Professional Documents

Culture Documents

Print pdf-914b1134

Uploaded by

Rikk Venzuela LandinginOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Print pdf-914b1134

Uploaded by

Rikk Venzuela LandinginCopyright:

Available Formats

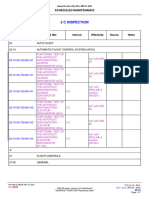

MAINTENANCE MANUAL 05-20-00 - SCHEDULED MAINTENANCE CHECKS

Manual Part No. 3075742 Rev. 10.1 - 15/APR/19

05-20-00

B. Periodic Inspections

(1) Do the scheduled maintenance checks at the intervals given in Table2.

Table 2 Scheduled Inspection Maintenance Tasks (Task 05-20-00-210-801)

Maintenance

Task No. Type Component/Inspection Interval

1. ENGINE EXTERNALS

Task 72-00- GVI Do a visual inspection of the MINOR

00-212-801 Control Linkages and wiring

See Note

NOTE: Inspect initially at 100 hours with extension to relevant airframe zone inspection

based on inspection results but not to exceed 200 hours.

Task 70-00- DET Do a visual inspection of all ROUTINE

00-200-801 tubes and hose assemblies

N/A GVI Do a visual inspection of the MINOR

engine exhaust duct welds.

N/A GVI Do a visual inspection of the MINOR

engine exhaust duct for

cracks. 25 hours if crack is

identified

Task 72-50- DET Do a detailed inspection of MINOR

05-210-801 the turbine exhaust duct.

N/A GVI Do a visual inspection of the ROUTINE

propeller sha oil seal for

leakage.

Task 72-00- GVI Do a visual inspection of the MINOR

00-212-802 gas generator case and the

center fireseal.

Export Classification: ECCN=Contains 10-25% 9E991;ECL=NSR Page 1

Printed on 06/FEB/24 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 05-20-00 - SCHEDULED MAINTENANCE CHECKS

Manual Part No. 3075742 Rev. 10.1 - 15/APR/19

Maintenance

Task No. Type Component/Inspection Interval

Task 72-00- GVI Do a visual inspection of the MINOR

00-212-803 rear fireseal mounting ring.

Task 72-20- GVI Do a visual inspection of the MINOR

01-210-801 air inlet screen.

Task 70-00- GVI Do a visual inspection of the ROUTINE

00-200-801 engine externals.

Task 72-60- GVI Do an inspection of the At starter-generator

01-210-801 starter-gearsha splines for removal/replacement

wear. only.

2. INTERNAL

Task 72-30- GVI Do a visual inspection with MINOR

00-200-801 a mirror or a borescope

inspection of the First-stage

Compressor Rotor and the

inlet case for corrosion (Ref.

NOTE)

NOTE: If any FOD has caused the engine to become prone to engine surges or causes

unusual compressor whining, the large bent airfoil will make the whining sound.

Remove the engine immediately.

Task 72-50- DET Do an inspection of the CT TBO

02-210-801 disk and blade set

N/A DIS Replace the CT blades. 12000 hours

N/A DIS Replace the PT blades. 12000 hours

3. OIL SYSTEM

Task 72-00- GVI Do a visual inspection of the ROUTINE

00-640-803 engine oil quantity.

Export Classification: ECCN=Contains 10-25% 9E991;ECL=NSR Page 2

Printed on 06/FEB/24 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 05-20-00 - SCHEDULED MAINTENANCE CHECKS

Manual Part No. 3075742 Rev. 10.1 - 15/APR/19

Maintenance

Task No. Type Component/Inspection Interval

Task 79-10- SDI Do a check of the ROUTINE

01-400-801 installation of the oil filler

cap.

Task 79-30- GVI Do a visual inspection of the Every 200 hours.

01-210-801 chip detector for debris.

Task 79-30- FC Do a functional check of the Every 600 hours.

01-770-801 chip detector.

Task 79-20- DIS Remove and discard the oil 1000 hours

01-000-801 filter element.

Task 79-20- Install a new oil filter

01-400-801 element.

Task 79-20- GVI Inspect and clean oil filter MINOR (See Notes 2

01-000-801 for debris. and 3)

Task 79-20-

01-280-801

Task 79-20-

01-160-801

or

Task 79-20-

01-160-801-

01

Task 79-20-

01-400-801

NOTE:

1. Light traces of sediment only may be removed from the main filter screen.

All other contamination requires replacement of filter element. Any

foreign material found in main oil filter or on chip detector, should be

identified before further inspection/operation (Ref. Task 79-20-01-280-

801).

