Professional Documents

Culture Documents

T013515001V0F1

T013515001V0F1

Uploaded by

haseebrazvi1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T013515001V0F1

T013515001V0F1

Uploaded by

haseebrazvi1Copyright:

Available Formats

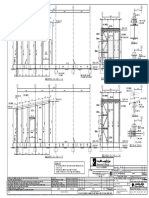

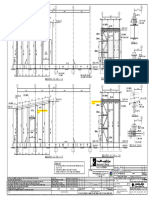

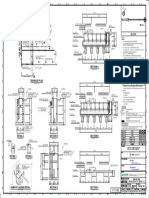

UP -------------------- STANDARD DETAIL REFERENCE DRAWINGS

| BILL OF MATERIAL |

DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

-------------------- CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING AD-036627

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

AWAY AWAY

N PT NPD INSULATION DETAILS FOR HOT PIPING

INSULATION DETAILS FOR COLD PIPING

AA-036911

AA-036913

NO DESCRIPTION (IN) CMDTY CODE QTY INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

-- PIPE ----------- -- ----- ---- ---

----

TOWARD TOWARD

1 PIPE SCH 80 SEAMLESS, BE API 5L GR.B PSL 2 P_3LE2P021 5.312 M

2, (INTERNAL FBE LINED) (NACE

DOWN

MR-0175/ISO 15156), ASME B36.10M

NOTES

FITTINGS 1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

-------- FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

2 90 DEG LR ELBOW SCH 80 SEAMLESS, BW, 2 E_3LE2P021 4 2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

ASTM A234 GR.WPB, (INTERNAL FBE 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

2 LINED) (NACE MR-0175/ISO 15156), ASME 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO C OR FACE OF FLANGES.

(B) BOLT HOLES ON FLANGES STRADDLE C. (C) WELDING ELBOWS ARE LONG RADIUS.

B16.9

5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION

01-SAMSS-10.

FLANGES

6. GASKET ALLOWANCE PER SPEC

F3 -------

7. PIPING MATERIAL IS PER BOM

146

3 FLANGE CLASS 300, SCH 80, WN, RF ASTM 2 F3_1LE2P021 10

PIPE SIZE SCHEDULE SPECIFICATION

A105N, (INTERNAL FBE LINED) (NACE

MR-0175/ISO 15156), ASME B16.5

F3 G4 B5

GASKETS

-------

4 4.5 MM THK GASKETS SPIRAL-WOUND, SS316 2 G3_5CS9U2 6

WINDINGS, FLEXIBLE GRAPHITE FILLED,

2

8. WELDING STRESS RELIEF - YES NO

PER SAES-W-011 TABLE 17.6.2.1

21

WITH SS316 OUTER RING, ASME B16.20, 100% X-RAY SPOT X-RAY 01-SAMSS-10

ASME B16.5, CL 300

9. TESTING SHOP HYDROSTATIC TEST - YES NO

THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS

1

BOLTS FLANGED. HYDROSTATIC TEST PRESSURE PER HYDROTEST DIAGRAM

----- 10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING

5 BOLTING ASTM A193 GR.B7M STUD BOLTS, 5/8 B_9CS9P1 48 SPECIFICATION SAES-L-105 CLASS 3LE2P02 .

458

ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

SEMI-FINISHED HEAVY PATTERN, ASTM

A194 GR.2HM, W/2 HEAVY HEX NUTS,

1

11. INSULATION

95.0MM BOLT LENGTH INSULATION TYPE & THK. ON DWG.

12. TIE-IN LOCATIONS AND DETAILS SHALL BE FIELD VERIFIED BEFORE START OF WORK.

VALVES/IN-LINE ITEMS 13. FOR SMALL BORE LINES (UPTO 1-1/2") DIMENSIONS, ROUTING & SUPPORTING SHALL

-------------------- BE FIELD ADJUSTED.

6 GATE VALVE CLASS 300 RF, FLANGED, BODY: 2 VA_3LE2P023 1 14. ALL DIMENSIONS AND COORDINATES ARE IN MM. CONTRACTOR TO FIELD VERIFY ALL

ASTM A351 GR.CK3MCUN, UNS S31254, DIMENSIONS PRIOR TO CONSTRUCTION.

15. FOR INTERNAL LINED PIPE, LINING SHALL BE DONE AFTER SPOOL FABRICATION

ALLOY-6 HARD FACED SEAT, OS&Y, SOLID

& COMPLETION OF ALL HOT WORKS.

WEDGE, GRAPHITE PACKING, API 600,

16. FOR GALVANIZED PIPE, GALVANIZING SHALL BE DONE AFTER SPOOL FABRICATION

(NACE MR-0175/ISO 15156)

& COMPLETION OF ALL HOT WORKS.

