Professional Documents

Culture Documents

GM 1927-16b Bending Application Process Audit-GM Confidential

Uploaded by

Gabriel SánchezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GM 1927-16b Bending Application Process Audit-GM Confidential

Uploaded by

Gabriel SánchezCopyright:

Available Formats

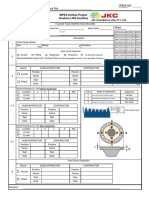

Process Name - Bending Application

Version: Initial Release Issue Date: July 4, 2010

Auditor: Date: Score

Supplier: Location: 0%

Duns: Part Name: RED

A. Section A Title AUDIT WORKSHEET

EVIDENCE/ G

QUESTION: DOCUMENTATION QUESTIONS TO ASK AND WHAT TO LOOK FOR Answer Y OBSERVATIONS

REQUIRED R

Enter required evidence NR NR ###

1 Does Supplier steel hardness check when material income description Hardness must in Spec.

Are the steel surface clean(have no dirty,grain,scratch)? Incoming material check guidance NR NR ###

2

Is the bending tool surface clean and take maintenance Verification check in Process Control Plans and Work Instructions

each shift?

NR NR ###

3

Are the bending machine clips robust? Check the movement clip which hold part position when bending. NR NR ###

4

Does the supplier put the part in right position? How to Verify the position datum of the bend machine / the lock

make sure the position, How to hold the position? mechanism/error proofing device.

NR NR ###

5

Do supplier have the oil bending machine parameter?(based One chart mark out the raw material hardness and the oil pressure a

on oil bending machine) judgment relationship

NR NR ###

6

How can supplier make sure the section change before and If the bending tool is robust and good maintained ?If the supplier

after bending is in spec have section check each batch?

NR NR ###

7

If supplier have some assistant equipment/attachment to keep the

How could supplier make sure parts is continually bended whole parts bended smoothly?( Youli stick? Snake bone)How about NR NR ###

the attachment changeover frequency and maintenance?

8

Are the operators using gloves that do not leave fibers or Identified in Operator Work Instructions

lint on the part surface?

NR NR ###

9

10 Are operators using due care while handling parts? Standardized work instructions for protecting material. NR NR ###

Is the supplier allowing sufficient time to keep the pressure Bending cycle time check, no time adjust without engineer

on the parts when bending? authorization.

NR NR ###

11

If a manual operation exists, are the proper checks robust? Error proofing, defect data. NR NR ###

12

Is the Control Plan, PFMEA, and Work Instructions updated Approved Boundary Samples

with good boundary samples?

NR NR ###

13

Are the check aid match the GD&T or have been modified according

to the real assembly status? How about the parts status without NR NR ###

locked on the check fixture? Can the check fixture grasp the

14 How about the checking aid status? deviation of the bending curve degree?

Are the check fixture maintained /calibrated regularlly?No NR NR ###

15 How about the checking aid Maintenance status? attachment lost of the check aid, no rust, right calibrated

16 How about the checking aid use status Are the check fixture used according to the WI? NR NR ###

Total

SCORE

Rating:

Green ≥ 90% / Yellow 70-89% / Red ≤ 69%

Sections Percent of compliance Results score

A. Section A Title 0% RED ###

If any of the single sections is rated RED, overal audit result is RED with 0% score

Summary score 0% RED Pts Element Scoring

Requirements not met, needs immediate correction

0 SQE to assure actions are in place prior to leaving the facility,

including CS1/2 implementation if necessary

Requirements not met, process acceptable with additional controls in

1 place

2 Requirements met, process has improvement potential

3 Requirements fully met, best practice process in place

NA Not Applicable (does not impact audit score)

Supplier Representative Name with Signature

GM Representative Name with Signature NR Not Rated (impacts audit score)

Audit form 746188963.xlsx Version 1.0

GM Confidential 3 Issue Date: July 4, 2010

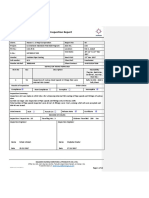

Supplier Start Date: SQE

Location Rev. Date: SQE Phone:

Duns Grad Date: Manager:

Commodity Program: Group:

Prepared by: Creativity Team:

G Green - Task Completed on Time

Y Yellow - Task May Be Late

R Red - Task is Late

W White - Task Re-Timed, No Status

B Blue - Task Status is Incorrect / Not Updated

On Track (Bold Box/No Color)

