Professional Documents

Culture Documents

Advabond TDS

Uploaded by

Mohammed AbugharbiehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advabond TDS

Uploaded by

Mohammed AbugharbiehCopyright:

Available Formats

ADVABOND

Concrete and Plaster Bonding Agent

DESCRIPTION

ADVABOND is a VAE based re-emulsifiable bonding agent. ADVABOND is

used to bond new concrete, stucco, tile setting beds and terrazzo to any

structural sound surface, interior and exterior.

USES

Use on concrete, concrete block, cement board, hardboard, plywood, brick,

plaster, tile, gypsum, or stone.

Interior or Exterior use

Bond new concrete to new old concrete

Vertical or Horizontal

APPLICATION INSTRUCTIONS

Surface preparation

Surface must be clean and sound.

Remove all deteriorated concrete, dirt, oil, grease, and other

AL SA’FAT - GREEN BUILDING

bond-inhibiting materials from the surface.

Certificate No. CL20020739

Preparation work should be done by high pressure water blast, scabbler, or

other appropriate mechanical means to obtain an aggregate-fractured

surface with a minimum CSP 3 surface profile or greater.

Ensure there are no curing compounds or other contaminants remaining

on the substrate before application.

Substrate must be dry before application.

MIXING:

Prior to installation, stir ADVABOND before use for consistent dispersion.

Apply undiluted.

APPLICATION:

Apply ADVABOND uniformly over the substrate using a stiff brush, broom,

roller or spray to form a continuous film.

Reapply ADVABOND that are not covered entirely.

Allow film to dry for approximately 1 hour prior to application of mortars,

concrete or stucco.

Dry time can be affected by temperature and humidity, check to make sure

product is dry to the touch before topping.

Extremely porous substrates may require 2 coats of ADVABOND.

Protect newly applied ADVABOND from dust, dirt, debris and moisture.

Al Mutathawir Insulation Materials Industries L.L.C.

T: +971 6 5345585 | F: +971 6 5347717

E: info@aim-insu.com | W: www.aim-insu.com

P.O. Box: 22704,Sharjah-UAE

ADVABOND

COVERAGE

5m² per liter

(Coverage figures do not include allowance for surface profile and porosity or material waste)

HEALTH & SAFETY

As with all Chemical products caution should always be exercised. Protective clothing such as gloves and goggles should be worn. Treat any splashes

to the skin or eyes immediately with fresh water. Should any of the products be accidentally swallowed, do not induce vomiting call for medical

assistance immediately. Ensure that the container is available for medical attendant to examine any relevant instructions and content details.

TECHNICAL SPECIFICATIONS

Color White

Viscosity 1,000 cps

Waiting / Recoat Times 1 hour

Shelf Life 12 months from date of production if stored properly in original, unopened and undamaged

sealed packaging.

Storage Store in cool, frost-free conditions with temperatures between 50 °F to 90 °F (10 °C to 32 °C).

Condition product to between 50 °F to 90 °F (10 °C to 32 °C).

Packing 5 Ltr/Jerry Can

The information given in this datasheet is based on both current

development work and many years of field experience. Whilst every

effort is made to ensure that the information is reliable, we cannot Al Mutathawir Insulation Materials Industries L.L.C.

accept responsibility for any work carried out with our materials as T: +971 6 5345585 | F: +971 6 5347717

E: info@aim-insu.com | W: www.aim-insu.com

we have no control over methods of application, site, conditions, etc. P.O. Box: 22704,Sharjah-UAE

You might also like

- 03 - TDS - Concresive 1414Document3 pages03 - TDS - Concresive 1414aahtagoNo ratings yet

- Recebond HD: Product Data SheetDocument2 pagesRecebond HD: Product Data SheetAmira RamleeNo ratings yet

- Smartcare Tile Adhesive For Tile On Tile ApplicationDocument2 pagesSmartcare Tile Adhesive For Tile On Tile ApplicationDesign Group India IndiaNo ratings yet

- Mastertop 195 AF PDFDocument2 pagesMastertop 195 AF PDFFrancois-No ratings yet

- Weberdry Protect 01Document2 pagesWeberdry Protect 01adelsaqqaNo ratings yet

- Smartbond C2S1: Product DescriptionDocument2 pagesSmartbond C2S1: Product DescriptionMalak HindiNo ratings yet