Export Classification: ECCN=Contains 10-25% 9E991;ECL=NSR Page 3

Printed on 06/FEB/24 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 05-20-00 - SCHEDULED MAINTENANCE CHECKS

Manual Part No. 3075742 Rev. 10.1 - 15/APR/19

Maintenance

Task No. Type Component/Inspection Interval

2. Inspect initially at 100 hours with extension to relevant airframe zone

inspection based on inspection results but not to exceed 200 hours.

3. If the engine has a recent history (within 200 flight hours) of generating

carbon debris, do the inspection at 100 hours interval and replace the

filter element at 300 hours interval. Refer to Task 72-00-00-810-807,

ENGINE - FAULT ISOLATION.

4. If carbon like deposits are found, drain accessory gearbox oil into a clean

container and examine debris.

Task 70-00- GVI Do a visual inspection of the ROUTINE

00-200-801 scavenge oil pump housing

for leaks.

79-30-01- GVI Do a visual inspection of the 200 hours or

210-803 AGB internal scavenge oil

pump inlet screen 6 months (at

operator’s option)

for engines operating

in high relative

humidity/tropical

environment

(above 70% for most

of the year).

(See NOTE)

NOTE: Extension in steps of 50 hours to 500 hours maximum, based on operator

experience. 1000 hours for engines NOT operating in high relative

humidity/tropical environment.

4. FUEL SYSTEM

DELETED.

Task 73-10- GVI Do a check for the fuel MINOR

02-790-801 pump installation and

leaks. (See NOTE)

Export Classification: ECCN=Contains 10-25% 9E991;ECL=NSR Page 4

Printed on 06/FEB/24 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 05-20-00 - SCHEDULED MAINTENANCE CHECKS

Manual Part No. 3075742 Rev. 10.1 - 15/APR/19

Maintenance

Task No. Type Component/Inspection Interval

NOTE: If airframe fuel boost pump fails or is inadvertently le off for an accumulative

time in excess of 10 hours, the engine driven fuel pump must be removed and

replaced. The removed pump should be sent to an approved overhaul facility.

73-10-05- GVI Do a visual inspection of the 600 hours

210-801 fuel pump inlet screen.

(See NOTE)

NOTE: On new aircra , check filter a er each flight until no contamination is evident.

check a er first flight or ground run whenever any component upstream of filter

is replaced.

73-10-05- GVI Do a visual inspection of the MINOR

210-801 fuel pump outlet filter (See

Note).

NOTE: Install the new filter as service condition dictate, not to exceed 600 hours and

when fuel system contamination is suspected.

Task 73-10- SDI Do a check of the drain MINOR

06-400-801 valve for installation and

leaks

Task 73-20- SDI Do a check of the FCU for MINOR

01-400-801 installation, linkages and

pneumatic tubes.

Task 71-00- OPC Do a check of the FCU MINOR

00-760-810 manual override system for

static operation. Not more than 200

hours.

For the engines installed

with a manual override

system only.

Task 73-10- SDI Do a check of the flow MINOR

07-400-801 divider for installation and

leaks.

Task 73-10- OPC Do a leak test and a See Notes

Export Classification: ECCN=Contains 10-25% 9E991;ECL=NSR Page 5

Printed on 06/FEB/24 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 05-20-00 - SCHEDULED MAINTENANCE CHECKS

Manual Part No. 3075742 Rev. 10.1 - 15/APR/19

Maintenance

Task No. Type Component/Inspection Interval

04-790-801 functional test of the fuel

manifold adapter and

nozzle assemblies.

NOTE:

1. Do the periodic borescope inspection of the hot section components in

conjunction with the following tests.

2. Regular fuel nozzle maintenance is important for hot section durability.

Inspection recommended at routine intervals according to:

Engines ON fuel nozzle in-situ cleaning program (Ref. Task 71-00-00-160-

808). Test fuel nozzles and refurbish as necessary. Where fuel quality may

be questionable, and/or for operators new to PT6A operation, inspection

is recommended at 400 hours initially, with extension of 200 hours based

on inspection results. For other operators, inspection is recommended at

600 hours initially, with extension, of 200 hours based on inspection

results.

