Professional Documents

Culture Documents

VSM Exercise

VSM Exercise

Uploaded by

valeria0 ratings0% found this document useful (0 votes)

2 views3 pagesOriginal Title

VSM exercise

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views3 pagesVSM Exercise

VSM Exercise

Uploaded by

valeriaCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Lean manufacturing: The Value Stream Map (VSM)

Please elaborate the VSM for the following processes, using MS Visio, and answer the questions

below.

Exercise 1: Tequila Distillation (Reposado)

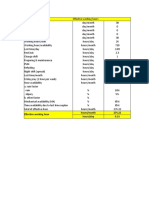

Process step First Pass Yield Cycle Time (CT) Scrap (%) Shifts

(FPY)

Cooking 99.8% 72 h 0.2% 2

Pressing 100% 24 h 0 1

Fermentation 98% 70 h 2% 3

Distillation 97% 36 h 3% 3

Aging 100% 30 day (720 h) 0 3

Bottling 98.5% 2h 1.5% 1

Total 93.44% 924 h / 500 l 2.7% N/A

Please consider the following inventory (WIP = Work in process) in between processes:

Before cooking: 1 day

After cooking: zero

After pressing: zero

After fermentation: 1 day

After distillation: 0.5 day

After aging: 1 month

Questions:

1. Where are the bottlenecks?

FERMENTATION

2. Which actions do you propose to fix them?

Adding more than one tank in the process

3. How could you reduce inventory?

Make the warehouse bigger and make able for the tequila pass from one process to

another without being stored.

Exercise 2: Tuna processing

Process step First Pass Yield Cycle Time (CT) Scrap (%) Shifts

(FPY)

Catching 85% 10 day 15% 3

Washing 100% 2h 0 1

Cooking 98% 12 h 2% 3

Cleaning 100% 24 h 0 3

Cutting 95% 8h 5% 3

Deeping 100% 2h 0 1

Packing in can 98% 6 h / 500 kg 2% 1

Palletizing 100% 2 h / 500 kg 0 1

Totals N/A

- Please calculate the totals and include them in the VSM

- Consider the following inventory and transportation in the process:

o After catching: 16 h of transportation to the ground

o After cooking: 2 days inventory

o After deeping: 1 day inventory

Questions:

1. Where are the bottlenecks?

CLEANING

2. Which actions do you propose to fix them?

Increase the capacity of cleaning equipment or improve methods to reduce the time

needed to clean.

3. How could you reduce inventory?

Optimize processes so that the tuna does not take so much time in storage

You might also like

- Design and Scheduling of Batch Processess PDFDocument23 pagesDesign and Scheduling of Batch Processess PDFjokishNo ratings yet

- Applichem Case: OM 888 Supply Chain Modeling and AnalysisDocument14 pagesApplichem Case: OM 888 Supply Chain Modeling and Analysisajay135No ratings yet

- Chapter 4 Process AnalysisDocument6 pagesChapter 4 Process Analysispbpotter43100% (1)

- Lean Manufacturing - TWI Case Study Model Answers PDFDocument11 pagesLean Manufacturing - TWI Case Study Model Answers PDFBianka NaulaNo ratings yet

- Biscuit, Cookie and Cracker Manufacturing Manuals: Manual 4: Baking and Cooling of BiscuitsFrom EverandBiscuit, Cookie and Cracker Manufacturing Manuals: Manual 4: Baking and Cooling of BiscuitsNo ratings yet

- Bancassurance Black Book Sem 6 FinalDocument89 pagesBancassurance Black Book Sem 6 FinalPrateek Mathur78% (9)

- Value Stream Mapping in Chutney Manufacturing PlantDocument17 pagesValue Stream Mapping in Chutney Manufacturing PlantSandipan Samuel Das 2027402No ratings yet

- Group 2 BlanchingDocument8 pagesGroup 2 BlanchingdaphneNo ratings yet

- 02 - Dec-17 To 08-Dec-17Document60 pages02 - Dec-17 To 08-Dec-17shamb2020No ratings yet

