Professional Documents

Culture Documents

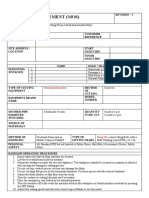

KA30 Checklist For FULL BODY HARNESS

Uploaded by

PRIYESH . K. PRIYAN0 ratings0% found this document useful (0 votes)

4 views2 pagesOriginal Title

KA30 Checklist for FULL BODY HARNESS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesKA30 Checklist For FULL BODY HARNESS

Uploaded by

PRIYESH . K. PRIYANCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

HEALTH, SAFETY & ENVIRONMENT PLAN

FULL BODY HARNESS CHECKLIST

Project Name: FBH No.:

Contractor Name: Inspection Date:

FBH Specs.: Next Inspection Date:

SNo. Description Pass (✓) / Fail

(×)

Webbing

1 Cuts, nicks or tears

2 Broken fibers/cracks

3 Overall deterioration

4 Modifications by user

5 Fraying/Abrasions

6 Discoloration of material (Depend on cause of discoloration)

7 Hard or shiny spots (Indicates heat damage)

8 Mildew (Clean lanyard)

9 Missing or popped flag (Indicates possible fall)

10 Undue Stretching (Indicates possible fall)

11 Burnt, charred or melted fibers (Indicates Heat Damage)

12 Material marked with permanent maker (Check manufacturer)

13 Excessive hardness or brittleness (Indicates heat or uv damage)

14 Knots in lanyard

Stitching

1 Pulled stitches

2 Stitching that is missing

3 Hard or shiny spots (Indicates heat damage)

4 Cut stitches

5 Discoloration of stitching (Depend on cause of discoloration)

Snap hook

1 Snap hook should be self-locking type

2 No hook or eye distortion (twists, bends or elongations)

3 Latch/keeper should seat into the nose w/o binding

4 Latch/keeper should not be distorted or obstructed

5 Overall deterioration/Excessive wear

6 Modifications by the user

7 Rust/pitting/corrosion

8 No cracks, No excessive wear, No missing parts, No rough or sharp edges

Snap Hook Locking Mechanism

1 Disengage locking mechanism and open keeper(Keeper should open freely)

2 Disengage locking mechanism and release (locking mechanism should return to the position)

Snap Hook Keeper

1 Check keeper spring action by opening the keeper and releasing (Keeper should return to close position

without hanging up it should not close slowly)

2 Push on keeper without engaging locking mechanism (keeper should not open)

3 Check to see the keeper is seated firmly on the snap hook nose – there should be no side play. (lateral

movement)

Tagging system

1 Check tag for date of manufacturer and remove from service if past adopted service life policy.

2 If tagging system is missing remove lanyard from service.

Rope Lanyards (Synthetic)

1 Rope diameter (Uniformity of diameter along the rope)

2 If areas appear to be reduced more than 5% from original diameter remove from service.

3 Fiber, cuts or nicks / Broken fibers / worn fibers / Overall deterioration / Modifications by user

4 Fraying/Abrasions

5 Hard or shiny spots (Indicates heat damage) / Fused fibers or strands (Indicates heat damage)

6 Kinks, hockling or knots / Discoloration of rope & brittle fibers

HEALTH, SAFETY & ENVIRONMENT PLAN

7 Change in original diameter (Indicates possible fall) / Burnt, charred or melted fibers (Indicates heat damage)

Thimbles and Eyes

1 Missing / Loose thimble(s)

2 Damaged thimbles – white stress marks, thimble collapse over itself

3 Eye damage due to cuts, nicks, abrasions, and fraying, fused indicators as you would for the rope body itself.

4 Eyes with metal thimbles – look for rust in or around the eye.

Rope Splices

1 Splices not secured properly from unvraveiling look for tape, shrink wrap tube, stiffening agent.

2 Splices starting to unravel / Splices showing damage or deterioration

Any Observations:

Checked by Name Signature Date

Contractor Safety

Officer

Status Of

Inspection by

M Moser Accepted…………………………………. Rejected……………………………….