Engine NOT ON fuel nozzle in-situ cleaning program. Test fuel manifold

adapter. Where fuel quality may be questionable, and/or for operators

new to PT6A operation, cleaning/inspection is recommended at 200 hours

initially, with extension, if applicable, based on inspection results. For

other operators, inspection is recommended at 400 hours initially, with

extension, based on inspection results.

Task 73-10- SDI Do a check of the oil-to-fuel MINOR

03-400-801 heater installation

Task 73-10- GVI Do a visual inspection of the MINOR

05-210-802 fuel filter. (See NOTE)

but not more than

600 hours and if you

found that the fuel

system

contamination is

there.

NOTE: On new aircra , examine filter a er each flight until you see no contamination. Do

a check a er first flight or ground run whenever any component upstream of

filter is replaced.

Export Classification: ECCN=Contains 10-25% 9E991;ECL=NSR Page 6

Printed on 06/FEB/24 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 05-20-00 - SCHEDULED MAINTENANCE CHECKS

Manual Part No. 3075742 Rev. 10.1 - 15/APR/19

Maintenance

Task No. Type Component/Inspection Interval

N/A GVI Do a visual inspection of the ROUTINE

fuel filter impending bypass

indicator pop-up button.

(See NOTE)

NOTE: There will be an indication in the pop-up indicator when you replace the fuel

system components or the fuel filters. Make sure that the FOHE filter is clean,

then set the pop-up indicator.

5. IGNITION SYSTEM

Task 74-10- GVI Do a visual inspection of the 400 Hours

01-210-801 ignition exciter.

Task 74-10- GVI Do a visual inspection of the 400 Hours

01-210-801 ignition cables.

Task 74-20- FC Do a functional check of the 400 Hours

01-750-801 ignition cable.

Task 74-20- GVI Do a visual inspection of the 400 Hours

02-210-801 spark igniter/glow plugs.

See NOTE

NOTE: Examine initially at 200 hours. Use the same spark igniter/glow plugs based on the

inspection results but not more than 400 hours.

6. PNEUMATIC SYSTEM

Task 73-10- GVI Do a visual inspection of the See NOTE

08-210-803 P3 filter and drain valve.

NOTE: Inspect initially at 100 hours with extension to relevant airframe zone inspection

based on inspection results, but not to exceed 200 hours.

Task 73-10- SDI Clean or replace the filter Every 200 hours.

Export Classification: ECCN=Contains 10-25% 9E991;ECL=NSR Page 7

Printed on 06/FEB/24 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 05-20-00 - SCHEDULED MAINTENANCE CHECKS

Manual Part No. 3075742 Rev. 10.1 - 15/APR/19

Maintenance

Task No. Type Component/Inspection Interval

08-100-802 based on condition, service

experience or environment. 100 hours for harsh

Subtask 73- environment.

10-08-000- (See NOTE)

001

Subtask 73-

10-08-400-

002

NOTE: Do a visual inspection of the P3 filter for corrosion. If filter shows presence of

corrosion, discard the filter and replace with a new filter.

Task 73-10- SDI Clean or replace the Every 1000 hours

08-100-802 permanent filter based on

condition, service

Subtask 73- experience or environment.

10-08-000- Ship to an approved P&WC

001 overhaul facility for

Subtask 73- ultrasonic cleaning.

10-08-400-

002

Task 75-30- GVI Do a visual inspection of the Every 600 hours

01-210-801 compressor bleed valve.

See NOTES

NOTE:

1. For the engines operating in salt-laden or harsh environments or in high

cyclic conditions. Extension can be based on the operators experience.

2. For other engines NOT operating in conditions mentioned in NOTE above,

inspect in conjunction with a Hot Section inspection.

Export Classification: ECCN=Contains 10-25% 9E991;ECL=NSR Page 8

Printed on 06/FEB/24 P&WC Proprietary – subject to restrictions in Technical Data Agreement

You might also like

- FJ44-2C Line Maintenance Manual - FJ44-2CDocument1,049 pagesFJ44-2C Line Maintenance Manual - FJ44-2CLuisJunniorRomeroManzueta88% (8)

- TR PDFDocument3 pagesTR PDFAnonymous 298xlo3uUNo ratings yet

- Maintenance Manual HTCM-001: Main Rotor Blades (Installation and Maintenance)Document59 pagesMaintenance Manual HTCM-001: Main Rotor Blades (Installation and Maintenance)robbertmdNo ratings yet

