Professional Documents

Culture Documents

Photovoltic Cell As 3 D Printer

Uploaded by

vermashalini10100 ratings0% found this document useful (0 votes)

1 views2 pagesOriginal Title

photovoltic cell as 3 D printer

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views2 pagesPhotovoltic Cell As 3 D Printer

Uploaded by

vermashalini1010Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Photovoltic cell as 3D printer

Team members: Project Mentor: Dr. Nancy Sidana (Assistant

1. Arshdeep Singh 2336776

Professor)

2. Vivek Rana 2337128

3. Yash Rajput 2337131

4. Vanshika Chauhan 2337114

5. Vinay Kumar 2337121

Subject/Category: Chemistry

Brief Description / Abstract

Recent years have seen tremendous progress in the field of 3D printing, which has revolutionized

many industries, including the production of solar cells. This study investigates the use of several 3D

printing and fabrication processes in the manufacture of solar cells.

1. Electrohydrodynamic Printing (EHDP): EHDP is a high-precision 3D printing method that

regulates the deposition of functional materials using electric fields. EHDP makes it possible to

precisely arrange photoactive layers during the solar cell fabrication process, which improves the

efficiency and performance of the solar cells.

2. Using Fused Deposition Modeling (FDM) to Fabricate Solar Cells:

A popular 3D printing method called fused deposition modeling (FDM) uses thermoplastic materials to

be extruded layer by layer to produce three-dimensional objects. FDM can be used in the production of

solar cells to create unique structures.

3. Ag-Line 3D Printing: This technique uses conductive inks based on silver (Ag) nanoparticles to

build conductive patterns on solar cell substrates. This method reduces optical losses and increases

electrical conductivity in the production of highly efficient interdigitated back contact (IBC) solar cells.

4. 3D Printing Using a Solution:

Solution-based deposition techniques are used in solution-processed 3D printing to create thin-film

solar cells. This technique makes it possible to produce flexible and lightweight solar panels that are

appropriate for a wide range of applications in a scalable manner through the controlled deposit of

precursor materials.

5. Inkjet Printing:

Inkjet printing offers a versatile approach for depositing functional inks onto solar cell substrates with

high precision and resolution. By jetting ink droplets onto the surface, inkjet printing allows for the

deposition of multiple layers, including active materials and electrodes, facilitating the fabrication of

efficient solar cells.

6. Slot-Die Coating Process:

The slot-die coating process is a roll-to-roll manufacturing technique used for large-scale production of

thin-film solar cells. By coating uniform layers of photoactive materials onto flexible substrates, slot-

die coating enables the cost-effective fabrication of lightweight and flexible solar panels.

7. Gravure Printing on Flexible Substrates: This technique allows for the quick creation of patterned

and textured surfaces for solar cell applications by transferring ink from etched cylinders to flexible

substrates. This technique can deposit functional layers over a large area because of its excellent

precision and throughput.

In conclusion, new avenues for the creation of efficient, lightweight, and reasonably priced solar panels

have been made possible by developments in 3D printing and solar cell fabrication techniques. In order

to advance renewable energy technologies and create a sustainable future, manufacturers and

researchers can make use of cutting-edge printing and fabrication techniques.

Block Diagram/Flow chart/layout/Algorithm/Picture of final project:

You might also like

- Moors Sovereign Dollarium 500 Gold Backed Dollarium PicautoDocument2 pagesMoors Sovereign Dollarium 500 Gold Backed Dollarium Picautoakil kemnebi easley elNo ratings yet

- 100 IC CircuitsDocument34 pages100 IC CircuitselektrorwbNo ratings yet

- 3D Printing of Robotic Soft Actuators WithDocument9 pages3D Printing of Robotic Soft Actuators WithPringgo Widyo LaksonoNo ratings yet

- On 3 D Printing and DronesDocument72 pagesOn 3 D Printing and DronesDurgesh TripathiNo ratings yet

- 1.1 Objectives: Reverse Engineering of Plastic & Metal PartsDocument27 pages1.1 Objectives: Reverse Engineering of Plastic & Metal PartsSoham Nikam100% (1)

- Standard Welding Procedure SpecificationsDocument2 pagesStandard Welding Procedure SpecificationsAnonymous dh6DITNo ratings yet

- Design and Fabrication of Arduino Based Flexible Manufacturing Process On The Desk 3D PrintingDocument10 pagesDesign and Fabrication of Arduino Based Flexible Manufacturing Process On The Desk 3D PrintingIJRASETPublicationsNo ratings yet