Checked by Name Signature Date

M Moser /

Client

You might also like

- 03 Safety Harness Inspection SheetDocument4 pages03 Safety Harness Inspection Sheetxiangjintao100% (1)

- 04 Check List For Fire Extinguisher - pdf-1Document1 page04 Check List For Fire Extinguisher - pdf-1med touailab100% (1)

- Beam ClampDocument1 pageBeam ClampTrust EmmaNo ratings yet

- FORM-03-OHSE-46 Weekly Basic Blower ChecklistDocument1 pageFORM-03-OHSE-46 Weekly Basic Blower ChecklistSri Eko50% (2)

- ACETAL COPOLYMER AMCEL KP20 Safety Data SheetDocument8 pagesACETAL COPOLYMER AMCEL KP20 Safety Data SheetHector VelezNo ratings yet

- 006 PLI - Form - Inspection Lifting GearDocument3 pages006 PLI - Form - Inspection Lifting GearRicky Stormbringer ChristianNo ratings yet

- IMS HSE CL 39 Checklist For ShacklesDocument1 pageIMS HSE CL 39 Checklist For Shacklesgopakumar p dNo ratings yet

- 5 Full Body Harness Safety Belt Check List 22.6.15-1Document2 pages5 Full Body Harness Safety Belt Check List 22.6.15-1ankitNo ratings yet

- 63) SHER-REG-FRM58-LI Rev0Document1 page63) SHER-REG-FRM58-LI Rev0REHOBOTH YAMBO KAHILUNo ratings yet

- 06 JSE - Form - Inspection Lifting GearDocument4 pages06 JSE - Form - Inspection Lifting GearMawan Aghna100% (2)

- MCB2111B - 15 - 156 - Comm - Bin - NC Manual de Ensamble Silos Fondo Plano Serie E (OK)Document52 pagesMCB2111B - 15 - 156 - Comm - Bin - NC Manual de Ensamble Silos Fondo Plano Serie E (OK)Nicolas LondoñoNo ratings yet

- Full Body Harness Inspection Checklist: Labels and Markings Pass Fail RemarksDocument1 pageFull Body Harness Inspection Checklist: Labels and Markings Pass Fail RemarksYoh FuhNo ratings yet

- Contractor Check SheetsDocument36 pagesContractor Check Sheetsraunak kerkarNo ratings yet

- 5 - Bulldozer ChecklistDocument1 page5 - Bulldozer ChecklistWalton FonikNo ratings yet

- Pressure Vessel - Inspectin CertificateDocument3 pagesPressure Vessel - Inspectin CertificateSpectex dubaiNo ratings yet

- Crane Inspection ChecklistDocument2 pagesCrane Inspection Checklistputra farithNo ratings yet

- SPM Safety Iron Inspection and Maintenance ProcedureDocument19 pagesSPM Safety Iron Inspection and Maintenance ProcedureIvan RojasNo ratings yet

- Hse Master ChecklistDocument541 pagesHse Master ChecklistVinay Tunge100% (2)

- Halliburton Multi Chem Batch Plant Project Safety Inspection Checklist - Angle GrinderDocument1 pageHalliburton Multi Chem Batch Plant Project Safety Inspection Checklist - Angle GrinderMuhammad Umar GondalNo ratings yet

- Verif EPI Casque PRO Suivi enDocument1 pageVerif EPI Casque PRO Suivi eneastNo ratings yet

- NDT - PBLDocument1 pageNDT - PBLSusil Kumar SahooNo ratings yet

- Sample - Inspection & Test Procedure - Rev.A - ADocument8 pagesSample - Inspection & Test Procedure - Rev.A - AJiwoo A-TechNo ratings yet

