Professional Documents

Culture Documents

5mm Plate

Uploaded by

Deepak PawarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5mm Plate

Uploaded by

Deepak PawarCopyright:

Available Formats

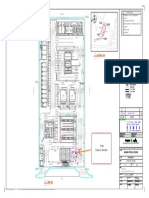

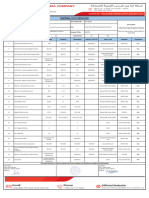

SWOLOGIS/FI03 Vehicle

No.tAode

transportInvoice

ofNo.Billing

DocNo. nons

ReHS Ths is Heat Castl

cz23927294

2916259 Hezt Cst To, Test

}

No.

NaPeetNo PLOT Apl

Certificate

IPeket CoflNo. ! Col

No. I Apollo

Total

hat

NO.

Requirements

Specification

he No. Specificalon weight Specifkcaton: Ye

abve Specificaton Tubes

M-1

ceuned No.:

:MH46BU2245:Truck

:23D0Z700110341edeBOF:7105810354

Baslc = ADDITIONAL

5.00 Nominal

(mm)

Sre TXWXLNomna

(mm)

Sze

menioneJ TXWXL in5.00 he Ltd

7105810354

x Requirements

1500 Metric

: x Scheme hat

1S 1500 IS

products 2062-2011 xC 20622011 he

x

C Tonnes

material

The

We klled

Fuly

steel

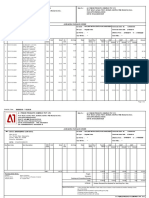

BOF-ARS-HF-CCM-HSM

Process

Route:produced

MIDC,MURBAD

of

E250A E25OA Testing

certy

materal

described Regd.

IRCVNE

= Chemical

that HojHERe MAE=GL=GawgeContnuous

CCM= and Pes Pes and

supplled Incslon TEST Dolvi

materal = supplied Inspection Office

Mlcro Charpy analyss 28.822T MT

aty. Max MIr 28.822 MT

Cty.

Max

MIn

(PLEASE below CERTIFICATE

conloms

Expanslon Length,YS

28,8220.1540 Works,

compBy AlofngRang,V-notch, Oxygen by

SW dkectloTensile

MPa l

0.2301.500 JSW :

the

Casting

Laddle

ECV conlained fully

Elements,

Rato,RoHS

the

to

L = Furmace, Steel REFER

confoms

No.SO Date

Product

DateSO

Taluk

cerificaton a Yi=

ekd 328.00 250.0 Mn

%

Centre,

Enchsen sample

specihled Longitudinal, Machine, Lid, 0.650o.0050

YS FOR

LIMITED

STEEL

JSW

Srengh,UTS

C ARS Grand TO in

Do HOT CIN

Eq%= anaBysls, |462.005.65SR

o.7oT

31.00 410.0 ¯TS O.045

NO. Pen,

asand Cupping

dlmeslons

tolerances

Resticlon RH = works MP total ISthe to Bandra

per T Argon : ROLLED

20.07.2023 :

Carbon RH 2062:2011 IS

BIS 17.07.2023

401978616 Hot

EN Trarsverse. = 1Rinsing

MPa

do o.019 0.045D.400

of

P% 2062:2011. L27102MH1994PLC152925 :

District

10204:2004 Value, UUmale Degasser, not

GL

Certification Rolled

of

Equvalenl coils MEDIUM Kurla

Hazardous stalon conan SI%

Sei 1Nmm2 0.055o.038

Ralgad, -

30 I FOR

"C=DegreoTensle HSMe packets Chemical Coils Complex,

type Stange LHELdale nyreoacuve 0.020 AND

DETAILSMarks

Mrv6"(CrNoysNeBFADUGrS

1/1

Subsances

3.1. Strength Hol

Stp

rto YSUTS

Bend

Bend

HIGH

Centrigradeo, drectlor 37.0 120

WppraBppm Licence

composition

Maharashtra

EmbrhtemeTT EB Heatng

Mal TENSILE Bandra

eenet OF

Tolal

TxWxL=Thckness

ReviewDate REVINoK

OTEOK

WEDBY:. Furance

2.0t di, SPECIFICATION

No.CL-7189081,

elongaton

GS ngner mn

ASTM STRUCTURAL (East)

