Professional Documents

Culture Documents

PEE 711 - Module III - Drilling Methods and Technologies 1

Uploaded by

Isianya JoelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PEE 711 - Module III - Drilling Methods and Technologies 1

Uploaded by

Isianya JoelCopyright:

Available Formats

Federal University of Petroleum Resources

Effurun

Drilling Engineering & Well

Completion

Course Code: PEE 711

Ogbon Drilling Engineering & Well Completionm Slide #1

Drilling Engineering & Well Completion

Lecturer:

Ogbarode N. Ogbon

Ogbon Drilling Engineering & Well Completionm Slide #2

Drilling Engineering & Well Completion

Module III

Drilling Methods & Technologies

Ogbon Drilling Engineering & Well Completionm Slide #3

Drilling Methods and Technologies

Introduction to Natural Gas Processing

Introduction

Drilling Methods

The process of well construction include

Rock Breaking - in consolidated formations

Sediment stirring – in unconsolidated formations

There are two basic types of drills(hole construction tools):

Drills that generate rock chips, and

Drills that produce Rock Core Sample

Drilling Methods consist of the body of techniques and equipment

employed to break rock into fragments or core in drilling(constructing or

making hole) in the subsurface rock in the oil and gas industry

Methods of Rock breaking and sediment stirring

Modern well drilling methods may be grouped into these general classes

in accordance to their mechanism of drilling

Percussion.

Abrasion.

Hydraulic.

High Power Vibration

High Power Laser

Ogbon Drilling Engineering & Well Completionm Slide #4

Drilling Methods and Technologies

Introduction Introduction to Natural Gas Processing

Drilling Methods

The drilling methods can also be classified in accordance to their

depth capacity, rate of penetration and sample produced.

In many wells a single method is not employed, therefore drilling a

from surface through the pay zone can consist of;

Sediments stirring (hydraulic) in the top soil

Rock cutting with bit scraping, gouging, crushing (Abrasion) of medium

to hard formations

Pounding with mud motor (Percussion) to kick-off(deviate) the well.

Drilling Method applied in constructing a well depends on

Hole Size

Engineering Specifications

Equipment Availability

Technology

Geology

Ogbon Drilling Engineering & Well Completionm Slide #5

Drilling Methods and Technologies

Introduction Introduction to Natural Gas Processing

Drilling Methods

Several methods, including boring, punching, and driving, as well

as digging, employed to drill shallow water wells and not employed

in the oil and gas industry do not come within the above

classification.

Drilling Technology

On the other hand, Drilling Technology involves the application of other

equipment, tools and drilling methods in the construction of a well

Ogbon Drilling Engineering & Well Completionm Slide #6

Drilling Methods and Technologies

Introduction to Natural Gas Processing

Types of Drilling Methods

Percussion Method

Percussion drilling developed by the Chinese over 4000

years ago, is basically the raising and dropping of heavy

piercing tools to cut and loosen formation rock.

This method uses a heavy drill bar or other tool, with suitable

apparatus for lifting it and allowing it to drop, to pound the

rock into fragments small enough to be readily removed from

the hole.

In 1859 Colonel F. L. Drake completed the first oil well using a

cable tool percussion-type machine.

Ogbon Drilling Engineering & Well Completionm Slide #7

Drilling Methods and Technologies

Introduction to Natural Gas Processing

Drilling Methods

Percussion Method

Drilling Tools for Percussion Drilling

Downhole hammer

Percussion hammer

Down-The-Hole hammer(DHH)

Drilling Technologies Applying Percussion Drilling

Cable Tool Drilling Technology

Percussion rotary air blast drilling (RAB)

Mud-hammer drilling

Rotary percussion drilling

Ogbon Drilling Engineering & Well Completionm Slide #8

Drilling Methods and Technologies

Introduction to Natural Gas Processing

Drilling Methods

Percussion Method

Percussion Drilling Advantages

Improve hole geometry,

Increased ROP

Reduces drillstring stresses,

Generates better and larger cuttings which yields a better

representation for geological study

Lower drilling cost per foot substantially

Most efficient drilling method in hard formations – generally

2-3 times higher than conventional drilling method and 7.3

times higher in medium-hard granite

Because it involves less contact time with rock - only 1 or 2

percent of total operational drilling time - bit has less

abrasion and hence a longer bit life.

Less use of other bottom hole assembly – saving equipment

rental cost

Less hole deviation and easier control of deviation problem

for straight hole drilling.