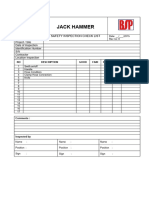

- Jack HammerDocument3 pagesJack HammerEko SpdNo ratings yet

- Hse Master ChecklistDocument429 pagesHse Master ChecklistLantNo ratings yet

- AEG JSA 107 Angle GrinderDocument3 pagesAEG JSA 107 Angle GrinderSai PrasathNo ratings yet

- Welding Machine & Travo InspectionDocument1 pageWelding Machine & Travo InspectionBayu BiroeNo ratings yet

- Longdar SM906 InspectionDocument2 pagesLongdar SM906 InspectionLê Anh MinhNo ratings yet

- Welding Machine Inspection ChecklistDocument1 pageWelding Machine Inspection Checklistwahajyameen308No ratings yet

- Inspection Logs - All PDFDocument11 pagesInspection Logs - All PDFfery buyaNo ratings yet

- Welder's Qualification Test CertificateDocument1 pageWelder's Qualification Test CertificatekannanNo ratings yet

- En Iso 9606 1Document1 pageEn Iso 9606 1Ümitcan TanrıkuluNo ratings yet

- Form-HSE-TMR-011 Bar Cutter InspectionDocument1 pageForm-HSE-TMR-011 Bar Cutter Inspectionkenia infoNo ratings yet

- Pressure Vessel InspectionDocument3 pagesPressure Vessel InspectionSpectex dubaiNo ratings yet

- Adapters and Drilling SpoolsDocument2 pagesAdapters and Drilling SpoolsKaleem UllahNo ratings yet

- Pour CardDocument2 pagesPour Cardsuchendra singhNo ratings yet

- BC 1Document4 pagesBC 1Linh nguyễnNo ratings yet

- Pt. Krakatau Engineering: Sling InspectionDocument2 pagesPt. Krakatau Engineering: Sling InspectionAngga FajarudinNo ratings yet

- Chain Pulley Block Inspection Checklist Global EHS 030Document1 pageChain Pulley Block Inspection Checklist Global EHS 030Safety MohiniNo ratings yet

- Safety Harness Inspection Checklist 1Document1 pageSafety Harness Inspection Checklist 1Erica Araceli Gallegos AriasNo ratings yet

- Insulation & Liner Application Report: V17491/PO V0009815Document1 pageInsulation & Liner Application Report: V17491/PO V0009815pstechnical_43312697No ratings yet

- PSHSA Sample FallEquipmentInspectionFormDocument2 pagesPSHSA Sample FallEquipmentInspectionFormNarantsatsralt RavdandorjNo ratings yet

- Fall ArrestersDocument1 pageFall ArrestersTrust EmmaNo ratings yet

- Cold Cut Method of Statement - Rev0Document2 pagesCold Cut Method of Statement - Rev0Lim S LNo ratings yet

- Grinding Machine ChecklistDocument1 pageGrinding Machine ChecklistBiswaranjan SahooNo ratings yet

- CL-29. Concrete BucketDocument1 pageCL-29. Concrete BucketRavi thokalNo ratings yet

- Service and Maintenace Report FormDocument1 pageService and Maintenace Report Formmj santosNo ratings yet

- Inspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadDocument1 pageInspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadilyasNo ratings yet

- Petunjuk Pengisian Form HSEDocument3 pagesPetunjuk Pengisian Form HSENovia Zulfa HanumNo ratings yet

- L021 - OHSE Piling Work Permit Cum Checklist FormatDocument1 pageL021 - OHSE Piling Work Permit Cum Checklist FormatRajib MondalNo ratings yet

- Checklist - Ascenders - Petzl Hand & Chest - 050717Document1 pageChecklist - Ascenders - Petzl Hand & Chest - 050717Max BeeksNo ratings yet

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseDocument2 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseKaleem UllahNo ratings yet

- Gear Failure AnalysisDocument22 pagesGear Failure AnalysisKarthick Kumar100% (1)