146 PIPE SUPPORTS

------------- SPOOLS TO BE FABRICATED BY VENDOR

F3 7 PIPE SUPPORT 2 GL01-2 1 NO. WEIGHT NO. WEIGHT

MARK NO. SIZE MARK NO. SIZE

PIECES LBS PIECES LBS

F3

F3 G4 B5

EL.103639 2 2

F3 G4 B5

14

6

EL.103030 S7

35

359

8

1

GL01-2

SPOOLS TO BE FABRICATED BY SAUDI ARAMCO

F3 NO.

MARK NO. SIZE

NO.

MARK NO. SIZE

1 PIECES PIECES

31

08

F3 G4 B5

2

2"NS

REFERENCE DRAWINGS

F3 G4 B5

CONT.ON DWG. CONTROL FOR J.O. 10-12862-0001 TD-718027

2"-WBD-14614-3LE2P02

2"NS

2"-WBD-14615-3LE2P02-N_01 146 PIPING PLAN BA-752286

/ B97 HYDROTEST DIAGRAM TA-011935001

1

1897

013517-001

DWG. NO. BA-752286

E 215630

N 373373

EL.103276 F3 G4 B5

216

6 REVISION VALIDATION

VALVE STEM SOUTH THIS REVISION NO. IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

0F1

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

CONT.ON 10-12862-0001-029

SHT 2 DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

E 215963 ENG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

FAW LAK ASD AHB

N 370109 06/12/23 06/12/23 06/12/23 06/12/23

EL.100913 REV.NO.DATE REVISION DESCRIPTION

0F1 06/12/23 ISSUED FOR CONSTRUCTION

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

10-12862-0001 CONSTRUCTION UNTIL CERTIFIED AND DATED

STRESS SYSTEM (SYS-) NA

PIPING CLASS 3LE2P02 SAUDI ARABIAN OIL COMPANY

DRAWING TYPE

P & ID No. BA-747596001 ISO 2"-WBD-14614-3LE2P02-B97

ISO

OPER/DESN PRESS.(psig) 424 / 506

INLET & GAS TREATMENT SHAYBAH

OPER/DESN TEMP.( F) 108 / 200

INLET FACILITIES

FLUID PHASE LIQUID

MODULE NO: SHAYBAH SAUDI ARABIA

PAINT SPEC (APCS-) 1D

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

LINE ID B97-WBD-14614-B97-01

B97 L TB-013515 001 0F1

Saudi Aramco 5994 ENG. (09/03)

RESTRICTED VECTOR CADD-05

20/03/2024 10:33:01 Wison

You might also like

- d6n Hydraulic Ds PilotDocument2 pagesd6n Hydraulic Ds PilotEmmanuel solomonNo ratings yet

- Naked Mole RatDocument1 pageNaked Mole RatIisha karmela AldayNo ratings yet

- TH360B TH560B - CAT - Hydr System.Document2 pagesTH360B TH560B - CAT - Hydr System.Zeck33% (3)

- Calibration - Qualification and ValidationDocument60 pagesCalibration - Qualification and ValidationPardeep Kumar100% (1)

- Caterpillar 3406BDocument2 pagesCaterpillar 3406BAnner Moreno Garcia100% (1)

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- T013482002V0F1Document1 pageT013482002V0F1haseebrazvi1No ratings yet

- T013461001V0F1Document1 pageT013461001V0F1haseebrazvi1No ratings yet

- T013519001V0F1Document1 pageT013519001V0F1haseebrazvi1No ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- T013458001V0F1Document1 pageT013458001V0F1haseebrazvi1No ratings yet

- T013482001V0F1Document1 pageT013482001V0F1haseebrazvi1No ratings yet

- T013514003V0F1Document1 pageT013514003V0F1haseebrazvi1No ratings yet

- R901085031P00Document1 pageR901085031P00Rene HebaNo ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- R82-002 - Done 5Document1 pageR82-002 - Done 5rsmjuleyNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- R901085028P00Document1 pageR901085028P00Rene HebaNo ratings yet

- R901085032P00Document1 pageR901085032P00Rene HebaNo ratings yet

- D43 P 11004 21 - Rev02fDocument1 pageD43 P 11004 21 - Rev02fSajeed ZaheerNo ratings yet

- C254977001P Rev01cDocument1 pageC254977001P Rev01cRAJA MOHD IRFAN KHANNo ratings yet

- SF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsDocument2 pagesSF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsSENTHILNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- SF6-A-100-450-100-6-CS: Bill of MaterialsDocument7 pagesSF6-A-100-450-100-6-CS: Bill of MaterialsSENTHILNo ratings yet

