Professional Documents

Culture Documents

1test Procedure, Cyl Oil Non-Return Valves

1test Procedure, Cyl Oil Non-Return Valves

Uploaded by

carma0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

1Test procedure, cyl oil non-return valves

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 page1test Procedure, Cyl Oil Non-Return Valves

1test Procedure, Cyl Oil Non-Return Valves

Uploaded by

carmaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

MAN Diesel 2/2

Check procedure for the cylinder liner lubricating valves:

Check for blow-back:

The functionality of the LEE non-return valve in the

cylinder liner can be checked, by loosening the pipe

connections on each lubrication pipe, one by one on the

lubricator. This procedure should be carried out during

low load.

The pipe connections on the lubricator, should be

loosened approximately one or two revolutions, until

cylinder oil from the lubricator flows out, following the

sequence of the lubricator. At low load, this will happen

approximately once every six revolutions.

If a non-return valve is defect, it will allow combustion

gasses to pass backwards, from the combustion

chamber, towards the lubricator. This will blow out the

cylinder oil from the pipe, in sequences that follows the

piston strokes. This operation will give an immediate and

clear indication, of a defect non-return valve, when

loosening the pipe connections one by one.

IMPORTANT NOTICE !!

When the above procedure is carried out, protection

glasses or face shield should be used, together with heat

resistant gloves. The combustion gas is very hot and it

can cause injuries, if these safety precautions are not

used!

Check through the scavenge ports

In addition to the above procedure, we recommend to

check the functionality of the lubrication valves, from the

scavenge air receiver.

This can be done in connection with a normal scavenge

port inspection, by activating the pre-lube function of the

lubricators.

When the piston is in BDC, the lubricating grooves can be

seen through the scavenge ports. Check carefully that oil

is entering the cylinder liner, when the pre-lube is

activated. A good flashlight and a mirror is useful to carry

out this inspection.

You might also like

- Keihin CVK32 Carburetor Carb Tuning Service Rebuild ManualDocument6 pagesKeihin CVK32 Carburetor Carb Tuning Service Rebuild Manualsteinhansen33% (3)

- 2 - Canrig Top Drive Rig Crew TrainingDocument104 pages2 - Canrig Top Drive Rig Crew TrainingDiego Fabian Ruiz Vacaflor89% (9)

- Wärtsilä 32 Engine Instruction Manual 04. Maintenance ScheduleDocument12 pagesWärtsilä 32 Engine Instruction Manual 04. Maintenance ScheduleSalman Kapoor100% (1)

- Slide Type Fuel ValveDocument14 pagesSlide Type Fuel ValveNitin Sharma93% (14)

- Lubricating Oil System For A Marine Diesel EngineDocument9 pagesLubricating Oil System For A Marine Diesel EngineJohn FredyNo ratings yet

- Autolube System (HYD) OverviewDocument21 pagesAutolube System (HYD) OverviewDaniel Alfonso Diaz FloresNo ratings yet

- 2016 Grand Cherokee - 3.0L TURBO DIESEL PDFDocument665 pages2016 Grand Cherokee - 3.0L TURBO DIESEL PDFprueba2No ratings yet

- Instruct For OperationDocument1 pageInstruct For OperationAriel Martinez NNo ratings yet

- Study of Automobile ValveDocument6 pagesStudy of Automobile Valvepsmonu54No ratings yet

- Chapter13 enDocument10 pagesChapter13 enboubou213No ratings yet

- Geareducer Model 32.2: UsermanualDocument8 pagesGeareducer Model 32.2: UsermanualR BhattacharyaNo ratings yet

- Preparing The Engine For Maintenance and Repair E.G. For Overhauling of Piston - AgonoyDocument4 pagesPreparing The Engine For Maintenance and Repair E.G. For Overhauling of Piston - AgonoyRAE ANGELO AGONOYNo ratings yet

- Instruction Manual For SSP-70D-ACMEVACDocument15 pagesInstruction Manual For SSP-70D-ACMEVACParjanya MandalNo ratings yet

- Udor Maintenance Trouble ShootingDocument4 pagesUdor Maintenance Trouble ShootingMONA100% (1)

- KXR50 Cap 05 (Alimentazione)Document17 pagesKXR50 Cap 05 (Alimentazione)tutifruti649No ratings yet

- Generator Seal Oil SystemDocument40 pagesGenerator Seal Oil Systembanukiran samboju100% (4)

- 95、Type QYJB Oil Purifier Operation Manual (QYJB型油净化装置使用说明书)Document15 pages95、Type QYJB Oil Purifier Operation Manual (QYJB型油净化装置使用说明书)onlyichwan wicaksono0% (1)

- KeihinDocument6 pagesKeihinBradley Govender0% (1)

- Fitting Steering Pump SpidDocument15 pagesFitting Steering Pump SpidJuan GarcNo ratings yet

- Mep Oral AnswersDocument28 pagesMep Oral AnswersAshjo Gamer100% (1)