- Satellite Image Processing Using Radiometric Resolution & Spectral ResolutionDocument11 pagesSatellite Image Processing Using Radiometric Resolution & Spectral ResolutionIJRASETPublicationsNo ratings yet

- Heat Shrink CoatingDocument5 pagesHeat Shrink CoatingMekhmanNo ratings yet

- Lymphatic System PowerpointDocument20 pagesLymphatic System Powerpointabisantiago6131No ratings yet

- Listeria Monocytogenes Guidance On: Environmental Monitoring and Corrective Actions in At-Risk FoodsDocument35 pagesListeria Monocytogenes Guidance On: Environmental Monitoring and Corrective Actions in At-Risk FoodsGaganpreet KaurNo ratings yet

- Addresses Contact Details of InstitutesDocument16 pagesAddresses Contact Details of Institutesanon_961232893No ratings yet

- Esmm 974Document19 pagesEsmm 974santanuNo ratings yet

- Direct Light ProjectionDocument4 pagesDirect Light ProjectionAdnan AhmadNo ratings yet

- PCB Fabrication Unit For Electronics Circuit PrototypingDocument5 pagesPCB Fabrication Unit For Electronics Circuit PrototypingCláudio RegisNo ratings yet

- 3D Printing Practice LabDocument36 pages3D Printing Practice LabvidyaNo ratings yet

- Lorenz 2015 MetalWorkshop 5 EvaluationofFlexographicPrintingTechnologyforMulti-busbarSolarCellsDocument13 pagesLorenz 2015 MetalWorkshop 5 EvaluationofFlexographicPrintingTechnologyforMulti-busbarSolarCellssơn đinhNo ratings yet

- Proceedings of Spie: Design and Characterization of A 3d-Printer-Based Diode Laser EngraverDocument7 pagesProceedings of Spie: Design and Characterization of A 3d-Printer-Based Diode Laser EngraverAzan AliNo ratings yet

- Automatic 3D Reconstruction and Visualization of Microscopic Objects From A Monoscopic Multifocus Image SequenceDocument8 pagesAutomatic 3D Reconstruction and Visualization of Microscopic Objects From A Monoscopic Multifocus Image Sequencenatra2k2No ratings yet

- 3dprintingpracticelab 230710091102 b46f4fddDocument36 pages3dprintingpracticelab 230710091102 b46f4fddchantiNo ratings yet

- 12 ChemistryDocument17 pages12 ChemistrySri jothi textileNo ratings yet

- Review mực dẫn điệnDocument16 pagesReview mực dẫn điệnGiang Hoang HuongNo ratings yet

- A Comprehensive Study On 3D Printing Technology Investigation of Heat Storage Performance of A Solar Pond With P..Document8 pagesA Comprehensive Study On 3D Printing Technology Investigation of Heat Storage Performance of A Solar Pond With P..Garapati MurarjiNo ratings yet

- A L D S: Nalysis of Ithography Based Approaches in Evelopment of EmiconductorsDocument12 pagesA L D S: Nalysis of Ithography Based Approaches in Evelopment of EmiconductorsAnonymous Gl4IRRjzNNo ratings yet

- Thesis On Thin Film Solar CellDocument6 pagesThesis On Thin Film Solar CellBuyingCollegePapersOnlineSingapore100% (2)

- 3D Printing The Dawn of A New Era in ManufacturingDocument4 pages3D Printing The Dawn of A New Era in ManufacturingEditor IJRITCCNo ratings yet

- ManufacturingDocument24 pagesManufacturingMiled HoussemNo ratings yet

- Shallan2014 - Cost-Effective Three-Dimensional Printing of Visibly Transparent Microchips Within MinutesDocument7 pagesShallan2014 - Cost-Effective Three-Dimensional Printing of Visibly Transparent Microchips Within MinutesDinoNo ratings yet

- New Horizontal Frustum Optical Waveguide Fabrication Using UV Proximity PrintingDocument6 pagesNew Horizontal Frustum Optical Waveguide Fabrication Using UV Proximity Printingchiuchan888No ratings yet

- Digital Assembly and Direct Fabrication of Mechanism Based On Selective Laser MeltingDocument12 pagesDigital Assembly and Direct Fabrication of Mechanism Based On Selective Laser MeltingAshu AdsulNo ratings yet

- Amin2016 - 3d Printed Microfluidic DevicesDocument17 pagesAmin2016 - 3d Printed Microfluidic DevicesDinoNo ratings yet

- Sensors 23 00043 v2Document15 pagesSensors 23 00043 v2Vikashanand SasikumarNo ratings yet