- M-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Document1 pageM-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Hesi KusumaNo ratings yet

- C533131003VDocument1 pageC533131003VMohamed Wasim ShaikhNo ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument11 pagesBill of Materials: Standard Detail Reference DrawingsSENTHILNo ratings yet

- M-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Document1 pageM-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Hesi KusumaNo ratings yet

- M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Document1 pageM-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Hesi KusumaNo ratings yet

- Notes: M-CB-767101-A-0865 00 004Document1 pageNotes: M-CB-767101-A-0865 00 004Hesi KusumaNo ratings yet

- BB 016304 001Document1 pageBB 016304 001Abir MohdNo ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument8 pagesBill of Materials: Standard Detail Reference Drawingsadeelaslam1211No ratings yet

- M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnDocument1 pageM-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnHesi KusumaNo ratings yet

- Mark Up Priority 5Document11 pagesMark Up Priority 5SAGARNo ratings yet

- 9 13 Notes:: Construction IssueDocument1 page9 13 Notes:: Construction IssueХөгжилтэй ЗугаатайNo ratings yet

- Hug 98 104071 CS 2358 00001 0003 01Document1 pageHug 98 104071 CS 2358 00001 0003 01anandNo ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- Anchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedDocument1 pageAnchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedbillNo ratings yet

- 980H PDFDocument2 pages980H PDFIgnacio Lazo JhsúsNo ratings yet

- Twby 07 10048 0007 - 2 - Ifc - 2019 07 26 - 01Document1 pageTwby 07 10048 0007 - 2 - Ifc - 2019 07 26 - 01aung aungNo ratings yet

- X 7305 1973 GMC Truck Wiring Manual CK 10 30 Pgs OnlyDocument4 pagesX 7305 1973 GMC Truck Wiring Manual CK 10 30 Pgs OnlyStreloc MarcadoNo ratings yet

- WHP121 ASFCA 10 Q0103 0001 Rev.20Document3 pagesWHP121 ASFCA 10 Q0103 0001 Rev.20Minh DoNo ratings yet

- Component Locations: Hydraulic System 730 Ejector Articulated TruckDocument2 pagesComponent Locations: Hydraulic System 730 Ejector Articulated Truckmrcruzito_2099No ratings yet

- 321d Esquema Hidraulico Excavadora CatDocument2 pages321d Esquema Hidraulico Excavadora CatWilson CamachitoNo ratings yet

- HUG 98 104071 CS 2358 00001 0003 01 CommentedDocument1 pageHUG 98 104071 CS 2358 00001 0003 01 CommentedanandNo ratings yet

- Cat - Dcs.sis - Controller Shema Hydrolic de TH 360 SleDocument2 pagesCat - Dcs.sis - Controller Shema Hydrolic de TH 360 SleLhsan Rajawi100% (1)

- QT1-0-C-UZR-01-00027 - 2 - Trestle Pier Drainage Plan & SectionDocument1 pageQT1-0-C-UZR-01-00027 - 2 - Trestle Pier Drainage Plan & SectionĐỨC ĐOÀN NGỌCNo ratings yet

- Planos Electricos Invertex 2 Serie 31875 UpDocument23 pagesPlanos Electricos Invertex 2 Serie 31875 UpHéctorHernándezDíazNo ratings yet

- 416 eDocument2 pages416 earmando vara chavezNo ratings yet

- Condensate Water Recovery SchematicDocument1 pageCondensate Water Recovery SchematicAmando GonzalesNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- 904-AR-301 Rev 1Document1 page904-AR-301 Rev 1OmarNo ratings yet

- 320dlrr HydraulicDocument2 pages320dlrr HydraulicEmmanuel solomonNo ratings yet

- For Approval: Isometric ViewDocument1 pageFor Approval: Isometric Viewgmyktw7crrNo ratings yet

- List of Typical Drawing - Nabi KarimDocument30 pagesList of Typical Drawing - Nabi Karimvarun sainiNo ratings yet

- Angloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Document1 pageAngloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Pedro ChaucaNo ratings yet

- HS523217-63-CIV-DTL-0001-0001 REV4-ModelDocument1 pageHS523217-63-CIV-DTL-0001-0001 REV4-ModelAlparslan GureNo ratings yet

- HS523217-63-CIV-DTL-0001-0001 REV4-Model PDFDocument1 pageHS523217-63-CIV-DTL-0001-0001 REV4-Model PDFAlparslan GureNo ratings yet

- 143H and 163H Motor Grader Hydraulic System Ripper AttachmentDocument2 pages143H and 163H Motor Grader Hydraulic System Ripper AttachmentMohamed Harb100% (1)

