Professional Documents

Culture Documents

430 Actuator Centering

430 Actuator Centering

Uploaded by

beommokooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

430 Actuator Centering

430 Actuator Centering

Uploaded by

beommokooCopyright:

Available Formats

Print Exit

Copyright Ferrari S.p.A. - P.IVA 00159560366

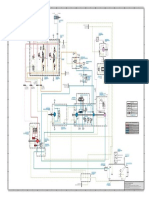

D6.08 Centring the gear shift-selection actuator lever (finger)

Centring the gear shift-selection actuator lever (finger)

The procedure to centre the lever may be carried from underneath the car, after removing the gear engagement-selection

actuator.

Remove the gear engagement-selection hydraulic actuator ( D6.05).

To centre the lever correctly, the tool (AV 3271) must be fitted

with the nine centring dowels (A), which more precisely locate

tool on the contact surface of the actuator body and the

machined area (X), to prevent contact with the sensor located

inside the F1 gearbox actuator.

The modification (X) must be made using the measurements

given in the figure as reference.

The modification (X) must be made using the measurements

given in the figure as reference.

Loosen the screw (1 fastening )the lever mount onto the control

rod.

Measure the diameter (D of the spherical end of the lever with

a )micrometer: the new, nominal diameter ranges between

14.75 and 14.85 mm.

This measurement is necessary to work out the thickness of the shim to be inserted between the finger's terminal ball joint

and the tool's resting surface, according to the read diameter.

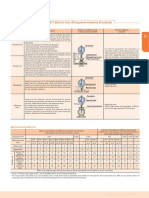

The table indicates the correct shim (S) to be installed for the diameter (D measured):

If the diameter read is not within the values listed, determine the correct shim (S) to be installed following the same ratios

used in the table (eg: with D= 14.90 use a shim S= 0.10, with D= 14.70 use S= 0.30).

Thickness values

Diameter (D) Thickness (S)

(mm) 14.75 0.25

14.8 0.2

14.85 0.15

Tightening torque Nm Class

Gearbox control lever (finger) - rod Screw 32 Nm A

Fit the tool (AV 3271) on the actuator

Fit the blade (B) of a feeler gauge of the thickness calculated

between the spherical end of the lever and the contact

surface on the tool: Push the lever's end against the tool.

In this position, with the shim (B) still installed, tighten the screw

and ensure that the solenoid valves are still activated.

Tightening torque Nm Class

Screw 32 Nm A

Check again that the clearance between the lever and the tool

corresponds with the defined shim size.

Refit the gear engagement-selection actuator ( D6.05).

Carry out the gearbox self-learning cycle.

Check that the value for engagement travel is correct.

The centring value must be correct within ± 3°.

You might also like

- Study On Tool Pre-Setter: Fig. 1. Different Offset For Different ToolsDocument5 pagesStudy On Tool Pre-Setter: Fig. 1. Different Offset For Different ToolsAnonymous 5AmJ13mLkNo ratings yet

- 430 Ope 10-4changedDocument20 pages430 Ope 10-4changedNéstor CastilloNo ratings yet

- Work 2Document5 pagesWork 2David DanielNo ratings yet

- Alignment of The Tool Turret MT-HT-E en V2xDocument10 pagesAlignment of The Tool Turret MT-HT-E en V2xAdnan MehmoodNo ratings yet

- LAB Content - PH1016Document24 pagesLAB Content - PH1016son caoNo ratings yet

- 7.4 GraphcalcDocument1 page7.4 GraphcalcLila AlwaerNo ratings yet

- LAB ContentDocument24 pagesLAB Contenttrantienson2707No ratings yet

- Measurement of Lines & SurfacesDocument84 pagesMeasurement of Lines & Surfacessushil.vgiNo ratings yet

- Torsion TestDocument4 pagesTorsion Testsrujan varma kaithojuNo ratings yet

- CE331 - Lab Report 3Document2 pagesCE331 - Lab Report 3Aman JainNo ratings yet

- Physics Labwork: For MechanicsDocument24 pagesPhysics Labwork: For MechanicsSang NguyễnNo ratings yet

- Angular MeasurementDocument19 pagesAngular MeasurementswarnnaNo ratings yet

- Touch ProbesDocument40 pagesTouch ProbesmarchmtetNo ratings yet

- Different Probe Use enDocument34 pagesDifferent Probe Use enkravchenkovdimNo ratings yet

- Heidenhain 920Document68 pagesHeidenhain 920Angel Alvarez CarrilloNo ratings yet

- Torsion TestDocument3 pagesTorsion Testmjayrajsharma19No ratings yet

- Ch-25 Measurement of Lines - SurfacesDocument92 pagesCh-25 Measurement of Lines - SurfacesManojNo ratings yet