STATUS

Most

Oldest Recent

AUDIT DATE TARGET ACTUAL LAST

ITEM Priority ACTION ITEM ACTION LEADER 1 2 3 4 5 6 COUNTER MEASURES

SECTION OPENED CLOSE DATE CLOSE DATE UPDATE

1

2

3

4

5

6

7

8

9

10

Action Form 746188963.xlsx Version 1.0

GM Confidential 3 Issue Date: July 4, 2010

Audit form developed by:

Name Department Region Phone Mail

Frank Luo Dept

Changes Log:

Date Version Description

7/4/2010 Initial Release Initial audit release

Change Log 746188963.xlsx Version 1.0

GM Confidential 3 Issue Date: July 4, 2010

You might also like

- GM 1927-16b Exhaust Pipe Bending Process AuditDocument4 pagesGM 1927-16b Exhaust Pipe Bending Process AuditJOHNNo ratings yet

- GM 1927 16b Resistance Spot Welding Process AuditDocument6 pagesGM 1927 16b Resistance Spot Welding Process AuditGabriel SánchezNo ratings yet

- GM 1927-16b MIG-Gas Weld Process AuditDocument5 pagesGM 1927-16b MIG-Gas Weld Process AuditJOHNNo ratings yet

- GM 1927 16b Gas Mig Weld Process AuditDocument6 pagesGM 1927 16b Gas Mig Weld Process AuditGabriel SánchezNo ratings yet

- GM 1927-16b Welding Process AuditDocument5 pagesGM 1927-16b Welding Process AuditJOHNNo ratings yet

- Dimensional Inspection ReportDocument2 pagesDimensional Inspection ReportShanty WibowoNo ratings yet

- PSWDocument1 pagePSWKunal KarmakarNo ratings yet

- GM 1927-16b Tiered Supplier Process AuditDocument5 pagesGM 1927-16b Tiered Supplier Process AuditJOHNNo ratings yet

- ITR For Electrical Instrument PDFDocument4 pagesITR For Electrical Instrument PDFCokro YudhaNo ratings yet

- Ultrasonic Inspection (UT)Document2 pagesUltrasonic Inspection (UT)Ankit KumarNo ratings yet

- Auditoria de Mezcla de GasesDocument4 pagesAuditoria de Mezcla de GasesTeo de los SantosNo ratings yet

- Laporan Hasil & Dokumentasi CondenserDocument10 pagesLaporan Hasil & Dokumentasi CondensernbagarNo ratings yet

- Inspection and Test Plan - Steel AssemblyDocument1 pageInspection and Test Plan - Steel AssemblyAvinash LalNo ratings yet

- Inspection Checklist: HFO Pipes and Fittings Material Receiving PipingDocument2 pagesInspection Checklist: HFO Pipes and Fittings Material Receiving PipingSardarFaisalHameedNo ratings yet

- Control PlanDocument1 pageControl Planlingkungan.agathaNo ratings yet

- 5 ITP Block WorkDocument2 pages5 ITP Block Workahmsami91No ratings yet

- RF003 Road MarkingsDocument1 pageRF003 Road MarkingsSyerifaizal Hj. MustaphaNo ratings yet

- Daily Welding Fixture Condition Monitoring Sheet - F0926 - CDocument2 pagesDaily Welding Fixture Condition Monitoring Sheet - F0926 - CPearlsgodNo ratings yet

- Initial Sample Assurance Report: Reason For SubmissionDocument2 pagesInitial Sample Assurance Report: Reason For SubmissionSuraj RawatNo ratings yet

- Inspection and Test Plan - ErectionDocument2 pagesInspection and Test Plan - ErectionAvinash LalNo ratings yet

- Inspection Checklist: Pipes and Fittings Material Receiving PipingDocument2 pagesInspection Checklist: Pipes and Fittings Material Receiving PipingSardarFaisalHameed100% (1)

- SECL-CV420-A4 Foundation Check ListDocument2 pagesSECL-CV420-A4 Foundation Check ListhadefNo ratings yet

- QCR W 2016Document1 pageQCR W 2016Madhan KannanNo ratings yet

- Internal Dispatch Clearance ChecklistDocument54 pagesInternal Dispatch Clearance ChecklistMahesh2101No ratings yet

- Compliance Sheet FormatDocument1 pageCompliance Sheet Formatdaud hafizNo ratings yet

- Saudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistNickath BanuNo ratings yet

- Short Audit Readiness Checksheet ResultDocument2 pagesShort Audit Readiness Checksheet ResultArdy AlkaafNo ratings yet

