Professional Documents

Culture Documents

NK 50250235 Aa2f2aesbaqerw1

Uploaded by

rifanderiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NK 50250235 Aa2f2aesbaqerw1

Uploaded by

rifanderiCopyright:

Available Formats

Qty.

Description

1 NK 50-250/235 AA2F2AESBAQERW1

Note! Product picture may differ from actual product

Product No.: On request

Non-self-priming, single-stage, centrifugal pump designed according to ISO 5199 with dimensions and rated

performance according to EN 733. Flanges are PN 16 with dimensions according to EN 1092-2. The pump has an

axial suction port, a radial discharge port and horizontal shaft. It is of the back pull-out design enabling removal of the

motor, coupling, bearing bracket and impeller without disturbing the pump housing or pipework.

The unbalanced rubber bellows seal is according to DIN EN 12756.

The pump is fitted with a foot-mounted, fan-cooled asynchronous motor. Pump and motor are mounted on a common

base frame.

Pump and motor are mounted on a common steel base frame in accordance with ISO 3661.

The back pull-out design together with a spacer coupling makes it possible to service the pump without dismantling

the pump housing and motor from the base frame.

This saves realignment of pump and motor after service.

1) Remove coupling.

2) Remove the bolts in the bearing bracket support foot.

3) Remove the bearing bracket from the pump housing.

Pump

The pump is fitted with an unbalanced rubber bellows seal with torque transmission across the spring and around the

bellows. Due to the bellows, the seal does not wear the shaft, and the axial movement is not prevented by deposits

on the shaft.

Seal faces:

• Rotating seal ring material: carbon graphite, metal-impregnated

• Stationary seat material: silicon carbide (SiC)

Due to the favourable lubricating properties of carbon graphite, the seal is suitable for use even under poor lubricating

conditions, such as hot water.

However, under such conditions, wear on the carbon graphite face can be expected, and seal life will be reduced .

The material pairing is not recommended for liquids containing particles as this will result in wear on the SiC face.

Secondary seal material: EPDM (ethylene-propylene rubber)

EPDM has excellent resistance to hot water. EPDM is not suitable for mineral oils.

The shaft is made of stainless steel and has a diameter of 24 mm where the coupling is mounted.

The pump uses a spacer coupling between the pump and motor shaft.

Printed from Grundfos Product Centre [2023.26.006] 1/6

Qty. Description

1 Motor

The motor is a totally enclosed, fan-cooled motor with principal dimensions to IEC and DIN standards. Electrical

tolerances comply with IEC 60034.

The motor efficiency is classified as IE3 in accordance with IEC 60034-30-1.

The motor has thermistors (PTC sensors) in the windings in accordance with DIN 44081/DIN 44082. The protection

reacts to both slow- and quick-rising temperatures, e.g. constant overload and stalled conditions.

Thermal switches must be connected to an external control circuit in a way which ensures that the automatic reset

cannot cause accidents. The motors must be connected to a motor-protective circuit breaker according to local

regulations.

The motor can be connected to a variable speed drive for adjustment of pump performance to any duty point.

Grundfos CUE offers a range of variable speed drives. Please find more information in Grundfos Product Center.

Further product details

Cast-iron parts have an epoxy-based coating made in a cathodic electro-deposition (CED) process. CED is a

high-quality dip-painting process where an electrical field around the products ensures deposition of paint particles as

a thin, well-controlled layer on the surface.

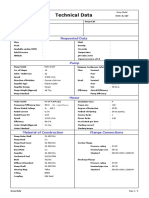

Technical data

Controls:

Frequency converter: NONE

Pressure sensor: N

Liquid:

Pumped liquid: Water

Liquid temperature range: 0 .. 120 °C

Selected liquid temperature: 20 °C

Density: 998.2 kg/m³

Technical:

Pump speed on which pump data are based: 2955 rpm

Actual calculated flow: 90.42 m³/h

Pump with motor (Yes/No): Y

Resulting head of the pump: 60.63 m

Actual impeller diameter: 235 mm

Nominal impeller diameter: 250

Code for shaft seal: BAQE

Mechanical seal type: Single

Curve tolerance: ISO9906:2012 3B

Bearing design: Standard

MaxPowerP2AlongTheCurve: 22.52 kW

Materials:

