Professional Documents

Culture Documents

STEELGirder Beam Design

Uploaded by

Lee Jasper SabenianoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STEELGirder Beam Design

Uploaded by

Lee Jasper SabenianoCopyright:

Available Formats

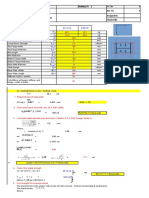

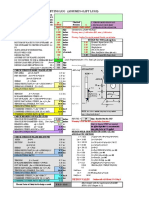

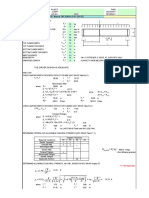

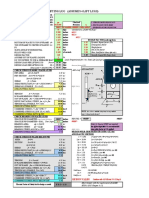

DESIGN OF GIRDER BEAM

Project Name/Title:

Site/Location:

Engineer/Designer:

A. PRELIMINARY DATA (From Structural Analysis): Remarks

Frame No. C

Level No. 5th

Beam No. 678

Member Designation: C4-5th

Material Specification ASTM A992

Minimum Yield Stress Fy 50 ksi

Tensile Stress Fu 65 ksi

Modulus of Elasticity E 29000 ksi

Length of Beam 9.2 m 30.18 ft

Unsupported lengLb 4.62 m 15.16 ft Inflection point maximum under

Load Comb # 22 (see Design of

Type of Connection FR Moment Connection Structures by Salmon pp. 508)

Load Combination No. (GOVERNS) 22

STAAD OUTPUT Pu Vu Mu

(kN) (kN) (kN-m)

1 Ez -17.40 -0.95 160.08

5 D -33.98 -77.59 192.79

6 L -27.67 -66.77 152.98

8 1.0D + 1.0L -61.64 -144.36 345.76

23 1.2D + 1.0Ez + fL -98.15 -181.19 626.54

Strength Limit: LRFD

B. DESIGN FOR FLEXURE

φbMn ≥ Mu

Mu = 462.11 ft-kip

φb = 0.9 for bending Strength Reduction Factor

Required Mn Mu/φ = 513.46 ft-kip

3

Required Zx (Mu/φb)*Fy = 123.23 in ←

Try W 18 x 86 AISC Manual Table 3-2

4

Ix = 1530 in

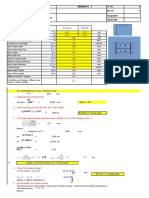

CHECK FOR SERVICEABILITY

Required Moment of Inertia, I x for Live-Load Deflection Criterion

Δmax = L/360 for D + L

4

Δmidspan= wL /185EI= ML2/23.125EI 1.01 in

Ma = n/a ft-kip 0.17 < Δmax

Ms = n/a ft-kip

Mb = n/a ft-kip

4

Required Ix = ML2/23.125EΔmax 263.23 in

Enter AISC Table 3-3:

W 18 x 86 AISC Manual Table 1-1

3

beam weight wb = 86 lb/ft Zx = 186 in

2 4

A= 25.3 in Iy = 175 in

d= 18.4 in ry = 2.63 in

tw = 0.48 in rts = 3.05 in

bf = 11.1 in ho = 17.6 in

4

tf = 0.77 in J= 4.1 in

6

kdes = 1.17 in Cw = 13600 in

4

Ix = 1530 in c= 1

3

Sx = 166 in

Is flange compact?

λ = bf / 2*tf 7.21 check AISC Manual Table 1-1

λpf = 0.38*sqrt(E/Fy) 9.15 > λ OK AISC Manual Table B4.1

Is web compact?

