Professional Documents

Culture Documents

Article Linear Weigh Filler Packaging Machine

Uploaded by

Mayank ShekharCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Article Linear Weigh Filler Packaging Machine

Uploaded by

Mayank ShekharCopyright:

Available Formats

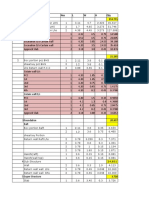

WP1002 WP100

Linear Weigh Filler Packaging Machine

Author : Mayank Shekhar Shekhar Brothers Email: mayank@munky.in

Introduction to Weigh fillers As the name suggests Linear weigh fillers utilize weigh filling technology to pack the materials. Linear vibratory feeders are used to feed the material from the storage hopper to the weighing pan. Sophisticated electronic hardware and software form the backbone of the electro electronic control panel which controls the rate of vibration and continuously measures the weight that falls inside the weighing pan. Initially the vibration / feed rate is high (coarse mode) and material flows into the weighing pan at a high speed. Once the material in the weighing pan reaches nearly 80 90% of the target weight the machine erial 80-90% enters the fine mode where the material trickles down and the vibration finally stops as soon as the target weight is echieved. The weighed material is then dropped automatically or by press of a foot switch in the automatically final packet / pouch/ carton as the case may be. Each of this system is called a weighing head. A weighing head has a speed of approximately 8 12 pouches per minute and to achieve higher packing 8-12 speeds more than one weighing heads are cascaded together and speeds upto 60 pouches /min can be echieved. Shekhar Brothers specialises in manufacturing weigh fillers in semi automatic and fully automatic versions. Both these categories utilize the same weighing technology only the speed of fully automatic only machines is higher.

Packing on the basis of weight Ideal for all granular and powder material Versatile machine, run different products on the same machine Fill different nett weights on same machine Fill in Bottles and pouches Ideal for products with variable density Range o 1 - 50gms o 50 - 250gms o 500 - 1000gms o 1kg 10kg Nano Power technology : 250W only Less Floor space No Requirement of compressor

Our machines have a few distinct advantages over the conventional filling systems :

Filling by weight and not by volume. Products where density is not consistent can be easily packed. Products that are susceptible to breakage or damage can be easily run on such machines. Can be used for different types of materials granular, powders, tablets, materials with irregular shape and size.

Applications of Weigh Filling System Granular Material : Tablets Powders : : Tea, Coffee beans, Namkeen Mixture, Rice, Suji, Rye, Spices- Pepper, Cardamom, , Flour, Besan, Chips, Corn Puffs. Ayurvedic Medicines, Seeds Spices such as Dhania, Zeera, Sambar Powder, Rice powder, zeera, Wheat Flour, Besan, Desiccated Coconut Powder, Ayurvedic Medicinal powders, Animal feed mineral mixtures

Patent Pending: Any unlawful copying of the product is subject to legal prosecution

The author is the director of business development at Shekhar Brothers, a company that manufactures state of the art weigh filling and packing equipment from low end to high end segment. Contact us at email : sales@munky.in to enable us suggest you the right solution for your product packing. For more information visit www.munky.in Shekhar Brothers No. 58, Sector 6, Faridabad, Haryana, India Ph: +91-129-2241089, 2240858 e-mail: sales@munky.in

You might also like

- Packaging Machine Tablet Filler Webpage Rev01Document1 pagePackaging Machine Tablet Filler Webpage Rev01Mayank ShekharNo ratings yet

- Tea Packaging MachineDocument1 pageTea Packaging MachineMayank ShekharNo ratings yet

- Semi Automatic Cartoning Machine SpecificationDocument9 pagesSemi Automatic Cartoning Machine SpecificationArkaNo ratings yet

- Capsule Filling Machine, Automatic Capsule Filling Machine, Semi Automatic Capsule Filling MachineDocument10 pagesCapsule Filling Machine, Automatic Capsule Filling Machine, Semi Automatic Capsule Filling MachineDhananjay LodhaNo ratings yet

- Supertech Packing Machine - FaridabadDocument4 pagesSupertech Packing Machine - Faridabadrajesh_rbpNo ratings yet

- MR - Ranjeet Kumar Kurkure Process Line With PackingDocument12 pagesMR - Ranjeet Kumar Kurkure Process Line With PackingRanjeet BhaiNo ratings yet

- Ertical Type Cosmetic Cream Ointment Sauce Filler Equipment With HeatingDocument13 pagesErtical Type Cosmetic Cream Ointment Sauce Filler Equipment With HeatingAbd Al-Rahmman Al-qatananiNo ratings yet