- Portable Grinder-Pre Inspection ChecklistDocument2 pagesPortable Grinder-Pre Inspection ChecklistMartine Otieno100% (1)

- Checklist - Lanyard - Petzl ABSORBICA-I-YDocument1 pageChecklist - Lanyard - Petzl ABSORBICA-I-YMax BeeksNo ratings yet

- Full Body Harnest: Pt. Unilever Oleochemical Indonesia Sei Mangkei Kab. SimalungunDocument1 pageFull Body Harnest: Pt. Unilever Oleochemical Indonesia Sei Mangkei Kab. SimalungunMahar DikaNo ratings yet

- Editable ISO 9606-1-2013 WQTDocument1 pageEditable ISO 9606-1-2013 WQTAshish PatelNo ratings yet

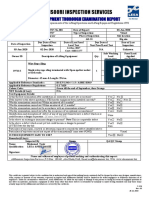

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 3 Con 8749 Rec 324 - Welder Approval Test ReportDocument1 page3 Con 8749 Rec 324 - Welder Approval Test ReporttinzarmoeNo ratings yet

- Hot Work Permit: Welding Bracing/Cutting/Grinding/SolderingDocument2 pagesHot Work Permit: Welding Bracing/Cutting/Grinding/Solderingsindarth raveendrakrishnan100% (4)

- Protective Material Coatings for Preserving Cultural Heritage Monuments and ArtworkFrom EverandProtective Material Coatings for Preserving Cultural Heritage Monuments and ArtworkNo ratings yet

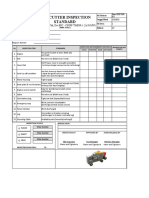

- KA 43 Excavator Safety ChecklistDocument1 pageKA 43 Excavator Safety ChecklistPRIYESH . K. PRIYANNo ratings yet

- HYD 20 - HIRA Cable Laying and TerminationDocument8 pagesHYD 20 - HIRA Cable Laying and TerminationPRIYESH . K. PRIYANNo ratings yet

- Cable Laying &termination HIRADocument66 pagesCable Laying &termination HIRAPRIYESH . K. PRIYANNo ratings yet

- R 12 Hot Work Permit FormatDocument2 pagesR 12 Hot Work Permit FormatPRIYESH . K. PRIYANNo ratings yet

- Wall Tile Fixing-Risk AssessmentDocument3 pagesWall Tile Fixing-Risk AssessmentPRIYESH . K. PRIYANNo ratings yet

- Tower Crane Maintenance ChecklistDocument2 pagesTower Crane Maintenance ChecklistPRIYESH . K. PRIYANNo ratings yet

- Lux Level CheckingDocument1 pageLux Level CheckingPRIYESH . K. PRIYANNo ratings yet

- KA 40 Pic-Checklist For Generator (DG)Document2 pagesKA 40 Pic-Checklist For Generator (DG)PRIYESH . K. PRIYANNo ratings yet

- Emergency Vehicle ChecklistDocument1 pageEmergency Vehicle ChecklistPRIYESH . K. PRIYANNo ratings yet

- Check List For Legal Compliance by ContractorDocument2 pagesCheck List For Legal Compliance by ContractorPRIYESH . K. PRIYANNo ratings yet

- Fire Extinguisher Inspection 01Document1 pageFire Extinguisher Inspection 01PRIYESH . K. PRIYANNo ratings yet

- R 02 Fitouts General Work PermitDocument1 pageR 02 Fitouts General Work PermitPRIYESH . K. PRIYANNo ratings yet

- Checklist For Sling InspectionDocument1 pageChecklist For Sling InspectionPRIYESH . K. PRIYANNo ratings yet

- Modulare Systems For Conveyor PlantsDocument36 pagesModulare Systems For Conveyor Plantsado31No ratings yet

- Basf Masterseal Roof 3000 TdsDocument2 pagesBasf Masterseal Roof 3000 TdsmidaNo ratings yet