Pump housing: Cast iron

EN-GJL-250

ASTM class 35

Wear ring: Brass

Impeller: Cast iron

EN-GJL-200

ASTM class 30

Internal pump house coating: CED

Shaft: Stainless steel

EN 1.4301

AISI 304

Installation:

Maximum ambient temperature: 55 °C

Maximum operating pressure: 16 bar

Pipe connection standard: EN 1092-2

Type of inlet connection: DIN

Type of outlet connection: DIN

Pressure rating for connection: PN 16

Coupling type: Flexible w/spacer

Printed from Grundfos Product Centre [2023.26.006] 2/6

Qty. Description

1 Base frame design: EN/ISO

Code for base frame: 8

Grouting (Yes/No): N

Electrical data:

Motor type: SIEMENS

Rated power - P2: 30 kW

Mains frequency: 50 Hz

Rated voltage: 3 x 380-420D/660-725Y V

Rated current: 53/31 A

Starting current: 700-700 %

Cos phi - power factor: 0.87

Rated speed: 2955 rpm

IE efficiency: IE3 93,3%

IE Efficiency class: IE3

Motor efficiency at full load: 93.3-93.3 %

Motor efficiency at 3/4 load: 93.5-93.5 %

Motor efficiency at 1/2 load: 92.9-92.9 %

Number of poles: 2

Enclosure class (IEC 34-5): IP55

Insulation class (IEC 85): F

Motor No: 98943360

Bearing insulation type N-end: STEEL BEARING

Others:

Minimum efficiency index, MEI ≥: 0.61

Net weight: 413 kg

Gross weight: 440 kg

Shipping volume: 0.962 m³

Printed from Grundfos Product Centre [2023.26.006] 3/6

NK 50-250/235 AA2F2AESBAQERW1 50 Hz

H NK 50-250/235, 3*400 V, 50Hz eta

[m] [%]

80

235 mm

70

60

50 100

40 80

30 60

20 40

10 20

0 0

0 10 20 30 40 50 60 70 80 90 Q [m³/h]

Q = 90.42 m³/h H = 60.63 m

Pumped liquid = Water Liquid temperature during operation = 20 °C

Density = 998.2 kg/m³ Eta pump = 68.9 %

Eta pump+motor = 64.4 %

P NPSH

[kW] [m]

25 P1 25

P2

20 20

15 15

10 10

5 5

0 0

P1 = 23.15 kW

P2 = 21.63 kW

NPSH = 6.74 m

Max power P2 required along the curve = 22.52 kW

Printed from Grundfos Product Centre [2023.26.006] 4/6

H NK 50-250/235, 3*400 V, 50Hz eta

Description Value [m] [%]

General information:

Product name: NK 50-250/235 80

AA2F2AESBAQERW1 235 mm

Product No: On request 70

Based on: 98318434

60

EAN number: On request

Technical: 50 100

Pump speed on which pump data 2955 rpm

are based: 40 80

Actual calculated flow: 90.42 m³/h

30 60

Pump with motor (Yes/No): Y

Resulting head of the pump: 60.63 m 20 40

Actual impeller diameter: 235 mm

Nominal impeller diameter: 250 10 20

Shaft diameter: 24 mm

0 0

Code for shaft seal: BAQE 0 10 20 30 40 50 60 70 80 90 Q [m³/h]

Mechanical seal type: Single Q = 90.42 m³/h H = 60.63 m

Pumped liquid = Water Density = 998.2 kg/m³

Curve tolerance: ISO9906:2012 3B

Eta pump = 68.9 % Eta pump+motor = 64.4 %

Pump version: A2 Liquid temperature during operation = 20 °C

Bearing design: Standard P NPSH

[kW] [m]

Max power P2 along the curve: 22.52 kW P1

Materials: P2

20 20

Pump housing: Cast iron

Pump housing: EN-GJL-250 15 15

Pump housing: ASTM class 35 10 10

Wear ring: Brass

5 5

Impeller: Cast iron

Impeller: EN-GJL-200 0 0

Impeller: ASTM class 30 P1 = 23.15 kW

P2 = 21.63 kW

Internal pump house coating: CED NPSH = 6.74 m

Max power P2 required along the curve = 22.52 kW

Material code: A

Code for rubber: E

Shaft: Stainless steel

Shaft: EN 1.4301

Shaft: AISI 304

Installation:

Maximum ambient temperature: 55 °C

Maximum operating pressure: 16 bar

Pipe connection standard: EN 1092-2

Type of inlet connection: DIN

Type of outlet connection: DIN

Pressure rating for connection: PN 16

Coupling type: Flexible w/spacer

Base frame design: EN/ISO

Code for base frame: 8

Grouting (Yes/No): N

Connect code: F

Liquid:

Pumped liquid: Water

Liquid temperature range: 0 .. 120 °C

Selected liquid temperature: 20 °C

Density: 998.2 kg/m³

Electrical data:

Motor type: SIEMENS

Rated power - P2: 30 kW

Mains frequency: 50 Hz

Rated voltage: 3 x 380-420D/660-725Y V

Rated current: 53/31 A

Starting current: 700-700 %

Cos phi - power factor: 0.87

Rated speed: 2955 rpm

IE efficiency: IE3 93,3%

IE Efficiency class: IE3

Motor efficiency at full load: 93.3-93.3 %

Printed from Grundfos Product Centre [2023.26.006] 5/6

Description Value

Motor efficiency at 3/4 load: 93.5-93.5 %

Motor efficiency at 1/2 load: 92.9-92.9 %

Number of poles: 2

Enclosure class (IEC 34-5): IP55

Insulation class (IEC 85): F

Built-in motor protection: PTC

Motor No: 98943360

Bearing insulation type N-end: STEEL BEARING

Controls:

Frequency converter: NONE

Pressure sensor: N

Others:

Minimum efficiency index, MEI ≥: 0.61

Net weight: 413 kg

Gross weight: 440 kg

Shipping volume: 0.962 m³

Printed from Grundfos Product Centre [2023.26.006] 6/6

You might also like

- Modul 5 Indices & LogarithmsDocument12 pagesModul 5 Indices & Logarithmshasnitajb100% (10)

- Electric Power Systems. Vol. I. Electric NetworksDocument843 pagesElectric Power Systems. Vol. I. Electric Networksluciantoma75% (4)

- Impact Loads On A Self-Elevating Unit During Jacking OperationDocument84 pagesImpact Loads On A Self-Elevating Unit During Jacking OperationMILADNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Interview QuestionsDocument108 pagesInterview Questionsiamswapnatv0% (1)

- Grundfos - NB 50 250 254 A F2 A E BAQEDocument13 pagesGrundfos - NB 50 250 254 A F2 A E BAQEHoria AliNo ratings yet

- Grundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetDocument13 pagesGrundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetLeduța DomnescuNo ratings yet

- Grundfos - NK 125 315 317 A2 F A E BAQEDocument14 pagesGrundfos - NK 125 315 317 A2 F A E BAQEMaryasa RobedNo ratings yet

- NK125-315/336A2F2AE-SBAQE: Grundfos Pump 98318597Document14 pagesNK125-315/336A2F2AE-SBAQE: Grundfos Pump 98318597Geovanni MZNo ratings yet

- Qty. Description CR 10-2 A-A-A-E-HQQE: Further Product DetailsDocument7 pagesQty. Description CR 10-2 A-A-A-E-HQQE: Further Product DetailsBrata PatandeanNo ratings yet

- Grundfos - CM10 2 A R A E AQQEDocument11 pagesGrundfos - CM10 2 A R A E AQQEmanusnair247No ratings yet

- Grundfos - TP 150 220 4 A F A BAQEDocument12 pagesGrundfos - TP 150 220 4 A F A BAQEYoesoef HasyimNo ratings yet

- CR 313 AfgjaehqqeDocument10 pagesCR 313 AfgjaehqqeTatiana Mejías SeguraNo ratings yet

- Grundfos - TP 25 50 2 A O A GQQEDocument11 pagesGrundfos - TP 25 50 2 A O A GQQEJovisa MaricNo ratings yet

- CRN32-14 A-F-G-V-HQQV 3x400/690 50 HZ: Grundfos Pump 96122405Document14 pagesCRN32-14 A-F-G-V-HQQV 3x400/690 50 HZ: Grundfos Pump 96122405Hamed YazidiNo ratings yet

- Grundfos CRN 1s 10 A FGJ G e HqqeDocument15 pagesGrundfos CRN 1s 10 A FGJ G e HqqeANDRESNo ratings yet