Ogbon Drilling Engineering & Well Completionm Slide #9

Drilling Methods and Technologies

Introduction to Natural Gas Processing

Drilling Methods

Percussion Method

Percussion Drilling Disadvantages

Poor understanding of rock properties and mechanics

Processes associated with combined percussion and rotary

drilling have not been fully defined and adequately modelled

to help design and optimize drilling operations due to Lack of

practical simulations tools that can provide reliable

estimation of optimized values for

hammer type,

number of blows,

energy per blow that is directly related to length of the

stroke,

area of piston,

supplied pressure, etc.

Hammer bits (cutters) may get balled quicker in soft

formations and lose the ability to drill ahead

Ogbon Drilling Engineering & Well Completionm Slide #10

Drilling Methods and Technologies

Introduction to Natural Gas Processing

Drilling Methods

Percussion Method

Percussion Drilling Disadvantages

Excessive hammer energy may cause severe vibration to

drill string and rig structure leading to mechanical failure.

Vibrations may lead to wellbore instability, such as cavity

creation in shale, or even collapse

Performance in shale and other soft rocks is poor

No evidence of the performance in either directional,

horizontal wells, slim hole drilling, or coiled tubing

drilling

Ogbon Drilling Engineering & Well Completionm Slide #11

Drilling Methods and Technologies

Drilling Methods Introduction to Natural Gas Processing

Abrasion Method

In abrasion, the rock is worn, gorged, pealed and chipped off by rotating

action upon the rock of a shoe or bit armed with some harder material

buttons or teeth.

It is the most applicable method in drilling oil and gas wells in the industry

Drilling Tools for Abrasion Drilling

Drill bit

Mud motor

Drilling Technologies Applying Abrasion Drilling

Auger Drilling

Rotary Drilling

Mud Motor Drilling

Rotary percussion drilling

Directional Drilling

Horizontal Drilling

Multi-Lateral Drilling

Ogbon Slim Hole Drilling Drilling Engineering & Well Completionm Slide #12

Drilling Methods and Technologies

Drilling Methods

Introduction to Natural Gas Processing

Hydraulic Method

This method uses water under high pressure jet to loosen the rock

material and bring the pieces generated to the surface.

It is mostly applicable in soft and unconsolidated rocks

The Hydraulic Rotary Method was developed in recent times to drill

the newly discovered oil field in Texas in unconsolidated formations.

Penetration is accomplished by the rotation of an annular toothed

shoe on the bottom of the string of casing

Drilling Tools for Abrasion Drilling

Jet Bit

Cutting Shoe

Drilling Technologies Applying Abrasion Drilling

Jet Drilling

Air Drilling

Hydraulic Rotary Drilling

Directional Drilling

Ogbon Drilling Engineering & Well Completionm Slide #13

Drilling Methods and Technologies

Introduction to Natural Gas Processing

Drilling Method

High Vibration Drilling

Sonic (Vibratory) Drilling

This method involves

transmission of high frequency

resonant vibrations down the drill

string to the drill bit which

fluidizes the soil particles at the

bit face resulting in easy

penetration through formation

rock.

The operator controls the

frequencies to suit the specific

conditions of the soil/rock

geology.

An internal spring system serves

as absorber to isolate these

vibrational forces from the rest of

Ogbon the drill rig. Drilling Engineering & Well Completionm Slide #14

Drilling Methods and Technologies

Introduction to Natural Gas Processing

High Laser Drilling

This involved the application of laser to first destroy the rock's

strength, allowing a conventional mechanical bit to then remove

the softened rock.

The beam that is used to destroy the rock surface at the bottom

of the borehole is shown in Figure 1 during a system test firing

The Edge of the Laser-Mechanical Drilling Method include:

Step changes in drilling rate (2-4x)

Extremely low WOB (<1000 lbs)

Extremely low torque (<300 ft-lbs)

Longer bit life and

Lower drilling cost per foot.

The 20 kW laser-mechanical drill bit,

as integrated into the commercial

coil tube drilling rig.

Ogbon Drilling Engineering & Well Completionm Slide #15

Drilling Methods and Technologies

Introduction to Natural Gas Processing

Drilling Method

Core Sample Drilling

One way to get more detailed samples of a formation is by coring,

where formation sample is drilled out by means of special bit.

Core Sample Drilling is a drilling method for obtaining formation

rock core sample

A rotating drill string composed of hollow centered core-drilling bit

cuts formation to advance the bore hole while obtaining the core

sample.

Diamond Core Bit Rock Core Sample

Conventional Core Bit

Ogbon Drilling Engineering & Well Completionm Slide #16

Drilling Methods and Technologies

Drilling Technology

Introduction to Natural Gas Processing

Drilling Technology involves the application of other equipment, tools

and drilling methods in the construction of a well.