- Dulux Trade Ecosure Plaster PrimerDocument2 pagesDulux Trade Ecosure Plaster Primerfopoku2k2No ratings yet

- Davco TTB EcoDocument2 pagesDavco TTB Ecopiakhong.cheongNo ratings yet

- 531 Prosfas GBDocument2 pages531 Prosfas GBQuoc AnNo ratings yet

- Marble & Granite Glue: Product Data SheetDocument2 pagesMarble & Granite Glue: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- Advatile Adhesive TDSDocument2 pagesAdvatile Adhesive TDSMohammed AbugharbiehNo ratings yet

- Brochure Penofin Architectural Grade HardwoodDocument4 pagesBrochure Penofin Architectural Grade HardwoodMegTri SalesNo ratings yet

- Wall Primer Exteriors-PIS-2Document2 pagesWall Primer Exteriors-PIS-2Arssalaan Engineering EnterprisesNo ratings yet

- ZNR-22 Zinsser Mold Killing PrimerDocument2 pagesZNR-22 Zinsser Mold Killing PrimerAjay PanchalNo ratings yet

- Davco TTB ECO Brochure 1Document2 pagesDavco TTB ECO Brochure 1hinal pNo ratings yet

- Tuf Bond EPDocument2 pagesTuf Bond EPPanruti S SathiyavendhanNo ratings yet

- Elastoroof PUDocument2 pagesElastoroof PUSunilNo ratings yet

- Basf Masterprotect 2020Document2 pagesBasf Masterprotect 2020SHAIK ASIMUDDIN100% (1)

- Product Data Sheet: Product Description Technical SpecificationDocument2 pagesProduct Data Sheet: Product Description Technical SpecificationVaittianathan MahavapillaiNo ratings yet

- Concresive 1414: Epoxy Bonding Agent For Concrete Repairs, Bonding Concrete To Concrete, Steel and Granolithic ToppingsDocument3 pagesConcresive 1414: Epoxy Bonding Agent For Concrete Repairs, Bonding Concrete To Concrete, Steel and Granolithic ToppingsFrancois-No ratings yet

- TEC-030100.2-MET-DoR-003-MAT-TDS-BASF-Concresive 1414Document3 pagesTEC-030100.2-MET-DoR-003-MAT-TDS-BASF-Concresive 1414Eli MatucadNo ratings yet

- Dura Grout: A.B.E. Construction ChemicalsDocument3 pagesDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNo ratings yet

- Buffa Datasheet COPER EVOLUZIONE PDFDocument2 pagesBuffa Datasheet COPER EVOLUZIONE PDFJurgen VassalloNo ratings yet

- Polymastic: Single Component Acrylic Co-Polymer MasticDocument2 pagesPolymastic: Single Component Acrylic Co-Polymer MasticaahtagoNo ratings yet

- Expangrout AGDocument2 pagesExpangrout AGPMG04 EKLNo ratings yet

- Renderoc PlasterDocument1 pageRenderoc PlasterNarutojane BorutoNo ratings yet

- Renderoc Plaster PDFDocument1 pageRenderoc Plaster PDFNarutojane BorutoNo ratings yet

- Flowprime WBDocument1 pageFlowprime WBMuthukumar JayaveerapandianNo ratings yet

- ADVA PRIM (Primer)Document2 pagesADVA PRIM (Primer)hazelNo ratings yet

- Bit U MasticDocument2 pagesBit U MasticramodNo ratings yet

- Product Description Primer (Activation of Surface)Document2 pagesProduct Description Primer (Activation of Surface)abcdNo ratings yet

- Solvent Free, Low Viscosity, Epoxy Primer: Mixing DescriptionDocument2 pagesSolvent Free, Low Viscosity, Epoxy Primer: Mixing DescriptionSameehu TVNo ratings yet

- Biotech Tile GroutDocument1 pageBiotech Tile GroutSara MillerNo ratings yet

- Basf Masterbrace Adh 1414 TdsDocument3 pagesBasf Masterbrace Adh 1414 TdsAzhar ShaikhNo ratings yet

- Supreme Wall-Base Adhesive: BasebondDocument2 pagesSupreme Wall-Base Adhesive: BasebondYASHICA VAITTIANATHANNo ratings yet

