Professional Documents

Culture Documents

A MAR DS 570fill EN

A MAR DS 570fill EN

Uploaded by

amine19zorgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A MAR DS 570fill EN

A MAR DS 570fill EN

Uploaded by

amine19zorgCopyright:

Available Formats

Accurate and Reliable Material Delivery

Weighing Applications

With the Powerful Fill-570 Application

Flexible Control Options

The Fill-570 offers easy-to-program filling,

blending and dosing sequences, together

with fast-updating discrete I/O. These ca-

pabilities combine to create a reliable and

accurate stand-alone process controller of-

fering real potential for savings.

Performance Monitoring

The Pac Statistics function in the Fill-570

calculates performance statistics for the

weigh-in or weigh-out cycle. It provides

data to help identify system adjustments

that can shorten cycle times, reduce waste

and improve margins.

IND570fill: IND570 + Fill-570

Integrated Data Storage For Advanced Filling and Dosing Control

The Fill-570 features large libraries for

materials, formulas and containers.

Quickly recall stored data for use in Install the specialized Fill-570 application into an

production with just a few key presses or IND570 terminal and the result is a high-performance

barcode scan, to improve process

efficiency and avoid the introduction of

controller designed to make automated filling and dos-

errors. ing processes straightforward and reliable.

Modular, multi-functional and easy to program, the

Expandable Solution IND570fill supports quick adaptation of material deliv-

The IND570 terminal with Fill-570 offers

ery processes to changing business needs. Whether

multiple PLC interfaces and a broad

command set that ease integration into integrated into an existing control system or functioning

existing control structures, capitalizing on as a stand-alone process controller, the IND570fill pro-

existing investments.

vides flexibility to deploy workforce and manufacturing

resources to best drive productivity.

Fill-570 Application

Enhanced Material Handling Capability for IND570

Supported Material Transfer Cycles

Fill During a Fill cycle, the IND570fill controls the addition of a single material to a container or vessel using either a 1- or

2-speed weigh-in procedure until a desired weight is achieved. The built-in Target Table stores weight targets and tolerances

for 200 individual materials.

Blend The Blend cycle involves filling from 2 to 6 materials into a vessel in a fixed order. Each material in the formula has its own

target value and acceptable +/- tolerances, and can be delivered using 1- or 2-speed feed control. The IND570fill provides a

dedicated data table for storage and efficient recall of these multiple material Formulas.

Dump When executing the Dump cycle, the IND570 monitors the weight on the scale until all material in a vessel is completely

emptied out of it.

Dose In a Dose cycle, the IND570fill accurately controls the discharge of material from a supply vessel until the targeted loss in

weight is achieved. 1- and 2-speed dosing control is possible. By combining the Dose cycle with a Fill or Blend cycle, the

IND570fill has further capability to control the on-going availability of material(s) in the supply vessel.

Cycle Combinations Weigh-in cycles (Fill, Blend) are easily combined with weigh-out cycles (Dump, Dose) to create broader control solutions.

Additional Features

• Cycles can be further customized using complementary process control features such as automatic or semi-automatic process transitions,

looping of cycles for continuous processing, before- and after-cycle timers, and tracking of the number of cycles.

• Configurable softkeys make procedures logical and easy for manufacturing personnel to follow.

• Accuracy is ensured: A final tolerance check is an automatic step in every available cycle. Customers have the flexibility to reject out of toler-

ance cycles automatically, or allow for manual or automatic adjustments of the material weight prior to final tolerance check.

• Automatic Spill Adjustment maintains accuracy by accounting for environmental changes that can affect the amount of material still in flight

after all the feeding equipment is shut off.

• New material setup is simplified by the terminal’s Learn Mode feature: Program a new target with +/- tolerance values and let the IND570fill

calculate the ideal fine feed and spill values for that material.

• With safety in mind, the IND570fill offers several functions including interlocks (permissive inputs) and container tare checking that help to

avoid wasteful and potentially dangerous product spills.