- Kbu KBZ1Document4 pagesKbu KBZ1Andrew VNo ratings yet

- Brake System BleedingDocument2 pagesBrake System BleedingToua YajNo ratings yet

- ALgbDocument2 pagesALgbOlivier MontagueNo ratings yet

- WBHE ManualDocument3 pagesWBHE ManualBruno DelgadoNo ratings yet

- Joyride 125-4Document13 pagesJoyride 125-4شاكر عبد الهادي الاسديNo ratings yet

- Oh LolDocument5 pagesOh Lolrhomel hamoyNo ratings yet

- Fuel PUMP Overhauling Class IVDocument8 pagesFuel PUMP Overhauling Class IVRutvikNo ratings yet

- Oil Pump SpindleDocument3 pagesOil Pump SpindleAsefshaNo ratings yet

- Carb Tuning1Document7 pagesCarb Tuning1Giovanni De SantisNo ratings yet

- MODEL V305000000 PMV 5:1 Oil Pump Series "A": Form 404421 MAR - 2012 SectionDocument12 pagesMODEL V305000000 PMV 5:1 Oil Pump Series "A": Form 404421 MAR - 2012 SectionFaidh Maulana Aksyar FaidhNo ratings yet

- Wet SumpingDocument3 pagesWet SumpingBimal Amarnath MenonNo ratings yet

- Maintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingDocument12 pagesMaintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingAdarsh AnilNo ratings yet

- Image Server HandlerDocument12 pagesImage Server Handlerbobcat1810No ratings yet

- Seal Oil System CommissioningDocument42 pagesSeal Oil System Commissioningpushpa latha100% (1)

- Name: Anup Singh A BT 7A ROLL NO: 1736608007: Mice AssignmentDocument9 pagesName: Anup Singh A BT 7A ROLL NO: 1736608007: Mice AssignmentPawan kumarNo ratings yet

- Engine Oil Pump and Asociated UnitsDocument19 pagesEngine Oil Pump and Asociated Unitsanon_828948057No ratings yet

- 26850A005Document12 pages26850A005Luciano AlencastroNo ratings yet

- Janoel Lucañas 2a Aux Mach Ass. #3Document4 pagesJanoel Lucañas 2a Aux Mach Ass. #3Janoel LucañasNo ratings yet

- Cylinder Lub Oil Sampling MethodDocument4 pagesCylinder Lub Oil Sampling MethodRathne AbeynayakeNo ratings yet

- Service Information: October/04 II 25 01/04Document3 pagesService Information: October/04 II 25 01/04Marcelo GiussaniNo ratings yet

- Centrifugal Pump Checklist 2023Document7 pagesCentrifugal Pump Checklist 2023Caesar MutizeNo ratings yet

- Bs IV Himalayan Parts CatalogueDocument3 pagesBs IV Himalayan Parts CatalogueAnonymous O9TX7Yl100% (3)

- Hoists 22: Check The Oil Level Through The Inspection GlassDocument6 pagesHoists 22: Check The Oil Level Through The Inspection GlassM RefaiNo ratings yet

- 200 MW - Unit, Generator Seal Oil SystemDocument3 pages200 MW - Unit, Generator Seal Oil SystemNikhilNo ratings yet

- Fuel Injector CleaningDocument12 pagesFuel Injector Cleaningapi-26140644100% (1)

- Marine Engineering PracticeDocument24 pagesMarine Engineering PracticeVijay PrakashNo ratings yet

- Hydrostatic Lubricator For Steam LocomotivesDocument6 pagesHydrostatic Lubricator For Steam LocomotivesVikk SuriyaNo ratings yet

- Pump ManualDocument42 pagesPump Manualnelforu100% (2)

- Marine Engineering PracticeDocument19 pagesMarine Engineering PracticeAnoop Vijayakumar100% (1)

- Odes 800cc1000cc - WorkshopDocument131 pagesOdes 800cc1000cc - WorkshopIvan RochfordNo ratings yet

- KXR50 Cap 04 (Lubrificazione)Document13 pagesKXR50 Cap 04 (Lubrificazione)tutifruti649No ratings yet

- 912 Oil ChangeDocument4 pages912 Oil ChangeGaberNo ratings yet

- 15 Evacuacion y Carga PDFDocument10 pages15 Evacuacion y Carga PDFAnel ValdesNo ratings yet

- 471 Part%205%20maintenance PDFDocument16 pages471 Part%205%20maintenance PDFLê Thanh NgọcNo ratings yet

- Manual HSD PumpDocument5 pagesManual HSD PumpAhmad Tedjo RukmonoNo ratings yet

- Afloat Lube Oil and Mogas Systems and Operations: LEARNING OBJECTIVES: Describe A TypicalDocument26 pagesAfloat Lube Oil and Mogas Systems and Operations: LEARNING OBJECTIVES: Describe A TypicalYerixon Daniel Aguilar SequerasNo ratings yet