- M 14 0005 PDFDocument5 pagesM 14 0005 PDFrolandNo ratings yet

- Armado Caja Diferen YarisDocument3 pagesArmado Caja Diferen YarisDouglas DuarteNo ratings yet

- HNC-21T ProgramDocument86 pagesHNC-21T ProgramLuna SDNo ratings yet

- Mechanical Planimeter PDFDocument12 pagesMechanical Planimeter PDFchristianvanNo ratings yet

- 1.7 Backlash TechnicalData KGSTOCKGEARSDocument5 pages1.7 Backlash TechnicalData KGSTOCKGEARSGanapathy SubramaniamNo ratings yet

- Angular MeasurementDocument9 pagesAngular MeasurementAnish AmanNo ratings yet

- Ex 2metrologyDocument6 pagesEx 2metrologyPiyush ChaulaNo ratings yet

- Test Indicator BasicsDocument12 pagesTest Indicator Basicskostas mauroNo ratings yet

- Dial IndicatorDocument15 pagesDial IndicatorDhaval MaheshwariNo ratings yet

- Dial Indicator Standard B7503: 2011 (Extract From JIS/Japanese Industrial Standards)Document1 pageDial Indicator Standard B7503: 2011 (Extract From JIS/Japanese Industrial Standards)NGuyenThaiNo ratings yet

- Ta/Tb Direct Input of Offset Value Measured B For 2 Spindle LatheDocument13 pagesTa/Tb Direct Input of Offset Value Measured B For 2 Spindle LathemikeNo ratings yet

- CNC - Chapter 11 - Offsets & Polar Coordinate SystemDocument10 pagesCNC - Chapter 11 - Offsets & Polar Coordinate Systembarbu ioanNo ratings yet

- Alin.-51-100Document50 pagesAlin.-51-100Edgar MedinaNo ratings yet

- Mit (T) MQC Sy (B.Tech)Document10 pagesMit (T) MQC Sy (B.Tech)Kishor PatilNo ratings yet

- 10 InstDocument12 pages10 InstreretreNo ratings yet

- Screw Gauge 4Document3 pagesScrew Gauge 4Uchiha ItachiNo ratings yet

- Lab - Manual - 8 - MECH 350Document3 pagesLab - Manual - 8 - MECH 350FANo ratings yet

- 21 Me 435,435,435,435Document40 pages21 Me 435,435,435,435Faisal MehrbanNo ratings yet

- Belt Drive and Belt FrictionDocument6 pagesBelt Drive and Belt FrictionAmeer HamzaNo ratings yet

- Engineering Metrology: Prof. J. RamkumarDocument44 pagesEngineering Metrology: Prof. J. RamkumarSachin AnguralNo ratings yet

- Basic CNC Programming V2Document76 pagesBasic CNC Programming V2nuzul hamdaniNo ratings yet

- Bell CrankDocument4 pagesBell CrankRajuKumar100% (1)

- Adjustment: LEXUS Hand Held TesterDocument7 pagesAdjustment: LEXUS Hand Held TesteranzorNo ratings yet

- Calibracion 1C EnglishDocument5 pagesCalibracion 1C EnglishJuan BrunoNo ratings yet

- HT - Part Probe CalibrationDocument5 pagesHT - Part Probe CalibrationCarbon JackNo ratings yet

- FIRST Global Gear GuideDocument13 pagesFIRST Global Gear Guidetapas ranjan jenaNo ratings yet

- All Types: Edition AnglaiseDocument3 pagesAll Types: Edition AnglaiseMihaela SuteuNo ratings yet

- ABC11Document7 pagesABC11Ahmad SaeedNo ratings yet

- Shaft AlignmentDocument44 pagesShaft Alignmentrodolfosti100% (1)

- Straightness Measurement Using AutocollimatorDocument5 pagesStraightness Measurement Using Autocollimatorविशाल पुडासैनीNo ratings yet

- MMI Lab ManualDocument46 pagesMMI Lab ManualArvind KumarNo ratings yet

- Valve Clearance (1Hz, 1Hd T) : InspectionDocument4 pagesValve Clearance (1Hz, 1Hd T) : InspectionArief SoehartoNo ratings yet

- MMM Ex 2 and 3Document6 pagesMMM Ex 2 and 3SANDEEP BUDANIANo ratings yet

- E1 Q EnglishDocument12 pagesE1 Q English66 SB jay gotiNo ratings yet

- FD QG Po 013 IntDocument36 pagesFD QG Po 013 Intherysyam1980No ratings yet

- Lab No 3Document4 pagesLab No 3qadir aliNo ratings yet

- Bending Moment Experiment 7Document6 pagesBending Moment Experiment 7Law Yong CingNo ratings yet