- Seaoil LubricantsDocument1 pageSeaoil LubricantsCasmir TayagNo ratings yet

- 2326 B 0019Document5 pages2326 B 0019Anonymous AA30q4No ratings yet

- DC Ranger 2008 PDFDocument33 pagesDC Ranger 2008 PDFPecheche CabreraNo ratings yet

- T013514003V0F1Document1 pageT013514003V0F1haseebrazvi1No ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- Kent STructural Engineer JobDocument1 pageKent STructural Engineer Jobhaseebrazvi1No ratings yet

- UMTS Access KPI Troubleshooting Guide - RRCDocument49 pagesUMTS Access KPI Troubleshooting Guide - RRCAdhitya RamdhaniNo ratings yet

- 04.port Said To CanakkaleDocument2 pages04.port Said To CanakkaleAlexandru Visan100% (1)

- Bellwork: 1. Write An Equation of The Line in Slope-Intercept Form. y 4x - 3Document8 pagesBellwork: 1. Write An Equation of The Line in Slope-Intercept Form. y 4x - 3Mrs. HedrickNo ratings yet

- 2011 Maserati GranTurismo MC Stradale Technical PresentationDocument58 pages2011 Maserati GranTurismo MC Stradale Technical PresentationWyattNo ratings yet

- DanielMartins ThesisDocument114 pagesDanielMartins ThesisHamedNo ratings yet

- SSD TC 3 7 Prehistory and Archaeology StudentDocument25 pagesSSD TC 3 7 Prehistory and Archaeology StudentyokirendrapriyantokoNo ratings yet

- ERACS JournalDocument8 pagesERACS Journalmahasiswaprofesi2019No ratings yet

- Mathematics 11 2021-22 Term 1 SyllabusDocument4 pagesMathematics 11 2021-22 Term 1 SyllabusBetaBeast12No ratings yet

- Mohsmicrographic Surgerytechnique: Paul X. Benedetto,, Christine Poblete-LopezDocument11 pagesMohsmicrographic Surgerytechnique: Paul X. Benedetto,, Christine Poblete-LopezDaniel Holthausen NunesNo ratings yet

- Analog Drive Control Module (DSZA)Document11 pagesAnalog Drive Control Module (DSZA)PradeepNo ratings yet

- Lecture On Asphalt2Document39 pagesLecture On Asphalt2Stephen Dela CruzNo ratings yet

- Tablet of MaqsudDocument44 pagesTablet of MaqsudMarco Oliveira100% (1)

- South Africa CMV Viral Load Testing May2015Document4 pagesSouth Africa CMV Viral Load Testing May2015EnergadeNo ratings yet

- Lecture 8 Chapter 10 Weldin Joints 12 - 3 - 2020Document20 pagesLecture 8 Chapter 10 Weldin Joints 12 - 3 - 2020Adnan WattooNo ratings yet

- Btech Me R17 MPDocument101 pagesBtech Me R17 MPSRKR AMENo ratings yet

- English 7 HandoutDocument5 pagesEnglish 7 HandoutMarie Kris MolinaNo ratings yet

- Berkeleyworks: The Art of Berkeley Breathed - From Bloom County and Beyond PreviewDocument16 pagesBerkeleyworks: The Art of Berkeley Breathed - From Bloom County and Beyond PreviewGraphic Policy0% (1)

- Ee202laplacetransform PDFDocument85 pagesEe202laplacetransform PDFFairusabdrNo ratings yet

- Mechanism of Plastic DeformationDocument7 pagesMechanism of Plastic Deformationrujikulo hunterNo ratings yet

- Reaffirmed 1995Document37 pagesReaffirmed 1995Jainco Transmission LimitedNo ratings yet

- Boxing Bag Gloves Price LIstDocument11 pagesBoxing Bag Gloves Price LIstIresha UdayangiNo ratings yet

- Quick Review of The First Operation: 1. Select Signifier (Or Significator) CardDocument4 pagesQuick Review of The First Operation: 1. Select Signifier (Or Significator) CardAsh RNo ratings yet

- Harnois Greenhouse Catalogue 2018Document395 pagesHarnois Greenhouse Catalogue 2018D MNo ratings yet

- Sci 6 DLL Week 6 q4Document11 pagesSci 6 DLL Week 6 q4Christinne Anne LupoNo ratings yet

- Mil HDBK 1013 08Document73 pagesMil HDBK 1013 08mariodoreNo ratings yet

- In Style: TravelDocument1 pageIn Style: Travelapi-245791728No ratings yet

- Lecture 9 NotchesDocument25 pagesLecture 9 NotchesCh ZainNo ratings yet