Ok and

nan rsuk

402107, -

Bend

on no ChemlcalMechanical

ComposiBon

Mumbal ,

Mechancal

Propartes

Graln

standard o.002

o.o01 V% Test

x nalural alrectlon CVW Results

Test

3103|23 Stza

GL

Wdh

leveL

Resutts

Test

mpact REQUIREMENTS)

are

Methods STEEL

CO, x properles

Length

400 -

CW

PVIELI he as

produc npact Cr% indicated :

1608-1:2022

Tensile: 051

vgeney

CN

17571:2020

of

Impact: 1S

1599:2019

Bend; IS IS

Chemical

or Mo

%

packng tmpct the

below

product,

materlaB Nrdness

N$% Compostion:

against

Cu% as

does 0.o.02620c030s

HanesGS eactested

ya contbln

not

%CE% MAEing oroer in

aeeordae

8811:1998,ASTM

IS

av J0420

Manager

General

Deputy

hadous o

For and Pankaj

System

Qualty Khasne WER

JSW CL-7189081

Steel

subetancs

ECVSET

u E415:2021 ST IS:2062

as

Ld per

You might also like

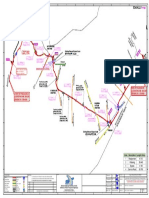

- Compiled Tender Drawings - CompressedDocument20 pagesCompiled Tender Drawings - CompressedMukul PrasadNo ratings yet

- NA-3, NA-4 & NA-5 Control & Heads: FeaturesDocument1 pageNA-3, NA-4 & NA-5 Control & Heads: FeaturesDhrumil ChauhanNo ratings yet

- This Is New PDFDocument1 pageThis Is New PDFAnonymous BZQOJwWIh6No ratings yet

- 13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Document1 page13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Anonymous BZQOJwWIh6No ratings yet

- 115Kv Busbar & BF Proection Panel-1 (D01/D02) : A P HA556 3-1313003.05 4400004657 EA-381637Document1 page115Kv Busbar & BF Proection Panel-1 (D01/D02) : A P HA556 3-1313003.05 4400004657 EA-381637Anonymous BZQOJwWIh6No ratings yet

- Speedtec® 180C Speedtec® 200C Speedtec® 215C: Many Tasks, Many LocationsDocument1 pageSpeedtec® 180C Speedtec® 200C Speedtec® 215C: Many Tasks, Many LocationsCharlie AltaNo ratings yet

- 0846-ON-JSS-1701-002-Rev 2Document7 pages0846-ON-JSS-1701-002-Rev 2Salman ShaikhNo ratings yet

- TR-8105 Series RTCDocument2 pagesTR-8105 Series RTCBaCresNo ratings yet

- PT Scheme (Feb To Mar 2024)Document8 pagesPT Scheme (Feb To Mar 2024)rajasekar KannaiyanNo ratings yet

- Canada Carte DétailléeDocument1 pageCanada Carte DétailléePasymal Pas Si MalNo ratings yet

- General Notes:: WC DP SHDocument9 pagesGeneral Notes:: WC DP SHDT DESIGN STUDIONo ratings yet

- Guidewall Plan SampleDocument1 pageGuidewall Plan Samplegeorge santiagoNo ratings yet

- Renc - Cilling 1Document1 pageRenc - Cilling 1trio alfajarNo ratings yet

- 13.8Kv Automatic Bus Transfer Scheme Panel +abts: A EA-381674 P HA556 3-1313003.05 4400004657Document1 page13.8Kv Automatic Bus Transfer Scheme Panel +abts: A EA-381674 P HA556 3-1313003.05 4400004657Anonymous BZQOJwWIh6No ratings yet

- CV-425 & CV-510: High Output. Reliable Workhorses!Document1 pageCV-425 & CV-510: High Output. Reliable Workhorses!Rachid DoumaNo ratings yet

- Plano Alc GeneralDocument1 pagePlano Alc GeneralDaniel Espinoza SuazoNo ratings yet

- 115/13.8kV TRANSFORMER (T602) PROTN. SET-1 PANEL-1 +TRPA.21Document1 page115/13.8kV TRANSFORMER (T602) PROTN. SET-1 PANEL-1 +TRPA.21Anonymous BZQOJwWIh6No ratings yet