- OIT NotesDocument8 pagesOIT NotesDamienKettudNo ratings yet

- Lean Assignment 4Document11 pagesLean Assignment 4Hozefa Ajmerwala100% (1)

- Project Feasibility Study: Technical Aspect: Prepared byDocument76 pagesProject Feasibility Study: Technical Aspect: Prepared byBarbara Beatriz Mariano CariñoNo ratings yet

- Q.1What Is The Competitive Priorities For Synthite?: Input DataDocument4 pagesQ.1What Is The Competitive Priorities For Synthite?: Input DatarakeshNo ratings yet

- Solution MNE 407/507 in Class 2 Production RequirementsDocument4 pagesSolution MNE 407/507 in Class 2 Production RequirementsJazamNo ratings yet

- Fiber Aoac PDFDocument1 pageFiber Aoac PDFArellanes JmzNo ratings yet

- ProductivityDocument349 pagesProductivitydimar agusriawanNo ratings yet

- Davao Asia Plastic Corporation: A Case Company For Operations and Supply Chain Management StudyDocument42 pagesDavao Asia Plastic Corporation: A Case Company For Operations and Supply Chain Management StudyRichie DonatoNo ratings yet

- Davao Asia Plastic Corporation: A Case Company For Operations and Supply Chain Management StudyDocument42 pagesDavao Asia Plastic Corporation: A Case Company For Operations and Supply Chain Management StudyRichie DonatoNo ratings yet

- Sadie Ikeda - Cheese Lab Write UpDocument10 pagesSadie Ikeda - Cheese Lab Write Upapi-342516670No ratings yet

- Drying Line HDocument24 pagesDrying Line HSBNo ratings yet

- Solucion MNE 407/507 HW #2 Production Requirements: 210,000 Tons Ore 420,000 Tons WasteDocument3 pagesSolucion MNE 407/507 HW #2 Production Requirements: 210,000 Tons Ore 420,000 Tons WasteJazamNo ratings yet

- Bakery Unit: Project Report OnDocument9 pagesBakery Unit: Project Report OnShyamal Dutta75% (4)

- Evaluation of The Behavior of The American Genipa (Jagua) in The Dehydration Process by ConvectionDocument7 pagesEvaluation of The Behavior of The American Genipa (Jagua) in The Dehydration Process by ConvectionPedro Felipe RiveraNo ratings yet

- Operation ManagmentDocument17 pagesOperation ManagmentSatheeshNo ratings yet

- SoybeansDocument48 pagesSoybeansВалентин И'в100% (1)

- Sher-Loxane 800Document2 pagesSher-Loxane 800Sleyda MunozNo ratings yet

- Laboratory Title: Determination of Moisture Date of Experiment: 21 APRIL 2020 Laboratory Group: TuesdayDocument12 pagesLaboratory Title: Determination of Moisture Date of Experiment: 21 APRIL 2020 Laboratory Group: TuesdayIman FarhaNo ratings yet

- Seoul National University Operations Management Assignment 1Document3 pagesSeoul National University Operations Management Assignment 1mariushesNo ratings yet

- Lab Report 1 Ibg 112 Wong Kar JinDocument14 pagesLab Report 1 Ibg 112 Wong Kar JinJimmy WongNo ratings yet

- Riza Development Corporation: Weekly Progress Report No. 031Document12 pagesRiza Development Corporation: Weekly Progress Report No. 031Debussy PanganibanNo ratings yet

- Preparing Sodium Chlorite Solutions From Technical Sodium Chlorite (Dry) ProductDocument2 pagesPreparing Sodium Chlorite Solutions From Technical Sodium Chlorite (Dry) ProductJaime PachacamaNo ratings yet

- #1energy Balance WholeDocument5 pages#1energy Balance WholeRhea MambaNo ratings yet

- Moisture Exp1Document10 pagesMoisture Exp1Fadhlin Sakinah100% (1)

- Dura-Plate UHS: Protective & Marine CoatingsDocument2 pagesDura-Plate UHS: Protective & Marine CoatingsABIMAELNo ratings yet