- Attachment 1638181293Document5 pagesAttachment 1638181293Faizan AlyNo ratings yet

- Proj 2021-2Document5 pagesProj 2021-2RAUL J COLON-OLIVERASNo ratings yet

- Lecture 4 RDDocument28 pagesLecture 4 RDasr8948222209No ratings yet

- 3d-Finder Manual R04 ENGDocument13 pages3d-Finder Manual R04 ENGAlexandru BuduNo ratings yet

- Sigma ComparatorDocument4 pagesSigma ComparatorJonathan SequeiraNo ratings yet

- And Forhed Parts, Modified Acrylic Base, Honolitmc. Propagation RssistantDocument5 pagesAnd Forhed Parts, Modified Acrylic Base, Honolitmc. Propagation RssistantIlyan MaiaNo ratings yet

- Sluice CatalogueDocument40 pagesSluice CatalogueLungisaniNo ratings yet

- Carbon and Stainless Steel Flanges - ASME ANSI Class 150Document1 pageCarbon and Stainless Steel Flanges - ASME ANSI Class 150Ross KingNo ratings yet

- DG450 Hook Instruction ManualDocument12 pagesDG450 Hook Instruction ManualMohamed el attar0% (1)

- The Efficient Niti System: User InformationDocument28 pagesThe Efficient Niti System: User InformationPRDAkNo ratings yet

- ClutchDocument24 pagesClutchJayson B. Cadelina100% (1)

- Hardware Schedule: Hafr Al Batin Project Add'LDocument2 pagesHardware Schedule: Hafr Al Batin Project Add'LBilal AhmedNo ratings yet

- M GN 350Document30 pagesM GN 350Integrity EngineerNo ratings yet

- Technidal Date Sheet of PumpDocument1 pageTechnidal Date Sheet of Pumpkev YNo ratings yet

- DSR-2014 in MS ExcelDocument646 pagesDSR-2014 in MS ExcelSubrata Paul50% (4)

- Me 2120 Finals 15Document12 pagesMe 2120 Finals 15Mohammed IbrahimNo ratings yet

- Kea Oilfield Engineering Pte LTDDocument9 pagesKea Oilfield Engineering Pte LTDFabio ParceroNo ratings yet

- BAYLX - ULP Parts Manual NADocument24 pagesBAYLX - ULP Parts Manual NAJonah RagleNo ratings yet

- Element 50 Manual 1Document27 pagesElement 50 Manual 1Karvi LapizNo ratings yet

- Air Compressor Inlet Valve (Or Intake Valve - Unloader Valve)Document6 pagesAir Compressor Inlet Valve (Or Intake Valve - Unloader Valve)anup_nairNo ratings yet

- Bellow Installation Guideline For Expansion BellowsDocument5 pagesBellow Installation Guideline For Expansion BellowsPravin SatheNo ratings yet

- Inst CDJ UsaDocument50 pagesInst CDJ UsaBranZzZzZNo ratings yet

- HB HA: HPDL HPTRDocument1 pageHB HA: HPDL HPTRivan rojasNo ratings yet

- 1.crankshaft DeflectionDocument2 pages1.crankshaft DeflectionPraveen Singh Chauhan60% (5)

- Practical Assignment of Manufacturing Processes Open Ended LabDocument9 pagesPractical Assignment of Manufacturing Processes Open Ended LabMeer UmarNo ratings yet

- Mould Loading Unloading SystemDocument1 pageMould Loading Unloading SystemRAHUL YADAV100% (1)

- Lathe Accessories: Work Holding Tool HoldingDocument33 pagesLathe Accessories: Work Holding Tool HoldingSuhasNo ratings yet

- ARSA - Verification ManualDocument77 pagesARSA - Verification ManualJoão DuarteNo ratings yet

- University of ZakhoDocument4 pagesUniversity of ZakhoNasih AhmadNo ratings yet

- HRSG 02 OperationDocument23 pagesHRSG 02 OperationPremadi SetyokoNo ratings yet

- Ione Aa07 Pid 0021 039 01Document1 pageIone Aa07 Pid 0021 039 01dhiaa mohammedNo ratings yet

- LineBodies (HYDAC)Document12 pagesLineBodies (HYDAC)Ânderson Silva BrasilNo ratings yet

- Hazop Condesate LoadingDocument9 pagesHazop Condesate LoadingMugeshNo ratings yet

- MARK V 249905 311363hDocument18 pagesMARK V 249905 311363hIgnacio Vallejos CaballeroNo ratings yet

- A Presentation On Automotive GearboxesDocument21 pagesA Presentation On Automotive GearboxesSumedh DeshpandeNo ratings yet