- DOST DTVS BS6 POWER CircuitDocument1 pageDOST DTVS BS6 POWER Circuitak ramNo ratings yet

- Anza-Borrego Desert State Park MapDocument1 pageAnza-Borrego Desert State Park MapCalifornia State ParksNo ratings yet

- As-Built Plans: Vicinity MapDocument1 pageAs-Built Plans: Vicinity Mapinno de los santosNo ratings yet

- Great Wall Engineering Demolition PlanDocument2 pagesGreat Wall Engineering Demolition PlanCattleya PenalosaNo ratings yet

- J3BGDF02BR012 01 05Document1 pageJ3BGDF02BR012 01 05Naheed AkhtarNo ratings yet

- Test Pile Drawing For Major bridge02-LT-002Document1 pageTest Pile Drawing For Major bridge02-LT-002mrinal kayalNo ratings yet

- Marjan Increment Program Jubail Area-Pipeline Projact PKG#18 Electrical Equipment Sizing CalculationDocument22 pagesMarjan Increment Program Jubail Area-Pipeline Projact PKG#18 Electrical Equipment Sizing CalculationAfzal AsifNo ratings yet

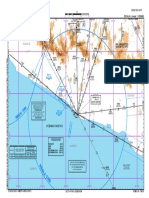

- Vomm Parking Line - PlaneDocument1 pageVomm Parking Line - PlaneTwotawan ThepilotNo ratings yet

- 02 - PREVIEW - Roomi Tower Booking Floor PlanDocument11 pages02 - PREVIEW - Roomi Tower Booking Floor PlanSaleem SaleemNo ratings yet

- Vomm Parking General - AviationDocument1 pageVomm Parking General - AviationTwotawan ThepilotNo ratings yet

- 1 Cover Page1508150590934Document1 page1 Cover Page1508150590934mohd sumerNo ratings yet

- SA04C2-03-WP-D-42103-01-1: Shuqaiq 3 Independent Water ProjectDocument1 pageSA04C2-03-WP-D-42103-01-1: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- WABBDocument16 pagesWABBhanungNo ratings yet

- VFD10OPDocument2 pagesVFD10OPzubkomi87No ratings yet

- 950G Wheel Loader and 962G Wheel Loader Electrical System: Machine Harness Connector and Component LocationsDocument2 pages950G Wheel Loader and 962G Wheel Loader Electrical System: Machine Harness Connector and Component LocationsGabino GaytánNo ratings yet

- FINCA PROVIDENCIA-TOLU - AREA 563haDocument1 pageFINCA PROVIDENCIA-TOLU - AREA 563haAlfredo VareloNo ratings yet

- MagenDocument1 pageMagenHirushan MenukaNo ratings yet

- Staf, Staf-Sg, Staf-R, Stag 5-5-15 Bih: Balancing Valves Mengenabgleichventile 1996.08Document12 pagesStaf, Staf-Sg, Staf-R, Stag 5-5-15 Bih: Balancing Valves Mengenabgleichventile 1996.08SiktonNo ratings yet

- 2022-07-01 - BOM Cable Schedule Makassar - Rev.1Document18 pages2022-07-01 - BOM Cable Schedule Makassar - Rev.1Teguh WahyonoNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- EP AD 2 EPPO 6-1-1 enDocument2 pagesEP AD 2 EPPO 6-1-1 enpiwowarczykptNo ratings yet

- S.No. 34. Petrol Interceptor Approved DrawingDocument1 pageS.No. 34. Petrol Interceptor Approved DrawingJOv ElNo ratings yet

- Plano Topografico-A1Document1 pagePlano Topografico-A1HomeroEdwinNo ratings yet

- Key Plan Pkg-2Document1 pageKey Plan Pkg-2Rakibul JamanNo ratings yet

- Overview Q595500Document1 pageOverview Q595500Asif Abbasov100% (1)

- EDDFDocument55 pagesEDDFkarimmomamNo ratings yet

- Asber America - Catalog 2023Document2 pagesAsber America - Catalog 2023Monserrat SorianoNo ratings yet

- Oktnp 2018 08 23 A 001 PDFDocument1 pageOktnp 2018 08 23 A 001 PDFNewcastle NewsNo ratings yet

