Professional Documents

Culture Documents

2mm Sheet TC

Uploaded by

Deepak PawarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2mm Sheet TC

Uploaded by

Deepak PawarCopyright:

Available Formats

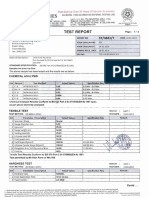

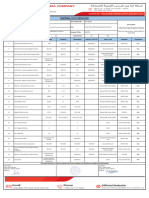

'JSW STEEL LIMITED IS:2062:2011

: lJSi'I

, i 'I

... Dolvi Works, Taluka - Pen, District - Raigad, Maharashtra_ -.402107, India

Re9d. Office : JSW Centre, Sandra Kurla Complex, Sandra (East) , Mumbai - 400 051 : 1· I ,·

,1 CIN NO.: L27102MH1994PLC15292·

' 5 CM/l-7189081

I l 1•

,

·t: t.•

test CERTIFICATE FOR HOT ROLLED MEDIUM AND HIGH TENSILE.STRUCTURAL STEEL

Test Certificate No.: ·7104477114 Date 21.05.2022 Test Methods: Chemical Co�postion: IS:8811�1998,ASTM E415:2021

Product Hot Rolled Coils Tensile: �S 1608-1 :2022

PO No. Bend :.IS.1599:20.1.9.

SO No. 144872022051811384939 Impact: IS 1757-1 :2020

SO Date 4277

We. certified that: the material described below fully �o�forms to' IS 2062 :2011. Chemical composition and Mechanical properties of the· product, as tested In ·a·ccordanc·e with

· · "; the Scheme of Testing and Inspection contained in the BIS Certification Marks Licence No.CM/L-7189081, are as indicated-below against each order No.· ·

I· 'I. I (PLEASE REFER TO IS 2062:2011 FOR DETAILS OF SPEGIF.ICATION REQUIREMENTS) . . ••·• . . ... -·· ... .. .

·specification : IS 2062:2011 E250A

.!.'. .. .. ' ..

-·

Nppm B ppm

Chemical Composition

Ti% Ni%

.:!

Cu%-

. '

MAE% c·Ea% Killina

C¾ Mn% S% P¾ Si% Al% Nb% V% Cr% Mo%

...

Specification Requirements Min 0.020 b

..

- ...

Max 0.230 1.500 0.045 0.045 0.400 120

.. � ··• .

b

..

·0·_4·20

' '

Cast I Coil No./ No'l'inal, Size (mm) Pcs t . Test Results

... 19 y . . .... .. - -

Heat No. Packet No. TX w·x l MT

.. - .

22202430 2220243001 °2.00 ·x 1250 x C .21.275 0.0550 0.443 0.0080 0.010 0.083 0.043 56.0 0.005 0.026 0:005 0.0:i-1 0.1292

Total weight in Metric Tonnes 21.275 Grand total of coils / packets 1

Specification: IS 2062:2011 E250A

' Mechanical Properties

.. .. Tensile YS UTS GL El YS/UTS Bend Bend Bend CVN lmoact CVN lmoact CVN Impact Hardness Hardness GS IR HER ECV SET

-

,.

temo,. 0c ava.enerav .J

--

direction MPa MPa mm % ratio direction dia,. mm result direction HV,n HRb No. % mm

I '

Specification Requirements Min T 25b.o 410.0 23.0 T

f--...-

, Max

Cast I Coil No. I Nominal Size (mm) Pcs 'Qty. KTL'"32... Test Results �- ·. I

Heat No. Packet No. TX WX l MT

22202430 2220243001 2.00 x 1250 x C I

21.275 T 378 00 440.00 5.65SR 34.00 I o.859 T 2.0t Ok I

This 1s to certify that the above mentioned products· produced and supplied by JSW Steel Ltd. Dolvi works do not conlain any rad1oact1ve element higher than the natural level. The product or packing material does not c_o�1�1n any hazardous substances as per

I I I

_ _

RoHS norms

Billing Doc No. :7104477114 Process Route: CONARC-lHF-CSP.