λ = h/tw 33.5 check AISC Manual Table 1-1

λp = 3.76*sqrt(E/Fy) 90.55 > λ OK AISC Manual Table B4.1

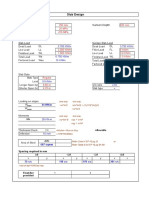

Limit State:

YIELDING AND LATERAL TORSIONAL BUCKLING (AISC Manual F2) AISC Table User Note F1.1

1. Yielding

Mn = M p = Zx*Fy = 775.00 > 513 ft-kip AISC Manual Eq F2-1

OK

2. Lateral Torsional Buckling

Lb = 15.16 ft

Lp = 1.76*ry*sqrt(E/Fy) 9.29 < Lb check AISC Eq F2-5/Table 3-2

Lr = 1.95*rts*(E/0.7Fy)*sqrt(Jc/Sxho)*sqrt{1+ 28.5 > Lb check AISC Eq F2-6/Table 3-2

sqrt(1+6.76*[(0.7*Fy*Sx*ho)/(E*Jc)]^2)}

Therefore: Lp < Lb < Lr

(a) When Lp > Lb AISC Manual F2.2

the limits of lateral torsional buckling does not apply

(b) When Lp < Lb < Lr ←

Mn = Cb*[Mp - (Mp-0.7FySx)((Lb-Lp)/(Lr-Lp))] ≤ Mp AISC Manual Eq F2-2

or Mn = Cb*[ φbMpx - BF(L≤ Mpx 609.29 > 513.46 ft-kip OK (for W-shapes) AISC pp3-8

Cb = 1.0 conservatively assumed

Mpx = 698.00 ft-kip AISC Manual Table 3-2

BF = 13.6 kip AISC Manual Table 3-2

(c) When Lb > Lr

Mn = Fcr*Sx ≤ Mp 1311.8 > 513.456 ft-kip

2 2 2

Fcr = [(Cb*π *E)/(Lb/rts) ]*sqrt(1+0.078(J*c/Sxho)(Lb/rts) ) = 94.8 ksi OK AISC Manual Eq F2-4

rts = bf / sqrt {12*[1 + [(h*tw)/(6*bf*tf)]} = 3.05 in

Lb / rts = 59.65

OR Enter AISC Table 3-10 with: for most economical secton

Lb = 15.16 ft however,make sure it conforms

Mu = 462.11 ft-kip with the required Ix

THEREFORE FOR FLEXURE, ADOPT W 18 x 86

φMn = 548.36 ft-kip > Mu = 462.11 ft-kip

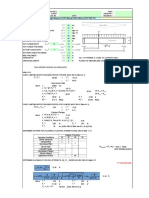

B. CHECK DESIGN FOR SHEAR

φvVn > Vu

Vu = 40.73 kip

φv = 1.0 Shear reduction factor

Required Vn Vu/φv = 40.73 kip

Check Adequacy of W 18 x 86

Vn = 0.6*Fy*Aw*Cv = 264.96 > Required Vn OK AISC Manual Eq G2-1

2

Aw = d*tw = 8.83 in

h/tw = 33.5 < 2.24*sqrt(E/Fy) AISC Eq G2-2 governs

use Cv = 1.0 refer to table below

(a) For webs of rolled I-shaped members with h/tw ≤ 2.24*sqrt(E/Fy) ←

2.24*sqrt(E/Fy) = 53.95

Cv = 1.0 AISC Manual Eq G2-2

(b) For webs of other doubly symmetric shapes and singly symmetric shapes and chanels, except

round HSS, the web shear coefficient, Cv, is determined as follows:

(i) For h/tw ≤ 1.10*sqrt(kv*E/Fy)

1.10*sqrt(kv*E/Fy) =

Cv = 1.0 AISC Manual Eq G2-3

(ii) For 1.10*sqrt(kv*E/Fy) < h/tw ≤ 1.37*sqrt(kv*E/Fy)

Cv = 1.10*sqrt(kv*E/Fy) / (h*tw) = AISC Manual Eq G2-4

(iii) For h/tw > 1.37*sqrt(kv*E/Fy)

Cv = (1.51*E*kv)/[(h/tw)2*Fy] =

kv is determined as follows: web plate buckling coefficient

(i) For unstiffened webs with h/t w < 260

kv = 5

(ii) For stiffened webs

2

kv = 5 + (5/(a/h) =

or kv = 5 when a/h >3.0

or a/h > [ 260/ (h/t w)]2

SUMMARY: Use: W 18 x 86

FOR FLEXURE φbMn Mu

548.36 > 462.11 ft-kip OK!

FOR SHEAR φvVn Vu

264.96 > 40.73 kip OK!