- Dual Axis Solar Tracker SystemDocument24 pagesDual Axis Solar Tracker SystemSrushti KilledarNo ratings yet

- Volumetric 3D Printing: A New Approach To 3D PrintingDocument2 pagesVolumetric 3D Printing: A New Approach To 3D PrintingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Sistem Minimum Mekatronika Printer 3D Berbasis DLP Untuk Perkembangan Teknologi IndonesiaDocument8 pagesSistem Minimum Mekatronika Printer 3D Berbasis DLP Untuk Perkembangan Teknologi IndonesiaBotNo ratings yet

- Bahir Dar UniversityDocument43 pagesBahir Dar UniversityFìrœ Lōv MånNo ratings yet

- Sensors and Actuators: B. ChemicalDocument10 pagesSensors and Actuators: B. ChemicalSagnik ChowdhuryNo ratings yet

- 1 s2.0 S2666412721000441 MainDocument10 pages1 s2.0 S2666412721000441 MainBM20623 Wan Mohamad Danial Bin Wan SyariffudinNo ratings yet

- 3D Printer Based Slot-Die Coater As A Lab-to-Fab Translation Tool For Solution-Processed Solar CellsDocument8 pages3D Printer Based Slot-Die Coater As A Lab-to-Fab Translation Tool For Solution-Processed Solar CellsBhabani Sankar SwainNo ratings yet

- To Explore The Nature and Composition of Unknown NanomaterialDocument19 pagesTo Explore The Nature and Composition of Unknown NanomaterialSaba SohailNo ratings yet

- Met A MaterialsDocument11 pagesMet A MaterialsSambit Kumar GhoshNo ratings yet

- Importance of Molds For Nanoimprint LithographyDocument13 pagesImportance of Molds For Nanoimprint LithographyRamesh SoniNo ratings yet

- Colson 2013Document19 pagesColson 2013Hongquan PhanNo ratings yet

- Cleaing of Solar Panel (2nd Review 6th Sem) 2021Document17 pagesCleaing of Solar Panel (2nd Review 6th Sem) 2021manish yadavNo ratings yet

- Fabrication of Tactile Graphics Using ManufacturingDocument38 pagesFabrication of Tactile Graphics Using ManufacturingSiva KrishnanNo ratings yet

- Evaluation of Flexographic Printing Technology For Multi Busbar Solar CellsDocument12 pagesEvaluation of Flexographic Printing Technology For Multi Busbar Solar CellsLong HàNo ratings yet

- Materials Today: ProceedingsDocument5 pagesMaterials Today: ProceedingsSANGAM SRIKANTHNo ratings yet

- Research Paper On StereolithographyDocument7 pagesResearch Paper On Stereolithographyc9q0c0q7100% (1)

- 138 MohammedDocument13 pages138 MohammedBruna LannesNo ratings yet

- Experimental Evaluationand Developmentof Artificial NeuralDocument16 pagesExperimental Evaluationand Developmentof Artificial NeuralArnavRaj JoshiNo ratings yet

- Vaagdevi Engineering College Department of ECE: Bollikunta, Warangal Technical Seminar ONDocument15 pagesVaagdevi Engineering College Department of ECE: Bollikunta, Warangal Technical Seminar ONJeevan JeevaNo ratings yet

- Fresh Water: Using The Sun To GenerateDocument20 pagesFresh Water: Using The Sun To GeneraterakeshNo ratings yet

- Method For Making A Single-Step Etch Mask For 3D Monolithic NanostructuresDocument11 pagesMethod For Making A Single-Step Etch Mask For 3D Monolithic NanostructuresDiana GrishinaNo ratings yet

- 42 Single MaskDocument6 pages42 Single MaskShashikant PathakNo ratings yet

- ABSTRACT - Aru Manikam SilterraDocument1 pageABSTRACT - Aru Manikam SilterraAru ManikamNo ratings yet

- Image Super Resolution Using DCNN: Bachelor of Technology Computer Science and EngineeringDocument21 pagesImage Super Resolution Using DCNN: Bachelor of Technology Computer Science and EngineeringThrisha ButhamNo ratings yet

- Research PaperDocument10 pagesResearch PaperMalik ahxanNo ratings yet

- Materials: Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template CompressionDocument12 pagesMaterials: Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template CompressionLalit HingweNo ratings yet

- Solar Tracking SystemDocument31 pagesSolar Tracking SystemShivam Mishra100% (1)

- Efficient Hybrid Tree-Based Stereo Matching With Applications To Postcapture Image RefocusingDocument15 pagesEfficient Hybrid Tree-Based Stereo Matching With Applications To Postcapture Image RefocusingIsaac AnamanNo ratings yet