Invoice No.· :22002700037527

Fully killed steel .,, .' '. ' ' • •. - � .. ..- . - .. : . . : .. .. -

Legends: CONARC = ConArc Furnance.LHF = Laddie Heating Furance. CSP =Compact Strip Production

I

Mode of transport .. T X w X l= Thickness X Width X Length

�-

:Truck

Vehicle No. :MH06B01402 Chemical analysis= laddie sample analysis. 1 MPa= 1N/mm2

Gl= Gauge lenglh.YS= Yield Strength.LITS = Ullimate Tensile Strength. El= Total elongation on standard GL.

...

.. CVN = Charpy V-nolch. l= longitudinal. T = Transverse. 0c Degree Centrigrade. GS ASTM Grain Size.

= = Subha?is Chakraborty

IR= Inclusion Rating, ECV = Erichsen Cupping Value, SET= Strainag Embrittlement Test,

MAE= Micro Alloying Elements. C Eq¾ = Carbon Equivalent= [C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15] · Assistant General Manager

=

HER = Hole Expansion Ratio. RoHS Restriction of Hazardous Substances For JSW Steel Ltd.

The material supplied conforms to lhe specified dimensions and tolerances.

.. . ..

We certify that malerial comply the certification as per EN 10204:2004 type 3.1. ,.

HSM/Q/LOGIS/F/03 1 /1

You might also like

- Tuerca 1-1-1 2HDocument1 pageTuerca 1-1-1 2Hcomercial 3No ratings yet

- Round Bar 60mm, Square Bar 50 MM - MTCDocument1 pageRound Bar 60mm, Square Bar 50 MM - MTCMohammad Adil0% (1)

- Elbow 6in 90N SCH 40 63e00m077Document1 pageElbow 6in 90N SCH 40 63e00m077Mygame 1402No ratings yet

- 6X1250 JSWDocument1 page6X1250 JSWParesh MehtaNo ratings yet

- Bridas VariasDocument1 pageBridas Variassaul dussanNo ratings yet

- Metala: Nter IseDocument10 pagesMetala: Nter IseatulNo ratings yet

- Mix Design M-20 (SVVV)Document5 pagesMix Design M-20 (SVVV)shailendra pachauriNo ratings yet

- Elecon Financial Reports Q1 2023 24Document16 pagesElecon Financial Reports Q1 2023 24g_sivakumarNo ratings yet

- Phatoil Single Essential Oil MSDS Certificate - Lavender Essential OilDocument60 pagesPhatoil Single Essential Oil MSDS Certificate - Lavender Essential OilPhatoilNo ratings yet

- Universal Cplleg of Engineering: /lidva Education 'TrustDocument1 pageUniversal Cplleg of Engineering: /lidva Education 'TrustPrasad KalekarNo ratings yet

- Universal Cplleg of Engineering: /lidva Education 'TrustDocument1 pageUniversal Cplleg of Engineering: /lidva Education 'TrustPrasad KalekarNo ratings yet

- Inspection Certificate 3.1 - ,: According EN 10204: 2005Document1 pageInspection Certificate 3.1 - ,: According EN 10204: 2005B.M Industrial WorksNo ratings yet

- Test Report PDFDocument4 pagesTest Report PDFHarshad ArondkarNo ratings yet

- 10MM - MD80Document3 pages10MM - MD80Civil structureNo ratings yet

- Binder1 PDFDocument31 pagesBinder1 PDFAris van RaiserNo ratings yet

- Img 0027Document1 pageImg 0027MukeshNo ratings yet

- 3?Kf!Fl+ - &N-WFJTMF: VGLD'WDocument14 pages3?Kf!Fl+ - &N-WFJTMF: VGLD'WHPCL VR QC LABNo ratings yet

- ToDocument2 pagesToGTMNo ratings yet

- Ramy Abou El SoaadDocument10 pagesRamy Abou El SoaadAhmed Ayman AhmedNo ratings yet

- CT - PT MQPDocument12 pagesCT - PT MQPGnanavel GNo ratings yet

- 1mg 200g CertificateDocument2 pages1mg 200g CertificateAmirNo ratings yet

- Duplex PQR and WPSDocument11 pagesDuplex PQR and WPSHussein AboulelaNo ratings yet

- CBR Curve PDFDocument1 pageCBR Curve PDFMathias OnosemuodeNo ratings yet

- SonaliDocument1 pageSonaliSOMA ROYNo ratings yet

- Somnatu N. Swamy: P 'ToftDocument10 pagesSomnatu N. Swamy: P 'ToftviahulNo ratings yet