You might also like

- Columna de SotanoDocument40 pagesColumna de SotanoMed SbitiNo ratings yet

- The Girder Design Is Adequate.: F E JC E Ysh X L R R E JC SH F FDocument22 pagesThe Girder Design Is Adequate.: F E JC E Ysh X L R R E JC SH F FBang OchimNo ratings yet

- Bridge Crane Load CalculationDocument20 pagesBridge Crane Load Calculationcadsultan100% (2)

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Daniel Tian Li: Simply Supported Beam Design With Torsional Loading Based On AISC 13th (AISC 360-05)Document11 pagesDaniel Tian Li: Simply Supported Beam Design With Torsional Loading Based On AISC 13th (AISC 360-05)Nabil YassarNo ratings yet

- Plate GirderDocument15 pagesPlate GirderRayodcNo ratings yet

- 8Document6 pages8Mohan BhalmeNo ratings yet

- Beam With TorsionDocument22 pagesBeam With TorsionAlphaNo ratings yet

- Free Standing Hoist CraneDocument16 pagesFree Standing Hoist CranecadsultanNo ratings yet

- Beam With TorsionDocument11 pagesBeam With TorsionR ASTUSNo ratings yet

- Enhanced Composite BeamDocument5 pagesEnhanced Composite BeamgalatiansNo ratings yet

- Design of Moment and Shear ConnectionDocument4 pagesDesign of Moment and Shear ConnectionAndro RebuyasNo ratings yet

- Lifting Lug Stress - 4 - Points - Rev - 1 - 5Document11 pagesLifting Lug Stress - 4 - Points - Rev - 1 - 5John PacelloNo ratings yet

- Book 3Document6 pagesBook 3Sasikumar Jothi100% (1)

- Steel Design LatestDocument52 pagesSteel Design LatestAhsan HabibNo ratings yet

- Clean - Copy - LiftingLugStress - 4 - Points - Rev - 1 - 5Document11 pagesClean - Copy - LiftingLugStress - 4 - Points - Rev - 1 - 5Hansen A JamesNo ratings yet

- Plate Girder Design Based On AISC Manual PDFDocument5 pagesPlate Girder Design Based On AISC Manual PDFஆல்வின் ரோஜர் பின்னிNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- BOX Sec-Beam-Column-AiscDocument6 pagesBOX Sec-Beam-Column-AiscWintun73No ratings yet

- ASD-Design of Steel BeamDocument5 pagesASD-Design of Steel BeamsivakumarNo ratings yet

- Tank FootingDocument102 pagesTank Footingjorge1952No ratings yet

- Tank Footing Design Based On ACI 318-14: Input DataDocument12 pagesTank Footing Design Based On ACI 318-14: Input DataMaraLeonNo ratings yet

- Circular Platform Design AISC - ImperialDocument54 pagesCircular Platform Design AISC - ImperialRajveer SinghNo ratings yet

- Plate GirderDocument15 pagesPlate GirderPriodeep ChowdhuryNo ratings yet

- Beam With TorsionDocument11 pagesBeam With TorsionAmey GudigarNo ratings yet

- Composite Beam Design With Verco Floor Deck Based On AISC Manual 9thDocument6 pagesComposite Beam Design With Verco Floor Deck Based On AISC Manual 9thnugroho87No ratings yet

- How To Automate SSIS and SQL Agent Job DeploymentsDocument34 pagesHow To Automate SSIS and SQL Agent Job DeploymentsMayank KukretiNo ratings yet

- Design of Mullion For C W Wall System: Project NameDocument3 pagesDesign of Mullion For C W Wall System: Project NameSales AlufacadesNo ratings yet

- Technical Writing Guidebook PDFDocument106 pagesTechnical Writing Guidebook PDFaliomairNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- Steel Beam DesignDocument2 pagesSteel Beam DesignYasserNo ratings yet

- Slab DetailsDocument2 pagesSlab Detailsnavneet3bawaNo ratings yet

- Crosstalk Noise and Crosstalk Delay - Effects of Crosstalk - Team VLSIDocument13 pagesCrosstalk Noise and Crosstalk Delay - Effects of Crosstalk - Team VLSIKaifeng Liu100% (2)