The economic and strategic significance of drilling technology has

prompted the oil & gas industry to seek for new drilling tools and

systems that increase both the rate and efficiency of drilling wells.

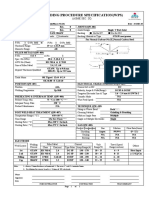

Table below shows the various drilling methods and the drilling

technologies that apply the methods to drill wells in the oil and gas

industry

Drilling Method Drilling Technology

Percussion Cable Tool

Down the Hole Hammer

Percussion rotary air blast drilling (RAB)

Abrasion Rotary Drilling

Air Drilling

Rotary percussion

Hydraulic Jetting

Vibration Sonic Drilling

Ogbon Core Engineering

Drilling Cable tool & Rotary

& Well Completionm Slide #17

You might also like

- Dynamic Strategies For Small BusinessDocument11 pagesDynamic Strategies For Small BusinessBusiness Expert Press0% (1)

- Introduction To Drilling Technology PDFDocument37 pagesIntroduction To Drilling Technology PDFgggicutza67% (3)

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- EASY PIPE - A New Technology For Trenchless Installation of Large Diameter Steel PipelinesDocument13 pagesEASY PIPE - A New Technology For Trenchless Installation of Large Diameter Steel PipelinesrameshkaaNo ratings yet

- ADL 12 Business Laws V4Document26 pagesADL 12 Business Laws V4Aditya BhatNo ratings yet

- Introduction To Special EducationDocument27 pagesIntroduction To Special EducationIsianya JoelNo ratings yet

- Drilling and Technology10Document12 pagesDrilling and Technology10Aryan el-BerwarîNo ratings yet

- English Grammar ExerciseDocument4 pagesEnglish Grammar Exerciseanca_2402No ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Drilling and Technology4Document11 pagesDrilling and Technology4Aryan el-BerwarîNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Drilling and Technology8Document11 pagesDrilling and Technology8Aryan el-BerwarîNo ratings yet

- Project Report On Multi Speciality Hospital (70 Beds)Document5 pagesProject Report On Multi Speciality Hospital (70 Beds)EIRI Board of Consultants and PublishersNo ratings yet

- Lecture 1 Well Planning BDocument17 pagesLecture 1 Well Planning BAryan RajNo ratings yet

- Mapeh-Arts: Quarter 2 - Module 2: Technology-Based ArtDocument24 pagesMapeh-Arts: Quarter 2 - Module 2: Technology-Based ArtTrecia Roxas SajolNo ratings yet

- Well LoggingDocument22 pagesWell LoggingSubham H Verma100% (1)

- Study Material of Fe &WLDocument103 pagesStudy Material of Fe &WLSoundar SamuelNo ratings yet

- Well PlanningDocument22 pagesWell PlanningVIRU SINGH100% (1)

- New Burn Cut Blast Design in Drives Enhances Drilling & Blasting Efficiency With Economy - A Case StudyDocument10 pagesNew Burn Cut Blast Design in Drives Enhances Drilling & Blasting Efficiency With Economy - A Case Studypartha das sharma100% (3)

- Basic of Well Drilling ProcessDocument96 pagesBasic of Well Drilling ProcessMajedur RahmanNo ratings yet

- Drilling and Technology6Document11 pagesDrilling and Technology6Aryan el-BerwarîNo ratings yet

- Drilling and Technology3Document12 pagesDrilling and Technology3Aryan el-BerwarîNo ratings yet

- 02 Rock Drilling Methods and MachineryDocument108 pages02 Rock Drilling Methods and MachineryBernardoEnriqueArgandoñaAlfaro100% (1)

- Candidate Guide SCR24Document16 pagesCandidate Guide SCR24Michael JunusNo ratings yet

- Surface Logging in The Oil Industry Apr 2011Document73 pagesSurface Logging in The Oil Industry Apr 2011Junaid Sajid100% (1)

- 1.0 Basic Drilling Engineering CourseDocument66 pages1.0 Basic Drilling Engineering CourseSamuel OkezieNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Drilling and Technology2Document12 pagesDrilling and Technology2Aryan el-BerwarîNo ratings yet

- Drilling and Technology7Document11 pagesDrilling and Technology7Aryan el-BerwarîNo ratings yet

- Drilling and Technology1Document12 pagesDrilling and Technology1Aryan el-BerwarîNo ratings yet

- Introduction To Drilling TechnologyDocument37 pagesIntroduction To Drilling Technologyguddisaha100% (4)

