Professional Documents

Culture Documents

Weld Paramater Card ISO21307 24.02.20

Uploaded by

James DickinsonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Paramater Card ISO21307 24.02.20

Uploaded by

James DickinsonCopyright:

Available Formats

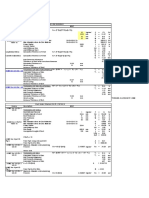

HDPE BUTT WELDING PARAMETER CARD

ISO:21307 / PIPA

Customer/ S.O No: Welder's Name/ No:

Drawing No: Weld Date:

Pipe Nominal Diameter (D): Pipe Wall Thickness (t): mm

Machine No:

Cylinder Area (Ac): mm²

Parameter Unit Calculation Measured Value

Heater Plate Temp.

Heater Plate Temperature °C 225 ± 10 IR thermometer: °C

Bead Up Pressure

(D-t) x t x 1.7 x 3.142 + Measured Drag: Total:

Pressure Bar

Cylinder Area (Ac) Drag

Minimum Bead Width Size mm (0.1 x t) + 0.5 mm

Soak

Total:

Pressure Bar Soak at Drag Pressure or less (see note 1)

Minimum Soak Time Sec (13.5 ± 1.5) x Nominal Wall Thickness sec

Heater Out

Maximum Time Allowed Sec See Table 1 below: ISO 12176-1 sec

Time to Weld Pressure

Maximum Time Allowed to Achieve

Sec 3 + (0.03 x D) sec

Weld Pressure

Weld Pressure

(D-t) x t x 1.7 x 3.142 + Measured Drag: Total:

Pressure Bar

Cylinder Area (Ac) Drag

Cool

Time if t<18mm Min t+3 (see note 2) min

Time if t≥18mm Min (0.015 x t2) – (0.47 x t) + 20 (see note 2) min

Cool Out of Machine Min D (see note 3) min

1. Use the lowest possible pressure during the heat soak that will allow the pipe to remain in contact with the heater plate,

up to a maximum of the current drag pressure.

2. The minimum cooling time in the machine under pressure is en + 3 or 0,015 × en2 − 0,47 × en + 20,

(depending on the wall thickness) at an ambient temperature of (23 ± 2) °C.

This is the cooling time for the butt joint when still in the machine and under pressure.

Cooling times may be shortened and should be lengthened depending on ambient temperatures (approx 1 % per 1 °C).

3. A cooling time out of the machine and before rough handling may be recommended.

Document: F551 Date: 14/02/2020 Version: 0

You might also like

- HDD Calculation - CH 15Document23 pagesHDD Calculation - CH 15Binay Kumar100% (1)

- Demister SizingDocument3 pagesDemister SizingD K SNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNo ratings yet

- Flat Slab ExcelDocument6 pagesFlat Slab Excelasad_naqvi67% (3)

- Design Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021Document1 pageDesign Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021pratyaNo ratings yet

- Project 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataDocument13 pagesProject 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataP s Jagatheesan100% (1)

- Calculation of RC PAD2Document1 pageCalculation of RC PAD2m 418No ratings yet

- Design Calculations - 1Document3 pagesDesign Calculations - 1Engineering1 SaraNo ratings yet

- FormulaeDocument33 pagesFormulaeLcm TnlNo ratings yet

- Buffer Tank DesignDocument1 pageBuffer Tank DesignSuresh Damu BhadNo ratings yet

- Frame ConnectionsDocument14 pagesFrame ConnectionsShawkat Ali KhanNo ratings yet

- Miter Bend Calculation: E W S D T' BDocument4 pagesMiter Bend Calculation: E W S D T' BSong TaoNo ratings yet

- Northstart Meat Mercant Inc PDFDocument22 pagesNorthstart Meat Mercant Inc PDFAppleuk SudarNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- 2.3.3 - DQR - DS Capacity-Rev B2Document33 pages2.3.3 - DQR - DS Capacity-Rev B2Sudip ShresthaNo ratings yet

- Nozzle Check 211039CDocument3 pagesNozzle Check 211039CGaurav BedseNo ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Bellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004Document4 pagesBellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004himsdNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- 12 Bar Air Receiver Thickness Calculation of Pressure Vessel ShellDocument16 pages12 Bar Air Receiver Thickness Calculation of Pressure Vessel ShellVipul GandhiNo ratings yet

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- TrunnionDocument5 pagesTrunnionTanvirNo ratings yet

- Allowable Stress SA 285 GR CDocument4 pagesAllowable Stress SA 285 GR Cdianita nurnandaNo ratings yet

- Slno Description Symbol Unit Value: Calculation of Shell ThicknessDocument2 pagesSlno Description Symbol Unit Value: Calculation of Shell ThicknessalvinchuanNo ratings yet

- Piping Calculation Program For ASME B31 1 CodeDocument3 pagesPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- Typ Base PlateDocument19 pagesTyp Base PlateHabibur RahmanNo ratings yet