- Tube Light..p.r..4133Document1 pageTube Light..p.r..4133roniNo ratings yet

- Control Plan m10x1.5 HhsDocument9 pagesControl Plan m10x1.5 HhsDhanluxmi AutomaticsNo ratings yet

- Kalibrasi SLTDocument8 pagesKalibrasi SLTBryan HermawanNo ratings yet

- THINK GAS WITNESS REPORT - Vishal PipesDocument10 pagesTHINK GAS WITNESS REPORT - Vishal PipesGururaj P KundapurNo ratings yet

- Company (K.S.C.) : - ,::1 Kuwait OilDocument16 pagesCompany (K.S.C.) : - ,::1 Kuwait OilRELLA ROSHAN KUMARNo ratings yet

- 1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Document7 pages1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Mohamed Reda Hussein SengarNo ratings yet

- Test Report SsDocument3 pagesTest Report SsAnuragNo ratings yet

- Check Valve 6in HT 6YF4Document1 pageCheck Valve 6in HT 6YF4Juan Pablo Perdomo OrtizNo ratings yet

- Calibration Proving Ring 50KNDocument1 pageCalibration Proving Ring 50KNmanish upadhyay100% (1)

- SEC02 - Chung Lik Jia - Part 1Document8 pagesSEC02 - Chung Lik Jia - Part 1latifah dasangNo ratings yet

- Part 2Document23 pagesPart 2Christoper AsuarNo ratings yet

- Simplex Flexitube PDFDocument24 pagesSimplex Flexitube PDFKaushalKishoreNo ratings yet

- 02 - Proposed C&G Soil Stack YardDocument1 page02 - Proposed C&G Soil Stack YardRamesh BabuNo ratings yet

- P.O. Bc23-00002 Drawing For Approval r.0Document1 pageP.O. Bc23-00002 Drawing For Approval r.0Hadjer BouchlaghemNo ratings yet

- Cargo Pump Curve - MT BourneDocument2 pagesCargo Pump Curve - MT Bournetimayaa1000100% (1)

- Calibración Termohigrometro 2019Document1 pageCalibración Termohigrometro 2019Chirley Jazmin Bayona BautistaNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank ItpHgagselim SelimNo ratings yet

- ASIANPAINT 14062019174800 CorrigendumAnnualReport 256Document310 pagesASIANPAINT 14062019174800 CorrigendumAnnualReport 256Aniket DasNo ratings yet

- Am - .... MN ... ..... : Ma UmDocument3 pagesAm - .... MN ... ..... : Ma Umdshkll88No ratings yet

- SS Data Sheet 2MMDocument1 pageSS Data Sheet 2MMm.aliNo ratings yet

- Equipment Process Data Sheet: 'GYPT "".SCDocument3 pagesEquipment Process Data Sheet: 'GYPT "".SCMo ZeroNo ratings yet

- Kundalia RB Project - Cage Ladder QAPDocument2 pagesKundalia RB Project - Cage Ladder QAPHarshit AdwaniNo ratings yet

- P I ? I ' I : Ail-Is /lee 17025 Accredit D Ovt Approved Tes Ing L B RatoryDocument1 pageP I ? I ' I : Ail-Is /lee 17025 Accredit D Ovt Approved Tes Ing L B RatoryPRAVIN PATELNo ratings yet

- Zdocs - Hu 773007136-ADocument1 pageZdocs - Hu 773007136-AMohamed RaafatNo ratings yet

- AS-BUILT DRG. - 33KV VCB Panel PDFDocument54 pagesAS-BUILT DRG. - 33KV VCB Panel PDFrana abrar100% (1)

- 02 X 1250 X CoilDocument1 page02 X 1250 X CoilBhavik PanchalNo ratings yet

- 3.1digital Vernier Caliper Calibration CertificateDocument1 page3.1digital Vernier Caliper Calibration CertificateGolden RosesNo ratings yet

- DZ1610Document1 pageDZ1610Dany LeaNo ratings yet

- Codo 90 6 SCH STD Astm A234 348205Document1 pageCodo 90 6 SCH STD Astm A234 348205antoniosofwareNo ratings yet

- HOT Induction Bend MPS - CommentedDocument11 pagesHOT Induction Bend MPS - CommentedHASAN SHAHRIAR100% (1)