- Exercise No. 5 Sample DryingDocument4 pagesExercise No. 5 Sample DryingRoma Felice TuizaNo ratings yet

- FPPKG Tutorial 1 AY19-20 QDocument2 pagesFPPKG Tutorial 1 AY19-20 QRaysonChooNo ratings yet

- Caustic TankDocument5 pagesCaustic TankMuhammad Aftab AhmedNo ratings yet

- Drying of Oyster Mushroom in Different Dryers: (Pleurotus Florida)Document8 pagesDrying of Oyster Mushroom in Different Dryers: (Pleurotus Florida)Fibra NurainyNo ratings yet

- Cassava China PDFDocument47 pagesCassava China PDFKarisma Lumban Gaol100% (2)

- Moisture Best Practices WorkingDocument26 pagesMoisture Best Practices Workingmukhamad lutfiNo ratings yet

- Meagal Stelplast: Steering A New PathDocument7 pagesMeagal Stelplast: Steering A New PathArjun JoshiNo ratings yet

- OEE Analysis - Assignment 2-1Document1 pageOEE Analysis - Assignment 2-1ʆƠƘЄƦ 6No ratings yet

- Cash Flow V.1.4Document29 pagesCash Flow V.1.4sigit l.prabowoNo ratings yet

- All CH Kpi February 23Document96 pagesAll CH Kpi February 23INDFAB PROJECTSNo ratings yet

- Moisture ContentDocument6 pagesMoisture ContentJM BoylesNo ratings yet

- MMCE EnglishDocument14 pagesMMCE EnglishrikanazmiliaNo ratings yet

- Production of Biodiesel From Waste Cooking Oil by Using Homogeneous CatalystDocument11 pagesProduction of Biodiesel From Waste Cooking Oil by Using Homogeneous CatalystnslhhhhhhhhNo ratings yet

- SA & SP Semi Mechanised Zerobase Revision - April 2019Document19 pagesSA & SP Semi Mechanised Zerobase Revision - April 2019MikeNo ratings yet

- Operations HW & SolDocument4 pagesOperations HW & Solfoon.dionne47No ratings yet

- Homework For Lecture Date 26 - 9Document12 pagesHomework For Lecture Date 26 - 9Hạ Phạm NhậtNo ratings yet

- Dore Dore1Document5 pagesDore Dore1yuveesp5207No ratings yet

- Summary Upto 8thDocument1 pageSummary Upto 8thjagramanNo ratings yet

- Fat NewDocument13 pagesFat NewMohammed ElsenduonyNo ratings yet

- Lubricating Oil Blending Process A) Definition of The ProcessDocument3 pagesLubricating Oil Blending Process A) Definition of The ProcessBulent ErdoganNo ratings yet

- Batchwise and Semibatch Processing: Sizing Plant ItemsDocument21 pagesBatchwise and Semibatch Processing: Sizing Plant ItemsIhsan KerrNo ratings yet

- Supplier CustomerDocument1 pageSupplier CustomerPepe Luis RoReyNo ratings yet

- Nevoeiro Salino AutomotiveUpdate4-806CCTDocument1 pageNevoeiro Salino AutomotiveUpdate4-806CCTMiguel QueirosNo ratings yet

- K0830 Laundry Report - April 12, 2009 PDFDocument97 pagesK0830 Laundry Report - April 12, 2009 PDFArun Jacob CherianNo ratings yet

- Practicum AZG Makro 4 - Moisture-Ash - GravimetriDocument4 pagesPracticum AZG Makro 4 - Moisture-Ash - GravimetriUlis SalsabilaNo ratings yet

- Equipment ProductivityDocument8 pagesEquipment ProductivityHary AntoNo ratings yet

- Types of Bank AccountsDocument13 pagesTypes of Bank AccountsD PNo ratings yet

- 2ND Floor Plan PDFDocument1 page2ND Floor Plan PDFEngineering MarcosNo ratings yet

- 10 Sangguniang Barangay of North Poblacion Maramag, BukidnonDocument2 pages10 Sangguniang Barangay of North Poblacion Maramag, BukidnonAnne Abellanosa0% (1)