- Kirby - Typ Base PlateDocument19 pagesKirby - Typ Base PlateNitesh Singh100% (1)

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoeNo ratings yet

- Vdocuments - MX - Calculation of The Minimum Thickness Required For A Heat ExchangerDocument1 pageVdocuments - MX - Calculation of The Minimum Thickness Required For A Heat ExchangerriccardoNo ratings yet

- MP Condensate Flash VesselDocument4 pagesMP Condensate Flash VesselGanesh BhardwajNo ratings yet

- Superheated Steam Condensate TankDocument4 pagesSuperheated Steam Condensate TankGanesh BhardwajNo ratings yet

- Base Plate - LSDDocument14 pagesBase Plate - LSDrelu59No ratings yet

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Document7 pagesSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Hgagselim SelimNo ratings yet

- 6 Inch NB Nozzle Calculation Appendex 1-7Document11 pages6 Inch NB Nozzle Calculation Appendex 1-7SACHIN PATELNo ratings yet

- Reinforcement Calculations For Nozzle (N1) : OD ID Thick NessDocument15 pagesReinforcement Calculations For Nozzle (N1) : OD ID Thick NessMuhammad Hassan MaqsoodNo ratings yet

- Progen: Pipe Thickness Calculation As Per IBR 350 Eqn.Document4 pagesProgen: Pipe Thickness Calculation As Per IBR 350 Eqn.P s JagatheesanNo ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- Typ Base PlateDocument19 pagesTyp Base Platehardik033No ratings yet

- Single Zone Air Conditioner SVC MANUAL (Exploded View) : CautionDocument7 pagesSingle Zone Air Conditioner SVC MANUAL (Exploded View) : CautionCORRECTIVOS AYANo ratings yet

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- Calculation of Flat Covers According To UG-34: Drawing No.: ItemDocument3 pagesCalculation of Flat Covers According To UG-34: Drawing No.: Itemwassim2014No ratings yet

- Thickness Calculation of Cylindrical Shell and TubeDocument1 pageThickness Calculation of Cylindrical Shell and TubeThanhNo ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- EJ CalculationDocument16 pagesEJ CalculationAmit NayakNo ratings yet

- Calc WT - Lbm-Tanara - Z2Document6 pagesCalc WT - Lbm-Tanara - Z2bertaNo ratings yet

- Design and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016Document13 pagesDesign and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016renu rani100% (1)

- Final ExaminationDocument7 pagesFinal ExaminationAwanNo ratings yet

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- Asme Demo 125lDocument10 pagesAsme Demo 125lUdoy Hossen KhanNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFBimal DeyNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFRakeshNo ratings yet

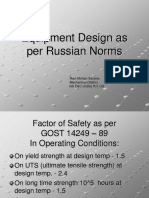

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Shell (S) : ASME Code VIII Div I 2010 Edition 2012 AddendaDocument1 pageShell (S) : ASME Code VIII Div I 2010 Edition 2012 AddendaPhát NguyễnNo ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- HDD Installation CalculationsDocument4 pagesHDD Installation Calculationslive4sankar100% (1)

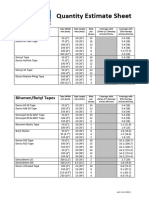

- Denso Quantity Estimate SheetDocument3 pagesDenso Quantity Estimate SheetJames DickinsonNo ratings yet

- EN Supplementary Instructions Mounting Brackets KV 31 Pipes Ø 50 200 MM Horizontal Sensor MountingDocument20 pagesEN Supplementary Instructions Mounting Brackets KV 31 Pipes Ø 50 200 MM Horizontal Sensor MountingJames DickinsonNo ratings yet

- Franna MAC 25 Load Chart 3B6Document36 pagesFranna MAC 25 Load Chart 3B6James DickinsonNo ratings yet

- Duo Wafer Cast enDocument2 pagesDuo Wafer Cast enJames DickinsonNo ratings yet

- Cable Supports Catalogue Complete 20131003Document124 pagesCable Supports Catalogue Complete 20131003James DickinsonNo ratings yet

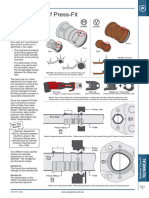

- AusPress Press Fit Technical CatalogueDocument10 pagesAusPress Press Fit Technical CatalogueJames DickinsonNo ratings yet

- 17.HB158 Welding Manual301 V30713Document38 pages17.HB158 Welding Manual301 V30713James DickinsonNo ratings yet

- Go & NoGo GaugesDocument4 pagesGo & NoGo GaugesAneez ShresthaNo ratings yet

- 01-SAMSS-044 PDF Download - CRA Clad Pipe SpoolsDocument4 pages01-SAMSS-044 PDF Download - CRA Clad Pipe SpoolsZahidRafiqueNo ratings yet