- Ortigas ZA BX STDocument1 pageOrtigas ZA BX STMarkLloydValleNo ratings yet

- BOS ACK: Rober Two ArrivalDocument1 pageBOS ACK: Rober Two ArrivalAnonymous PJwr26RFWnNo ratings yet

- 1 PDFDocument1 page1 PDFAsrolNo ratings yet

- FL3B-474-P-2634 AsbuiltDocument1 pageFL3B-474-P-2634 AsbuiltAlbet MulyonoNo ratings yet

- Handbook For TA CloningDocument24 pagesHandbook For TA CloningAmrizal MuchtarNo ratings yet

- Adobe Scan 31 Jul 2021Document1 pageAdobe Scan 31 Jul 2021arnabNo ratings yet

- Addressable Fire Detection and Control Miniplex TranspondersDocument8 pagesAddressable Fire Detection and Control Miniplex TransponderswaerwNo ratings yet

- Wineries of The Napa ValleyDocument1 pageWineries of The Napa ValleyFabrizio DandreamatteoNo ratings yet

- Panchshil Realty (Msetcl) : PROJECT - 132kV-D/C Monopoles Option-1 Summary SheetDocument2 pagesPanchshil Realty (Msetcl) : PROJECT - 132kV-D/C Monopoles Option-1 Summary SheetMOHAMMAD ZUEF - SKIPPER LIMITEDNo ratings yet

- Pia Mex H3-L3Document1 pagePia Mex H3-L3Uriel Torres ZagalNo ratings yet

- Indoor and Outdoor Lighting System Design Calculations: Saudi Electricity CompanyDocument9 pagesIndoor and Outdoor Lighting System Design Calculations: Saudi Electricity CompanySomnath DasNo ratings yet

- Tacoma Snow MapDocument1 pageTacoma Snow MapKING 5 NewsNo ratings yet

- 6 Ad - 2-Mmaa-TmaDocument1 page6 Ad - 2-Mmaa-TmaHector OlsonNo ratings yet

- Carrier IdlerDocument22 pagesCarrier Idlerwawan setiawanNo ratings yet

- Universal: WiresDocument2 pagesUniversal: WiresDeepak PawarNo ratings yet

- 2mm Sheet TCDocument1 page2mm Sheet TCDeepak PawarNo ratings yet

- Hog RingDocument1 pageHog RingDeepak PawarNo ratings yet

- Gi+Tpc Assembled Chs Post 67.4 - 1.20 - 150.0 - Bolted - HDG - CM - 20!2!00490 - A1 ArabiaDocument1 pageGi+Tpc Assembled Chs Post 67.4 - 1.20 - 150.0 - Bolted - HDG - CM - 20!2!00490 - A1 ArabiaDeepak PawarNo ratings yet

- Analysis of Quality Management System Audit in A Selected OrganizationDocument6 pagesAnalysis of Quality Management System Audit in A Selected OrganizationDeepak PawarNo ratings yet

- Avg DFT Report For KCIMDocument1 pageAvg DFT Report For KCIMDeepak PawarNo ratings yet

- Elevation Section A-A: Concertina Coil Crank PanelDocument1 pageElevation Section A-A: Concertina Coil Crank PanelDeepak PawarNo ratings yet

- GI+TPC BOTTOM AKAT PANEL GREEN 6005 - 3.00 - 3.00 - 2209.8 - 3055.6 - 12.7 - 76.2 - 55-75 - 275 - 30X20X1.0 - 20X3.0 - WM - A1 ArabiaDocument1 pageGI+TPC BOTTOM AKAT PANEL GREEN 6005 - 3.00 - 3.00 - 2209.8 - 3055.6 - 12.7 - 76.2 - 55-75 - 275 - 30X20X1.0 - 20X3.0 - WM - A1 ArabiaDeepak PawarNo ratings yet

- A-1 Fence Products Co. Pvt. LTD.: Hot Dip Galvanized Steel ProductsDocument1 pageA-1 Fence Products Co. Pvt. LTD.: Hot Dip Galvanized Steel ProductsDeepak PawarNo ratings yet

- A-1 Fence Products Company Pvt. LTDDocument2 pagesA-1 Fence Products Company Pvt. LTDDeepak PawarNo ratings yet

- 4892 1Document22 pages4892 1Idrish Shaikh100% (2)