- Oslo Guide PDFDocument10 pagesOslo Guide PDFDevan BhallaNo ratings yet

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3043512Document12 pagesPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3043512Michael Quintero100% (1)

- Fall Prevention and Protection ProcedureDocument23 pagesFall Prevention and Protection Procedureibrahim100% (1)

- Pratt & Whitney Canada: List of Effective PagesDocument8 pagesPratt & Whitney Canada: List of Effective PagesChristianNo ratings yet

- Saab Sf340A Daily Inspection, When Operating in Enhanced Procedures Zone, Checklist Daily CheckDocument2 pagesSaab Sf340A Daily Inspection, When Operating in Enhanced Procedures Zone, Checklist Daily CheckVytautas 13No ratings yet

- Saab Sf340A Daily Inspection Checklist Daily Check: MRB Ref. Scope of Work Ref. SignDocument2 pagesSaab Sf340A Daily Inspection Checklist Daily Check: MRB Ref. Scope of Work Ref. SignVytautas 13No ratings yet

- Detector, Master Chip - Inspection/Check: Service Bulletin No. Service Bulletin TitleDocument4 pagesDetector, Master Chip - Inspection/Check: Service Bulletin No. Service Bulletin Titletanveer malikNo ratings yet

- Appendix B - Emb RecomDocument7 pagesAppendix B - Emb Recomokolofo ojonugwaNo ratings yet

- Section 6 - CMRDocument4 pagesSection 6 - CMRokolofo ojonugwaNo ratings yet

- Appendix D - RIIDocument4 pagesAppendix D - RIIokolofo ojonugwaNo ratings yet

- A320 NE0 Fuel or Hydraulic or Oil Leakage LimitsDocument19 pagesA320 NE0 Fuel or Hydraulic or Oil Leakage LimitsArjuna SamaranayakeNo ratings yet

- LPT Shaft InspectionDocument6 pagesLPT Shaft InspectionSonny RaymundoNo ratings yet

- 100 HourDocument9 pages100 HoursibolelNo ratings yet

- 72-00-00-200-008-A - Inspection - Check After The Engine Has Exceeded The Operational LimitsDocument16 pages72-00-00-200-008-A - Inspection - Check After The Engine Has Exceeded The Operational Limits尹兴旺No ratings yet

- Cleaning of Contact Points and Wiring HarnessesDocument3 pagesCleaning of Contact Points and Wiring HarnessesRafa Montes MOralesNo ratings yet

- Tasks Ferramentas B727Document14 pagesTasks Ferramentas B727Ivo SilvaNo ratings yet

- 1APMMBKDocument1,647 pages1APMMBKmarioNo ratings yet

- Saudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDocument4 pagesSaudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDilshad Ahemad100% (1)

- Throttle Linkage CheckDocument4 pagesThrottle Linkage Checkjbert55No ratings yet

- Bettis NG SeriesDocument2 pagesBettis NG SeriesNazim SalehNo ratings yet

- Alert: Service BulletinDocument34 pagesAlert: Service BulletinCristiano Poças MolarNo ratings yet

- 05-10-1 C InspectionDocument14 pages05-10-1 C InspectionAldo CarmonaNo ratings yet

- Site Acceptance Test (SAT) Protocol: Project No. 2205 100 GPM Amine Sweetening Unit PlantDocument28 pagesSite Acceptance Test (SAT) Protocol: Project No. 2205 100 GPM Amine Sweetening Unit PlantIsaias de la CruzNo ratings yet

- DAILY CHECK Rev 9Document9 pagesDAILY CHECK Rev 9Samirnov IcNo ratings yet

- Chapter 7 - Ai: ParagraphDocument4 pagesChapter 7 - Ai: Paragraphchiri003No ratings yet

- 05-51-00 DVI 10000-002 Dvi of Parked Aircraft After Wind Exceeded Limitation 1 JUL14Document21 pages05-51-00 DVI 10000-002 Dvi of Parked Aircraft After Wind Exceeded Limitation 1 JUL14Jhon LaverdeNo ratings yet

- Maintenance Manual HTCM-002: Helicopter Technology CompanyDocument45 pagesMaintenance Manual HTCM-002: Helicopter Technology CompanyrobbertmdNo ratings yet