- Checklist For Turnstile FixingDocument1 pageChecklist For Turnstile FixingGabriel GabeNo ratings yet

- Process Discipline Equipment List Checklist: Jacobs Logo - Blue - SmallDocument5 pagesProcess Discipline Equipment List Checklist: Jacobs Logo - Blue - SmallShubham CholeNo ratings yet

- 5.2. Internal Light & Wiring Device Function TestDocument2 pages5.2. Internal Light & Wiring Device Function TestMariam AwadNo ratings yet

- Inspection-Test-plan For Block WorkDocument3 pagesInspection-Test-plan For Block WorkAbdulrahman Alkilani100% (2)

- Flange Face Inspection Record CCPP R5Document1 pageFlange Face Inspection Record CCPP R5asfaruk2556100% (1)

- SECL-CV210-A4 Pre-Pouring InspectionDocument1 pageSECL-CV210-A4 Pre-Pouring InspectionhadefNo ratings yet

- ELECT-TIC-2.8 (Torque Testing and Final Inspection)Document4 pagesELECT-TIC-2.8 (Torque Testing and Final Inspection)Muhammad IrfanNo ratings yet

- MCF c023 1861 50 Cleat Plate Powerstone IrDocument1 pageMCF c023 1861 50 Cleat Plate Powerstone IrIveel PurevdorjNo ratings yet

- ITP For Installation of Structured Cabling For CommunicationDocument1 pageITP For Installation of Structured Cabling For CommunicationInfas YahyaNo ratings yet

- Non Conformity ReportDocument1 pageNon Conformity ReportBasker Balu0% (1)

- Formulir Premob Inspection LoaderDocument3 pagesFormulir Premob Inspection LoaderElni Gita Girsang100% (1)

- ETP - Reinforcement Concrete WorksDocument7 pagesETP - Reinforcement Concrete WorksjiniNo ratings yet

- SKN - 004 JRA Lift and Run Electrical CableDocument3 pagesSKN - 004 JRA Lift and Run Electrical Cable121212No ratings yet

- Rev. Description Date Prepared by Checked by Checked by Approved byDocument5 pagesRev. Description Date Prepared by Checked by Checked by Approved byYasser FathiNo ratings yet

- ITP For Testing & Commissioning SwitchgearDocument1 pageITP For Testing & Commissioning SwitchgearguspriyNo ratings yet

- QCR W 2009Document2 pagesQCR W 2009Madhan KannanNo ratings yet

- Non Conformance ReportDocument2 pagesNon Conformance Reporttar99que99No ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- Precision Equipments (Chennai) Pvt. LTD.: Ultrasonic Examination ReportDocument5 pagesPrecision Equipments (Chennai) Pvt. LTD.: Ultrasonic Examination ReportqaNo ratings yet

- GM 1927-16b Injection Molding Process AuditDocument6 pagesGM 1927-16b Injection Molding Process AuditfernandoNo ratings yet

- Construction Check Sheet Orifice Plate Pre-Installation Check I-005ADocument1 pageConstruction Check Sheet Orifice Plate Pre-Installation Check I-005AKailash PandeyNo ratings yet

- QCR W 2035Document1 pageQCR W 2035Madhan KannanNo ratings yet

- Check Sheet I QCDocument4 pagesCheck Sheet I QCEri ParihahNo ratings yet

- Inspection Report For Installation of Fire & Gas DetectorsDocument1 pageInspection Report For Installation of Fire & Gas Detectorsnayum0% (1)

- TS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIDocument3 pagesTS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIict petrexNo ratings yet

- Project Name Project No.: OOOO: Installation of Lighting Fixture, Switch and OutletDocument10 pagesProject Name Project No.: OOOO: Installation of Lighting Fixture, Switch and OutletReynante AlimNo ratings yet

- CW2099436 Q006 0003 - R1Document1 pageCW2099436 Q006 0003 - R1D S Sagar TripuramalluNo ratings yet

- Sample QAPDocument3 pagesSample QAPArjun ChouhanNo ratings yet

- Asa-146 NSH Apco Ir 040Document10 pagesAsa-146 NSH Apco Ir 040Fahad AhmadNo ratings yet

- GM 1927 16b Stamping Process Audit-GM ConfidentialDocument6 pagesGM 1927 16b Stamping Process Audit-GM ConfidentialGabriel SánchezNo ratings yet

- Underground Drainage Pipes - Installation & TestingDocument1 pageUnderground Drainage Pipes - Installation & TestingBharathraj RajNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementFrom EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementRating: 4.5 out of 5 stars4.5/5 (2)