- Grundfos - CR 10 2 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 2 A FJ A E HQQEMario PatarroyoNo ratings yet

- Grundfos Pompa PDFDocument9 pagesGrundfos Pompa PDFAnastasia Lova DiantoroNo ratings yet

- Company Name: Created By: Phone: Date:: Qty. Description CR 20-12 A-F-A-E-HQQEDocument7 pagesCompany Name: Created By: Phone: Date:: Qty. Description CR 20-12 A-F-A-E-HQQEGusEgy GrundfosNo ratings yet

- Brosur Grondfus CR 5-32Document7 pagesBrosur Grondfus CR 5-32CV Aliance JayaNo ratings yet

- Datasheetcr 3210 AfaehqqeDocument7 pagesDatasheetcr 3210 Afaehqqedtt000001No ratings yet

- Company Name: Created By: Phone: Date:: Qty. Description NK 80-200/195 AA2F2KESBQQESW1Document8 pagesCompany Name: Created By: Phone: Date:: Qty. Description NK 80-200/195 AA2F2KESBQQESW1SantoshNo ratings yet

- Jockey Pump Balsam (Grundfosh) PDFDocument11 pagesJockey Pump Balsam (Grundfosh) PDFm khaeronNo ratings yet

- Company Name: Created By: Phone: Date:: Qty. Description NB 80-250/247 AF2ABQQEDocument9 pagesCompany Name: Created By: Phone: Date:: Qty. Description NB 80-250/247 AF2ABQQEriyas.hvacworkNo ratings yet

- Grundfos - CR 15 10 A F A E HQQE PDFDocument15 pagesGrundfos - CR 15 10 A F A E HQQE PDFdimasNo ratings yet

- En 96122027 Grundfos CR 32 11 A F A e HqqeDocument13 pagesEn 96122027 Grundfos CR 32 11 A F A e HqqeNguyễn Kỳ TúNo ratings yet

- Qty. Description CR 45-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument2 pagesQty. Description CR 45-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateJulio César MirandaNo ratings yet

- Grundfos Tpe2!50!240 N A F A BqqeDocument10 pagesGrundfos Tpe2!50!240 N A F A BqqeLuca OvidiuNo ratings yet

- Grundfos - CR 10 4 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 4 A FJ A E HQQErosneyNo ratings yet

- Grundfos - CM1 5 A R I E AQQEDocument13 pagesGrundfos - CM1 5 A R I E AQQEVimal KalariaNo ratings yet

- Grundfos - CM10 3 A R G V AQQVDocument12 pagesGrundfos - CM10 3 A R G V AQQVD Manmath RaoNo ratings yet

- TP 10012002 A3fodaqf2w1Document15 pagesTP 10012002 A3fodaqf2w1Ilham RochadiNo ratings yet

- CR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Document15 pagesCR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Muhammad GhufranNo ratings yet

- Grundfos CR 5 13 A FGJ A e HqqeDocument15 pagesGrundfos CR 5 13 A FGJ A e HqqeRadu-Stefan MusatNo ratings yet

- CR 1517 AfaehqqeDocument4 pagesCR 1517 Afaehqqerizkidwi639No ratings yet

- Jockey Pump 96517052 - CR - 520 - AFGJAEHQQEDocument8 pagesJockey Pump 96517052 - CR - 520 - AFGJAEHQQEShafa AlmaliyaNo ratings yet

- Grundfos CM5-3Document13 pagesGrundfos CM5-3Kiyimba DanielNo ratings yet

- NBG 10080125137 Aaf2aesbaqemw1 PT CampinaDocument7 pagesNBG 10080125137 Aaf2aesbaqemw1 PT CampinaJoko SuwarnoNo ratings yet

- Grundfos - CR 10 16 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 16 A FJ A E HQQEJafar SidiqNo ratings yet

- CRN15-08 A-FGJ-G-E-HQQE 3x400/690 50 HZ: Grundfos Pump 96501965Document15 pagesCRN15-08 A-FGJ-G-E-HQQE 3x400/690 50 HZ: Grundfos Pump 96501965PysasaIrapuatoNo ratings yet

- Grundfos - CR 5 3 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 3 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Grundfos - CRI 3 23 A P I E HQQEDocument15 pagesGrundfos - CRI 3 23 A P I E HQQEHeinium DannemannNo ratings yet

