorNo ratings yet

- 5s and KaizenDocument28 pages5s and KaizenSatya KumarNo ratings yet

- 5S and Kaizen PDFDocument28 pages5S and Kaizen PDFShinta Nugraha Mughni100% (2)

- 192 ReportDocument3 pages192 ReportKirt Menard UGAYNo ratings yet

- Mod 9 PDCA Problem SolvingDocument10 pagesMod 9 PDCA Problem SolvinghobbesatoNo ratings yet

- Hoshin KanriDocument11 pagesHoshin KanriSumesh Kumar ManimalaNo ratings yet

- The Power of Business Process Improvement: 10 Simple Steps to Increase Effectiveness, Efficiency, and AdaptabilityFrom EverandThe Power of Business Process Improvement: 10 Simple Steps to Increase Effectiveness, Efficiency, and AdaptabilityNo ratings yet

- Plan Do Study ActDocument8 pagesPlan Do Study ActsandeepNo ratings yet

- Monitoring and Evaluation FinalDocument20 pagesMonitoring and Evaluation FinalNational Child Health Resource Centre (NCHRC)No ratings yet

- Performance MGT 5 - 1Document20 pagesPerformance MGT 5 - 1Mr DamphaNo ratings yet

- wEEK 6Document21 pageswEEK 6Alvia MagnoNo ratings yet

- 50 Basic Predictive Project Management Questions: A great primer for the PMP® and CAPM® ExamsFrom Everand50 Basic Predictive Project Management Questions: A great primer for the PMP® and CAPM® ExamsNo ratings yet

- The Disney WayDocument6 pagesThe Disney Way2k18.russia.world.cupNo ratings yet

- SCAR Supplier Change NotificationDocument3 pagesSCAR Supplier Change Notification2k18.russia.world.cupNo ratings yet

- Leadership Story A3 Template v2.0Document3 pagesLeadership Story A3 Template v2.02k18.russia.world.cupNo ratings yet

- PDSA A3 Template GUIDE CF Color CFDocument1 pagePDSA A3 Template GUIDE CF Color CF2k18.russia.world.cupNo ratings yet

- 05d A3 Problem Solving Template VisioDocument2 pages05d A3 Problem Solving Template Visio2k18.russia.world.cupNo ratings yet

- Learning A3 BlankDocument1 pageLearning A3 Blank2k18.russia.world.cupNo ratings yet

- 1116 3366 1 PBDocument5 pages1116 3366 1 PB2k18.russia.world.cupNo ratings yet