- Go Dsag s1nb60Document2 pagesGo Dsag s1nb60Muresan SanduNo ratings yet

- 05 X 1830 X 6300Document1 page05 X 1830 X 6300Bhavik PanchalNo ratings yet

- Pha4054902 02Document2 pagesPha4054902 02German BernalNo ratings yet

- Universal: WiresDocument2 pagesUniversal: WiresDeepak PawarNo ratings yet

- Gi+Tpc Assembled Chs Post 67.4 - 1.20 - 150.0 - Bolted - HDG - CM - 20!2!00490 - A1 ArabiaDocument1 pageGi+Tpc Assembled Chs Post 67.4 - 1.20 - 150.0 - Bolted - HDG - CM - 20!2!00490 - A1 ArabiaDeepak PawarNo ratings yet

- GI+TPC BOTTOM AKAT PANEL GREEN 6005 - 3.00 - 3.00 - 2209.8 - 3055.6 - 12.7 - 76.2 - 55-75 - 275 - 30X20X1.0 - 20X3.0 - WM - A1 ArabiaDocument1 pageGI+TPC BOTTOM AKAT PANEL GREEN 6005 - 3.00 - 3.00 - 2209.8 - 3055.6 - 12.7 - 76.2 - 55-75 - 275 - 30X20X1.0 - 20X3.0 - WM - A1 ArabiaDeepak PawarNo ratings yet

- Hog RingDocument1 pageHog RingDeepak PawarNo ratings yet

- GI+TPC BOTTOM AKAT PANEL GREEN 6005 - 3.00 - 3.00 - 2209.8 - 3055.6 - 12.7 - 76.2 - 55-75 - 275 - 30X20X1.0 - 20X3.0 - WM - A1 ArabiaDocument1 pageGI+TPC BOTTOM AKAT PANEL GREEN 6005 - 3.00 - 3.00 - 2209.8 - 3055.6 - 12.7 - 76.2 - 55-75 - 275 - 30X20X1.0 - 20X3.0 - WM - A1 ArabiaDeepak PawarNo ratings yet

- 3 in 1 Withworth Mechanism PDFDocument8 pages3 in 1 Withworth Mechanism PDFvidyadhar GNo ratings yet

- Export Packing List For Dallas 07-06-2017 WednesdayDocument1 pageExport Packing List For Dallas 07-06-2017 WednesdayDeepak PawarNo ratings yet

- Analysis of Quality Management System Audit in A Selected OrganizationDocument6 pagesAnalysis of Quality Management System Audit in A Selected OrganizationDeepak PawarNo ratings yet

- Avg DFT Report For KCIMDocument1 pageAvg DFT Report For KCIMDeepak PawarNo ratings yet

- Elevation Section A-A: Concertina Coil Crank PanelDocument1 pageElevation Section A-A: Concertina Coil Crank PanelDeepak PawarNo ratings yet

- A-1 Fence Products Company Pvt. LTDDocument2 pagesA-1 Fence Products Company Pvt. LTDDeepak PawarNo ratings yet

- 10 21008j 2083-4950 2017 7 4 3 PDFDocument9 pages10 21008j 2083-4950 2017 7 4 3 PDFParveen ChauhanNo ratings yet

- Corrective Action RequestDocument1 pageCorrective Action RequestDeepak PawarNo ratings yet

- INSPECTION of Galvanize Product PDFDocument24 pagesINSPECTION of Galvanize Product PDFNasikhatul AmanahNo ratings yet

- A-1 Fence Products Co. Pvt. LTD.: Hot Dip Galvanized Steel ProductsDocument1 pageA-1 Fence Products Co. Pvt. LTD.: Hot Dip Galvanized Steel ProductsDeepak PawarNo ratings yet

- 4892 1Document22 pages4892 1Idrish Shaikh100% (2)

- Lesson Plan in Science Grade 9Document3 pagesLesson Plan in Science Grade 9Liezl BallesterosNo ratings yet

- Experimental Organic Chemistry Post-Lab 6 Benzopinacolone SynthesisDocument5 pagesExperimental Organic Chemistry Post-Lab 6 Benzopinacolone Synthesisapi-235187189100% (5)

- Well Head Gas Price Period July 2017Document5 pagesWell Head Gas Price Period July 2017Saad AliNo ratings yet

- Arunkumar 2013Document6 pagesArunkumar 2013Virender KumarNo ratings yet

- ENZYME Akansha Tyagi 1Document43 pagesENZYME Akansha Tyagi 1rahulprajapNo ratings yet