Mettler-Toledo, LLC

1900 Polaris Parkway

www.mt.com/IND570

Columbus, OH 43240 For more information

Phone 800 638 8537

Subject to technical changes

© 01/2021 Mettler-Toledo, LLC

Document Nr. 30260433 A

You might also like

- Doosan Dx140Document114 pagesDoosan Dx140Trọng100% (3)

- Doosan DL450 Wheel Loader Service Repair Workshop ManualDocument10 pagesDoosan DL450 Wheel Loader Service Repair Workshop ManualManuals CE & Ag33% (3)

- Overall Weighting Equipment EffectivenessDocument5 pagesOverall Weighting Equipment EffectivenessHeriSaputraNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNo ratings yet

- CAT 950H Wheel LoaderDocument28 pagesCAT 950H Wheel Loaderojhawk1380% (5)

- Pws 002863Document7 pagesPws 002863charly2490No ratings yet

- 1 - Bottled Uht Milk and Dairy Drinks - UsDocument6 pages1 - Bottled Uht Milk and Dairy Drinks - UswisokresnoNo ratings yet

- Stock bv-d6408gb Disoconttersus dt9 PDFDocument2 pagesStock bv-d6408gb Disoconttersus dt9 PDFS LIKITNo ratings yet

- Key Performan Indicators SoftwareIndustry1.2Document8 pagesKey Performan Indicators SoftwareIndustry1.2Aaron_GeaNo ratings yet

- Colby - Sapac BrochureDocument16 pagesColby - Sapac Brochureshogun billings100% (1)

- 1-2 Fadin - Overview of Current and Upcoming StandardsDocument46 pages1-2 Fadin - Overview of Current and Upcoming StandardsVaibhav DhinganiNo ratings yet

- Epicor Production Management Suite BR ENSDocument15 pagesEpicor Production Management Suite BR ENSHuong NguyenNo ratings yet

- IPLOOK HSS Product Information V1.3Document13 pagesIPLOOK HSS Product Information V1.3IPLOOK TechnologiesNo ratings yet

- FusionCube 1000 (Hypervisor) - DatasheetDocument4 pagesFusionCube 1000 (Hypervisor) - DatasheetCarlos LeonardoNo ratings yet

- IND560 Brochure IN034372E LTRDocument4 pagesIND560 Brochure IN034372E LTRAgusNo ratings yet

- R01 - Drive-570 - DB - EN A4Document2 pagesR01 - Drive-570 - DB - EN A4amine19zorgNo ratings yet

- PUB CM P8 10299 10 en SKF Aptitude AnalystDocument20 pagesPUB CM P8 10299 10 en SKF Aptitude AnalystWongChi LiekNo ratings yet

- SKF @ptitude Analyst Software For MultilogDocument20 pagesSKF @ptitude Analyst Software For MultilogFendyNo ratings yet

- 2PAA117748 Sugar Industry Customer Brochure - v10Document12 pages2PAA117748 Sugar Industry Customer Brochure - v10habtamu tesfayeNo ratings yet

- Chap 4 Maintenance ProceduresDocument41 pagesChap 4 Maintenance ProceduresErichCastrejónRodriguezNo ratings yet

- 3BDD010078R0001Document6 pages3BDD010078R0001Asesoría y Consultoria.No ratings yet

- ICS68x Speed-Up BrochureDocument3 pagesICS68x Speed-Up BrochureSergeyNo ratings yet

- PeopleWare - Release Notice 19.0.03.303Document5 pagesPeopleWare - Release Notice 19.0.03.303LeeNo ratings yet

- WP Inthepressurecooker LT enDocument11 pagesWP Inthepressurecooker LT encrazy8scribdNo ratings yet

- Indexing Cup FillerDocument2 pagesIndexing Cup FillerCY LeeNo ratings yet

- Training Documents ACS SYSTEM 22.3.2023Document30 pagesTraining Documents ACS SYSTEM 22.3.2023mhnd.issmlcNo ratings yet

- VolvoDocument20 pagesVolvosijithNo ratings yet

- 3BUS092073R0001 - en MOD 300 Enhanced With Industrial ITDocument16 pages3BUS092073R0001 - en MOD 300 Enhanced With Industrial ITMoez BellamineNo ratings yet

- Flygt Mas711 Brochure 895034 PDFDocument2 pagesFlygt Mas711 Brochure 895034 PDFAraujo Felipe AndrésNo ratings yet

- Máquina 2 VF 610-PlusDocument8 pagesMáquina 2 VF 610-PlusJosé VieiraNo ratings yet