- 14 - TDS - Concresive 2020Document2 pages14 - TDS - Concresive 2020aahtagoNo ratings yet

- Seal N Flex Advance Labels 300ml FinalDocument4 pagesSeal N Flex Advance Labels 300ml Finalumer ChNo ratings yet

- Admix 210 Pv-A4Document1 pageAdmix 210 Pv-A4lee_cur_van4883No ratings yet

- Ep 300Document2 pagesEp 300mathewsujith31No ratings yet

- Elastomeric Paint 2Document4 pagesElastomeric Paint 2noly ticsayNo ratings yet

- WPM 300 TDSDocument2 pagesWPM 300 TDSPetrus PaulusNo ratings yet

- TDS Araldite Standard 2016 enDocument2 pagesTDS Araldite Standard 2016 endantewow1No ratings yet

- Current Multiprime Pail 20l FaDocument1 pageCurrent Multiprime Pail 20l Faumer ChNo ratings yet

- Single Component Shrink-Free Structural Grout: FeaturesDocument2 pagesSingle Component Shrink-Free Structural Grout: Featuresmathewsujith31No ratings yet

- Boscoflex: Flexible Cementitious Waterprofing MembraneDocument2 pagesBoscoflex: Flexible Cementitious Waterprofing MembraneCLENTH FLORentinoNo ratings yet

- Tds - Tile Adhesive 711v1910Document2 pagesTds - Tile Adhesive 711v1910Susana KhoNo ratings yet

- Semstone 6325 Sealant PDSDocument3 pagesSemstone 6325 Sealant PDSaleerossNo ratings yet

- LASIQ EASY10 Data SheetDocument2 pagesLASIQ EASY10 Data SheetChristos LeptokaridisNo ratings yet

- Sikatop - 107 Seal: Cementitious Waterproof CoatingDocument4 pagesSikatop - 107 Seal: Cementitious Waterproof CoatingacarisimovicNo ratings yet

- TDS Weberfloor EposilDocument2 pagesTDS Weberfloor EposilMaha MuflehNo ratings yet

- 3/4" Solid Hardwood Flooring Installation Instructions: CautionDocument6 pages3/4" Solid Hardwood Flooring Installation Instructions: CautionRacer XNo ratings yet

- TDS Adesilex VZ (241-1-2012)Document4 pagesTDS Adesilex VZ (241-1-2012)aleksandar.hbtNo ratings yet

- Plast: Very Fast. Absolutely SmoothDocument2 pagesPlast: Very Fast. Absolutely Smoothsachinkarape4844100% (1)

- Neoshield Plus Matt - TDSDocument2 pagesNeoshield Plus Matt - TDSaboali8686No ratings yet

- AWAZEL WB SubmittalDocument26 pagesAWAZEL WB SubmittalAbdel Mongy AhmedNo ratings yet

- Homey 577 TDSDocument3 pagesHomey 577 TDSKelly WuNo ratings yet

- Concrete Bonding Agent CICOBOND EPYDocument2 pagesConcrete Bonding Agent CICOBOND EPYSharookhan ShajahanNo ratings yet

- Segmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureDocument4 pagesSegmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureAmar Babu ChNo ratings yet

- Polyprime PS: Primer For Porous JointsDocument2 pagesPolyprime PS: Primer For Porous JointsaahtagoNo ratings yet

- Advafelt TDSDocument1 pageAdvafelt TDSMohammed AbugharbiehNo ratings yet

- Advastop TDSDocument2 pagesAdvastop TDSMohammed AbugharbiehNo ratings yet

- Advabond SBR TDSDocument2 pagesAdvabond SBR TDSMohammed AbugharbiehNo ratings yet

- Advaboard TDSDocument1 pageAdvaboard TDSMohammed AbugharbiehNo ratings yet

- Adva SBR TDSDocument2 pagesAdva SBR TDSMohammed AbugharbiehNo ratings yet

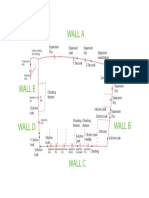

- Wall A: Surface Grinding and Chiseling 13.horizontal LeakDocument1 pageWall A: Surface Grinding and Chiseling 13.horizontal LeakMohammed AbugharbiehNo ratings yet