- ATA Task CodeDocument118 pagesATA Task CodeStalin DavidNo ratings yet

- ATA 61 Turbohelice PT6Document12 pagesATA 61 Turbohelice PT6Daniel Vásquez Cabrera100% (1)

- Weekly Check: AIRBUS A320-214 & A320-232 Maintenance Check ListDocument5 pagesWeekly Check: AIRBUS A320-214 & A320-232 Maintenance Check ListMuskan GuptaNo ratings yet

- 600 Hour InspectionDocument1 page600 Hour InspectionAdielNo ratings yet

- Control Gear Exhaust AHUs enDocument14 pagesControl Gear Exhaust AHUs enlsaishankarNo ratings yet

- HPT Stage 1 Blades and Duct SegmentsDocument28 pagesHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekNo ratings yet

- 5-12-05 Inspection Phase 5Document12 pages5-12-05 Inspection Phase 5Lady Laura Sierra RuizNo ratings yet

- FD Dci 001 Daily CheckDocument7 pagesFD Dci 001 Daily ChecksubinperuvallurNo ratings yet

- Airframe-Mounted Oil-Tank Drain Valve - Removal/InstallationDocument6 pagesAirframe-Mounted Oil-Tank Drain Valve - Removal/InstallationAdrian LauNo ratings yet

- CFM56 5B Esm Rev 72-32-20-200-001-PGK08-001-0 TSN.78 R 20220315Document5 pagesCFM56 5B Esm Rev 72-32-20-200-001-PGK08-001-0 TSN.78 R 20220315Mochsella Bramantio -No ratings yet

- Amm72 00 00 06Document234 pagesAmm72 00 00 06Ale Torrico TamayoNo ratings yet

- Ceb A-72-7002Document7 pagesCeb A-72-7002turboshaftNo ratings yet

- Commercial Engine Bulletin: Engine, Combustion Assembly - Inspection of Outer COMBUSTION CASE P/N M250 - 10404Document8 pagesCommercial Engine Bulletin: Engine, Combustion Assembly - Inspection of Outer COMBUSTION CASE P/N M250 - 10404turboshaftNo ratings yet

- MODEL 206 SERIES (1977 - 1986) : Listing of Supplemental Inspections 1. Supplemental Inspection ProceduresDocument4 pagesMODEL 206 SERIES (1977 - 1986) : Listing of Supplemental Inspections 1. Supplemental Inspection ProceduresAlejandro TorresNo ratings yet

- AMM Engine Master Chip Detector IndicatorDocument4 pagesAMM Engine Master Chip Detector Indicatorsyedumarahmed52No ratings yet

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitDocument2 pagesInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadNo ratings yet

- Temporary Revision: Aircraft Maintenance ManualDocument8 pagesTemporary Revision: Aircraft Maintenance Manualanon_18148243No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- 05-10-2 C InspectionDocument7 pages05-10-2 C InspectionAldo CarmonaNo ratings yet

- SECTION 14 - Combustion Chamber AssemblyDocument4 pagesSECTION 14 - Combustion Chamber AssemblyMichael CrivellariNo ratings yet

- 05-10-1 B InspectionDocument12 pages05-10-1 B InspectionAldo CarmonaNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 5Document32 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 5anony8103100% (1)

- Oil Filter 2Document5 pagesOil Filter 2Rameswar PradhanNo ratings yet

- SP7021M00U18 000 A PDFDocument3 pagesSP7021M00U18 000 A PDFPedro Casimiro GámizNo ratings yet

- LPT Case Piping InspectionDocument7 pagesLPT Case Piping InspectionSonny RaymundoNo ratings yet

- Operational Check of RAT Manual Deployment and Functional Check of RAT Using PDFDocument20 pagesOperational Check of RAT Manual Deployment and Functional Check of RAT Using PDFVladimir AmayaNo ratings yet

- Forma 061 - Insp. Semanal Motor Compressor Wash Aw119Document3 pagesForma 061 - Insp. Semanal Motor Compressor Wash Aw119William OnofreNo ratings yet

- Manual Title Manual Number - Paper Copy Temporary Revision NumberDocument106 pagesManual Title Manual Number - Paper Copy Temporary Revision NumberMijahil Yllescas MarquezNo ratings yet

- 5-12-04 Inspection Phase 4Document2 pages5-12-04 Inspection Phase 4Lady Laura Sierra RuizNo ratings yet