- MEMS Fabrication Methodology Used To Design Non-Invasive Bio-Nano-Sensor To Detect DiabeticsDocument6 pagesMEMS Fabrication Methodology Used To Design Non-Invasive Bio-Nano-Sensor To Detect DiabeticsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Nil SfilDocument19 pagesNil SfilPiranha TourniquetNo ratings yet

- Week 3 - Grey Scale For MEMSDocument2 pagesWeek 3 - Grey Scale For MEMSPreet Kamal SinghNo ratings yet

- Development of An Algorithm That Allows Improving Disparity Maps in Environments Contaminated With Suspended ParticlesDocument7 pagesDevelopment of An Algorithm That Allows Improving Disparity Maps in Environments Contaminated With Suspended ParticlesDaniel Fernando Quintero BernalNo ratings yet

- Pin MicroprojectDocument11 pagesPin Microprojectaadityamahadik00No ratings yet

- The Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsFrom EverandThe Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsNo ratings yet

- BCA 5005 Minor Project Synopsis Format & GuidelinesDocument7 pagesBCA 5005 Minor Project Synopsis Format & GuidelinesAnu VermaNo ratings yet

- ACE Inhibitors Vs ARBsDocument3 pagesACE Inhibitors Vs ARBsKo Phyo WaiNo ratings yet

- KIN LONG Shower Screen CatalogueDocument58 pagesKIN LONG Shower Screen CatalogueFaiz ZentNo ratings yet

- RS68-120 MLN ManuelDocument28 pagesRS68-120 MLN ManuelUmar MajeedNo ratings yet

- Concept Paper Group 1Document9 pagesConcept Paper Group 1Kaime KeilarNo ratings yet

- Yamaha Tank Removal wr250rDocument2 pagesYamaha Tank Removal wr250rMotoc Mircea-RazvanNo ratings yet

- Compliant Offshore StructureDocument50 pagesCompliant Offshore Structureapi-27176519100% (4)

- Algebra I m5 Topic B Lesson 6 TeacherDocument13 pagesAlgebra I m5 Topic B Lesson 6 TeacherjxhroyNo ratings yet

- Unit Operation QBDocument7 pagesUnit Operation QBsmg26thmayNo ratings yet

- SGK Tieng Anh 9 Thi Diem Tap 1Document73 pagesSGK Tieng Anh 9 Thi Diem Tap 1Nhu NguyenNo ratings yet

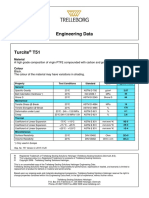

- Turcite T51 Engineering DataDocument1 pageTurcite T51 Engineering DataAntonio Rivera VillavicencioNo ratings yet

- Herpes Simplex KeratitisDocument20 pagesHerpes Simplex KeratitisriskhapangestikaNo ratings yet

- The National TerritoryDocument39 pagesThe National TerritoryRan RanNo ratings yet

- PIA Rivalry Strategy MapDocument16 pagesPIA Rivalry Strategy MapRomeo KhanNo ratings yet

- Laying Out Compoud Curve and Reverse by Deflection Angle MethodDocument10 pagesLaying Out Compoud Curve and Reverse by Deflection Angle MethodEljenColanggo0% (2)

- Equipment: MR 51 / MR 51V42 - Handy Power MR 56 / MR 56V42 - Strong PowerDocument4 pagesEquipment: MR 51 / MR 51V42 - Handy Power MR 56 / MR 56V42 - Strong PowerIsmailBelguithNo ratings yet

- Tecnical Data TYPE 139 L12R / L16RDocument1 pageTecnical Data TYPE 139 L12R / L16RLada LabusNo ratings yet

- Tuf Pneumatic Long Nose Hog Ring Gun Sc77xeDocument5 pagesTuf Pneumatic Long Nose Hog Ring Gun Sc77xearturoNo ratings yet

- BHHHJDocument10 pagesBHHHJAnonymous vLerKYANo ratings yet

- Lonza ManualsProductInstructions Determination of Protein Concentration 31460Document2 pagesLonza ManualsProductInstructions Determination of Protein Concentration 31460sydneypadillioNo ratings yet

- Reglas Digitales Mitutoyo Scale Units Linear ScalesDocument31 pagesReglas Digitales Mitutoyo Scale Units Linear ScalesAngelmambrinNo ratings yet

- Exercises On Algebra MI1036Document12 pagesExercises On Algebra MI1036Sâm Mai HuyềnNo ratings yet

- ActuatorsDocument24 pagesActuatorsharishcsharmaNo ratings yet