- Grundfos - CR 10 3A FJ A E HQQEDocument15 pagesGrundfos - CR 10 3A FJ A E HQQEArleene Mariano SalazarNo ratings yet

- Further Product Details: Position Qty. Description NB 150-500/521 A-F 2-A-BAQEDocument8 pagesFurther Product Details: Position Qty. Description NB 150-500/521 A-F 2-A-BAQEitsirc67No ratings yet

- POMPA Grundfos CM 5-2Document2 pagesPOMPA Grundfos CM 5-2Deby Eka ChandraNo ratings yet

- Grundfos Cm3 2 A R I e AqqeDocument12 pagesGrundfos Cm3 2 A R I e Aqqevksolarsystems2020No ratings yet

- Grundfos NB80-160 SpecsDocument5 pagesGrundfos NB80-160 SpecsSagar ApteNo ratings yet

- Grundfos CRN 3 3 A FGJ G e HqqeDocument15 pagesGrundfos CRN 3 3 A FGJ G e Hqqewmgb249529No ratings yet

- Grundfos - CRN 15 4Document15 pagesGrundfos - CRN 15 4Hamed YazidiNo ratings yet

- Grundfos CRI 5 3 A FGJ I E HQQE UnlockedDocument15 pagesGrundfos CRI 5 3 A FGJ I E HQQE UnlockedLEONARD CHRISTOPHER LIMANJAYANo ratings yet

- CR 513 AfgjaehqqeDocument2 pagesCR 513 AfgjaehqqeSuryansah MNo ratings yet

- CR - 3 31 - A FGJ A e Hqqe PDFDocument17 pagesCR - 3 31 - A FGJ A e Hqqe PDFLeduța DomnescuNo ratings yet

- Grundfos - CR 5 4 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 4 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Qty. Description CRE 45-2-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument2 pagesQty. Description CRE 45-2-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateVitor AntunesNo ratings yet

- Grundfos - SL1 50 65 22 2 50D CDocument13 pagesGrundfos - SL1 50 65 22 2 50D CThilina Lakmal Edirisingha100% (1)

- Pumps ArmstrogDocument9 pagesPumps ArmstrogEng Mohie EsaamNo ratings yet

- TP 1504504 Afabqqetw3 CHWPDocument6 pagesTP 1504504 Afabqqetw3 CHWPmakbul_363448467No ratings yet

- LTW Cooling PumpDocument15 pagesLTW Cooling Pumptim kaminskyNo ratings yet

- CR - 322 - AFAEHQQE Backwash PumpDocument2 pagesCR - 322 - AFAEHQQE Backwash PumpGuiver Santisteban IbañezNo ratings yet

- Grundfos PumpDocument8 pagesGrundfos PumpSmile ForeverNo ratings yet

- Qty. Description NK 80-315/311: Company Name: Created By: Phone: DateDocument7 pagesQty. Description NK 80-315/311: Company Name: Created By: Phone: Dateabhishek yadavNo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Further Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEDocument10 pagesFurther Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEitsirc67No ratings yet

- Grundfos - SEG 40 31 2 50BDocument17 pagesGrundfos - SEG 40 31 2 50BMarina CoskovicNo ratings yet

- Katalog WNS Series-2Document47 pagesKatalog WNS Series-2rifanderiNo ratings yet

- Data Sheet S6S-30 08, 7.5kW, 3 BSP Sub Pump 6 50HzDocument4 pagesData Sheet S6S-30 08, 7.5kW, 3 BSP Sub Pump 6 50HzrifanderiNo ratings yet

- Data Sheet 3.0HP MVS-3 21TR SSV 1 PUMPSETDocument3 pagesData Sheet 3.0HP MVS-3 21TR SSV 1 PUMPSETrifanderiNo ratings yet

- Data Sheet 4.0HP MVN-4 16TR TCV 1 PUMPSETDocument3 pagesData Sheet 4.0HP MVN-4 16TR TCV 1 PUMPSETrifanderiNo ratings yet

- Data Sheet S10S-215 05R-8, 93Kw, 6 BSP SD Sub Pump 50Hz (SPLINES)Document5 pagesData Sheet S10S-215 05R-8, 93Kw, 6 BSP SD Sub Pump 50Hz (SPLINES)rifanderiNo ratings yet