- Operations MotorDocument203 pagesOperations MotorjohnNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Pink and White PresentationDocument25 pagesPink and White PresentationAngela María SarmientoNo ratings yet

- Literary GenresDocument8 pagesLiterary GenresAnne Nicole CruzNo ratings yet

- Tobii Studio 1.X User ManualDocument116 pagesTobii Studio 1.X User ManualKingHodorNo ratings yet

- John Paulding MuseumDocument4 pagesJohn Paulding Museumapi-316020003No ratings yet

- Masurare Grosime Vopsea 1 - Fisa-tehnica-Extech-CG204Document1 pageMasurare Grosime Vopsea 1 - Fisa-tehnica-Extech-CG204RizzoRo1No ratings yet

- TTMA RP 32 EngDocument3 pagesTTMA RP 32 Englinh caca huynhNo ratings yet

- PBL Marketing Rahul YadavDocument8 pagesPBL Marketing Rahul YadavVIVEKANAND MISHRANo ratings yet

- IOT Door Buzzer & Home Security DeviceDocument5 pagesIOT Door Buzzer & Home Security Devicekutty vickyNo ratings yet

- Notice Requesting Pre-Qualification Packages12531-0 PDFDocument3 pagesNotice Requesting Pre-Qualification Packages12531-0 PDFjubo99No ratings yet

- Computer Science Lesson Plan Week 2-PracticalDocument3 pagesComputer Science Lesson Plan Week 2-PracticalIshrat JehanNo ratings yet

- Privacy Protection Based Access Control Scheme in Cloud-Based Services - 1crore ProjectsDocument5 pagesPrivacy Protection Based Access Control Scheme in Cloud-Based Services - 1crore ProjectsLalitha PonnamNo ratings yet

- PSTC-Appendix C - Cleaning Test SurfacesDocument4 pagesPSTC-Appendix C - Cleaning Test SurfacesChung LeNo ratings yet

- Patrol Central Infrastructure Best Practices GuideDocument104 pagesPatrol Central Infrastructure Best Practices GuideVINAYNo ratings yet

- Følstad & Brandtzaeg (2020)Document14 pagesFølstad & Brandtzaeg (2020)Ijlal Shidqi Al KindiNo ratings yet

- Anomaly Detection Using Machine LearningDocument4 pagesAnomaly Detection Using Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Transcript For Internal Controls For Cash and Cash Equivalents VideoDocument3 pagesTranscript For Internal Controls For Cash and Cash Equivalents VideoAsenathi SandisoNo ratings yet

- Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements ForDocument9 pagesSteel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements FormuhammadNo ratings yet

- Dividend PolicyDocument26 pagesDividend PolicyAnup Verma100% (1)

- Louis Vuitton Out Let On Lines LVDocument24 pagesLouis Vuitton Out Let On Lines LVLiu DehuaNo ratings yet

- Nur Shazleen Afina 2021794579 Forum DiscussionDocument4 pagesNur Shazleen Afina 2021794579 Forum DiscussionNur Shazleen AfinaNo ratings yet

- Engineering Mechanics: StaticsDocument44 pagesEngineering Mechanics: StaticsDaya AhmadNo ratings yet

- Mid Term Y2017 ACTL3151Document14 pagesMid Term Y2017 ACTL3151Zahid KhanNo ratings yet

- National Food Safety Standard - General Safety Requirements On Food Contact Materials and ArticlesDocument4 pagesNational Food Safety Standard - General Safety Requirements On Food Contact Materials and ArticlesShariq HaiderNo ratings yet

- UBG 04LX F01 Datasheet2Document6 pagesUBG 04LX F01 Datasheet2malirezazadeh5549No ratings yet

- There Are 4 Way Is The Factor AnalysisDocument8 pagesThere Are 4 Way Is The Factor Analysisapi-279431750No ratings yet

- Triple Screw PumpsDocument2 pagesTriple Screw PumpsSaravanan SelvaNo ratings yet

- The T.J. HopperDocument2 pagesThe T.J. HopperMadison MonzonNo ratings yet

- Dezurik Cast Stainless Steel Knife Gate Valves KGN RSB KGN Msu KGN RSB Resilient Seated Technical 29-00-1dDocument8 pagesDezurik Cast Stainless Steel Knife Gate Valves KGN RSB KGN Msu KGN RSB Resilient Seated Technical 29-00-1dOleg ShkolnikNo ratings yet