- Drilling and Technology9Document12 pagesDrilling and Technology9Aryan el-BerwarîNo ratings yet

- Directional Ddrilling Operations ManualDocument187 pagesDirectional Ddrilling Operations ManualToby Phillips100% (1)

- Letter of RecommendationDocument1 pageLetter of RecommendationIsaac Kocherla100% (1)

- Lesson Plan Ordinal NumbersDocument5 pagesLesson Plan Ordinal Numbersapi-329663096No ratings yet

- Introduction To Drilling TechnologyDocument37 pagesIntroduction To Drilling TechnologySam ShiddoNo ratings yet

- PEE 711 - Introduction To Driling and Completion 1Document34 pagesPEE 711 - Introduction To Driling and Completion 1Isianya JoelNo ratings yet

- Drilling and Blasting Techniques in MinesDocument3 pagesDrilling and Blasting Techniques in MinesAzaz Alam KhanNo ratings yet

- Fabrication of Ground DrillerDocument47 pagesFabrication of Ground DrillerAjith manjuNo ratings yet

- Drilling and Technology5Document11 pagesDrilling and Technology5Aryan el-BerwarîNo ratings yet

- Ripper Project, 2012 PDFDocument61 pagesRipper Project, 2012 PDFBismark Enoc Cruz AltamiranoNo ratings yet

- Advanced Snake Drill Technique Method For Improving of Oil Extraction PercentageDocument7 pagesAdvanced Snake Drill Technique Method For Improving of Oil Extraction PercentageAkhil GodavarthiNo ratings yet

- Oil Well Drilling Methods: University of Karbala College of Engineering Petroleum Eng. DepDocument8 pagesOil Well Drilling Methods: University of Karbala College of Engineering Petroleum Eng. DepAli MahmoudNo ratings yet

- 02 PDFDocument170 pages02 PDFQaisar Abbas KhokharNo ratings yet

- KB Introduction of Drilling, Rig Types & SelectionDocument16 pagesKB Introduction of Drilling, Rig Types & SelectionArpit UpadhyayNo ratings yet

- Methods of DrillingDocument39 pagesMethods of DrillingAnjumara HaiderNo ratings yet

- Hapugoda IMPC2010Document16 pagesHapugoda IMPC2010ParamesWaranNo ratings yet

- Lecture 7 - Well Drilling and DesignDocument61 pagesLecture 7 - Well Drilling and Designcrainvictor 45No ratings yet

- NSWMC Fact Sheet DrillingDocument3 pagesNSWMC Fact Sheet DrillingAnuj SinghNo ratings yet

- NSWMC Fact Sheet Drilling PDFDocument3 pagesNSWMC Fact Sheet Drilling PDFAnuj SinghNo ratings yet

- Universidad Nacional de CajamarcaDocument69 pagesUniversidad Nacional de CajamarcaSissy Vanessa Perez OrtegaNo ratings yet

- Applicability of Highwall MiingDocument27 pagesApplicability of Highwall MiingVetrivel VNo ratings yet

- Teknik PeledakanDocument43 pagesTeknik PeledakanandikaNo ratings yet

- 1 1 PDFDocument7 pages1 1 PDFsatishNo ratings yet

- SPE Pando x1Document15 pagesSPE Pando x1Fernando Mostajo RocaNo ratings yet

- Geological and Geophysical Investigation in Civil EngineeringDocument22 pagesGeological and Geophysical Investigation in Civil Engineeringamerhasnor pandapatanNo ratings yet

- Key Technologies of Drilling Process With Raise BoDocument11 pagesKey Technologies of Drilling Process With Raise BoSohaib SFAIRINo ratings yet

- project-717MN1024 - Checked 1Document10 pagesproject-717MN1024 - Checked 1Sʌţƴʌ PʀʌkʌsʜNo ratings yet

- Geo Steering and RSSDocument5 pagesGeo Steering and RSShany moh. mesallamNo ratings yet

- 1.underground Mining Methods and EquipmentDocument18 pages1.underground Mining Methods and EquipmentMihaelaCeciliaNo ratings yet

- Production of Rock MaterialsDocument4 pagesProduction of Rock Materialswilliam pasamonteNo ratings yet

- Title Defense: Yangon Technological University Department of Petroleum EngineeringDocument17 pagesTitle Defense: Yangon Technological University Department of Petroleum EngineeringJames MilzerNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19Jigneshkumar PatelNo ratings yet

- English - Identification of Reservoir With Geosteering Logging While Drilling TechnologyDocument3 pagesEnglish - Identification of Reservoir With Geosteering Logging While Drilling TechnologyHibiscus FibiNo ratings yet