- 2013 Book BiotechnologyForMedicinalPlantDocument465 pages2013 Book BiotechnologyForMedicinalPlantKenya100% (1)

- Karakterisasi Dan Modifikasi Karbon Aktif TempurunDocument11 pagesKarakterisasi Dan Modifikasi Karbon Aktif TempurunHasril Fauzul AziNo ratings yet

- Soal Soal Yang Penting BangetDocument7 pagesSoal Soal Yang Penting Bangetdexter137No ratings yet

- Quantitative Estimation of Vitamin C (Ascorbic Acid) by IodimetryDocument9 pagesQuantitative Estimation of Vitamin C (Ascorbic Acid) by IodimetryDeepak PradhanNo ratings yet

- Uns s32760Document3 pagesUns s32760NitinNo ratings yet

- Activity Lesson 1 and 2Document4 pagesActivity Lesson 1 and 2Jho Anne Ronquillo LasicNo ratings yet

- Liquid OralsDocument55 pagesLiquid OralsShraddha RNo ratings yet

- Cations and AnionsDocument22 pagesCations and AnionsDoe BlackNo ratings yet

- Common Ion Sheet: Symbols and Charges of Fixed Charge Mono-Atomic IonsDocument2 pagesCommon Ion Sheet: Symbols and Charges of Fixed Charge Mono-Atomic Ionskarl0% (1)

- Copeland ZP24K5E PFV 830Document16 pagesCopeland ZP24K5E PFV 830Reynnier MendozaNo ratings yet

- Full Download Book Quantum Dots Fundamentals Synthesis and Applications PDFDocument41 pagesFull Download Book Quantum Dots Fundamentals Synthesis and Applications PDFhilda.pellowski343100% (22)

- ATECPOOL Catalogue 2021 2022 Web LowDocument382 pagesATECPOOL Catalogue 2021 2022 Web LowMandar NadgaundiNo ratings yet

- Dee20023 - Chapter 1Document39 pagesDee20023 - Chapter 1Aiman AsyraafNo ratings yet

- Cape Chemistry, 2016, U1, P2, Q#4Document4 pagesCape Chemistry, 2016, U1, P2, Q#4Mariah BissoonNo ratings yet

- Drill Collars Tubing and Drill Pipe NS 1 A4 WatermarkedDocument12 pagesDrill Collars Tubing and Drill Pipe NS 1 A4 Watermarkedislam atifNo ratings yet

- CodeinaDocument3 pagesCodeinaclaudiaNo ratings yet

- 4sem U1 Carboxylic AcidDocument20 pages4sem U1 Carboxylic AcidNameirakpam satishNo ratings yet

- Safety Data Sheet - EN - (89985628) DIHYDRO-3 - (TETRAPROPENYL) FURAN-2,5-DIONE (26544-38-7)Document7 pagesSafety Data Sheet - EN - (89985628) DIHYDRO-3 - (TETRAPROPENYL) FURAN-2,5-DIONE (26544-38-7)castasoftNo ratings yet

- Stepan Formulation 1210Document2 pagesStepan Formulation 1210JULIAN STEVEN ALMECIGA RODRIGUEZNo ratings yet

- Synthesis and Characterization and Biological Activities of HydrazonesDocument9 pagesSynthesis and Characterization and Biological Activities of HydrazonesJolayemi Damilare SegunNo ratings yet

- Abstract: The New Compounds of Salicylic Acid Derivatives, 2 - (3 - (Chloromethyl) Benzoyloxy) Benzoic AcidDocument8 pagesAbstract: The New Compounds of Salicylic Acid Derivatives, 2 - (3 - (Chloromethyl) Benzoyloxy) Benzoic AcidFebria AnggraeniNo ratings yet

- Tank Wall Wash TestDocument6 pagesTank Wall Wash TestGiumba ClaudiuNo ratings yet

- Innovations in Semiochemical FormulationDocument20 pagesInnovations in Semiochemical FormulationgfermatuNo ratings yet

- Rubber As Material of ConstructionDocument15 pagesRubber As Material of ConstructionpandianvijaybharathiNo ratings yet

- Chemistry - Chemical Equations WorksheetDocument2 pagesChemistry - Chemical Equations WorksheetVasipalli Eshan AdityaNo ratings yet