- Five TemperamentDocument5 pagesFive TemperamentDhaivatPatelNo ratings yet

- 9th Computer Notes Full BookDocument14 pages9th Computer Notes Full BookKot Abdul Malik High SchoolNo ratings yet

- NationalMootCourtCompetition Moot ProblemDocument5 pagesNationalMootCourtCompetition Moot ProblemKarsin ManochaNo ratings yet

- Worksheet (Time and Motion) Answer KeyDocument7 pagesWorksheet (Time and Motion) Answer Keykatira rashmiNo ratings yet

- Thesis Chapter IiiDocument6 pagesThesis Chapter IiiJohn Rafael AtienzaNo ratings yet

- Types of Evidence DLPDocument9 pagesTypes of Evidence DLPMary Joy IgnacioNo ratings yet

- Regional Directorate General of Public Finance of BucharestDocument8 pagesRegional Directorate General of Public Finance of BucharestAnna MarissNo ratings yet

- Add-On Effect of Brahmi in The Management of SchizophreniaDocument3 pagesAdd-On Effect of Brahmi in The Management of SchizophreniaNAITIKNo ratings yet

- Topic 1.2 FormativeDocument3 pagesTopic 1.2 FormativeJunior Alexis Julon Ventura0% (1)

- Sequential StatementDocument12 pagesSequential Statementdineshvhaval100% (1)

- Understanding Culture, Society, and Politics Quarter 2 - Module 1Document21 pagesUnderstanding Culture, Society, and Politics Quarter 2 - Module 1Allaine's ChannelNo ratings yet

- Siddique, Tashfeen Coverletter 20170320Document1 pageSiddique, Tashfeen Coverletter 20170320Anonymous liUNtnyNo ratings yet

- Kinetic - Sculpture FirstDocument3 pagesKinetic - Sculpture FirstLeoNo ratings yet

- A Presentation ON Office Etiquettes: To Be PresentedDocument9 pagesA Presentation ON Office Etiquettes: To Be PresentedShafak MahajanNo ratings yet

- OP-COM Fault Codes PrintDocument2 pagesOP-COM Fault Codes Printtiponatis0% (1)

- Reflection and Refraction of LightDocument34 pagesReflection and Refraction of Lightseunnuga93No ratings yet

- Culture and Cultural GeographyDocument6 pagesCulture and Cultural GeographySrishti SrivastavaNo ratings yet

- Xaviers Institute of Social Service: Assignment On Quantitative TechniquesDocument20 pagesXaviers Institute of Social Service: Assignment On Quantitative Techniquesravi kumarNo ratings yet

- Remaking The Indian Historians CraftDocument9 pagesRemaking The Indian Historians CraftChandan BasuNo ratings yet

- Catalogo Molas PratoDocument176 pagesCatalogo Molas Pratocassio_tecdrawNo ratings yet

- Hostel Survey Analysis ReportDocument10 pagesHostel Survey Analysis ReportMoosa NaseerNo ratings yet

- AndragogyDocument7 pagesAndragogyRenee Gods-Creation BurgeNo ratings yet

- Els2204 Sinsis 1718 CepDocument7 pagesEls2204 Sinsis 1718 CepChristian MarpaungNo ratings yet

- Discovery Issues Resolution Naga NotesDocument7 pagesDiscovery Issues Resolution Naga NotesNagaPrasannaKumarKakarlamudi100% (1)

- A Lifetime of OpportunityDocument24 pagesA Lifetime of OpportunityCaleb Newquist100% (1)

- Third Periodical Assessment Test (Pat 3) Grade 8 - MathematicsDocument10 pagesThird Periodical Assessment Test (Pat 3) Grade 8 - Mathematicswerdubob100% (1)

- Genogram and Eco GramDocument5 pagesGenogram and Eco GramGitichekimNo ratings yet

- Trouble Shooting On Conveyor BeltingsDocument17 pagesTrouble Shooting On Conveyor BeltingsVimal Bhansali100% (1)

- A Typical "Jyotish - Vedic Astrology" SessionDocument3 pagesA Typical "Jyotish - Vedic Astrology" SessionMariana SantosNo ratings yet

- Norman Perrin-What Is Redaction CriticismDocument96 pagesNorman Perrin-What Is Redaction Criticismoasis115100% (1)