- Dipmeter Surveys in Petroleum ExplorationFrom EverandDipmeter Surveys in Petroleum ExplorationRating: 5 out of 5 stars5/5 (1)

- Memorandum On AmendmentDocument6 pagesMemorandum On AmendmentIsianya JoelNo ratings yet

- Day of Prayer 2023Document4 pagesDay of Prayer 2023Isianya JoelNo ratings yet

- UntitledDocument5 pagesUntitledIsianya JoelNo ratings yet

- Justification of Study in A Research Project Is The Rationale For The StudyDocument2 pagesJustification of Study in A Research Project Is The Rationale For The StudyIsianya JoelNo ratings yet

- What Seventh-Day Adventists BelieveDocument116 pagesWhat Seventh-Day Adventists BelieveIsianya JoelNo ratings yet

- Belief 22Document15 pagesBelief 22Isianya JoelNo ratings yet

- Problems of Lexicology and LexicographyDocument9 pagesProblems of Lexicology and LexicographyIsianya JoelNo ratings yet

- Research Misconduct and Other Unethical ConductDocument4 pagesResearch Misconduct and Other Unethical ConductIsianya JoelNo ratings yet

- PA SystemDocument1 pagePA SystemSherif SalamaNo ratings yet

- Cs2252 - MPMC 16 M With Answers Upto 2Document40 pagesCs2252 - MPMC 16 M With Answers Upto 2archumeenabaluNo ratings yet

- Penilaian Kelayakan Usaha Mikro Dengan Kredit Skoring Dan Pengaruhnya Terhadap Pembiayaan Bermasalah Best Practice Lembaga Keuangan Di IndonesiaDocument12 pagesPenilaian Kelayakan Usaha Mikro Dengan Kredit Skoring Dan Pengaruhnya Terhadap Pembiayaan Bermasalah Best Practice Lembaga Keuangan Di IndonesiaRiantriaNo ratings yet

- Reaction of Rhodium With AirDocument2 pagesReaction of Rhodium With AirVhandy RamadhanNo ratings yet

- Online Food Order ProjectDocument39 pagesOnline Food Order Projectrithik anbalaganNo ratings yet

- Sustainable Transportation and Electric VehiclesDocument17 pagesSustainable Transportation and Electric Vehicless131744No ratings yet

- Product Selector Guide Marine Protective Coatings en 196830Document1 pageProduct Selector Guide Marine Protective Coatings en 196830wilberizquierdo1No ratings yet

- Settlement Chart: Foundation Settlement Analysis - ElasticDocument2 pagesSettlement Chart: Foundation Settlement Analysis - ElasticCSEC Uganda Ltd.No ratings yet

- Reasearch ProposalDocument9 pagesReasearch Proposalamel amoulaNo ratings yet

- Oic Deck c10Document40 pagesOic Deck c10dexeldancabudolNo ratings yet

- 4 Insurance Sales Incentive Program Ideas That WorkDocument3 pages4 Insurance Sales Incentive Program Ideas That Workgeorge akamaNo ratings yet

- SynopsisDocument20 pagesSynopsisMohd ShahidNo ratings yet

- GRADE 9-National Reading ProgramDocument2 pagesGRADE 9-National Reading ProgramJulius Bayaga100% (1)

- Personal Information WorksheetDocument1 pagePersonal Information Worksheetdaniela cardonaNo ratings yet

- 3rd Quarterly Exam in Mathematics 4Document9 pages3rd Quarterly Exam in Mathematics 4Jaycer De MesaNo ratings yet

- Alak Tagadó Alak: Az Egyszerű Jelen Idő KépzéseDocument2 pagesAlak Tagadó Alak: Az Egyszerű Jelen Idő KépzéseJuliaNo ratings yet

- Fpso Revamp For A Marginal Field Ea-SpeDocument34 pagesFpso Revamp For A Marginal Field Ea-Spe고병석No ratings yet

- Project Title: Student Satisfaction in JetkingDocument24 pagesProject Title: Student Satisfaction in Jetkinganupam rainaNo ratings yet

- Final CV-Europass-20190916-MezakMatijević-EN (2) - Kopija PDFDocument4 pagesFinal CV-Europass-20190916-MezakMatijević-EN (2) - Kopija PDFMirela Mezak StastnyNo ratings yet

- Anushree - VivaDocument76 pagesAnushree - VivaCarolin R 16No ratings yet

- Connector GuideDocument20 pagesConnector GuideBastian VarelaNo ratings yet