- Crankcase Insp AeDocument4 pagesCrankcase Insp Aesumitsinha89No ratings yet

- Engine Lubrication and Cooling SystemsDocument20 pagesEngine Lubrication and Cooling SystemsGuillermo Alexamder Sanchez YbañezNo ratings yet

- Installation & Service Manual: Oil Cooler - OCWI 34 1Document9 pagesInstallation & Service Manual: Oil Cooler - OCWI 34 1Restu KrisnantoNo ratings yet

- Sabroe SBO ScheduleDocument2 pagesSabroe SBO SchedulecarmaNo ratings yet

- 7ZPSC0573 JUE-87 Common Use Type Operation GuideDocument12 pages7ZPSC0573 JUE-87 Common Use Type Operation GuidecarmaNo ratings yet

- Air Con. Compressor Shaft SealDocument5 pagesAir Con. Compressor Shaft SealcarmaNo ratings yet

- NRS SP EGB Cleaning Method 04.06.2013Document4 pagesNRS SP EGB Cleaning Method 04.06.2013carmaNo ratings yet

- MSC AMOS BS - Counters UpdateDocument6 pagesMSC AMOS BS - Counters UpdatecarmaNo ratings yet

- Truble Shooting L27-38 PDFDocument7 pagesTruble Shooting L27-38 PDFcarmaNo ratings yet

- AMOS BUSINESS SUITE GUIDE Edition 4Document42 pagesAMOS BUSINESS SUITE GUIDE Edition 4carmaNo ratings yet

- Graviner ManualDocument109 pagesGraviner ManualcarmaNo ratings yet

- MSC AMOS BS - Job DescriptionDocument9 pagesMSC AMOS BS - Job DescriptioncarmaNo ratings yet

- RN68 - 68M (RN76 - 76M and RN90 - 90M) Water Leakage at The Piston Cooling Running PipesDocument6 pagesRN68 - 68M (RN76 - 76M and RN90 - 90M) Water Leakage at The Piston Cooling Running PipescarmaNo ratings yet

- FX H LDocument9 pagesFX H LcarmaNo ratings yet

- RTA52 (U) - RTA62 (U) - RTA72 (U) Cylinder Liner With Insulation Tubes and Insulation BandagesDocument10 pagesRTA52 (U) - RTA62 (U) - RTA72 (U) Cylinder Liner With Insulation Tubes and Insulation BandagescarmaNo ratings yet

- VEC Settings 84T-DDocument3 pagesVEC Settings 84T-DcarmaNo ratings yet

- BM LED IndicationDocument5 pagesBM LED IndicationcarmaNo ratings yet

- Deco LineDocument1 pageDeco LinecarmaNo ratings yet

- 1444 UlDocument2 pages1444 UlcarmaNo ratings yet

- 1600 UlDocument1 page1600 UlcarmaNo ratings yet

- %Doodvw8Qlwiru) Orrgoljkwv: IP67 120-277V HPS 1000WDocument1 page%Doodvw8Qlwiru) Orrgoljkwv: IP67 120-277V HPS 1000WcarmaNo ratings yet

- Mctor ContactoresmagneticosDocument84 pagesMctor ContactoresmagneticoscarmaNo ratings yet

- Deco Spot LineDocument1 pageDeco Spot LinecarmaNo ratings yet

- ODVV'LY+36&DUJR/LJKW: Ip67 120V Hps 440V Max. 100WDocument1 pageODVV'LY+36&DUJR/LJKW: Ip67 120V Hps 440V Max. 100WcarmaNo ratings yet

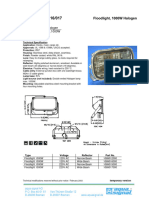

- ) Orrgoljkw:+Dorjhq: IP67 Max. Halogen 220V Max.1000WDocument1 page) Orrgoljkw:+Dorjhq: IP67 Max. Halogen 220V Max.1000WcarmaNo ratings yet

- 0648 LFDocument1 page0648 LFcarmaNo ratings yet

- Koyo Thrust BearingDocument72 pagesKoyo Thrust BearingcarmaNo ratings yet

- Ermeto FITTINGS Part 1Document36 pagesErmeto FITTINGS Part 1carmaNo ratings yet

- ) Orrgoljkw:+366Hsdudwhedoodvw: Ip67 Hps 1000WDocument1 page) Orrgoljkw:+366Hsdudwhedoodvw: Ip67 Hps 1000WcarmaNo ratings yet

- Barthel Temperature Control ApplicationsDocument11 pagesBarthel Temperature Control ApplicationscarmaNo ratings yet

- Ermeto FITTINGS Part 3Document36 pagesErmeto FITTINGS Part 3carmaNo ratings yet

- Ermeto FITTINGSDocument144 pagesErmeto FITTINGScarmaNo ratings yet

- Atf TQ DiiiDocument2 pagesAtf TQ DiiicarmaNo ratings yet