- The Market For Lemons Slides (Chapter 3.1)Document14 pagesThe Market For Lemons Slides (Chapter 3.1)Cally LekabeNo ratings yet

- Management AccountingDocument5 pagesManagement AccountingHamdan SheikhNo ratings yet

- Response To Gcr's N 03 High Risk Surveillance Report - 11 October 2023 (NSCR GCR n03 CRKSTN LTR Hs 000024) (NSCR Itd n03 ZWD RPT Hs 000519)Document14 pagesResponse To Gcr's N 03 High Risk Surveillance Report - 11 October 2023 (NSCR GCR n03 CRKSTN LTR Hs 000024) (NSCR Itd n03 ZWD RPT Hs 000519)Gian Carlo MiguelNo ratings yet

- C5 (MC) - Cost Accounting by Carter (Part2)Document6 pagesC5 (MC) - Cost Accounting by Carter (Part2)AkiNo ratings yet

- Coin Inventory Sheet TemplateDocument5 pagesCoin Inventory Sheet TemplateRene StassenNo ratings yet

- Addis Ababa Institutes of Technology (Aiot) Department of Civil EngineeringDocument36 pagesAddis Ababa Institutes of Technology (Aiot) Department of Civil EngineeringSamuel Minda100% (1)

- Sales Kza7ihj 1657241262009Document17 pagesSales Kza7ihj 1657241262009MARCELO TAVARESNo ratings yet

- Manual de Maniobras - Grúa KATO 10TNDocument4 pagesManual de Maniobras - Grúa KATO 10TNAlonso MedinaNo ratings yet

- Chapter 2Document17 pagesChapter 2Amanuel GenetNo ratings yet

- Trade Union Movements in IndiaDocument4 pagesTrade Union Movements in IndiaAshwini RaiNo ratings yet

- SI - Sales SI 2023 24 0467Document2 pagesSI - Sales SI 2023 24 0467Ankur GoelNo ratings yet

- LOI - Petroleum FZCDocument2 pagesLOI - Petroleum FZCMohamed Mehdi OuakdiNo ratings yet

- XEROXDocument25 pagesXEROXSALONY METHINo ratings yet

- Wise, Formerly TransferWise Online Money Transfers International Banking Features 2Document1 pageWise, Formerly TransferWise Online Money Transfers International Banking Features 2Rene PatrickNo ratings yet

- Kitchen Buying Guide en UsDocument53 pagesKitchen Buying Guide en UsLowtech23No ratings yet

- Zurich FundsDocument34 pagesZurich FundsSumanth MuvvalaNo ratings yet

- Stabilization of Black Cotton Soil by Using Fly AshDocument52 pagesStabilization of Black Cotton Soil by Using Fly AshManohar ManuNo ratings yet

- ECON 305 Lecture 1Document26 pagesECON 305 Lecture 1Kevin BaoNo ratings yet

- Ch4 641Document35 pagesCh4 641MubeenNo ratings yet

- VIDYA SAGAR Analysis-CA Final LAW For Dec - 2021Document6 pagesVIDYA SAGAR Analysis-CA Final LAW For Dec - 2021Ranjit BhogesaraNo ratings yet

- General Catalog Tools 2019 PDFDocument264 pagesGeneral Catalog Tools 2019 PDFphong nguyễn báNo ratings yet

- Internship Report (New)Document4 pagesInternship Report (New)ferdinaNo ratings yet

- Today The Topic of My Speech Is Bright Future of Pakistan: Respected President and Teachers!Document1 pageToday The Topic of My Speech Is Bright Future of Pakistan: Respected President and Teachers!Kazim HussainNo ratings yet

- Is LMDocument39 pagesIs LMParthNo ratings yet

- Midterm Examination - MAS REVIEWDocument7 pagesMidterm Examination - MAS REVIEWFrancis MateosNo ratings yet

- Laying & Testing of Fire Detection Cable Methods StatementDocument23 pagesLaying & Testing of Fire Detection Cable Methods StatementJanaka Kavinda100% (1)