- 0002-SPC-HOBWT03-ME-8006 - C General Mechanical Specification Bryn Estyn Water Treatment PlantDocument35 pages0002-SPC-HOBWT03-ME-8006 - C General Mechanical Specification Bryn Estyn Water Treatment PlantzufriateguiNo ratings yet

- Recycled Glass Utilization in Highway Construction Isaac Finkle, GRA, EITDocument25 pagesRecycled Glass Utilization in Highway Construction Isaac Finkle, GRA, EITUsama HeneashNo ratings yet

- App 10093Document9 pagesApp 10093Omkar BordeNo ratings yet

- Coursebook Answers: Science in Context: Lord of The RingsDocument39 pagesCoursebook Answers: Science in Context: Lord of The RingsEshanNo ratings yet

- Unit 5 - OnlineDocument31 pagesUnit 5 - OnlineVi NguyễnNo ratings yet

- Irostic para Adhesivo PCVDocument3 pagesIrostic para Adhesivo PCVlobocerna0% (1)

- Moles and Empirical FormulaDocument11 pagesMoles and Empirical FormulaZenoxu 7zNo ratings yet

- TDS-BS 3262 ThermoplasticsDocument2 pagesTDS-BS 3262 Thermoplasticsain kamarudinNo ratings yet

- Hxe ImDocument61 pagesHxe ImHồ Viết DuyNo ratings yet

- Irclea: Disposable Glass Fibre Air FiltersDocument2 pagesIrclea: Disposable Glass Fibre Air FiltersravichandranNo ratings yet

- SDS Carmeuse CaODocument6 pagesSDS Carmeuse CaOBagas Prasetyawan Adi NugrohoNo ratings yet

- Column Buckling - Inelastic: A Long TopicDocument43 pagesColumn Buckling - Inelastic: A Long TopicKishore BhatNo ratings yet

- Intercambiador de CalorDocument12 pagesIntercambiador de CalorCarlos MarrugoNo ratings yet

- The Fundamentals OF ELECTROCHEMISTRYDocument30 pagesThe Fundamentals OF ELECTROCHEMISTRYAshwaniNo ratings yet

- Encyclopedia of Polymers and CompositesDocument713 pagesEncyclopedia of Polymers and CompositesvladoferdNo ratings yet

- Zanussi ZWS 510801Document20 pagesZanussi ZWS 510801LoreelayNo ratings yet

- EDEXCEL A2 CHEMISTRY UNIT 4 January 2011Document24 pagesEDEXCEL A2 CHEMISTRY UNIT 4 January 2011Ghaleb W. MihyarNo ratings yet

- Is 15683 2006 PDFDocument39 pagesIs 15683 2006 PDFPrashant AgrawalNo ratings yet

- Basic Physical Properties of PVOH ResinDocument40 pagesBasic Physical Properties of PVOH ResinJavier RealNo ratings yet

- Ashrae 62-73Document20 pagesAshrae 62-73Jose Luis ZIMICNo ratings yet

- Mech 325-Strength of Materials SyllabusDocument2 pagesMech 325-Strength of Materials Syllabuspicefeati100% (1)

- ExerciseDocument4 pagesExerciseAshebirNo ratings yet

- ASR 213 V1.1 Materials Processes and Products ClassificationDocument40 pagesASR 213 V1.1 Materials Processes and Products ClassificationOUSMAN SEIDNo ratings yet

- Windows - Building in - G JamesDocument5 pagesWindows - Building in - G JamesAndrew VincentNo ratings yet

- Chemistry G12 Model Exam2016Document10 pagesChemistry G12 Model Exam2016Bereket AsefaNo ratings yet

- Aero HF 585 BDocument2 pagesAero HF 585 Bnauta007No ratings yet

- UNEP Guidelines For PCBsDocument40 pagesUNEP Guidelines For PCBskashifbutty2kNo ratings yet