- 300 Instructions BookDocument32 pages300 Instructions BookceltorNo ratings yet

- Food Processing MachineryDocument6 pagesFood Processing MachinerymukulNo ratings yet

- Name:-Ebrahim Abd EL-Hadi Ebrahim Section: - 1 Department: - Mechatronics (4 Year)Document22 pagesName:-Ebrahim Abd EL-Hadi Ebrahim Section: - 1 Department: - Mechatronics (4 Year)Ebrahim Abd El HadyNo ratings yet

- Sw-Pl1 Vertical Weighing Packaging System: 1. ApplicationDocument8 pagesSw-Pl1 Vertical Weighing Packaging System: 1. ApplicationAlvaro DiazNo ratings yet

- Smart Weigh ProjectsDocument6 pagesSmart Weigh ProjectsTCRemziCelikNo ratings yet

- Health Monitoring of VFFS Machine PDFDocument5 pagesHealth Monitoring of VFFS Machine PDFRakesh patelNo ratings yet

- VFJ-520 Automatic Vertical Packing Machine ManualDocument39 pagesVFJ-520 Automatic Vertical Packing Machine ManualIvan SaladinoNo ratings yet

- SVC Series enDocument5 pagesSVC Series enJulioNo ratings yet

- Form Fill Seal MachineDocument19 pagesForm Fill Seal MachineFrank GengNo ratings yet

- Versatility and precision with handtmann VF 600 vacuum fillerDocument12 pagesVersatility and precision with handtmann VF 600 vacuum fillermiloNo ratings yet

- Profil Venelteko 02 enDocument36 pagesProfil Venelteko 02 enguillermomolteniNo ratings yet

- Bosch Guide To Flow Wrapping enDocument30 pagesBosch Guide To Flow Wrapping engherla_bogdanNo ratings yet

- Honetop-Rotary Packing Machine HT-8GDocument27 pagesHonetop-Rotary Packing Machine HT-8GNathaniel FernandesNo ratings yet

- Romaco Liquid Filling BrochureDocument24 pagesRomaco Liquid Filling BrochureMina ZANo ratings yet

- fs1000 en PDFDocument2 pagesfs1000 en PDFLukito TitoNo ratings yet

- Operation Manual: Multihead WeigherDocument40 pagesOperation Manual: Multihead WeigherAlvaro DiazNo ratings yet

- Instruction Manual For CheckweigherDocument54 pagesInstruction Manual For Checkweigheralesia delgadoNo ratings yet

- Saint Gobain Furon Microe High Purity Fluid Handling Solutions CatalogDocument32 pagesSaint Gobain Furon Microe High Purity Fluid Handling Solutions CatalogXavierNo ratings yet

- Holac Cubixx100LDocument1 pageHolac Cubixx100LSamuel JoshuaNo ratings yet

- Ishida ACP-700 Series Case Packer Brochure (6200)Document10 pagesIshida ACP-700 Series Case Packer Brochure (6200)Kundan KumarNo ratings yet

- c660b Leak and Seal Strength TesterDocument3 pagesc660b Leak and Seal Strength TesterRizky RamadhaniNo ratings yet

- Optima Branch Brochure Food v2 enDocument24 pagesOptima Branch Brochure Food v2 enjohnb2bNo ratings yet

- AccelacotaBrochure2006 PDFDocument16 pagesAccelacotaBrochure2006 PDFlapandaNo ratings yet

- Blister Packaging Machine With Integrated CartonerDocument20 pagesBlister Packaging Machine With Integrated CartonerSatish HiremathNo ratings yet

- IRJET - Automatic Weighing and PackagingDocument10 pagesIRJET - Automatic Weighing and PackagingDaniel EmekaNo ratings yet

- Form Fill Seal BrochureDocument12 pagesForm Fill Seal BrochureMuhammad Alva Budi WardhanaNo ratings yet

- Tube Filling and Sealing Machine Operation ManualDocument43 pagesTube Filling and Sealing Machine Operation ManualEdhwinn Javier Popo MorenoNo ratings yet

- DQ BlisteadoraDocument15 pagesDQ Blisteadorasami2210No ratings yet

- XWZ-120A Operation Manual: Full Automatic Cartoning MachineDocument35 pagesXWZ-120A Operation Manual: Full Automatic Cartoning MachinealexjoelNo ratings yet

- XLD Series Vertical Stamper User ManualDocument78 pagesXLD Series Vertical Stamper User ManualGonzalo Marquez100% (1)