- Chapter 52 - Spread Sheet of Calculations Structural Design of Flexible Conduits Part 636 STR Eng - NEH June 2005Document51 pagesChapter 52 - Spread Sheet of Calculations Structural Design of Flexible Conduits Part 636 STR Eng - NEH June 2005Andri DoemeriNo ratings yet

- Valtek Maxflo: Control ValvesDocument11 pagesValtek Maxflo: Control Valvessaroat moongwattanaNo ratings yet

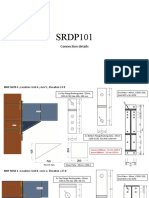

- SRDP101 Connection Input P1Document14 pagesSRDP101 Connection Input P1Ninad KhandagaleNo ratings yet

- 5 - Base Connection - Fixed Base Plate ExampleDocument23 pages5 - Base Connection - Fixed Base Plate ExampleTuanQuach100% (2)

- SC CounterDocument2 pagesSC CounterPapa IzanNo ratings yet

- How To Disassemble The Turret Clamp UnclampDocument13 pagesHow To Disassemble The Turret Clamp Unclampangeldorta2002No ratings yet

- Slip Formwork: Guided by Prof. VRK Murthy Submitted by Vikas B. More (73036) Aniruddha S. Namojwar (73038)Document27 pagesSlip Formwork: Guided by Prof. VRK Murthy Submitted by Vikas B. More (73036) Aniruddha S. Namojwar (73038)simple_ani100% (1)

- NDocument1 pageNGolfkung PairojNo ratings yet

- JSW Steel LimitedDocument1 pageJSW Steel LimitedVenkatesh KumarNo ratings yet

- Trunnion Mounted Ball Valve Series-8200 FO: Dembla Valves Ltd. ThaneDocument16 pagesTrunnion Mounted Ball Valve Series-8200 FO: Dembla Valves Ltd. ThaneDipalee TulaskarNo ratings yet

- RC 2012 04 Apr2 PDFDocument16 pagesRC 2012 04 Apr2 PDFDomenico ScorranoNo ratings yet

- Knurl ISO - 13444 - 2012 - ENDocument8 pagesKnurl ISO - 13444 - 2012 - ENVishal BhanderiNo ratings yet

- Massey Ferguson MF 4000 TRACTOR Service Parts Catalogue Manual (Part Number 651421EA)Document16 pagesMassey Ferguson MF 4000 TRACTOR Service Parts Catalogue Manual (Part Number 651421EA)qlb898316No ratings yet

- Volume-2. Design and Manufacturing of Hydraulic CylindersDocument53 pagesVolume-2. Design and Manufacturing of Hydraulic CylindersQ.S. Khan96% (49)

- EPB-Sub-01 Epic Residential Condensing Boiler Models Epb080-199Document2 pagesEPB-Sub-01 Epic Residential Condensing Boiler Models Epb080-199Keyur ShahNo ratings yet

- Masoneilan+ +78400+and+18400+Series+LincolnLog+IOMDocument28 pagesMasoneilan+ +78400+and+18400+Series+LincolnLog+IOMBalasubramaniam MuthusamyNo ratings yet

- Operating Instructions Disc Brake SF24 PB-SF-E1Document26 pagesOperating Instructions Disc Brake SF24 PB-SF-E1Torres Uli0% (1)

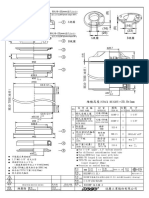

- H323MP半隱藏式開孔走線上塞 (15.2L) 組立圖 ModelDocument1 pageH323MP半隱藏式開孔走線上塞 (15.2L) 組立圖 ModelHudasenna ChannelNo ratings yet

- 01.bombas Cornell 6rb FDocument2 pages01.bombas Cornell 6rb FChristian Vega G.No ratings yet

- Piston Pump (Steering) High Pressure Stall - Test and AdjustDocument6 pagesPiston Pump (Steering) High Pressure Stall - Test and AdjustDidi PrawiraNo ratings yet

- Haas EC Series Operators ManualDocument307 pagesHaas EC Series Operators ManualsunhuynhNo ratings yet

- Premier ServiceS1 AM022 B20P16C 260C SRV Complete 01 84 PDFDocument84 pagesPremier ServiceS1 AM022 B20P16C 260C SRV Complete 01 84 PDFamer ibarissenNo ratings yet

- Muhammad Nur Aslam - Rancang Bangun Crusher Plastik 50 KGDocument4 pagesMuhammad Nur Aslam - Rancang Bangun Crusher Plastik 50 KGrestu yanuar salamNo ratings yet

- Construction Methodology TemplateDocument4 pagesConstruction Methodology TemplateIan Dela CruzNo ratings yet

- Ornitoptero PDFDocument5 pagesOrnitoptero PDFninonunezNo ratings yet

- Steam Turbines Curtis or Velocity Compounded StageDocument2 pagesSteam Turbines Curtis or Velocity Compounded StageaminardakaniNo ratings yet

- 16S1650Document46 pages16S1650Arpit Verma100% (1)