- Demulsifier Chemistry and Relative Solubility Number: Cudumbasseri@yahoo - Co.inDocument6 pagesDemulsifier Chemistry and Relative Solubility Number: Cudumbasseri@yahoo - Co.inMichael Medina100% (2)

- Astm D 6313Document4 pagesAstm D 6313Ing Kevin DÍaz100% (1)

- The Dow Chemical Company Engineering Specification Materials G8S-4001-60 Global 16-JAN-2003 Page 1 of 2Document2 pagesThe Dow Chemical Company Engineering Specification Materials G8S-4001-60 Global 16-JAN-2003 Page 1 of 2maheshNo ratings yet

- The Merck Index - Explanatory Monograph - tcm18-219796 PDFDocument1 pageThe Merck Index - Explanatory Monograph - tcm18-219796 PDFRogézio D'GuimaNo ratings yet

- IAAC SolutionsDocument7 pagesIAAC SolutionsAayush BorkarNo ratings yet

- DPF Cleaner Agent MSDS 2021Document5 pagesDPF Cleaner Agent MSDS 2021Jorge SepulvedaNo ratings yet

- Ejercicio 1 Actividad 4 - PhysioexDocument4 pagesEjercicio 1 Actividad 4 - PhysioexMayra MarroquinNo ratings yet

- Injection Molding of RubberDocument39 pagesInjection Molding of RubberadhityaNo ratings yet

- Steps For SPDB ViewerDocument10 pagesSteps For SPDB ViewerPrayukta PadelkarNo ratings yet

- Chapter 6 Chemistry in Biology QuestionsDocument102 pagesChapter 6 Chemistry in Biology QuestionsOlga OrtegaNo ratings yet

- Proper Piping For Vacuum SystemsDocument5 pagesProper Piping For Vacuum SystemsDowni Oader100% (1)

- Tutorial 2 Air-Standard CyclesDocument3 pagesTutorial 2 Air-Standard CyclesPhineas sehoanaNo ratings yet

- Experiment On Centrifugation Unit Ops 1Document4 pagesExperiment On Centrifugation Unit Ops 1Ryan VasquezNo ratings yet

- Biology Student's BookDocument15 pagesBiology Student's BookYelnur SholpanNo ratings yet

- Stoichiometry DocumentDocument43 pagesStoichiometry DocumentMoiz AhmedNo ratings yet

- MODULE 03 and 04 Problem SetDocument5 pagesMODULE 03 and 04 Problem SetIan Arnold FamiNo ratings yet

- Alfacylo MsdsDocument5 pagesAlfacylo Msdsvangeliskyriakos8998No ratings yet

- Akermanite Mineral Data1Document4 pagesAkermanite Mineral Data1BlacksacerdoteNo ratings yet

- Alu Alu Cold-Forming FoilDocument1 pageAlu Alu Cold-Forming FoilManivannan KathirvelNo ratings yet

- TB 291 Keystone Colorants For Wood Coatings (2!16!12)Document9 pagesTB 291 Keystone Colorants For Wood Coatings (2!16!12)Locer2011No ratings yet

- 4 Thick Cylinders AsgnDocument5 pages4 Thick Cylinders AsgnHILMAN NAZRINo ratings yet

- Sludge BulkingDocument24 pagesSludge BulkingEdo Fransiskus Aritonang100% (1)

- Expansive Soils PaperDocument7 pagesExpansive Soils PaperJhe TaguinesNo ratings yet

- DOWSIL™ 3037 Intermediate: Features & BenefitsDocument3 pagesDOWSIL™ 3037 Intermediate: Features & BenefitsZhan FangNo ratings yet

- Chemeo 18-027-2 TrioleinDocument3 pagesChemeo 18-027-2 TrioleinklpiNo ratings yet

- Poster IMIT SIC Versi 2Document1 pagePoster IMIT SIC Versi 2devi ratnawatiNo ratings yet

- Report With ConclusionDocument30 pagesReport With ConclusionAhmed YounisNo ratings yet

- Ijpbr 2011 04 77Document7 pagesIjpbr 2011 04 77Muslihatus SyarifahNo ratings yet

- Automotive Lubrication SystemDocument66 pagesAutomotive Lubrication SystemSadbin MiaNo ratings yet

- Activity 9.0 GeologyDocument4 pagesActivity 9.0 GeologyAbigail HibayaNo ratings yet