- Online Motor Vehicle Licensing SystemDocument78 pagesOnline Motor Vehicle Licensing Systempsalmistme100% (1)

- Const221 Document caughtInHazardsAccessibleDocument22 pagesConst221 Document caughtInHazardsAccessiblelurawi2023No ratings yet

- Challenger Ethical Case StudyDocument7 pagesChallenger Ethical Case StudySam GitongaNo ratings yet

- Flowserve Butterfly ValveDocument8 pagesFlowserve Butterfly ValveDGWNo ratings yet

- LATDocument12 pagesLATRicha SunnyNo ratings yet

- Design of Jigs and FixturesDocument3 pagesDesign of Jigs and FixturesRajueswarNo ratings yet

- Ch03 ChenDocument24 pagesCh03 ChenSri RNo ratings yet

- Getting Started With BitbucketDocument9 pagesGetting Started With BitbucketAmit Sharma100% (1)

- PPM Case Study AnswersDocument15 pagesPPM Case Study AnswersMohamed Kadri100% (2)

- Telelift 4514 ServiceDocument223 pagesTelelift 4514 ServiceDragan Lugonić75% (4)

- Preguntas de Certificación ABAPDocument61 pagesPreguntas de Certificación ABAPGabriel Gonzalez SalazarNo ratings yet

- Lecture2 Feb8Document11 pagesLecture2 Feb8Abhishek PuriNo ratings yet

- Construction ContractDocument3 pagesConstruction ContractLahiru WijethungaNo ratings yet

- Business Resilience and Risk Management PolicyDocument6 pagesBusiness Resilience and Risk Management PolicysarabNo ratings yet

- 2010 National Steel Design Awards The Bow Tower: A New Urban Giant New Q & A Column Ask Dr. Sylvie Goes GreenDocument28 pages2010 National Steel Design Awards The Bow Tower: A New Urban Giant New Q & A Column Ask Dr. Sylvie Goes GreenYuan SorensenNo ratings yet

- Secco Catalogo 1Document16 pagesSecco Catalogo 1emilio_707No ratings yet

- Catalog Feronerie Fereastra Termopan Tripan PVC SiegeniaDocument24 pagesCatalog Feronerie Fereastra Termopan Tripan PVC SiegeniaOmul Fara NumeNo ratings yet

- Thesis Proposal Lani BalanonDocument8 pagesThesis Proposal Lani BalanonKenneth GoNo ratings yet

- BQP ReportDocument5 pagesBQP ReportCristea RalucaNo ratings yet

- BoschHeft9 E 01 PDFDocument42 pagesBoschHeft9 E 01 PDFdiegomilitojNo ratings yet

- Muhammad Babar Muhammad Shahbaz Muhammad IshaqDocument2 pagesMuhammad Babar Muhammad Shahbaz Muhammad IshaqAdv Imran RehmanNo ratings yet

- Sharmistha Roy Chowdhury: SummaryDocument6 pagesSharmistha Roy Chowdhury: SummaryDeepak SimhadriNo ratings yet

- Modeling and Simulation of A Distillation Column Using MatlabDocument15 pagesModeling and Simulation of A Distillation Column Using Matlabrajtharun48No ratings yet

- Practice PLSQLDocument52 pagesPractice PLSQLEugenNo ratings yet

- Microsoft Flight Simulator X Game GUIDEDocument51 pagesMicrosoft Flight Simulator X Game GUIDEkress100% (1)

- Customer SC Collaboration at Heineken: Marc Bekkers Bart PrinsDocument27 pagesCustomer SC Collaboration at Heineken: Marc Bekkers Bart Prinsquỳnh nhưNo ratings yet

- E192 PDFDocument3 pagesE192 PDFDaniel Mauricio Prieto Valderrama100% (1)

- Lotus Sametime 3DDocument23 pagesLotus Sametime 3DsvrbchaudhariNo ratings yet

- Content Extraction From Marketing Flyers: (Ignazio - Gallo, A.zamberletti, Lucia - Noce) @uninsubria - ItDocument2 pagesContent Extraction From Marketing Flyers: (Ignazio - Gallo, A.zamberletti, Lucia - Noce) @uninsubria - ItcYbernaTIc enHancENo ratings yet

- BWA Overview Presentation: Clear Solutions For Water TreatmentDocument10 pagesBWA Overview Presentation: Clear Solutions For Water TreatmentByronNo ratings yet