- Base Plate (Template)Document3 pagesBase Plate (Template)li yongzhongNo ratings yet

- GondolaDocument20 pagesGondolatkofaiNo ratings yet

- Manual de Operación Vibro Compactador Hamm HD8W HD 10C WDocument84 pagesManual de Operación Vibro Compactador Hamm HD8W HD 10C Wjavier carreñoNo ratings yet

- Kashmiri Gate IsbtDocument6 pagesKashmiri Gate IsbthuhuhahaheheNo ratings yet

- SCL (NATM) TunnellingDocument74 pagesSCL (NATM) Tunnellingthauwui86100% (1)

- Manual Electrico Caravan 97 InglesDocument454 pagesManual Electrico Caravan 97 InglesGermán R VillelaNo ratings yet

- Lifting Lug Stress - 4 - PointsDocument2 pagesLifting Lug Stress - 4 - PointsDipak ZopeNo ratings yet

- Stair Case CalcuationsDocument2 pagesStair Case CalcuationsraghavendraNo ratings yet

- Simple Connection DesignDocument91 pagesSimple Connection Designwisnu_bayusaktiNo ratings yet

- Calculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBDocument12 pagesCalculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBinnovativekarthi0% (1)

- Suspended AnchorageDocument1 pageSuspended Anchoragejorge01No ratings yet

- Asd 4Document1 pageAsd 4Hatem AbdelfattahNo ratings yet

- Reference Computation OUTPUT (Imperial) Output (M: Transverse InteriorDocument4 pagesReference Computation OUTPUT (Imperial) Output (M: Transverse InteriordovermanNo ratings yet

- Tomo 1 - FlexionDocument10 pagesTomo 1 - FlexionangelicalbotacioaNo ratings yet

- Column Is800Document4 pagesColumn Is800rammohanNo ratings yet

- Flexure Strength of MC6x15.1Document2 pagesFlexure Strength of MC6x15.1G.DhanabalNo ratings yet

- Input Data & Design Summary: Project: Client: Design By: Job No.: Date: Review byDocument1 pageInput Data & Design Summary: Project: Client: Design By: Job No.: Date: Review byjklo12No ratings yet

- (Option Ii) Interior Floor Girder Selection Live Load Reduction Check - Bay Width 36 FTDocument2 pages(Option Ii) Interior Floor Girder Selection Live Load Reduction Check - Bay Width 36 FTclam2014No ratings yet

- Bu Tfl.u 1 2: Project Name Job RefDocument6 pagesBu Tfl.u 1 2: Project Name Job RefHatem AbdelfattahNo ratings yet

- Girder AISCDocument6 pagesGirder AISCWintun73No ratings yet

- Modified RatiosDocument3 pagesModified RatiosBassem KhaledNo ratings yet

- End PlateDocument1 pageEnd PlateJavier FcNo ratings yet

- 2 ND Order Analysis ExampleDocument76 pages2 ND Order Analysis ExampleChristian Pinto100% (1)

- Beam Column AiscDocument6 pagesBeam Column AiscWintun73No ratings yet

- Hanger Clamps - FabricationDocument10 pagesHanger Clamps - FabricationDario WicaksonoNo ratings yet

- Slab Thickness Sunken Depth: LoadingDocument10 pagesSlab Thickness Sunken Depth: LoadingSuson DhitalNo ratings yet

- Composite Beam Design With Verco Floor Deck Based On AISC Manual 9thDocument6 pagesComposite Beam Design With Verco Floor Deck Based On AISC Manual 9thridho ziskaNo ratings yet

- 9 in Wall FootingDocument6 pages9 in Wall FootingshanNo ratings yet

- Daniel Li Temelj Rez. FullDocument5 pagesDaniel Li Temelj Rez. FullNiko NištićNo ratings yet

- Ns 3472Document46 pagesNs 3472genergia100% (1)

- Beam Rolled Section (Rev.2.00)Document2 pagesBeam Rolled Section (Rev.2.00)HamOdy SadeqNo ratings yet