- Data Sheet 20HP MVS-15 17TR TCV 1 PUMPSETDocument3 pagesData Sheet 20HP MVS-15 17TR TCV 1 PUMPSETrifanderiNo ratings yet

- MMO Manual BookDocument16 pagesMMO Manual BookrifanderiNo ratings yet

- FSA Technical DatabookDocument72 pagesFSA Technical DatabookrifanderiNo ratings yet

- Instructions:: Question Paper Booklet CodeDocument20 pagesInstructions:: Question Paper Booklet CodeadiNo ratings yet

- Dougherty Valley HS Chemistry - Solutions Packet Name - Per - DateDocument4 pagesDougherty Valley HS Chemistry - Solutions Packet Name - Per - Date2413ramesh_snehaNo ratings yet

- Brksec 3021Document131 pagesBrksec 3021alfagemeoNo ratings yet

- Components of A CAD/CAM System: 2.1 General PointsDocument2 pagesComponents of A CAD/CAM System: 2.1 General PointsaffanNo ratings yet

- MRF1550 MotorolaDocument12 pagesMRF1550 MotorolaSILIO R PARAGUASSUNo ratings yet

- Formatting Numbers, Currency, and Percents in VB: ThevbprogramerDocument5 pagesFormatting Numbers, Currency, and Percents in VB: ThevbprogramerNoldy SinsuNo ratings yet

- PS4 Training GuideDocument35 pagesPS4 Training GuidecatalinccNo ratings yet

- Siteminder Ps Admin EnuDocument391 pagesSiteminder Ps Admin EnuHoyamu BalamuNo ratings yet

- Abstracts About WeldingDocument9 pagesAbstracts About WeldingVinayak BhustalimathNo ratings yet

- Marantz SR-7001 Service ManualDocument206 pagesMarantz SR-7001 Service ManualLucianoNo ratings yet

- Computer Literacy - Lesson 1 - Computer SystemsDocument1 pageComputer Literacy - Lesson 1 - Computer SystemscuddlesttNo ratings yet

- UH8 RF V2 1.5 LR ManualDocument12 pagesUH8 RF V2 1.5 LR Manualgarys12No ratings yet

- Manual Ricoh Aficio SG3110SFNwDocument128 pagesManual Ricoh Aficio SG3110SFNwvalentindanielNo ratings yet

- MKBasher MPPG ThesisDocument52 pagesMKBasher MPPG ThesisNayeem SazzadNo ratings yet

- Batch 2017 4th Semester CSEDocument28 pagesBatch 2017 4th Semester CSEAzeem KhanNo ratings yet

- Oracle® Database: Quick Installation Guide 11g Release 2 (11.2) For Linux x86Document26 pagesOracle® Database: Quick Installation Guide 11g Release 2 (11.2) For Linux x86kchukkapalliNo ratings yet

- Mlion-Catalogue (2020)Document28 pagesMlion-Catalogue (2020)M.ariefiryuqoriNo ratings yet

- Magnetic and Gravity Toolface and How To Interpret The Meaning For Directional Drilling - PDFDocument17 pagesMagnetic and Gravity Toolface and How To Interpret The Meaning For Directional Drilling - PDFHeberth DesbloqueoNo ratings yet

- Transformer Life Extention Methodlogy Thru LTC ReplacementDocument28 pagesTransformer Life Extention Methodlogy Thru LTC Replacementlbk50No ratings yet

- ANSI/ASME/ASA B16.5 Flange Slip On-RFDocument2 pagesANSI/ASME/ASA B16.5 Flange Slip On-RFtisnaNo ratings yet

- Chandigarh University Department of Electronics & Communication Engineering Assignment # 01Document6 pagesChandigarh University Department of Electronics & Communication Engineering Assignment # 01Jaspreet KaurNo ratings yet

- Aggregate Crushing ValueDocument8 pagesAggregate Crushing ValueEngineeri TadiyosNo ratings yet

- SBA5089ZDocument6 pagesSBA5089ZFrancisca Iniesta TortosaNo ratings yet

- Technical CataloguelDocument20 pagesTechnical CataloguelNgoc Vũ TrầnNo ratings yet

- IMWA1995 Vandersluis PDFDocument16 pagesIMWA1995 Vandersluis PDFAbie BadhurahmanNo ratings yet