- EC140D EC160D and EC220D BrochureDocument24 pagesEC140D EC160D and EC220D BrochureRomuald PogorzelczykNo ratings yet

- Operational AssuranceDocument36 pagesOperational AssuranceTony FiniganNo ratings yet

- Accounting Hub 19ADocument7 pagesAccounting Hub 19AvadefemiNo ratings yet

- The Essential Process Engineering Software, Created by Process Engineers For Process EngineersDocument4 pagesThe Essential Process Engineering Software, Created by Process Engineers For Process EngineersAntonioNo ratings yet

- We Make It Easy For You To Flex Your Application'S Muscle: Powerflex® 750-Series Ac DrivesDocument10 pagesWe Make It Easy For You To Flex Your Application'S Muscle: Powerflex® 750-Series Ac DrivesmarcelaNo ratings yet

- Gravfil Excel Servo FillerDocument3 pagesGravfil Excel Servo FillerStuart MelenNo ratings yet

- Catalog Altivar Process ATV600 Variable Speed DrivesDocument133 pagesCatalog Altivar Process ATV600 Variable Speed Drivesrabia akramNo ratings yet

- Mark Vie Control: Foundation Fieldbus™ InterfaceDocument55 pagesMark Vie Control: Foundation Fieldbus™ Interfacebmw316No ratings yet

- Software System Enables Effective Flow-Assurance Management: The ChallengeDocument3 pagesSoftware System Enables Effective Flow-Assurance Management: The ChallengeCarlos Alfredo Viloria RivasNo ratings yet

- Advanced Protection, Control and Automation Solutions For Distribution FeedersDocument8 pagesAdvanced Protection, Control and Automation Solutions For Distribution FeedersChristian VaNo ratings yet

- OM - ReviewerDocument5 pagesOM - ReviewerELLYSSA MAE CLEMENTENo ratings yet

- 07-Advanced Control ProductsDocument137 pages07-Advanced Control ProductsakramhomriNo ratings yet

- Thermo Scientific UltrasonicoDocument4 pagesThermo Scientific Ultrasonicodiego pardoNo ratings yet

- Cheetah Xi50 PDFDocument116 pagesCheetah Xi50 PDFCristian DominguezNo ratings yet

- Truesight Operations Management Smart Reporting: Superior Visibility To Drive Faster and Better Itops Decision MakingDocument2 pagesTruesight Operations Management Smart Reporting: Superior Visibility To Drive Faster and Better Itops Decision MakingPhuong ThaiNo ratings yet

- 5400 Series: Capacitor ControllerDocument12 pages5400 Series: Capacitor ControllerJorge Gutierrez MejiaNo ratings yet

- Integrated Control and Safety Systems (Icss) : Home About Us Our Business Contact UsDocument2 pagesIntegrated Control and Safety Systems (Icss) : Home About Us Our Business Contact Usanon_971443164No ratings yet

- PR10340EN R1 Robotware DispenseDocument2 pagesPR10340EN R1 Robotware DispenseCucu CatalinNo ratings yet

- AppNotes - Poultry by Interwave TechnologyDocument3 pagesAppNotes - Poultry by Interwave TechnologySandeep KulkarniNo ratings yet

- 3BDD015188 en G Freelance DCS Product CatalogDocument164 pages3BDD015188 en G Freelance DCS Product Catalogckati100% (1)

- Complying To The General Food Law: With Proficy Plant ApplicationsDocument3 pagesComplying To The General Food Law: With Proficy Plant Applicationsmatias matiasNo ratings yet

- Workpacks and Inspections - Asset Integrity Management Software - OnE IntegrityDocument5 pagesWorkpacks and Inspections - Asset Integrity Management Software - OnE IntegrityYRNo ratings yet

- E1205 E1210 Update 06.10 LoresDocument2 pagesE1205 E1210 Update 06.10 LoresBS anandNo ratings yet

- Cisco Covacsis Data SheetDocument4 pagesCisco Covacsis Data SheetShantanu PalNo ratings yet

- WhatIsNEW UPDATE HFIRDocument2 pagesWhatIsNEW UPDATE HFIRamarnath98252No ratings yet

- Datasheet: Control-M Output ManagementDocument2 pagesDatasheet: Control-M Output ManagementSongsakNo ratings yet

- Escafe Documentation UpdatedDocument8 pagesEscafe Documentation UpdatedlloyddagocNo ratings yet