- CB-VG52B Continuous Motion Machine (High Speed ManualDocument8 pagesCB-VG52B Continuous Motion Machine (High Speed ManualPaolo AltobelNo ratings yet

- Bouwpaco Powder Dosing & PackingDocument33 pagesBouwpaco Powder Dosing & PackingAlexander AeromodelistaNo ratings yet

- Knife BrochureDocument2 pagesKnife BrochurechinchotarngNo ratings yet

- LOT 2 JT-920 Sugar Packing Machine ManualDocument27 pagesLOT 2 JT-920 Sugar Packing Machine Manualzelalem100% (1)

- Bottle Unscrambling SystemsDocument2 pagesBottle Unscrambling SystemsAhmet MetinNo ratings yet

- TY-PLC Multihead Weigher ManualDocument27 pagesTY-PLC Multihead Weigher ManualAlvaro DiazNo ratings yet

- The Right Equipment For The Job: Helix® Flexible Screw ConveyorDocument6 pagesThe Right Equipment For The Job: Helix® Flexible Screw ConveyorjaimeNo ratings yet

- Ammeraal Envolsadoras LinatexDocument4 pagesAmmeraal Envolsadoras LinatexVictor MoralesNo ratings yet

- He Fam 1080 6 Brick Quotation Latest PriceDocument10 pagesHe Fam 1080 6 Brick Quotation Latest PriceSHASHANKDUBEY52No ratings yet

- Vertical Form Fill SealDocument29 pagesVertical Form Fill Sealrodolfo muñoz magañaNo ratings yet

- Article WJPR 1516154454 3 PDFDocument7 pagesArticle WJPR 1516154454 3 PDFEbrahim Abd El HadyNo ratings yet

- FILE - 20210527 - 222310 - GPK-40H18 ManualDocument53 pagesFILE - 20210527 - 222310 - GPK-40H18 ManualPak TetraNo ratings yet

- Area-Layer-Gripping-Systems Catalogue PDFDocument40 pagesArea-Layer-Gripping-Systems Catalogue PDFaidixon CAD designNo ratings yet

- Palletizer SelectionDocument4 pagesPalletizer Selectionred patriotNo ratings yet

- 11.machineries Required For A Bakery UnitDocument8 pages11.machineries Required For A Bakery UnitBharath JaganathanNo ratings yet

- Ficha Tecnica Correa Habasit Grammer (Vfha001h04) PDFDocument4 pagesFicha Tecnica Correa Habasit Grammer (Vfha001h04) PDFdavid caraoNo ratings yet

- Palletizer / Stretch Wrapper Combinations for End-of-Line PackagingDocument2 pagesPalletizer / Stretch Wrapper Combinations for End-of-Line Packagingred patriotNo ratings yet

- Cartoning Machines: by Shailesh JadhavDocument9 pagesCartoning Machines: by Shailesh JadhavShailesh Jadhav100% (1)

- DE-50-AV Dual Auger FillerDocument18 pagesDE-50-AV Dual Auger FillerJoão BaptistaNo ratings yet

- 1000Kg Foldable Engine Crane Crane: Owner'S Manual Product Code: 1001Document14 pages1000Kg Foldable Engine Crane Crane: Owner'S Manual Product Code: 1001CARLOS ANDRES CAICEDO PEREZNo ratings yet

- Your Packaging Specialists: C Ntour SalesDocument52 pagesYour Packaging Specialists: C Ntour SalesAhmad عfiaNo ratings yet

- Article Weigh Filling Vs Volumetric Filling SystemDocument2 pagesArticle Weigh Filling Vs Volumetric Filling SystemMayank ShekharNo ratings yet

- Types of Packaging Machines and There FunctionsDocument5 pagesTypes of Packaging Machines and There Functionsbottlingplant indiaNo ratings yet

- 1 Head SpecificationDocument2 pages1 Head SpecificationMayank ShekharNo ratings yet

- Article Weigh Filling Vs Volumetric Filling SystemDocument2 pagesArticle Weigh Filling Vs Volumetric Filling SystemMayank ShekharNo ratings yet

- Catalog Automatic Counting Machine Rev0Document1 pageCatalog Automatic Counting Machine Rev0Mayank ShekharNo ratings yet

- Catalog Automatic Counting Machine Rev0Document1 pageCatalog Automatic Counting Machine Rev0Mayank ShekharNo ratings yet

- Catalog Rice Grains Packaging Machine Rev0Document1 pageCatalog Rice Grains Packaging Machine Rev0Mayank ShekharNo ratings yet