- Pad Footing Design Based On ACI 318-14: Input Data Design SummaryDocument4 pagesPad Footing Design Based On ACI 318-14: Input Data Design SummaryBryan PerezNo ratings yet

- W Section (ASD) ExampleDocument5 pagesW Section (ASD) ExampleMallesh NenkatNo ratings yet

- PCS4 Project FormatFinalDocument4 pagesPCS4 Project FormatFinalLee Jasper SabenianoNo ratings yet

- Document WPS OfficeDocument1 pageDocument WPS OfficeLee Jasper SabenianoNo ratings yet

- Critical Elements Intermediate Beam Beam: 322 in Terms of Mu DesignDocument4 pagesCritical Elements Intermediate Beam Beam: 322 in Terms of Mu DesignLee Jasper SabenianoNo ratings yet

- AcknowledgementDocument2 pagesAcknowledgementLee Jasper SabenianoNo ratings yet

- LiquefactionDocument17 pagesLiquefactionLee Jasper SabenianoNo ratings yet

- Moment in TimeDocument1 pageMoment in TimeLee Jasper SabenianoNo ratings yet

- Cad DraftsmanDocument4 pagesCad DraftsmanPramod KumarNo ratings yet

- H-Beam Catalogue JindalDocument4 pagesH-Beam Catalogue JindalVikram DalalNo ratings yet

- Davis 1972Document16 pagesDavis 1972Akshat RastogiNo ratings yet

- Manual Stat PackDocument474 pagesManual Stat PacksuperocaziiNo ratings yet

- Perbedaan Hill Climbing Dan P&ODocument13 pagesPerbedaan Hill Climbing Dan P&Obaymax love spideyNo ratings yet

- TH THDocument4 pagesTH THmike millNo ratings yet

- Combo FixDocument4 pagesCombo FixAna MateiNo ratings yet

- Oneplus TwoDocument18 pagesOneplus TwoKishor ChaudharyNo ratings yet

- 1st AssignmentDocument2 pages1st AssignmentMAI 95No ratings yet

- Product DataDocument2 pagesProduct DatapoerwntiNo ratings yet

- Levation: Rigid Core SPC Flooring / Revêtement de Sol Structure SPCDocument13 pagesLevation: Rigid Core SPC Flooring / Revêtement de Sol Structure SPCABDULQURESHINo ratings yet

- S01100 PDFDocument14 pagesS01100 PDFBudi WaskitoNo ratings yet

- Anuj Agrawal: Home - Iitk.ac - In/ AnujDocument3 pagesAnuj Agrawal: Home - Iitk.ac - In/ AnujvishwajitNo ratings yet

- PPT II Plastics Materials and Its Applications II 20 221Document1 pagePPT II Plastics Materials and Its Applications II 20 221Raj ThakurNo ratings yet

- Unit Test Integral Calculus Set ADocument4 pagesUnit Test Integral Calculus Set ADEATH WISHNo ratings yet

- Experiment Result: Work of Catalase EnzymeDocument11 pagesExperiment Result: Work of Catalase EnzymeNikko AdhitamaNo ratings yet

- ITP For WeldingDocument2 pagesITP For WeldingKumar AbhishekNo ratings yet

- Standard Practice: 1995 EditionDocument8 pagesStandard Practice: 1995 EditionKaan TekinturhanNo ratings yet

- Kampa Tent Catalogue 2014Document32 pagesKampa Tent Catalogue 2014Richard100% (1)

- EsquemaDocument7 pagesEsquemaMarcyo LimaNo ratings yet

- CM Solutions 400LSeriesBarge SpecSheet 1Document2 pagesCM Solutions 400LSeriesBarge SpecSheet 1Ahmed HossamNo ratings yet

- Optical Transport Network (OTN) : Future Ready. TodayDocument4 pagesOptical Transport Network (OTN) : Future Ready. Todaypriyanka joshiNo ratings yet

- Kuantitas Barang Per Daftar Gudang: PT. Mahajaya Plastindo IndonesiaDocument10 pagesKuantitas Barang Per Daftar Gudang: PT. Mahajaya Plastindo IndonesiaDesain OMINo ratings yet