- ACS580 Catalog Abb VFDDocument76 pagesACS580 Catalog Abb VFDElaine MagcawasNo ratings yet

- Pel PDFDocument4 pagesPel PDFgulatimanish1985No ratings yet

- Restaurant Management System ProjectDocument15 pagesRestaurant Management System ProjectJaveria ShakilNo ratings yet

- Ds FJ Ism enDocument7 pagesDs FJ Ism enHamid Reza MoradiNo ratings yet

- Drum FillersDocument18 pagesDrum FillersAbid HameedNo ratings yet

- AMS10004 SKF Results Reporter PDFDocument8 pagesAMS10004 SKF Results Reporter PDFkarthimeenaNo ratings yet

- Pioneer Pd-f907 ManualDocument20 pagesPioneer Pd-f907 ManualandremassaNo ratings yet

- The History, Trends, and Future of Infrared Technology - DSIACDocument21 pagesThe History, Trends, and Future of Infrared Technology - DSIACg c agnihotriNo ratings yet

- Nirma University Library CatalogDocument1 pageNirma University Library CatalogNicholas ThompsonNo ratings yet

- Presentation 7sd610 enDocument29 pagesPresentation 7sd610 enMohamed WahidNo ratings yet

- Iso-Iec 14763-2Document32 pagesIso-Iec 14763-2Dan Emmanuel Casarrubias VillaNo ratings yet

- Preliminary Technical Proposal For Priority 1 Metering Points Site SurveyDocument11 pagesPreliminary Technical Proposal For Priority 1 Metering Points Site SurveyMOSES EDWINNo ratings yet

- Cyberoam Hotpin Integration GuideDocument5 pagesCyberoam Hotpin Integration GuidePavankumar RavinuthalaNo ratings yet

- Get Unlimited Downloads With A Free Scribd Trial!Document2 pagesGet Unlimited Downloads With A Free Scribd Trial!Neatha ChimNo ratings yet

- Scholarships SINGA 2023-06-21-ETDocument4 pagesScholarships SINGA 2023-06-21-ETk21106047No ratings yet

- Manual Ar5b95Document25 pagesManual Ar5b95daniel diazNo ratings yet

- Vlsi ProjectDocument13 pagesVlsi ProjectNarayan Mishra MishraNo ratings yet

- Microprocessor & Microcontrollers: Interrupts ProgrammingDocument31 pagesMicroprocessor & Microcontrollers: Interrupts ProgrammingAbdul Rehman AfzalNo ratings yet

- Teradata Alerts: Installation and Configuration GuideDocument46 pagesTeradata Alerts: Installation and Configuration Guidehejaw79186No ratings yet

- QT Pro Hanif Packages 540Document12 pagesQT Pro Hanif Packages 540Vishnu DwivediNo ratings yet

- Training Report PhaseDocument140 pagesTraining Report PhaseRamesh AnanthanarayananNo ratings yet

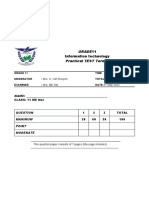

- Grade11 Information Technology Practical TEST Term 2Document7 pagesGrade11 Information Technology Practical TEST Term 2Thapelo MakateNo ratings yet

- RFM-01 RX ProgrammingDocument14 pagesRFM-01 RX Programmingpierregdlj9308No ratings yet

- Unit 1Document45 pagesUnit 1Abhishek Bose100% (2)

- East Grand Forks Recreation Facility ProjectsDocument8 pagesEast Grand Forks Recreation Facility ProjectsinforumdocsNo ratings yet

- 03 - Module 3-EditedDocument28 pages03 - Module 3-EditedAsad AbbasNo ratings yet

- Chrome 94 Enterprise Release NotesDocument15 pagesChrome 94 Enterprise Release NotesTruica DanielNo ratings yet

- Chapter 3Document12 pagesChapter 3Raymond LeoNo ratings yet

- Telefire Sniper Profile Dec23 06Document5 pagesTelefire Sniper Profile Dec23 06dalurzoagustinNo ratings yet

- Split Cycle EngineDocument2 pagesSplit Cycle EngineNani KotaNo ratings yet

- New Format (Jigar Patel)Document2 pagesNew Format (Jigar Patel)Eric StrifflerNo ratings yet