- Article Weigh Filling Vs Volumetric Filling SystemDocument2 pagesArticle Weigh Filling Vs Volumetric Filling SystemMayank ShekharNo ratings yet

- Mechanical Vibration WorksheetDocument6 pagesMechanical Vibration Worksheetduraiprakash83No ratings yet

- SL07 480Document5 pagesSL07 480GianNo ratings yet

- JNTUH Gold Medal Recipients ListDocument17 pagesJNTUH Gold Medal Recipients ListHarshitha KattaNo ratings yet

- Fluid Mechanics Question BankDocument11 pagesFluid Mechanics Question BankBharath Waj100% (1)

- Analysis Based On 15-16 SORDocument195 pagesAnalysis Based On 15-16 SORAjay SaikumarNo ratings yet

- E37447Document180 pagesE37447Bryan BowmanNo ratings yet

- Mooney M20R Ovation 2 GX - Pilot's Operating Handbook and Airplane Flight ManualDocument222 pagesMooney M20R Ovation 2 GX - Pilot's Operating Handbook and Airplane Flight Manuallegoulu100% (3)

- Guideline For Grade and Compensation FitmentDocument5 pagesGuideline For Grade and Compensation FitmentVijit MisraNo ratings yet

- SEMICONDUCTOR_CARRIERSDocument12 pagesSEMICONDUCTOR_CARRIERSPirvulescu RamonaNo ratings yet

- Fundamentals of SurveyingDocument14 pagesFundamentals of SurveyingZar Frianeza100% (1)

- Concept of Operations DRAFT v1Document84 pagesConcept of Operations DRAFT v1Ramesh dodamaniNo ratings yet

- CSE Application ChecklistDocument4 pagesCSE Application ChecklistArfan HaiderNo ratings yet

- Awwa d103 PotableDocument9 pagesAwwa d103 PotableAnonymous UArnIExNo ratings yet

- Stiffness Modifiers As Per IS 1893 (Part 1) - 2016Document6 pagesStiffness Modifiers As Per IS 1893 (Part 1) - 2016Kamal Rao100% (1)

- Resume PDFDocument1 pageResume PDFeminentlypracticalNo ratings yet

- Can Crusher SummaryDocument14 pagesCan Crusher SummaryOsama Abdelaleem100% (1)

- SAUDI ARAMCO VESSEL CLOSURE CERTIFICATEDocument1 pageSAUDI ARAMCO VESSEL CLOSURE CERTIFICATEAnonymous S9qBDVkyNo ratings yet

- MB09807UDocument27 pagesMB09807URavishka SilvaNo ratings yet

- ZAPOSH CONSULTANCY MAKES WORKPLACES SAFERDocument40 pagesZAPOSH CONSULTANCY MAKES WORKPLACES SAFERJohn Paul Marin ManzanoNo ratings yet

- Work Experience: Kamble Arti Navnath MOB: (+91) 8830600972Document3 pagesWork Experience: Kamble Arti Navnath MOB: (+91) 8830600972KambleNo ratings yet

- NTUST DCE Graduate Program ApplicationDocument1 pageNTUST DCE Graduate Program ApplicationDewi Hindra WijayaNo ratings yet

- Basics Configuration of PBX Nortel Meridain 81cDocument26 pagesBasics Configuration of PBX Nortel Meridain 81cGil HaleNo ratings yet

- Slide GP EV - SEMINARDocument57 pagesSlide GP EV - SEMINARPeng Keong LeongNo ratings yet

- Marvelous College of Technology, IncDocument7 pagesMarvelous College of Technology, Incthirsty liquidNo ratings yet

- A New and Unique Tool For Shrimp Feed Producers: Kristin Weel SundbyDocument8 pagesA New and Unique Tool For Shrimp Feed Producers: Kristin Weel SundbyrsuertoNo ratings yet

- Flex Wing Rotary Cutter (John Deere) MX15-HX15-HX20-CX15-CX20 Operator's ManualDocument100 pagesFlex Wing Rotary Cutter (John Deere) MX15-HX15-HX20-CX15-CX20 Operator's ManualJoe ZhaoNo ratings yet

- Anand Vihar Case StudyDocument4 pagesAnand Vihar Case StudyAnafNo ratings yet

- Answer Sa StemDocument7 pagesAnswer Sa Stemyvette garciaNo ratings yet

- Limiting FactorDocument4 pagesLimiting FactorVanesh Thakur0% (2)

- CV Imen KrifaDocument1 pageCV Imen Krifaapi-732929360No ratings yet